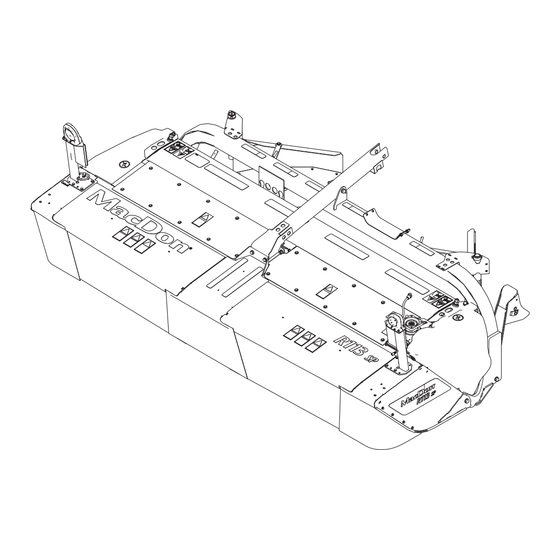

MacDon R113 Unloading And Assembly Instructions

Rotary disc header

Hide thumbs

Also See for R113:

- Operator's manual (294 pages) ,

- Unloading and assembly instructions (234 pages) ,

- Assembly instruction manual (212 pages)

Summary of Contents for MacDon R113

- Page 1 R113 Rotary Disc Header Unloading and Assembly Instructions 262300 Revision A Original Instruction The Harvesting Specialists.

- Page 2 © 2023 MacDon Industries, Ltd. The information in this publication is based on the information available and in effect at the time of printing. MacDon Industries, Ltd. makes no representation or warranty of any kind, whether expressed or implied, with respect to the...

- Page 3 Introduction This instruction describes the unloading, setup, and predelivery requirements for the MacDon R113 Rotary Disc Header. To ensure your customers receive all of the performance and safety benefits from this product, carefully follow the unloading and assembly procedure from the beginning through to completion.

- Page 4 Summary of Changes At MacDon, we’re continuously making improvements, and occasionally these improvements affect product documentation. The following list provides an account of major changes from the previous version of this document. Internal Use Summary of Change Only Section Throughout manual Removed discontinued R116 Rotary Disc Header content.

- Page 5 Internal Use Summary of Change Only Section Calibrating Header Position Added topic. Tech Pubs ™ Sensors on HarvestTouch Display, page 80 10.3.2 Setting Float – M2 Series Added topic. Tech Pubs Windrowers, page 114 10.4 Checking Float – M Series Changed to M Series Windrower to include M205 Windrower.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Introduction ..............................i Summary of Changes............................ ii Chapter 1: Safety ............................1 1.1 Safety Alert Symbols ..........................1 1.2 Signal Words ............................2 1.3 General Safety ............................3 1.4 Hydraulic Safety .............................5 1.5 Welding Precaution ..........................6 1.6 Safety Signs ............................7 Chapter 2: Unloading Header........................9 Chapter 3: Assembling Header......................... - Page 8 TABLE OF CONTENTS 6.3 Connecting Header Hydraulic and Electrical Systems – M1240 Windrower............83 6.4 Connecting Header Hydraulic and Electrical Systems – M1170 Windrower............89 6.4.1 Calibrating M1 Series Windrower Knife Drive and Header on Harvest Performance Tracker Display.... 92 6.5 Connecting Header Hydraulic and Electrical Systems –...

- Page 9 TABLE OF CONTENTS 11.3 Cutterbar Doors..........................138 11.3.1 Opening Cutterbar Doors......................138 11.3.2 Opening Cutterbar Doors – Export....................139 11.3.3 Closing Cutterbar Doors......................140 11.4 Torque Specifications ........................141 11.4.1 Metric Bolt Specifications ......................141 11.4.2 Metric Bolt Specifications – Cast Aluminum .................. 143 11.4.3 O-Ring Boss Hydraulic Fittings –...

-

Page 11: Chapter 1: Safety

Chapter 1: Safety Understanding and consistently following these safety procedures will help to ensure the safety of those operating the machine and of bystanders. 1.1 Safety Alert Symbols The safety alert symbol indicates important safety messages in this manual and on safety signs on the machine. This symbol means: •... -

Page 12: Signal Words

SAFETY 1.2 Signal Words Three signal words, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. Two signal words, IMPORTANT and NOTE, identify non-safety related information. Signal words are selected using the following guidelines: DANGER Indicates an imminently hazardous situation that, if it is not prevented, will result in death or serious injury. WARNING Indicates a potentially hazardous situation that, if it is not prevented, could result in death or serious injury. -

Page 13: General Safety

SAFETY 1.3 General Safety Operating, servicing, and assembling machinery presents several safety risks. These risks can be reduced or eliminated by following the relevant safety procedures and wearing the appropriate personal protective equipment. CAUTION The following general farm safety precautions should be part of your operating procedure for all types of machinery. - Page 14 SAFETY • Wear close-fitting clothing and cover long hair. NEVER wear dangling items such as hoodies, scarves, or bracelets. • Keep all shields in place. NEVER alter or remove safety equipment. Ensure that the driveline guards can rotate independently of their shaft, and that they can telescope freely.

-

Page 15: Hydraulic Safety

SAFETY 1.4 Hydraulic Safety Because hydraulic fluid is under extreme pressure, hydraulic fluid leaks can be very dangerous. Follow the proper safety procedures when inspecting hydraulic fluid leaks and servicing hydraulic equipment. • Always place all hydraulic controls in NEUTRAL before leaving the operator’s seat. -

Page 16: Welding Precaution

SAFETY 1.5 Welding Precaution To prevent damage to sensitive electronics, welding should never be attempted on the header while it is connected to a windrower. WARNING Severe damage to sensitive, expensive electronics can result from welding on the header while it is connected to the windrower. -

Page 17: Safety Signs

SAFETY 1.6 Safety Signs Safety signs are decals placed on the machine where there is a risk of personal injury, or where the Operator should take extra precautions before operating the controls. They are usually yellow. • Keep safety signs clean and legible at all times. •... -

Page 19: Chapter 2: Unloading Header

Chapter 2: Unloading Header To unload the header from the trailer safely and without damage, understand the weights and lifting requirements and familiarize yourself with the procedure. CAUTION To avoid injury to bystanders from being struck by machinery, do NOT allow people to stand in unloading area. CAUTION Equipment used for unloading must meet or exceed the requirements specified below. - Page 20 UNLOADING HEADER 1. Remove the hauler’s tie-down straps and chains. 2. Approach the header from its underside and slide the forks under the lifting framework as far as possible. IMPORTANT: Do NOT damage the hydraulic hoses hanging below the header. 3.

