YASKAWA Motoman NX100 Manual

Controller

Hide thumbs

Also See for Motoman NX100:

- Operator's manual (493 pages) ,

- Manual (405 pages) ,

- Instructions manual (309 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for YASKAWA Motoman NX100

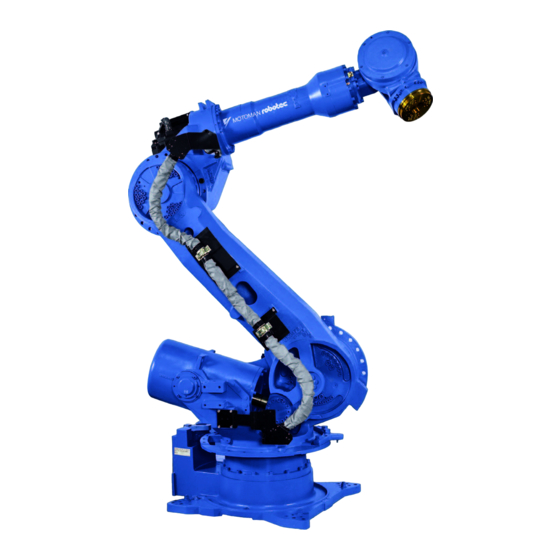

- Page 1 Motoman NX100 Controller HP165-100* Manipulator Manual Part Number: 151780-1CD Revision: Motoman, Incorporated 805 Liberty Lane West Carrollton, OH 45449 TEL: (937) 847-6200 FAX: (937) 847-6277 24-Hour Service Hotline: (937) 847-3200 * North American Naming International Naming - ES165N-100...

- Page 2 Motoman, Inc. ©2006 by MOTOMAN All Rights Reserved Because we are constantly improving our products, we reserve the right to change specifications without notice. MOTOMAN is a registered trademark of YASKAWA Electric Manufacturing.

- Page 3 HP165-100 151780-1 Chapter 1 Introduction About This Document This manual provides information for the HP165-100 manipulator and contains the following sections: CHAPTER 1 - INTRODUCTION Provides general information about the structure of this manual, a list of reference documents, and customer service information.

- Page 4 Manipulator Manual Chapter 1 Introduction Notes page 2 Final...

- Page 5 HP165-100 151780-1 Chapter 2 Safety Introduction It is the purchaser’s responsibility to ensure that all local, county, state, and national codes, regulations, rules, or laws relating to safety and safe operating conditions for each installation are met and followed. We suggest that you obtain and review a copy of the ANSI/RIA National Safety Standard for Industrial Robots and Robot Systems.

- Page 6 Manipulator Manual Chapter 2 Safety This safety section addresses the following: • Standard Conventions (Section 2.2) • General Safeguarding Tips (Section 2.3) • Mechanical Safety Devices (Section 2.4) • Installation Safety (Section 2.5) • Programming, Operation, and Maintenance Safety (Section 2.6) Standard Conventions This manual includes the following alerts in descending order of severity...

- Page 7 HP165-100 151780-1 General Safeguarding Tips All operators, programmers, plant and tooling engineers, maintenance personnel, supervisors, and anyone working near the robot must become familiar with the operation of this equipment. All personnel involved with the operation of the equipment must understand potential dangers of operation.

- Page 8 Manipulator Manual Chapter 2 Safety Installation Safety Safe installation is essential for protection of people and equipment. The following suggestions are intended to supplement, but not replace, existing federal, local, and state laws and regulations. Additional safety measures for personnel and equipment may be required depending on system installation, operation, and/or location.

- Page 9 HP165-100 151780-1 • Any modifications to PART 1, System Section, of the robot controller concurrent I/O program can cause severe personal injury or death, as well as damage to the robot! Do not make any modifications to PART 1, System Section. Making any changes without the written permission of Motoman will VOID YOUR WARRANTY! •...

- Page 10 Manipulator Manual Chapter 2 Safety Notes page 8 Final...

- Page 11 YASKAWA MOTOMAN-ES165N-100 INSTRUCTIONS YR-ES165N-A10 (STANDARD SPECIFICATION) YR-ES165N-A11 (SLU-AXES WITH L.S. SPECIFICATION) Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain for future reference. MOTOMAN INSTRUCTIONS MOTOMAN-ES165N-100 INSTRUCTIONS NX100 INSTRUCTIONS NX100 OPERATOR’S MANUAL NX100 MAINTENACE MANUAL The NX100 operator’s manuals above correspond to specific usage.

