Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Installation Manual

Advertisement

Table of Contents

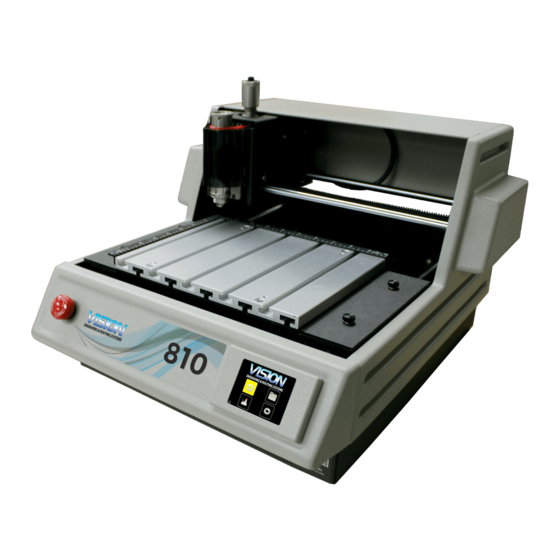

Summary of Contents for Vision VE810 S5

- Page 1 Vision VE810 S5 User Manual © 2018 Vision Engraving & Routing Systems Revised: 12/7/2018...

- Page 2 Vision VE810 S5 User Manual © 2018 Vision Engraving & Routing Systems All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without the written permission of the publisher.

-

Page 3: Table Of Contents

................................86 Example Job 4 - Profile Cutting ................................. 87 5 Vectorizing Bitmaps and Creating Vector Fills ........................... 93 Vectorizing a Bitm ap in Vision Express Softw are ................................93 Vector Hatch Fills ................................95 6 Advanced Operation ........................... 102 Setting and Using Custom Hom e Positions ................................ - Page 4 ........................... 139 Part VIII Optional Accessories 1 Vacuum Chip Removal System ........................... 141 2 Quick Lock Vise ........................... 142 3 Hold Down Clamps ........................... 143 4 Fixtures ........................... 145 5 Clamping Vises ........................... 148 © 2018 Vision Engraving & Routing Systems...

-

Page 5: Part I Introduction

Introduction About This Manual This manual provides you with information about the Vision Engraving or Routing system. Beginning with unpacking the machine and continuing through installation, operation and lifetime machine maintenance. This manual does not teach the user how to become an expert in engraving, computer usage, or engraving software. -

Page 6: Disclaimer And Warranty Information

Vision does not warrant defects caused by a failure to provide a suitable environment for the system, by unauthorized attachments, by modifications or repairs other than by Vision, by use of the System for other than its original intention, or by other misuse or abuse of the System. - Page 7 System, its fitness, quality, merchantability, or otherwise. Any warranties implied by law are hereby expressly disclaimed. No oral or written information or advice given by Vision, its Dealers, Distributors, Agents, or Employees shall create a warranty or in any way increase the scope of this warranty.

-

Page 8: Safety Precautions

User's Manual! Failure to comply may result in damage to the equipment and/or inflict serious personal injury! Ø Only trained personnel should operate the Vision Engraver or Router. All individuals operating this equipment must read and understand the User's Manual and have been trained by a competent authorized user. - Page 9 Ø If your machine does not operate properly; in particular, if there are any unusual sounds or smells coming from it, immediately unplug it and contact Vision's service department or your local distributor. Ø Unplug the machine when it is going to be left unused for an extended period of time.

- Page 10 Forcing the machine or its attachments to do work it was not intended to do may cause permanent damage to the machine and serious injury may occur to the operator. If there are any questions about the abilities of your machine, please call the Vision technical support team at 602-439-0600.

-

Page 11: Part Ii General Information

1 Vision VE810 Machine ü 1 Vision VE810 Warranty Card ü 1 Vision VE810 Installation Guide ü 1 White/Blue or Orange USB security dongle - Contains User Manual and Vision Software ü 1 Ethernet Network Cable (P/N 20-1074-00) ü 1 Power Cord ü... -

Page 12: Machine Description & Terminology

Also, you can control the speed at which the table moves and the spindle RPM. 7. Quick Lock Vise - This is the clamp assembly that is included with the Vision VE810 engraving system. It allows you to lock your material on the T-Slot table. - Page 13 15. Spindle Nose Cone - This is the part of the spindle that rides on the material while engraving. The cutter protrudes from the bottom of the nose cone creating your depth of cut. © 2018 Vision Engraving & Routing Systems...

