RADWAG WPY series User Manual

Hide thumbs

Also See for WPY series:

- User manual (188 pages) ,

- User manual (304 pages) ,

- User manual (22 pages)

Table of Contents

Advertisement

Quick Links

User Manual

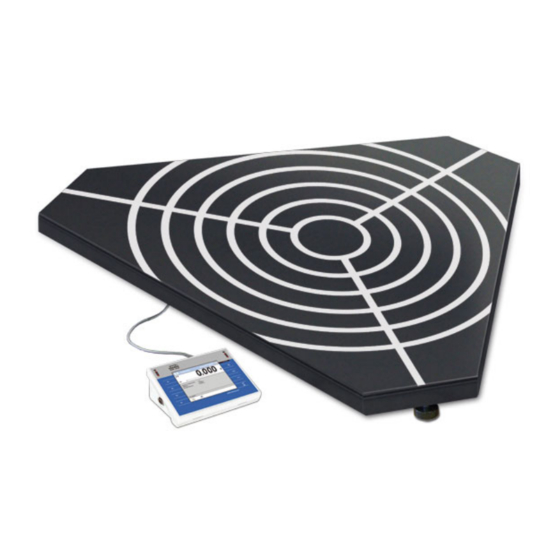

Scales of WPY/KO series

Manual number:

ITKU-47-09-01-11-A

Mass Comparator

M A N U F A C T U R E R O F E L E C T R O N I C

W E I G H I N G I N S T R U M E N T S

RADWAG Wagi Elektroniczne, 26–600 Radom Bracka 28 Street - POLAND

Phone +48 48 38 48 800, phone/fax. +48 48 385 00 10

Selling department +48 48 366 80 06

www.radwag.com

Advertisement

Table of Contents

Need help?

Do you have a question about the WPY series and is the answer not in the manual?

Questions and answers