-

Page 21: Chapter 3: Assembling Header

Chapter 3: Assembling Header Perform procedures in the order in which they are presented. 3.1 Removing Lower Shipping Support The skid shoes on both sides of the header must be lifted out of the way to remove the base support. 1. - Page 22 3. Remove bolt (A) from skid shoe (B). Retain the bolt for reinstallation. NOTE: R113 SP headers have one skid shoe per side. Figure 3.3: Left Skid Shoe Shown 4. Lift skid shoe (B) out of the way and support it with wire (A).

- Page 23 ASSEMBLING HEADER 5. Remove three bolts (A) from each side of base support (B). Figure 3.5: Base Shipping Support – Right Side Shown 6. Remove base support (A). Figure 3.6: Base Shipping Support 262300 Revision A...

- Page 24 ASSEMBLING HEADER 7. Remove wire (A) holding skid shoe (B). Figure 3.7: Left Skid Shoe Shown 8. Tilt skid shoe (B) inward, and align link (A) with the mounting hole in the skid shoe. 9. Install bolt, washer, and nut (C). 10.

-

Page 25: Lowering Header

ASSEMBLING HEADER 3.2 Lowering Header Complete the following steps to lower the header into field position after it has been lifted off of its shipping trailer and set down on the ground. CAUTION Ensure spreader bar is secured to the forks so that it cannot slide off the forks or towards the mast as the header is lowered to the ground. - Page 26 ASSEMBLING HEADER 5. Back up SLOWLY, while simultaneously lowering the header until the cutterbar rests on the ground. 6. Remove chains from the header. Figure 3.10: Lowering Header to the Ground 262300 Revision A...

-

Page 27: Removing Shipping Stands

ASSEMBLING HEADER 3.3 Removing Shipping Stands The shipping stand and other supports must be removed from the header prior to assembly. NOTE: This procedure must be completed on both sides of the header near the forming shields. 1. Remove four bolts (A). 2. -

Page 28: Installing Hydraulic Header Drive

ASSEMBLING HEADER 3.4 Installing Hydraulic Header Drive The R113 Rotary Disc Headers are assembled without a hydraulic header drive. The compatible hydraulic header drive kit must be installed at this stage of the assembly. 1. Use the instructions supplied with the kit to install the compatible hydraulic header drive kit. -

Page 29: Assembling Hazard Lights

ASSEMBLING HEADER 3.5 Assembling Hazard Lights Detach the hazard light bracket from the shipping bracket, and install onto the frame. 1. Detach hazard light bracket (A) from shipping bracket (B) by removing four bolts (C), washers (D), and nuts (E). Retain the hardware for installation. -

Page 31: Chapter 4: Changing Conditioner

Chapter 4: Changing Conditioner There are several ways that the conditioner can be configured, depending on your particular machine. The R1 Series Rotary Disc Header can be operated either with no conditioner, with a polyurethane roll conditioner, or with a steel roll conditioner. If the rotary disc header is not conditioner-equipped, a shield must be installed. NOTE: These instructions apply to all conditioners. - Page 32 CHANGING CONDITIONER 6. M1 and M2 Series and M205: Move hose bundle (A) clear of the frame and lay it on the header. Figure 4.3: M1 and M2 Series and M205 Hose Bundle 7. M155 and M155E4: Remove two bolts (A) securing hose bracket (B) to the header frame.

- Page 33 CHANGING CONDITIONER WARNING To prevent the frame from slipping off of the forks, ensure that the frame is secured to the forks. Failure to secure the frame to the forks could result in death or serious injury. 8. Support and secure the adapter frame for lifting. Use one of the two methods below: Method 1: Attach straps (A) to adapter frame (B) and to the forklift forks.

- Page 34 CHANGING CONDITIONER 10. Remove nut (A) securing bolt (B), washer (C), and washer shims (D) from the center-link support. If necessary, adjust the height of the forks lifting the frame. Retain the hardware for reinstallation. NOTE: Some sections are made hidden in the illustration to help clarify the position of shims (D).

- Page 35 CHANGING CONDITIONER 15. Loosen two M16 hex head bolts (A) at each side of the conditioner. Figure 4.11: Left Side of Conditioner – Right Side Similar 16. Loosen two carriage bolts (A) securing conditioner gearbox support (B) to the header. WARNING To prevent the conditioner from falling backward, ensure that the lifting chains are secure.

-

Page 36: Installing Conditioner

CHANGING CONDITIONER 4.2 Installing Conditioner The conditioner is very heavy. Installing it will require the use of a forklift or equivalent lifting device. 1. Attach spreader bar (A) to the forklift (or an equivalent lifting device) and attach chains to lugs (B) on the conditioner. - Page 37 CHANGING CONDITIONER 5. Align the holes in support (B) with the mounting holes in the header frame. Install two carriage bolts (A) to secure conditioner gearbox support (B) to the header. The bolt heads must face inboard. Torque the nuts to 69 Nm (51 lbf·ft).

- Page 38 CHANGING CONDITIONER Method 2: To protect the finish on the frame, wrap packing foam (A) (or equivalent) around the approximate frame locations shown. b. Position forks (B) under the packing foam on the frame as shown at right. Raise the forks and lift the frame slightly.

- Page 39 CHANGING CONDITIONER 14. Apply anti-seize compound to the shank of bolt (B). Do NOT apply anti-seize to the bolt threads. Install washer (A) onto bolt (B). 15. Install bolt (B) with washers (C) as determined in Step page 16. Install three washers (D) and nut (E) onto the bolt. Torque the bolt to 339 Nm (250 lbf·ft).

- Page 40 CHANGING CONDITIONER 22. M155 and M155E4 Windrowers: Position the hose bundle and hose support (B) onto the adapter and secure it with bolts and nuts (A). Figure 4.26: M155 and M155E4 Hose Support 23. M1 and M2 Series and M205 Windrowers: Reposition hose bundle (A) on the frame.

-

Page 41: Installing Conditioner Drive

CHANGING CONDITIONER 25. Measure the length of tensioner spring (C). Dimension (D) should be set to 365 mm (14 3/8 in.) to ensure that the belt is tensioned correctly. 26. To adjust the spring tension, loosen jam nut (A). 27. Turn adjuster nut (B) clockwise to increase the belt tension, or turn adjuster nut (B) counterclockwise to decrease the belt tension. - Page 42 CHANGING CONDITIONER 1. Remove drive cover (A) from left side of header by removing hex head bolt (B), flat washer (C), and nut (D), and sliding cover off pins (E). Figure 4.31: Drive Cover 2. Position tensioner assembly (A) as shown, and secure with M16 x 120 bolt (B) and nut (C).