- Page 14 Vision VE810 S5 User Manual VE810 Carriage View © 2018 Vision Engraving & Routing Systems...

-

Page 15: Part Iii Installation

General Information Installation NOTE: IT IS HIGHLY RECOMMENDED THAT THE COMPUTER USED TO OPERATE THE VISION ENGRAVER OR ROUTER BE CONNECTED TO THE INTERNET. THIS ALLOWS THE USER TO ALLOW VISION'S TECHNICAL SUPPORT TO ACCESS THE MACHINE AND TROUBLESHOOT IF NECESSARY. -

Page 16: Vision Software

Vision VE810 S5 User Manual Vision Software Insert the Vision USB dongle into the USB port on the computer. Navigate to the Devices and Drives area on your PC. Double click on the Vision icon to open the files on the USB dongle. - Page 17 Installation The Vision S5 Software Wizard will guide you through the process of installing the software. Press Next to continue. Press Install to continue © 2018 Vision Engraving & Routing Systems...

- Page 18 Vision VE810 S5 User Manual Setup wizard will install the program. Select Finish to continue the software installation. Choose your preferred language and click ok. © 2018 Vision Engraving & Routing Systems...

- Page 19 Installation The Vision 10 Setup Screen will appear. Press Next. After accepting the license agreement, click on the Next button. © 2018 Vision Engraving & Routing Systems...

- Page 20 Vision VE810 S5 User Manual Select Next (or change the destination folder - not recommended). Select Next to create the folder. © 2018 Vision Engraving & Routing Systems...

- Page 21 Installation The installation will continue. © 2018 Vision Engraving & Routing Systems...

- Page 22 Vision VE810 S5 User Manual Select the VE810 S5 by placing a check mark in the box to the left of VE810 in the Manufacturer list, then select Next. If you purchase another engraving system from Vision, it can be added to the machine list at a later date from within the Vision software.

- Page 23 Installation Select Continue to install True Type fonts and Vision Engraving Fonts on your computer. © 2018 Vision Engraving & Routing Systems...

- Page 24 Vision VE810 S5 User Manual Click yes to install all additional fonts from your C:\ Drive. All system fonts will be installed. © 2018 Vision Engraving & Routing Systems...

- Page 25 Installation Press OK Press on the Finish button. © 2018 Vision Engraving & Routing Systems...

- Page 26 Vision VE810 S5 User Manual Press the Exit button . The Vision manuals icon should now appear on your computer's desktop along with an icon for your version of Vision 10 software. © 2018 Vision Engraving & Routing Systems...

-

Page 27: Machine Connections

If the emergency stop screen appears on the LCD when the machine is powered on, then the emergency stop button is pressed in. Release the button twisting it until it "pops up". This will clear the emergency stop screen. © 2018 Vision Engraving & Routing Systems... - Page 28 The two options for connecting the VE810 to the computer are: - Direct connection to the computer or direct connection using a network hub or switch. Both of these methods require the same setup. - Connection through a company network © 2018 Vision Engraving & Routing Systems...

- Page 29 Installation Follow the steps from one of the two sections below to configure the IP address depending on the connection type above. © 2018 Vision Engraving & Routing Systems...

-

Page 30: Direct Connection To Computer

VE810 is located on the power supply box for the machine. Once the machine has initialized, the home screen will appear on the LCD screen. Select the Settings Screen icon. Select the Connectivity Screen icon. © 2018 Vision Engraving & Routing Systems... - Page 31 Confirm that the LCD shows the Mode is set to static. If the Mode displays DHCP, press the mode icon. This will change the Mode to display Static. Confirm that the LCD shows the Address is set to 192.168.5.101. © 2018 Vision Engraving & Routing Systems...