- Page 12 If such modification is made, the manual number will also be revised. • If your copy of the manual is damaged or lost, contact a YASKAWA rep- resentative to order a new copy. The representatives are listed on the back cover.

- Page 13 HW0481994 Notes for Safe Operation Read this manual carefully before installation, operation, maintenance, or inspection of the NX100. In this manual, the Notes for Safe Operation are classified as “WARNING”, “CAUTION”, “MANDATORY”, or “PROHIBITED”. Indicates a potentially hazardous situation which, if not avoided, WARNING could result in death or serious injury to personnel.

- Page 14 HW0481994 WARNING • Before operating the manipulator, check that servo power is turned off when the emergency stop buttons on the front door of the NX100 and programming pendant are pressed. When the servo power is turned off, the SERVO ON LED on the program- ming pendant is turned off.

- Page 15 • Read and understand the Explanation of the Warning Labels in the NX100 instructions before operating the manipulator. Definition of Terms Used Often in This Manual The MOTOMAN manipulator is the YASKAWA industrial robot product. The manipulator usually consists of the controller, the programming pendant, and manipulator cables.

- Page 16 Also, an identification label with important information is placed on the body of the manipula- tor. Prior to operating the manipulator, confirm the contents. WARNING WARNING MOTOMAN TYPE PAYLOAD MASS DATE ORDER NO. SERIAL NO. YASKAWA ELECTRIC CORPORATION JAPAN Moving parts may Do not enter cause injury robot work area 6/76...

- Page 17 HW0481994 Product Confirmation 1.1 Contents Confirmation ......1 1.2 Order Number Confirmation .

-

Page 18: Table Of Contents

HW0481994 Allowable Load for Wrist Axis and Wrist Flange 6.1 Allowable Wrist Load ....... 6 6.2 Wrist Flange . - Page 19 HW0481994 Grease Replenishment for B-Axis Speed Reducer (Refer to " Fig. 27 U-Arm Diagram ".) ....9-16 Grease Replenishment for T-Axis Speed Reducer (Refer to " Fig. 27 U-Arm Diagram ".) ....9-16 Grease Exchange for R-, B-, T-Axis Gears in the Casing (Refer to "...

- Page 20 HW0481994 1.1 Contents Confirmation 1 Product Confirmation CAUTION • Confirm that the manipulator and the NX100 have the same order num- ber. Special care must be taken when more than one manipulator is to be installed. If the numbers do not match, manipulators may not perform as expected and cause injury or damage.

- Page 21 HW0481994 1.2 Order Number Confirmation Order Number Confirmation Check that the order number of the manipulator corresponds to the NX100. The order number is located on a label as shown below. Label (Enlarged view) THE MANIPULATOR AND THE CONTROLLER SHOULD HAVE SAME ORDER NUMBER. Check that the manipulator and the NX100 have the same order number.

- Page 22 HW0481994 2.1 Transporting Method 2 Transporting CAUTION • Sling applications and crane or forklift operations must be performed by authorized personnel only. Failure to observe this caution may result in injury or damage. • Avoid excessive vibration or shock during transporting. Failure to observe this caution may adversely affect the performance as the system con- sists of precision components.

- Page 23 HW0481994 2.1 Transporting Method 2.1.1 Using a Crane As a rule, when removing the manipulator from the package and moving it, a crane should be used. The manipulator should be lifted using wire rope threaded through shipping bolts and brackets. Be sure the manipulator is fixed with the shipping bolts and brackets before trans- porting, and lift it in the posture as shown in "...

- Page 24 HW0481994 2.2 Shipping Bolts and Brackets Shipping Bolts and Brackets The manipulator is provided with shipping bolts and brackets at position A and with the hexa- gon socket head cap screws at point B. (" Fig. 2 Transporting Position "). Shipping bracket Shipping bolt Hook...

- Page 25 HW0481994 3 Installation WARNING • Install the safeguarding. Failure to observe this warning may result in injury or damage. • Install the manipulator in a location where the manipulator’s tool or the workpiece held by the manipulator will not reach the wall, safeguarding, or NX100 when the arm is fully extended.