-

Page 43: Discharge Shield - No Conditioner

CHANGING CONDITIONER 4.3 Discharge Shield – No Conditioner Discharge shields control the distribution of unconditioned crop when no conditioner is installed. • If a conditioner is being installed, the discharge shield needs to be removed. For instructions, refer to 4.3.1 Removing Discharge Shield –... -

Page 44: Installing Discharge Shield - No Conditioner

CHANGING CONDITIONER 4.3.2 Installing Discharge Shield – No Conditioner Discharge shields may need to be removed for machine service, but a rotary disc header without a conditioner should NOT be operated without the discharge shield. 1. Position shield (A) until pins (B) (one on each side) engage the slots in support (C) and the bolt holes in shield (A) align with holes (D) in the header. -

Page 45: Chapter 5: Attaching Rotary Disc Header To Windrower

5.4 Attaching Header – Hydraulic Center-Link without Self-Alignment, page 56 5.1 Attaching Header to M2 Series Windrower The R113 SP is compatible with the M2170 and M2260 Windrowers, but not the M2170NT Windrower. DANGER To prevent bodily injury or death from the unexpected start-up or fall of a raised machine, always stop the engine and remove the key before leaving the operator’s seat, and always engage the safety props before going under the... - Page 46 ATTACHING ROTARY DISC HEADER TO WINDROWER Figure 5.2: Float Removal 4. Remove the float as follows: • If the HarvestTouch Display shows the message “Resume Float?”, then select NO (A). ™ • If the HarvestTouch ™ Display does NOT show the message, then select FLOAT ADJUST (B), select switch (C), and confirm the switch and float settings (D) are grayed out.

- Page 47 ATTACHING ROTARY DISC HEADER TO WINDROWER 5. Prepare the center-link as follows: • If not equipped with the Center-Link Alignment kit: Relocate pin (A) in the frame linkage as needed to raise center-link (B) until the hook is above the attachment pin on the header.

- Page 48 ATTACHING ROTARY DISC HEADER TO WINDROWER 9. Windrowers equipped with the Center-Link Alignment kit: Press HEADER TILT UP (A) or HEADER TILT DOWN (B) switches on the GSL to extend or retract the center-link cylinder until hook (C) is aligned with the header attachment pin.

- Page 49 ATTACHING ROTARY DISC HEADER TO WINDROWER 11. Press HEADER UP switch (A) to raise the header to its maximum height. NOTE: If one end of the header does NOT fully rise, rephase the lift cylinders as follows: Press and hold HEADER UP switch (A) until both cylinders stop moving.

- Page 50 ATTACHING ROTARY DISC HEADER TO WINDROWER 15. Disengage the safety props on both lift cylinders as follows: Turn lever (A) away from the header to raise the safety prop until the lever locks into the vertical position. b. Repeat the previous step for the opposite cylinder. NOTE: If the safety prop will NOT disengage, raise the header to release the prop.

- Page 51 ATTACHING ROTARY DISC HEADER TO WINDROWER Figure 5.13: Float Adjustment 18. Select switch (A), so that it turns green, to activate the float. 19. If not already set up, set the float as follows: The float preset, which is selected using the operator’s console, is displayed at location (B). Confirm if the desired preset is selected.

- Page 52 ATTACHING ROTARY DISC HEADER TO WINDROWER 22. Proceed as follows: • If attaching the header to an M2170 Windrower: 6.1 Connecting Header Hydraulic and Electrical Systems – M2170 Windrower, page 63 • If attaching the header to an M2260 Windrower: 6.2 Connecting Header Hydraulic and Electrical Systems –...

-

Page 53: Attaching Header To M1 Series Windrower

NOTE: The R113 SP is compatible with the M1170 and M1240 Windrowers, but not the M1170NT and M1170NT5 Windrowers. DANGER To prevent bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. - Page 54 ATTACHING ROTARY DISC HEADER TO WINDROWER 4. Remove hairpin (A) from clevis pin (B), and remove the pin from header support (C) on both sides of the header. DANGER Ensure that all bystanders have cleared the area. 5. Start the windrower engine. For instructions, refer to the windrower operator’s manual.

- Page 55 ATTACHING ROTARY DISC HEADER TO WINDROWER 9. Press soft key 3 (A) to remove the header float. NOTE: If the header float is active, the icon at soft key 3 will display Remove Float; if the header float has been removed, then the icon will display Resume Float.

- Page 56 ATTACHING ROTARY DISC HEADER TO WINDROWER 14. Windrowers equipped with the Center-Link Alignment kit: Adjust the position of center-link cylinder (A) with the switches on the GSL until hook (B) is above the header attachment pin. IMPORTANT: Hook release (C) must be down to enable the self- locking mechanism to function.

- Page 57 ATTACHING ROTARY DISC HEADER TO WINDROWER 16. Press HEADER UP switch (A) to raise the header to its maximum height. NOTE: If one end of the header does NOT fully raise, rephase the lift cylinders as follows: Press and hold HEADER UP switch (A) until both cylinders stop moving.

- Page 58 ATTACHING ROTARY DISC HEADER TO WINDROWER 20. Disengage the safety props on both lift cylinders as follows: Turn lever (A) away from the header to raise the safety prop until the lever locks into the vertical position. b. Repeat the previous step for the opposite cylinder. NOTE: If the safety prop will NOT disengage, raise the header to release the prop.

- Page 59 ATTACHING ROTARY DISC HEADER TO WINDROWER 24. Press soft key 3 (A) to restore the header float. NOTE: If the header float is active, the icon at soft key 3 will display Remove Float; if the header float has been removed, then the icon will display Resume Float.

-

Page 60: Attaching Header To M155, M155E4, Or M205 Windrower - Hydraulic Center-Link With Self-Alignment

ATTACHING ROTARY DISC HEADER TO WINDROWER 5.3 Attaching Header to M155, M155E4, or M205 Windrower – Hydraulic Center-Link with Self-Alignment The header will need to be physically attached to the windrower, and the hydraulic and electrical connections completed. The windrower may be equipped with an optional self-aligning hydraulic center-link, which allows the Operator to control the vertical position of the center-link from the cab. - Page 61 ATTACHING ROTARY DISC HEADER TO WINDROWER 4. Remove the float engagement pin from hole (A) to disengage the float springs, and insert the float engagement pin into storage hole (B). Secure the pin with the lynch pin. Repeat this step for the opposite linkage. IMPORTANT: To prevent damage to the lift system when lowering the header lift linkages without a header or a weight box...

- Page 62 ATTACHING ROTARY DISC HEADER TO WINDROWER 7. Slowly drive the windrower forward until windrower feet (A) enter header supports (B). Continue driving slowly forward until the feet engage the supports and the header is nudged forward. Figure 5.36: Header Support 8.

- Page 63 ATTACHING ROTARY DISC HEADER TO WINDROWER 12. Press HEADER UP switch (A) to raise the header to its maximum height. 13. If one end of the header does NOT fully rise, rephase the lift cylinders as follows: Press and hold the HEADER UP switch until both cylinders stop moving.

- Page 64 ATTACHING ROTARY DISC HEADER TO WINDROWER 15. Install clevis pin (A) through the support and the windrower lift member, and secure it with hairpin (B). Repeat this step for the opposite side of the machine. IMPORTANT: Ensure that clevis pin (A) is fully inserted and that the hairpin is installed behind the bracket.

- Page 65 ATTACHING ROTARY DISC HEADER TO WINDROWER 19. Start the engine, and press HEADER DOWN switch (A) on the GSL to fully lower the header. 20. Stop the engine, and remove the key from the ignition. Figure 5.44: Ground Speed Lever 262300 Revision A...

-

Page 66: Attaching Header - Hydraulic Center-Link Without Self-Alignment

ATTACHING ROTARY DISC HEADER TO WINDROWER 5.4 Attaching Header – Hydraulic Center-Link without Self-Alignment The header will need to be physically attached to the windrower, and the hydraulic and electrical connections completed. If the windrower is equipped with a hydraulic center-link that lacks the self-alignment capability, the Operator will have to manually attach the hydraulic center-link’s hook to the header’s center pin. - Page 67 ATTACHING ROTARY DISC HEADER TO WINDROWER 4. To disengage the float springs, move the float engagement pin from engaged position (A) and insert the pin into storage hole (B). Secure the float engagement pin with a lynch pin. Repeat this step for the opposite linkage. IMPORTANT: To avoid damaging the lift system when lowering the header lift linkages without a header or a weight box...

- Page 68 ATTACHING ROTARY DISC HEADER TO WINDROWER 7. Slowly drive the windrower forward until windrower feet (A) enter header supports (B). Continue driving slowly forward until the feet engage the supports and the header nudges forward. Figure 5.50: Header Support 8. Use the following GSL functions to position the center-link hook above the header attachment pin: •...

- Page 69 ATTACHING ROTARY DISC HEADER TO WINDROWER DANGER Ensure that all bystanders have cleared the area. 12. Start the engine. 13. Press HEADER UP switch (A) to raise the header to its maximum height. 14. If one end of the header does NOT fully raise, rephase the lift cylinders as follows: Press and hold the HEADER UP switch until both cylinders stop moving.

- Page 70 ATTACHING ROTARY DISC HEADER TO WINDROWER 16. Install clevis pin (A) through the support and the windrower lift member, and secure it with hairpin (B). Repeat this step for the opposite side of the machine. IMPORTANT: Ensure that clevis pin (A) is fully inserted and that the hairpin is installed behind the bracket.

- Page 71 ATTACHING ROTARY DISC HEADER TO WINDROWER 20. Start the engine, and press HEADER DOWN switch (A) on the GSL to fully lower the header. 21. Stop the engine, and remove the key from the ignition. Figure 5.58: Ground Speed Lever 262300 Revision A...

-

Page 73: Chapter 6: Attaching Hydraulic And Electrical Components

1. Shut down the engine, and remove the key from the ignition. 2. Retrieve the hydraulic hoses from the header. The R113 SP is compatible with the M155, M155E4, and M205, but not with the M100, M105, M150, and M200. 262300... - Page 74 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 3. Push latch (A) to unlock platform (B). 1015478 Figure 6.1: Left Platform 4. Pull platform (A) toward the cab until it stops and the latch is engaged. Figure 6.2: Left Platform 5. Attach hose support (A) to the frame near the windrower left cab-forward leg.

- Page 75 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 6. If an auger header is being replaced by a rotary disc header: Disconnect hose (A) from knife pressure receptacle (C) on the frame. Move the hose to storage location (B). Figure 6.4: Knife Pressure Hose Positions 1 - Knife Pressure Hose in Storage Position –...

- Page 76 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 8. Push latch (A) to unlock platform (B). 1015478 Figure 6.6: Left Platform 9. Pull platform (A) toward the cab until it stops and the latch is engaged. 10. Calibrate the header on the windrower. For instructions, refer to 6.2.4 Calibrating M2 Series Windrower and Header ™...

-

Page 77: Connecting Header Hydraulic And Electrical Systems - M2260 Windrower

IMPORTANT: The Low Pressure Case Drain kit (B6698) must be installed on the M2260 windrower before an R113 Rotary Disc Header can be connected to it. -

Page 78: Auger/Rotary Disc/Draper-Ready Configuration - Quick Coupler Connections

ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS For rotary disc-ready configuration with quick couplers (A), 6.2.3 Rotary Disc-Only Configuration – Quick Coupler refer to Connections, page 73 for instructions. Figure 6.10: Header Hydraulics Configuration – Rotary Disc-Ready with Quick Couplers 6.2.1 Auger/Rotary Disc/Draper-Ready Configuration – Quick Coupler Connections Windrowers with the auger/rotary disc/draper-ready configuration are equipped with the hydraulic connections needed to pair with an auger, rotary disc, or a draper header. - Page 79 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 4. Attach hose support (A) to the frame near the windrower left cab-forward leg. Route the hoses under the frame. NOTE: Ensure that the hoses remain as straight as possible and that they are not subject to damage from abrasion. Figure 6.12: Hose Support Attachment 5.

- Page 80 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 7. Connect the hydraulic hoses to the windrower with the quick coupler fittings as follows: Connect the pressure hose female coupler to receptacle (A). b. Connect the return hose male coupler to receptacle (B). Connect case drain hose (C) to the mating 1/2 in. coupler on the frame.

-

Page 81: Rotary Disc-Only Configuration - Hard-Plumbed Fittings

ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 6.2.2 Rotary Disc-Only Configuration – Hard-Plumbed Fittings The rotary disc-only configuration allows the windrower to operate with compatible rotary disc headers. DANGER To prevent bodily injury or death from the unexpected start-up of the machine, always stop the engine and remove the key from the ignition before making adjustments to the machine. - Page 82 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 5. Remove the existing quick couplers and elbow fittings (if they are installed) from header hydraulic pressure hose (A) and return hose (B). Do NOT remove the fittings from case drain hose (C). Figure 6.20: Rotary Disc Header Hose Bundle 6.

-

Page 83: Rotary Disc-Only Configuration - Quick Coupler Connections

ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 8. Pull platform (A) toward the cab until it stops and the latch is engaged. 9. Calibrate the header on the windrower. For instructions, refer to 6.2.4 Calibrating M2 Series Windrower and Header ™ on HarvestTouch Display, page Figure 6.23: Left Platform 6.2.3 Rotary Disc-Only Configuration –... - Page 84 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 4. Attach hose support (A) to the frame near the windrower left cab-forward leg. Route the hoses under the frame. NOTE: Ensure that the hoses remain as straight as possible and that they are not subject to damage from abrasion. Figure 6.25: Hose Support Attachment 5.