- Page 26 HW0481994 3.1 Installation of the Safeguarding Installation of the Safeguarding To insure safety, be sure to install the safeguarding. They prevent unforeseen accidents with personnel and damage to equipment. The following is quoted for your information and guid- ance. Responsibility for Safeguarding (ISO 10218) The user of a manipulator or robot system shall ensure that safeguarding is provided and used in accordance with Sections 6, 7, and 8 of this standard.

- Page 27 HW0481994 3.3 Location 3.2.1 Mounting Example Fix the baseplate onto the floor. The baseplate should be rugged and durable to prevent shift- ing of the manipulator or the fixture. The thickness of the baseplate is 50mm or more, and an M20 size or larger anchor bolt is recommended.

- Page 28 HW0481994 4 Wiring WARNING • Ground resistance must be 100 Ω or less. Failure to observe this warning may result in fire or electric shock. • Before wiring, make sure to turn the primary power supply off, and put up a warning sign. (ex. DO NOT TURN THE POWER ON.) Failure to observe this warning may result in fire or electric shock.

- Page 29 HW0481994 4.1 Grounding Grounding Follow local regulations for grounding line size. A line of 5.5mm or more is recommended. • Do not use this line in common with other ground lines or grounding electrodes for other NOTE electric power, motor power, welding devices, etc. •...

- Page 30 HW0481994 4.2 Manipulator Cable Connection 4.2.2 Connection to the NX100 First connect the 2BC cable then 3BC and 1BC cables respectively after verifying the num- bers. The numbers are on both the manipulator cables and the NX100 board connectors. When connecting, insert cables adjusting the cable connector positions to the main key posi- tions of the NX100, and then set the lever until it clicks.

- Page 31 HW0481994 4.2 Manipulator Cable Connection molex molex molex Connector details (Manipulator side) Fig. 7 (a) Details of the Manipulator Cable Connectors (Manipulator Side) Fig. 7 (b) Manipulator Cable Connections to the NX100 21/76...

- Page 32 HW0481994 5.1 Basic Specifications 5 Basic Specifications Basic Specifications Table.3 Basic Specifications MOTOMAN-ES165N-100 Item Model MOTOMAN-ES165N-100 with external cabling for SRBT-axes Configuration Vertically Articulated Degree of Freedom Payload 100kg ±0.2mm Repeatability S-Axis (turning) ±180° L-Axis (lower arm) +76°, -60° Range of U-Axis (upper arm) +230°, -142.5°...

- Page 33 HW0481994 5.2 Part Names and Working Axes Part Names and Working Axes Wrist Upper arm (U arm) Wrist flange Rotary head Lower arm (L arm) (S head) Base Fig. 8 Part Names and Working Axes Manipulator Base Dimensions +0.021 290 0.1 290 0.1 Fitting surface dia.

- Page 34 HW0481994 5.4 Dimensions and P-Point Maximum Envelope Dimensions and P-Point Maximum Envelope 3410 5330 2320 3010 P-point maximum envelope 1590 P-point Units: mm Fig. 10 Dimensions and P-Point Maximum Envelope 24/76...

- Page 35 5.5 Alterable Operating Range Alterable Operating Range The operating range of the S-Axis can be altered according to the operating conditions as shown in “Table. 4 S-Axis Operating Range”. If alteration is necessary, contact your Yaskawa representative in advance. Table. 4...

- Page 36 HW0481994 5.5 Alterable Operating Range 5.5.1 Components for Altering Operating Range Arrange the components listed in " Fig. 11 The Components of the S-Axis Stopper ", when modifying the angle of S-axis. Pin (drawing No. HW0402104-1, 1 pin) Stopper (drawing No. HW0302424-2, 1 stopper) Hexagon socket head cap screw M20 (length;...

- Page 37 HW0481994 5.5 Alterable Operating Range 5.5.2 Notes on the Mechanical Stopper Installation • For S-Axis mechanical stopper, install the stopper (drawing No. HW0302424-2) with the pin which is used bottom up (drawing No. HW0402104-1) as in " Fig. 11 The Components of the S-Axis Stopper ".

- Page 38 HW0481994 5.5 Alterable Operating Range 5.5.3 Adjustment to the Pulse Limitation of S-Axis Apply the Instruction for NX100 Concurrent I/O Parameter (Manual No.:RE-CKI-A442) as part of reference materials for adjusting the programming pendant when modifying the range of motion of S-Axis. + 1st Axis ) : SICxG200 The limitation to the pulse (Pulse Soft Limit - 1st Axis ) : SICxG208...