- Page 85 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 7. Install the male quick coupler at windrower pressure receptacle (A). 8. Install the female quick coupler at windrower return receptacle (B). Figure 6.28: Quick Couplers on Rotary Disc Ready Windrower 9. Connect the hydraulic hoses to the windrower as follows: Connect pressure hose female coupler (A) as shown.

-

Page 86: Calibrating M2 Series Windrower And Header On Harvesttouch ™ Display

ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 11. Pull platform (A) toward the cab until it stops and the latch is engaged. 12. Calibrate the header on the windrower. For instructions, refer to 6.2.4 Calibrating M2 Series Windrower and Header ™ on HarvestTouch Display, page Figure 6.31: Left Platform ™... - Page 87 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 1. Start the engine. 2. Engage the header. NOTE: Once the header is engaged, header gauges (A) will appear ™ on the HarvestTouch Display home page. 3. Select MENU (B). ™ Figure 6.32: HarvestTouch Display 4.

- Page 88 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 6. Select CALIBRATION (A). Figure 6.35: Setup Menu 7. Select KNIFE DRIVE (A). Figure 6.36: Calibration Selection Page 8. Select PLAY icon (A). NOTE: The PLAY icon will only appear if the header is engaged. Figure 6.37: Engage Header Warning 262300 Revision A...

- Page 89 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS The display changes to show that the calibration procedure has started. Knife drive calibration consists of nine stages. NOTE: If the engine speed is less than 1500 rpm prior to starting the calibration procedure, the system will raise the engine speed to 1500 rpm.

-

Page 90: Calibrating Header Position Sensors On Harvesttouch ™ Display

ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS ™ Calibrating Header Position Sensors on HarvestTouch Display ™ The header position sensors need to be recalibrated whenever the HarvestTouch Display is replaced, a position sensor is replaced, sensor readouts are erratic, a pump has been replaced, or when a new header type or attachment is connected to the windrower. - Page 91 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 4. Select CALIBRATION (A). Figure 6.43: Setup Menu 5. Select POSITION (A). Figure 6.44: Calibration Selection Page NOTE: Pressing X icon (A) on the screen (or pressing the HOME, BACK or any GSL button [buttons not shown]) at any time during the calibration process will EXIT the calibration procedure without saving your progress.

- Page 92 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 6. When stage one of the calibration is complete, press PLAY icon (A) on the screen to continue with stage two of the calibration process. Figure 6.46: Calibration Page 7. When stage two of the calibration is complete, press RESUME icon (A) on the screen to configure the HEADER FLOAT setting, or press HOME or BACK button (not shown) to exit.

-

Page 93: Connecting Header Hydraulic And Electrical Systems - M1240 Windrower

The header hydraulics connection procedure varies depending on the windrower configuration: • Draper header ready windrowers include one set of hydraulic quick couplers which are compatible with the header drive hoses on the R113 Rotary Disc Header. • Rotary disc header ready windrowers include hard plumbed hydraulics connections. - Page 94 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS Proceed with the steps that are relevant to the following windrower configurations: Steps for Connecting Windrower Configuration Hydraulics and Electrical Step 5, page 84 to Step Rotary disc/draper ready page 85 configuration (A) Rotary disc only hard Step 8, page 85 to Step...

- Page 95 Connect case drain hose (C) to mating 1/2 in. coupler on frame—installed with the M1240 Low Pressure Case Drain kit (B6698). The other 1/2 in. flat faced coupler for case drain (E) is NOT suitable for the R113 Rotary Disc Header. d. Connect the electrical harness to receptacle (D).

- Page 96 Connect case drain hose (C) to mating 1/2 in. coupler on frame—installed with the M1240 Low Pressure Case Drain kit (B6698). The other 1/2 in. flat faced coupler for case drain (E) is NOT suitable for the R113 Rotary Disc Header. d. Connect the electrical harness to receptacle (D).

- Page 97 Connect case drain hose (C) to mating 1/2 in. coupler on frame—installed with the M1240 Low Pressure Case Drain kit (B6698). The other 1/2 in. flat faced coupler for case drain (E) is NOT suitable for the R113 Rotary Disc Header. d. Connect the electrical harness to receptacle (D).

- Page 98 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 16. Pull platform (A) toward the cab until it stops and the latch is engaged. 17. Calibrate the knife pump on the windrower. For instructions, refer to 6.4.1 Calibrating M1 Series Windrower Knife Drive and Header on Harvest Performance Tracker Display, page Figure 6.61: Left Platform 262300...

-

Page 99: Connecting Header Hydraulic And Electrical Systems - M1170 Windrower

ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 6.4 Connecting Header Hydraulic and Electrical Systems – M1170 Windrower IMPORTANT: To prevent contamination of the hydraulic system, use a clean rag to remove dirt and moisture from all (fixed and movable) hydraulic couplers. 1. Open the platform. For instructions, refer to the windrower operator’s manual. - Page 100 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 6. Remove coupling and cap (A) and plug (B) from fittings on the windrower. Figure 6.64: Windrower Hydraulics 7. Install the male coupler onto pressure fitting (A), and the female coupler onto return fitting (B) on the windrower. 8.

- Page 101 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 10. Install cap (A) on tee. 11. Reposition elbow (B) as shown. Figure 6.67: Windrower Header Drive 12. Remove two existing nuts (A) securing the multicoupler to bracket (B). 13. Position new bracket (C) onto the existing bolts and secure with existing nuts (A).

-

Page 102: Calibrating M1 Series Windrower Knife Drive And Header On Harvest Performance Tracker Display

ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 17. Attach the couplers to receptacles on the windrower as follows: Connect the pressure hose female coupler to receptacle (A) b. Connect the return hose male coupler to receptacle (B) Connect the case drain hose coupler to receptacle (C) d. - Page 103 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 1. Start the engine. 2. Press soft key 5 (A) to open the HPT main menu. NOTE: Calibrations MUST be performed with the engine running. Some calibrations will not be available with the engine off. 3.

-

Page 104: Connecting Header Hydraulic And Electrical Systems - M155 Or M155E4 Windrowers

NOTE: M155 or M155E4 Windrowers require Disc Drive Manifold kit (B4657) to hydraulically connect an R113 Rotary Disc Header. 1. Disengage and rotate lever (A) counterclockwise to the FULLY-UP position. - Page 105 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 4. Position the hose support with lower bolt (A) in the forward hole as shown. Loosen both bolts, and adjust as required. Figure 6.77: Hose Support 5. Move the windrower’s left (cab-forward) platform (A) to the OPEN position.

- Page 106 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 6. Route windrower hose bundle (A) through hose support (B) on the header. 7. Route pressure hose (C) from the header through support (B) to the windrower. Figure 6.79: Hose Bundle IMPORTANT: Keep the open lines and ports clean. 8.

- Page 107 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 9. Remove caps and plugs on hoses from the windrower and lines on the header. 10. Connect pressure hose (B) from drive manifold port M1 to steel line (A) attached to motor port A. Figure 6.81: Hydraulic Connections 11.

- Page 108 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS NOTE: If the windrower is equipped with a reverser valve (A) for an auger header, route return hose (C) from port R1 on the reverser valve to steel line (B) attached to motor port B. Figure 6.83: Windrower Hose Connections with Reverser 12.

- Page 109 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 13. Connect electrical harness (A) from the windrower to the electrical connector on the header. NOTE: Hydraulic hoses removed from the illustration to improve clarity. Figure 6.85: Electrical Connection 14. Lower and lock lever (A). Secure hose (B) with three cinch straps (C).

- Page 110 ATTACHING HYDRAULIC AND ELECTRICAL COMPONENTS 15. Move platform (A) to the CLOSED position. For instructions, refer to the windrower operator’s manual. Figure 6.87: Top View of Windrower 262300 Revision A...

-

Page 111: Connecting Header Hydraulic And Electrical Systems - M205 Windrower

Connect the header hydraulic and electrical components to the windrower to operate the header. Connect the R113 Rotary Disc Header to the M205 Windrower using the M205 Compatibility kit (MD #257188). For instructions, refer to the M205 Compatibility kit, or Connecting R113 Rotary Disc Header Hydraulics and Electrical – M205 Windrower in the header’s operator manual. -

Page 113: Chapter 7: Unpacking Curtains

Chapter 7: Unpacking Curtains The curtain is installed at the front of the header. It minimizes the risk of thrown objects ejected at high speed from the cutterbar area. WARNING Ensure that the cutterbar is completely clear of foreign objects. These objects can be ejected with considerable force when the machine is started, which can result in serious injury to bystanders or equipment damage. - Page 114 UNPACKING CURTAINS 3. Open the cutterbar doors. For instructions, refer to 11.3.1 Opening Cutterbar Doors, page 138. 4. Check the cutterbar area for debris and foreign objects. Ensure that all material is removed. Figure 7.3: Cutterbar Doors Open 5. Close the cutterbar doors. For instructions, refer to 11.3.3 Closing Cutterbar Doors, page 140.

-

Page 115: Chapter 8: Installing Options

Chapter 8: Installing Options Install options (if supplied with the shipment) according to the instructions supplied with each kit. 8.1 Installing Tall Crop Dividers To install the Tall Crop Divider kit (B5800), follow these steps: DANGER To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. -

Page 117: Chapter 9: Lubricating Rotary Disc Header

Chapter 9: Lubricating Rotary Disc Header The rotary disc header has been lubricated at the factory. However, you should lubricate the rotary disc header prior to delivery to offset the effects of weather during outside storage and transport. DANGER To prevent bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. -

Page 118: Lubrication Locations

LUBRICATING ROTARY DISC HEADER 9.1 Lubrication Locations The lubrication locations are identified according to the maintenance schedule for the header. 1024914 A - Idler/Tensioner Pivot B - Bearing, Roller Conditioner (4 Places) C - U-Joint, Upper Driveline (2 Places) D - Slip Joints, Conditioner Drivelines 3 E - U-Joint, Lower Driveline (2 Places) Use high-temperature, extreme-pressure (EP2) performance grease with 10% max molybdenum disulphide (NLGI grade 2) lithium base. -

Page 119: Chapter 10: Performing Predelivery Checks

Chapter 10: Performing Predelivery Checks Perform final checks and adjustments as listed on the Predelivery Checklist (yellow sheet at the back of this instruction) to ensure the machine is field-ready. Refer to the referenced pages as indicated on the Predelivery Checklist for detailed instructions. -

Page 120: Adjusting Conditioner Drive Belt

PERFORMING PREDELIVERY CHECKS 10.1.1 Adjusting Conditioner Drive Belt If necessary, adjust the conditioner drive belt tensioning spring to the correct length. 1. Open the left driveshield. For instructions, refer to 11.1 Opening Driveshields, page 135. 2. Turn jam nut (A) counterclockwise to unlock the tension adjustment. -

Page 121: Checking Skid Shoes

All skid shoes (A) should be at the same position, either up (shown at right) or down. NOTE: The R113 Rotary Disc Header is equipped with one skid shoe at each end of the machine. If adjustment is required, refer to the header operator’s manual. -

Page 122: Checking Float - M1 And M2 Series Windrowers

PERFORMING PREDELIVERY CHECKS 10.3 Checking Float – M1 and M2 Series Windrowers The instructions in this section will show you how to properly check the header float setting by measuring the force required to lift the header. DANGER To prevent bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. -

Page 123: Setting Float - M1 Series Windrowers

PERFORMING PREDELIVERY CHECKS 10.3.1 Setting Float – M1 Series Windrowers The float can be set for windrowing with the cutterbar on the ground. The optimum float setting lets the rotary disc header follow the contour of the terrain. 1. Set the center-link to the mid-range position (5.0 on the Harvest Performance Tracker [HPT]). -

Page 124: Setting Float - M2 Series Windrowers

PERFORMING PREDELIVERY CHECKS 10.3.2 Setting Float – M2 Series Windrowers The float can be set for windrowing with the cutterbar on the ground. The optimum float setting lets the rotary disc header follow the contour of the terrain. ™ 1. Set the center-link to the mid-range position (5.0 on the HarvestTouch Display). - Page 125 PERFORMING PREDELIVERY CHECKS 4. Press arrows (A) to adjust left or right float settings. NOTE: Float adjustments of 1.0 (out of 10) change the header weight at the cutterbar by approximately 91 kg (200 lb.). Adjust the float in increments of 0.05 to optimize field performance.

-

Page 126: Checking Float - M Series Windrower

PERFORMING PREDELIVERY CHECKS 10.4 Checking Float – M Series Windrower The windrower is equipped with primary (coarse) and secondary (fine) float adjustment systems. The primary adjustment allows the Operator to move the system’s drawbolts to change the tension on the springs in the lift linkages. The secondary adjustment allows the Operator to use hydraulic cylinders to change the spring tension. -

Page 127: Adjusting Float Using Drawbolts - M Series Windrowers

PERFORMING PREDELIVERY CHECKS 5. Set the left and right float fine adjustments on the CDM to approximately 5.0: Using FLOAT SELECTOR switch (B), push + to increase the float or – to decrease the float on the left side of the header. -

Page 128: Checking Roll Timing

PERFORMING PREDELIVERY CHECKS 10.5 Checking Roll Timing Check the roll timing if excessive noise is coming from the conditioner rolls. The roll timing is factory-set and should not require adjustment, however, if there is excessive noise coming from the conditioner rolls, the timing will need to be adjusted. Listen to the rollers. Excessive noise may come from dirt build up, or the rollers being out of time and would require adjustment.For instructions, refer to the header operator’s manual. - Page 129 PERFORMING PREDELIVERY CHECKS 3. Secure bottom roll (A). 4. Rotate upper roll (B) in a counterclockwise direction until it stops. 5. Make a mark (C) across yoke (D) and gearbox flange (E). Figure 10.15: Conditioner Drive 6. Secure bottom roll (A). 7.