- Page 39 HW0481994 5.5 Alterable Operating Range 29/76...

- Page 40 HW0481994 5.5 Alterable Operating Range Mounting the S-Axis Stopper by Settable Angles Hexagon socket head cap screws The stopper could be utlized by either side. The Settled Model of +180 Degree Hexagon socket head cap screws The stopper could be utlized by either side.

- Page 41 HW0481994 5.5 Alterable Operating Range The stopper only utlized by one side with this angle Hexagon socket head cap screws The Settled Model of +150 Degree The stopper could be utlized by either side. Hexagon socket head cap screws The Settled Model of +135 Degree Fig.

- Page 42 HW0481994 5.5 Alterable Operating Range The stopper is only utlized by one side with this angle Hexagon socket head cap screws The Settled Model of +120 Degree Hexagon socket The stopper could head cap screws be utlized by either side. The Settled Model of +105 Degree Fig.

- Page 43 HW0481994 5.5 Alterable Operating Range The stopper could be utlized by either side. Hexagon socket head cap screws The Settled Model of + 90 Degree The stopper could be utlized by either side. Hexagon socket head cap screws The Settled Model of + 75 Degree Fig.

- Page 44 HW0481994 5.5 Alterable Operating Range Hexagon socket The stopper is only utlized head cap screws by one side with this angle The Settled Model of + 60 Degree The stopper could be utilized by either side. Hexagon socket head cap screws The Settled Model of +45 Degree Fig.

- Page 45 HW0481994 5.5 Alterable Operating Range The stopper is only utlized Hexagon socket by one side with this angle head cap screws The Settled Model of +30 Degree The stopper could be utlized by either side. Hexagon socket head cap screws The Settled Model of +15 Degree Fig.

- Page 46 HW0481994 5.5 Alterable Operating Range The stopper could be utlized by either side. Hexagon socket head cap screws The Settled Model of 0 Degree Fig. 13 (g) The Properly-Mounted Models for S-Axis Stopper 5-15 36/76...

-

Page 47: Allowable Load For Wrist Axis And Wrist Flange

The allowable total inertia is calculated when the moment is at the maximum. Contact your Yaskawa representative when only inertia, or load moment is small and inertia is large. Also, when the load mass is combined with an outside force, contact your Yaskawa representative. -

Page 48: Wrist Flange

HW0481994 6.2 Wrist Flange Wrist Flange The wrist flange dimensions are shown in " Fig. 15 Wrist Flange ". In order to see the align- ment mark, it is recommended that the attachment be mounted inside the fitting. Fitting depth of inside and outside must be 8mm or less. -

Page 49: System Application

HW0481994 7.1 Peripheral Equipment Mounts 7 System Application Peripheral Equipment Mounts When peripheral equipment is attached to the manipulator, the following conditions should be observed. Tapped hole M8 (4 holes), (depth: 15) Tapped hole M8 (4 holes)(depth: 15) 137.5 Tapped hole M12 (4 holes), (depth: 24) Tappled hole M12 (4 holes)(depth: 24) -

Page 50: Internal User I/O Wiring Harness And Air Line

HW0481994 7.2 Internal User I/O Wiring Harness and Air Line Internal User I/O Wiring Harness and Air Line 3 cables for valves (0.75mm ), 18 internal user I/O wires (0.5mm x 6 wires, 0.75mm x 12 wires), the cables for the external axis (1.0mm x 4 cables, 0.5mm x 2 cables) , and an air line are used in the manipulator for the drives of the peripheral devices mounted on the upper... - Page 51 HW0481994 7.2 Internal User I/O Wiring Harness and Air Line Connector for the external axis (Encoder cable): JL05-2A20-29SC Exhaust port (air flow) (socket connector with cap). Tapped holes PT3/8 Prepare pin connector: JL05-6A20-29P. with pipe plug Connector for internal user I/O wiring harness (Casing): JL05-2A22-14SC (socket connector with cap).

- Page 52 HW0481994 7.2 Internal User I/O Wiring Harness and Air Line 0.5mm (6 pins) 0.5mm (6 pins) Pins used 0.75mm (12 pins) 0.75mm (12 pins) Pins used 0.75mm (3 pins) 17 18 Pin details for internal user I/O wiring harness (Casing side) 32 33 Pin details for internal user I/O wiring harness (Base side)

- Page 53 HW0481994 7.2 Internal User I/O Wiring Harness and Air Line 0.5mm (6 pins) 0.5mm (6 pins) Pins used 0.3mm (12 pins) 0.3mm (12 pins) Pins used (6 pins) 0.75mm 17 18 Pin details for internal user I/O wiring harness (Casing side) 32 33 1.25mm (4 pins)

-

Page 54: Motoman Construction

HW0481994 8.1 Position of S-Axis Limit Switch 8 Motoman Construction Position of S-Axis Limit Switch The limit switches are optional. For the S, L, and U-Axes with limit switches specifications, L.S. are located on S-Axis, L-Axis, and U-Axis respectively. For the location, refer to " Fig. 18 Location of Limit Switches ". -

Page 55: Internal Connections

HW0481994 8.2 Internal Connections Internal Connections High reliability connectors which can be easily put on and removed are used with each con- nector part. For the numbers, types, and locations of connectors, see " Fig. 19 Location of Connectors " and “Table.8 List of Connector Types”. Connector for external axis (Power cable) Connector for external axis... - Page 56 HW0481994 8.2 Internal Connections 0BAT11 0BAT1 BAT11 BAT1 0BAT12 0BAT2 Note) BAT12 BAT2 0BAT3 BAT3 1. This diagram is for the MOTOMAN-ES165N-100. 0BAT21 0BAT4 BAT21 BAT4 For the limit switch specification, the connection of the section A was changed. 0BAT22 0BAT5 BAT22 BAT5...

- Page 57 HW0481994 8.2 Internal Connections S-AXIS OVERRUN L.S. L-AXIS OVERRUN L.S.(OPTION) 2BC(8PX5+12PX1) CN1-1 CN1-1 CN1-2 CN1-2 CN1-3 CN1-3 S-axis L.S. CN1-5 CN1-5 CN1-6 CN1-6 No.9CN CN1-7 CN1-7 9CN-A S-AXIS OVERRUN L.S. CN2-1 CN2-1 S-AXIS CN2-2 CN2-2 L-AXIS OVERRUN L.S.(OPTION) CN2-3 CN2-3 CN1-4 CN1-4 CN1-8...

-

Page 58: Maintenance And Inspection

• Maintenance and inspection must be performed by specified personnel. Failure to observe this caution may result in electric shock or injury. • For disassembly or repair, contact your Yaskawa representative. • Do not remove the motor, and do not release the brake. - Page 59 • For any different or special applications, the inspection process should be developed on an case-by-case basis. • For axes which are used very frequently (in handling applications, etc.), it is recom- mended that inspections be conducted at shorter intervals. Contact your Yaskawa repre- sentative. Table. 9...

- Page 60 Inspection numbers correspond to the numbers in “ Fig. 21 Inspection Parts and Inspection Numbers “. The occurrence of a grease leakage indicates the possibility that grease has seeped into the motor. This can cause a motor breakdown. Contact your Yaskawa representative. 49/76...

- Page 61 HW0481994 9.1 Inspection Schedule Table. 10 Inspection Parts and Grease Used Grease Used Inspected Parts Molywhite RE No.00 Speed Reducers for all Axes 12 13 14 R-, B-, and T-Axes gears 15 16 Alvania EP Grease 2 L-Axis Balancer Inspection numbers correspond to the numbers in " Table. 9 Inspection Items ". 50/76...

- Page 62 HW0481994 9.1 Inspection Schedule R-axis B-axis T-axis S-axis Note: The manipulator is in the home position. U-axis L-axis Fig. 21 Inspection Parts and Inspection Numbers 51/76...

-

Page 63: Notes On Maintenance Procedures

HW0481994 9.2 Notes on Maintenance Procedures Notes on Maintenance Procedures 9.2.1 Battery Pack Replacement The battery packs are attached in the two positions indicated in “ Fig. 22 (a) Battery Location Back View “ and “ Fig. 22 (b) Battery Location (Top View). If a battery alarm occurs in the NX100, replace the battery in accordance with the following procedure: Plate... - Page 64 HW0481994 9.2 Notes on Maintenance Procedures Battery pack before replacement See procedure 5 Connector Board See procedure 4 New battery pack Fig. 23 Battery Connection 1. Turn the NX100 main power supply off. 2. Uninstall the plate from the base connector and pull the battery pack out to replace with a new battery pack.