- Page 130 PERFORMING PREDELIVERY CHECKS 9. Determine center point (A) between the two marks on the yoke plate, and place a third mark. 10. Rotate upper roll (B) counterclockwise until the mark on the gearbox flange lines up with the third (center) mark. Figure 10.17: Conditioner Drive 11.

-

Page 131: Checking And Adding Lubricant - Conditioner Roll Timing Gearbox

PERFORMING PREDELIVERY CHECKS 10.6 Checking and Adding Lubricant – Conditioner Roll Timing Gearbox The conditioner roll timing gearbox is located inside the drive compartment at the right side of the rotary disc header. DANGER To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. - Page 132 PERFORMING PREDELIVERY CHECKS CAUTION To avoid injury, keep hands and fingers away from corners of doors when closing. 10. Pull down on door (A) from the top to close. 11. Ensure that the curtains hang properly and completely enclose the cutterbar area. Figure 10.21: Cutterbar Doors and Curtains 262300 Revision A...

-

Page 133: Checking Header Drive Gearbox Lubricant

PERFORMING PREDELIVERY CHECKS 10.7 Checking Header Drive Gearbox Lubricant The header drive gearbox lubricant must be checked to ensure that it is slightly running out of the hole when the plug is removed. DANGER To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. -

Page 134: Checking And Adding Lubricant - Cutterbar

PERFORMING PREDELIVERY CHECKS 10.8 Checking and Adding Lubricant – Cutterbar Correct lubricant and levels are essential to the performance and longevity of the cutterbar. DANGER To prevent bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat. - Page 135 PERFORMING PREDELIVERY CHECKS 8. Reinstall the inspection plug. WARNING Ensure that all bystanders have cleared the area. 9. Clear all bystanders from the area. 10. Start the engine, and raise the header slightly. 11. Lower the header onto blocks, so that the left end is slightly higher than the right end. 12.

-

Page 136: Checking Roll Gap

PERFORMING PREDELIVERY CHECKS 10.9 Checking Roll Gap The correct roll gap is required for proper conditioning. The setting is different for steel and polyurethane rolls. DANGER To prevent injury or death from the unexpected startup of the machine, stop the engine and remove the key from the ignition before you leave the operator’s seat. -

Page 137: Adjusting Roll Gap - Polyurethane Rolls

PERFORMING PREDELIVERY CHECKS 3. Loosen jam nut (A) on both sides of the conditioner. 4. Turn lower nut (B) counterclockwise until the upper roll rests on the lower roll. Ensure the rolls intermesh. 5. Turn lower nut (B) two and a half full turns clockwise to raise the upper roll and achieve a 6 mm (1/4 in.) roll gap. -

Page 138: Checking Roll Tension

PERFORMING PREDELIVERY CHECKS 10.10 Checking Roll Tension Roll tension is indicated by the exposed thread on the roll tension adjuster bolt. 1. Measure the amount of exposed thread on the roll tension adjuster bolt (A) at each end of the conditioner. Measurement (B) should be 12–15 mm (1/2–9/16 in.) for polyurethane and steel roll conditioners. -

Page 139: Adjusting Conditioner Baffle Position

PERFORMING PREDELIVERY CHECKS 10.11 Adjusting Conditioner Baffle Position The position of the adjustable conditioner baffle, along with the forming shields, determines the height and width of the windrow: raising the baffle produces a fluffier, narrower windrow; lowering the baffle produces a flatter, wider windrow. 1. -

Page 140: Checking And Adjusting Forming Shield Deflector Position

PERFORMING PREDELIVERY CHECKS 10.12 Checking and Adjusting Forming Shield Deflector Position The position of the side deflectors controls the width and placement of the windrow. Both side deflectors must be evenly set at the same position. If the side deflectors are not evenly set, follow the steps below to adjust them: DANGER To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. -

Page 141: Checking Lights

PERFORMING PREDELIVERY CHECKS 10.13 Checking Lights Check the hazard lights to ensure that they are attached securely and functioning properly. 1. Check light mountings (A) for security and damage. 2. Check operation of hazard lights (B) during machine run-up. Figure 10.33: Lights 262300 Revision A... -

Page 142: Checking Manuals

(A) at the right end of the header: • R1 Series Rotary Disc Header Operator’s Manual • R113 and R116 Rotary Disc Headers Parts Catalog • R1 Series Rotary Disc Header Quick Card Open the right driveshield to access the manual case. For instructions, refer to 11.1 Opening Driveshields, page... -

Page 143: Checking Disc Timing Tool And Spindle Nut Wrench

PERFORMING PREDELIVERY CHECKS 10.15 Checking Disc Timing Tool and Spindle Nut Wrench The R113 Rotary Disc Headers are shipped with a two part disc timing tool and a spindle nut wrench on the panel at the left end of the header. -

Page 144: Running Up Header

PERFORMING PREDELIVERY CHECKS 10.16 Running up Header Running up the header to ensure that everything is working as expected, and that the machine is ready for delivery to the customer. WARNING • Ensure that bystanders remain at least 100 m (330 ft.) from the header while it is operating. Stones and other objects can be ejected from the header with great force. -

Page 145: Chapter 11: Reference

Chapter 11: Reference Additional information and commonly repeated procedures are included in the reference chapter. 11.1 Opening Driveshields The driveshields offer protection for its sensitive components. Open them only when you intend to service the header. WARNING To reduce the risk of personal injury, do NOT operate the machine without the driveshields in place and secured. NOTE: The illustrations shown in this procedure apply to the left driveshield;... - Page 146 REFERENCE 3. Insert the flat end of tool (A) into latch (B) and turn it counterclockwise to unlock the driveshield. Figure 11.3: Driveshield Latch 4. Pull the top of driveshield (A) away from the header to open it. NOTE: For improved access, lift the driveshield off the pins at the base of the shield, and lay the shield on the header.