-

Page 65: Grease Replenishment/Exchange

HW0481994 9.2 Notes on Maintenance Procedures 9.2.2 Grease Replenishment/Exchange for S-Axis Speed Reducer molex molex molex Grease inlet Grease exhaust port S-axis speed Hexagon socket head plug A-PT1/4 Hexagon socket head plug PT1/8 reducer Fig. 24 S-Axis Speed Reducer and Gear Diagram Grease Replenishment (Refer to "... -

Page 66: Grease Exchange (Refer To " Fig. 24 S-Axis Speed Reducer And Gear Diagram ".)

HW0481994 9.2 Notes on Maintenance Procedures Grease Exchange (Refer to " Fig. 24 S-Axis Speed Reducer and Gear Diagram ".) 1. Remove the hexagon socket head plug PT1/8 from the exhaust port. If grease is added with the plug on, the grease will go inside the motor and may damage it. NOTE It is absolutely necessary to remove the plug. -

Page 67: Grease Replenishment (Refer To " Fig. 25 L-Axis Speed Reducer Diagram ".)

HW0481994 9.2 Notes on Maintenance Procedures 9.2.3 Grease Replenishment/Exchange for L-Axis Speed Reducer Grease exhaust port Hexagon socket head plug PT1/8 Grease inlet Hexagon socket head plug PT1/8 Fig. 25 L-Axis Speed Reducer Diagram Grease Replenishment (Refer to " Fig. 25 L-Axis Speed Reducer Diagram ".) 1. -

Page 68: Grease Exchange

HW0481994 9.2 Notes on Maintenance Procedures Grease Exchange (Refer to " Fig. 25 L-Axis Speed Reducer Dia- gram ".) 1. Tilt the L-arm vertical to ground. 2. Remove the hexagon socket head plug PT1/8 from the grease exhaust port. If grease is added with the plug on, the grease will go inside the motor and may damage it. NOTE It is absolutely necessary to remove the plug. -

Page 69: Grease Replenishment/Exchange

HW0481994 9.2 Notes on Maintenance Procedures Grease Replenishment (Refer to " Fig. 26 U-Axis Speed Reducer Diagram ".) 1. Tilt the U-arm horizontal to ground. 2. Remove the hexagon socket head plug PT1/8 from the grease exhaust port. If grease is added with the plug on, the grease will go inside the motor and may damage it. NOTE It is absolutely necessary to remove the plug. -

Page 70: Grease Exchange

HW0481994 9.2 Notes on Maintenance Procedures Grease Exchange (Refer to " Fig. 26 U-Axis Speed Reducer Dia- gram ".) 1. Tilt the L-arm horizontal to ground. 2. Remove the hexagon socket head plug PT1/8 from the exhaust port. If grease is added with the plug on, the grease will go inside the motor and may damage it. NOTE It is absolutely necessary to remove the plug. -

Page 71: Grease Replenishment/Exchange For U-Arm

HW0481994 9.2 Notes on Maintenance Procedures 9.2.5 Grease Replenishment/Exchange for U-Arm T-axis speed reducer Grease exhaust port (T-axis speed reducer) Grease inlet (R-,B-, and T-gears in the casing) Hexagon socket head Hexagon socket head plug A-PT1/8 plug PT1/16 Grease Inlet (B-, and T-axis speed reducer) Hexagon socket head plug PT1/8 R-axis speed reducer... -

Page 72: Grease Replenishment For R-, B-, T-Axis Gears In The Casing (Refer To " Fig. 27 U-Arm Diagram ".)

HW0481994 9.2 Notes on Maintenance Procedures Grease Replenishment for R-, B-, T-Axis Gears in the Casing (Refer to " Fig. 27 U-Arm Diagram ".) 1. Remove the hexagon socket head plug PT1/8 from the grease exhaust port. If grease is added with the plug on, the grease will go outside the grease box and may NOTE damage it. -

Page 73: Grease Replenishment For B-Axis Speed Reducer

HW0481994 9.2 Notes on Maintenance Procedures Grease Replenishment for B-Axis Speed Reducer (Refer to " Fig. 27 U-Arm Diagram ".) 1. Remove the hexagon socket head plug PT1/8 from the grease exhaust port. If grease is added with the plug on, the grease will go outside the grease box and may NOTE damage it. -

Page 74: Grease Exchange For R-, B-, T-Axis Gears In The Casing

HW0481994 9.2 Notes on Maintenance Procedures Grease Exchange for R-, B-, T-Axis Gears in the Casing (Refer to " Fig. 27 U-Arm Diagram ".) 1. Remove the hexagon socket head plug PT1/8 from the grease exhaust port If grease is added with the plug on, the grease will go outside the grease box and may NOTE damage it. -

Page 75: Grease Exchange For B-Axis Speed Reducer

HW0481994 9.2 Notes on Maintenance Procedures 6. Remove the grease zerk from the grease inlet and reinstall the plug PT1/8. Tighten the plug with a tightening torque of 5 N・m (0.51 kgf・m). (Apply Three Bond 1211 to the screwed part of the plug.) Grease Exchange for B-Axis Speed Reducer (Refer to "... -

Page 76: Grease Exchange For T-Axis Speed Reducer

HW0481994 9.2 Notes on Maintenance Procedures Grease Exchange for T-Axis Speed Reducer (Refer to " Fig. 27 U- Arm Diagram ".) 1. Remove the hexagon socket head plug PT1/16 from the grease exhaust port If grease is added with the plug on, the grease will go outside the grease box and may NOTE damage it. -

Page 77: Grease Replenishment For Balancer Connection Part

HW0481994 9.2 Notes on Maintenance Procedures 9.2.6 Grease Replenishment for Balancer Connection Part Connection Grease inlet Grease zerk A-PT1/8 Exhaust port Hexagon socket head plug PT1/8 Exhaust port Hexagon socket head plug PT1/8 Connection Needle bearing Connection Tapered roller bearing (2 bearings) Connection Grease inlet... -

Page 78: Notes For Maintenance

HW0481994 9.2 Notes on Maintenance Procedures 9.2.7 Notes for Maintenance When performing maintenance such as replacement of a wire harness in the manipulator, NOTE the encoder connector may be necessary to be removed. In this case, be sure to connect the battery pack to the battery backup connector before removing the encoder connector. -

Page 79: Recommended Spare Parts

• Rank B: Parts for which replacement may be necessary as a result of frequent operation • Rank C: Drive Unit NOTE To replace parts in Rank B or Rank C, contact your Yaskawa representative. Table. 11 Spare Parts for the Motoman-ES165N-100... - Page 80 HW0481994 Table. 11 Spare Parts for the Motoman-ES165N-100 Parts Rank Name Type Manufacturer Remarks Unit Yaskawa U-Axis Input Gear HW0303272-1 Electric Corporation Yaskawa R-Axis HW0380500-B Electric Speed Reducer Corporation Yaskawa B-Axis HW9380961-D Electric Speed Reducer Corporation Yaskawa T-Axis HW9381400-D Electric...

-

Page 81: Parts List

HW0481994 11.1 Balancer Unit 11 Parts List 11.1 Balancer Unit 6011 6004 6007 6005 6001 6006 6016 6002 6015 6012 6003 6008 6003 6012 6013 6014 6010 6009 2006 2016 2014 2004 2013 2015 2008 2030 2029 11-1 64/76... - Page 82 HW0481994 11.1 Balancer Unit DWG No. Name 6001 HW0481740-A Coil spring 6002 HW0481741-A Coil spring 6003 SOB607440 Oiless 6004 HW0100477-1 Case 6005 HW0303580-1 Flange 6006 HW0200420-1 Flange 6007 HW0401112-1 Flange 6008 HW0303581-1 6009 HW9405057-1 Clevis 6010 FD3187A0 Dust seal 6011 EZ2228B0 6012 IRTW-75...

-

Page 83: S-Axis Driving Unit

HW0481994 11.2 S-Axis Driving Unit 11.2 S-Axis Driving Unit 1029 1030 1002 1004 1005 1003 1025 1015 7021 1006 (Zeroing Option) 1026 7022 (Zeroing Option) 7023 1032 (Zeroing Option) 1001 1031 1037 1038 7034 (Zeroing Option) 1016 7035 (Zeroing Option) 1020 1021 1008... - Page 84 HW0481994 11.2 S-Axis Driving Unit DWG No. Name 1001 HW0380936-A Reduction gear 1002 SGMRS-37A2A-YR11 Motor 1003 TC12015014 Oil seal 1004 STW-50 Retaining rinds 1005 6310 Bearing 1006 HW0301627-1 Gear 1007 HW0100193-2 Base 1008 HW0100471-1 S head 1009 HW0402102-1 Stopper 1010 HW0302424-2 Stopper 1011...