-

Page 147: Closing Driveshields

REFERENCE 11.2 Closing Driveshields Close the driveshields when your maintenance or repair tasks are complete. WARNING To reduce the risk of personal injury, do NOT operate the machine without the driveshields in place and secured. NOTE: The illustrations shown in this procedure apply to the left driveshield; the right driveshield is similar. 1. -

Page 148: Cutterbar Doors

REFERENCE 11.3 Cutterbar Doors Two doors with rubber curtains provide access to the cutterbar area. WARNING To reduce the risk of personal injury and machine damage, do NOT operate the machine without all the cutterbar doors down or without curtains installed and in good condition. Objects in the path of the blades can be ejected with considerable force when the machine is started. -

Page 149: Opening Cutterbar Doors - Export

REFERENCE 11.3.2 Opening Cutterbar Doors – Export Machines sold outside North America have a tool-operated latch on the cutterbar doors. DANGER To prevent bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat. -

Page 150: Closing Cutterbar Doors

REFERENCE 4. Lift up on doors (A) while pressing down on the latch. Figure 11.11: Cutterbar Doors 11.3.3 Closing Cutterbar Doors Do NOT operate the machine without closing the cutterbar doors. CAUTION To avoid injury, keep hands and fingers away from corners of doors when closing. 1. -

Page 151: Torque Specifications

REFERENCE 11.4 Torque Specifications The following tables provide torque values for various bolts, cap screws, and hydraulic fittings. Refer to these values only when no other torque value has been specified in a given procedure. • Tighten all bolts to the torque values specified in the charts below, unless you are directed otherwise in this manual. •... - Page 152 REFERENCE Table 11.2 Metric Class 8.8 Bolts and Class 9 Distorted Thread Nut Torque (Nm) Torque (lbf·ft) (*lbf·in) Nominal Size (A) Max. Max. Min. Min. 3-0.5 3.5-0.6 4-0.7 5-0.8 6-1.0 8-1.25 18.8 20.8 *167 *185 10-1.5 12-1.75 Figure 11.14: Bolt Grades 14-2.0 16-2.0 20-2.5...

-

Page 153: Metric Bolt Specifications - Cast Aluminum

REFERENCE Table 11.4 Metric Class 10.9 Bolts and Class 10 Distorted Thread Nut Torque (Nm) Torque (lbf·ft) (*lbf·in) Nominal Size (A) Max. Max. Min. Min. 3-0.5 3.5-0.6 4-0.7 5-0.8 6-1.0 10.7 11.8 *105 8-1.25 10-1.5 12-1.75 14-2.0 Figure 11.16: Bolt Grades 16-2.0 20-2.5 24-3.0... -

Page 154: O-Ring Boss Hydraulic Fittings - Adjustable

REFERENCE 11.4.3 O-Ring Boss Hydraulic Fittings – Adjustable The standard torque values are provided for adjustable hydraulic fittings. If a procedure specifies a different torque value for the same type and size of fitting found in this topic, refer to the value specified in the procedure instead. 1. -

Page 155: O-Ring Boss Hydraulic Fittings - Non-Adjustable

REFERENCE Table 11.6 O-Ring Boss (ORB) Hydraulic Fittings – Adjustable and Non-Adjustable Torque Value Thread Size (in.) SAE Dash Size lbf·ft (*lbf·in) 5/16–24 10–11 *89–97 3/8–24 18–20 *159–177 7/16–20 29–32 21–24 1/2–20 32–35 24–26 9/16–18 40–44 30–32 3/4–16 70–77 52–57 7/8–14 115–127 85–94... -

Page 156: O-Ring Face Seal Hydraulic Fittings

REFERENCE Table 11.7 O-Ring Boss (ORB) Hydraulic Fittings – Adjustable and Non-Adjustable (continued) Torque Value Thread Size (in.) SAE Dash Size lbf·ft (*lbf·in) 9/16–18 40–44 30–32 3/4–16 70–77 52–57 7/8–14 115–127 85–94 1 1/16–12 183–201 135–148 1 3/16–12 237–261 175–193 1 5/16–12 271–298 200–220... -

Page 157: Tapered Pipe Thread Fittings

REFERENCE 2. Apply hydraulic system oil to O-ring (B). 3. Align the tube or hose assembly so that the flat face of sleeve (A) or (C) comes into full contact with O-ring (B). 4. Thread tube or hose nut (D) until it is hand-tight. The nut should turn freely until it bottoms out. - Page 158 REFERENCE 4. Torque the connector to the appropriate torque angle. The turns from finger tight (TFFT) and flats from finger tight (FFFT) values are shown in Table 11.9, page 148. Ensure that the tube end of a shaped connector (typically a 45° or 90° elbow) is aligned to receive the incoming tube or hose assembly.

-

Page 159: Conversion Chart

REFERENCE 11.5 Conversion Chart This manual uses both SI units (including metric) and US customary units (sometimes referred to as standard units) of measurement. A list of those units along with their abbreviations and conversion factors is provided here for your reference. -

Page 160: Definitions

Touch screen display on an M2 Series Windrower Joint Industrial Council: A standards body that developed standard sizing and shape for original 37° flared fitting MacDon M100, M105, M150, M155, M155E4, M200, and M205 Windrowers M Series Windrowers M2 Series Windrowers... - Page 161 REFERENCE Table 11.11 Definitions (continued) Term Definition An axial load placed on a bolt or screw, usually measured in Newtons (N) or pounds (lb.). Tension This term can also be used to describe the force a belt exerts on a pulley or sprocket Turns from finger tight TFFT The product of a force * the length of a lever arm, usually measured in Newton-meters...

-

Page 162: Predelivery Checklist

Predelivery Checklist Perform these checks and adjustments before delivering the machine to your Customer. If adjustments are required, refer to the appropriate page number in this manual. The completed Checklist should be retained by either the Operator or the Dealer. WARNING Do NOT operate the machine with the driveshields open. - Page 163 REFERENCE Table .12 Predelivery Checklist (continued) ü ü Item Reference Check cutterbar area carefully for loose parts and hardware on the cutterbar. — WARNING These objects can be ejected with considerable force when the machine is started, and may result in serious injury or machine damage.

-

Page 165: Recommended Lubricants

Grade 2) lithium base Lubricant: Gear Lubricant High thermal and oxidation stability 8 L (8.5 qts [US]) SAE 80W-90 R113 Cutterbar API service class GL-5 Fully synthetic oil API GL-5 minimum, Conditioner roll timing 0.7 L (0.75 qts [US]) SAE 85W-140... - Page 166 CUSTOMERS M M a a c c D D o o n n . . c c o o m m DEALERS P P o o r r t t a a l l . . M M a a c c D D o o n n . . c c o o m m Trademarks of products are the marks of their respective manufacturers and/or distributors.

Need help?

Do you have a question about the R113 and is the answer not in the manual?

Questions and answers