-

Page 85: L-Axis Driving Unit

HW0481994 11.3 L-Axis Driving Unit 11.3 L-Axis Driving Unit 2033 2034 2018 2019 2020-26 2012 2005 2019 2010 2037 2038 2017 2009 6004 2031 2032 2045 2019 2027 2028 2019 2002 2009 2017 2005 1008 2012 2032 2020-26 2031 2018 2019 2003 2007... - Page 86 HW0481994 11.3 L-Axis Driving Unit DWG No. Name 2001 H9381442-B Reduction gear 2002 SGMRS-37A2A-YR11 Motor 2003 Y507212.5 Oil seal 2005 HR32916J Bearing 2006 HW0100472-1 L arm 2007 HW0303271-1 Gear 2008 HW9302054-1 Shaft 2009 HW9405055-1 Shaft 2010 EZ0094-A0 Air breather 2011 G300 O ring 2012...

-

Page 87: Urbt-Axis Driving Unit

HW0481994 11.4 URBT-Axis Driving Unit 11.4 URBT-Axis Driving Unit 3003 3002 3018 3042 3039 3040 3007 3041 3005 3021 3029 3013 3030 3004 3014 3042 3020 3022 3041 3041 3015 3003 3010 3028 3045 3008 3046 3027 3038 3005 3003 3042 3028 3009... - Page 88 HW0481994 11.4 URBT-Axis Driving Unit DWG No. Name 3001 HW9381465-C Reduction gear 3002 SGMRS-37A2A-YR11 Motor 3003 SGMRS-13A2A-YR11 Motor 3004 TAFI405520 Needle bearing 3005 Y507212.5 Oil seal 3006 Y507212.5 Oil seal 3007 HW0303963-1 Gear 3008 HW0303949-1 Gear 3009 HW0303947-1 Gear 3010 HW0303272-1 Gear 3011...

-

Page 89: U-Arm Unit

HW0481994 11.5 U-Arm Unit 11.5 U-Arm Unit 3011 4033 4034 4035 4021 4022 4029 4030 4028 4024 4023 4031 4032 4004 4016 4025 4024 4026 4031 4032 4027 4020 4019 4017 4003 4018 4011 4010 4005 4009 4013 4008 4012 4014 4009 4015... - Page 90 HW0481994 11.5 U-Arm Unit DWG No. Name 4001 HW0380500-B Reduction gear 4002 MSTH6-15 Parallel pin 4003 PT1/8 Plug 4004 HW0303937-A Shaft 4005 HW0301237-1 Shaft 4006 M8X95 Socket screw 4007 2H-8 Spring washer 4008 M4X12 Socket screw 4009 2H-4 Spring washer 4010 6904 Bearing...

-

Page 91: Wrist Unit

HW0481994 11.6 Wrist Unit 11.6 Wrist Unit 5003 4004 5024-28 5090 5004 5022 5045 5014 5089 5078 5035 5079 7020 5023 5090 5012 (Zeroing Option) 5073 5048 5074 7019 5041 7018 5040 (Zeroing Option) (Zeroing Option) 7017 5017 5011 (Zeroing Option) 5088 7016 5007... - Page 92 HW0481994 11.6 Wrist Unit DWG No. Name DWG No. Name 5063 SP-009010 Shim 5001 HW9380961-D Reduction gear 5064 SP-009020 Shim 5002 HW9381400-D Reduction gear 5065 SP-009050 Shim 5003 6908DB Bearing 5066 SP-009100 Shim 5004 6909 Bearing 5067 M12X35 Socket screw 5005 6009 Bearing...

- Page 93 49-8166-90103 YASKAWA ELECTRIC KOREA CORPORATION 1F Samyang Bldg. 89-1, Shinchun-dong, Donk-Ku, Daegu, Korea Phone 82-53-745-7844 82-2-784-8495 YASKAWA ELECTRIC (SINGAPORE) PTE. LTD. 151 Lorong Chuan, #04-01, New Tech Park, Singapore 556741, Singapore Phone 65-6282-3003 65-6289-3003 YASKAWA ELECTRIC (MALAYSIA) SDN. BHD. No.71, Jalan Bandar Rawang 2, 48000 Rawang, Selangor D.E., Malaysia...

Need help?

Do you have a question about the Motoman NX100 and is the answer not in the manual?

Questions and answers