- Page 32 The Mask value will be blank. Press the green check mark a second time and the mask will change to 255.255.255.0. If the Mask does not change to this value, enter it with the numbers on the LCD. The LCD should now look like below: © 2018 Vision Engraving & Routing Systems...

- Page 33 Select "Open Network & Internet settings". (In Windows 7 and Windows 8 select "Open Network and Sharing Center") Select "Change adaptor options". (In Windows 7 and Windows 8 select "Change adapter settings") © 2018 Vision Engraving & Routing Systems...

- Page 34 Vision VE810 S5 User Manual Right click on the Ethernet adapter shown and select "Properties". Select "Internet Protocol Version 4 (TCP/IPv5) and select "Properties". © 2018 Vision Engraving & Routing Systems...

- Page 35 Installation Select "Use the following IP address:" and enter 192.168.5.100 for the IP address and enter 255.255.255.0 for the Subnet mask. Select OK. The Windows network settings are the machine are now configured. © 2018 Vision Engraving & Routing Systems...

-

Page 36: Network Connection

Once the machine is connected to the company network port, power the machine on. The power switch for the VE810 is located on the power supply box for the machine. Once the machine has initialized, the home screen will appear on the LCD screen. © 2018 Vision Engraving & Routing Systems... - Page 37 Installation Select the Settings Screen icon. Select the Connectivity Screen icon. © 2018 Vision Engraving & Routing Systems...

- Page 38 Make a note of the address that is displayed. This will be needed at a later step in the setup. NOTE: If an IP address is not displayed, check with your network administrator to confirm that your network is configured for DHCP. Press the green check mark button. © 2018 Vision Engraving & Routing Systems...

- Page 39 Press the X to exit the connection screen. Press the X to return to the home screen. Open the Vision 10 Software by selecting the Vision Expert 10, Vision Express 10 or Vision Pro 10 icon from the Windows desktop.

- Page 40 Vision VE810 S5 User Manual In the Engraving defaults window select the setup button. Select the port tab. © 2018 Vision Engraving & Routing Systems...

- Page 41 Installation In the "IP address" box, enter the IP address that was displayed on the Vision Express in a previous step. You can see this address from the machine home screen by pressing settings icon and then the connectivity screen icon.

- Page 42 Vision VE810 S5 User Manual Next, press Apply and OK to save the settings. The machine and Vision software are now configured. © 2018 Vision Engraving & Routing Systems...

-

Page 43: Part Iv The Front Panel

Any jobs in the machine will be displayed under the Saved Jobs heading on the top left of the screen. If there are more jobs saved then fit on the screen you must use the up and down arrows to move to the desired job. © 2018 Vision Engraving & Routing Systems... - Page 44 The Z+ and Z- arrows jog the Z axis up and down and are usually used to set the surface. The jog speed button has no effect on the Z jog speed as this is constant. © 2018 Vision Engraving & Routing Systems...

- Page 45 Set Surface Press the Z+ and Z- buttons and jog the spindle/cutter to the surface. Press the set surface button. Surface will now display the current Z axis location above the surface. © 2018 Vision Engraving & Routing Systems...

- Page 46 IP address including (.) and then hit the Enter button. The Mask may be red now and using the numbers type in the mask address and hit the enter button. The screen will say changing IP and then the Addr and Mask will be displayed. © 2018 Vision Engraving & Routing Systems...

- Page 47 Remote Vacuum Port On or Off and will be Red when off and blank when on. Aux 2 and Aux 3 buttons are not used on the VE810 S5 machine. The Fan button turns the cooling fan On or Off and will be Red when off and blank when on.

- Page 48 Press the X button and the X display will turn red. Then type in the location using the number pad. Press the Y button and type in the location using the number pad. Then press the green check mark. The spindle will move to that exact location. © 2018 Vision Engraving & Routing Systems...

- Page 49 The Front Panel Measure Feature Press plate size, then measure in Vision software. The machine goes into measure mode, the laser pointer turns on, and the machine screen will change to the Measure screen shown below. Using the X and Y jog buttons on this screen, jog the laser pointer to the top left corner of the desired engraving area and press the green check (select) mark.

-

Page 50: Part V Step By Step Operation

Double-sided tape or Multi Mat material are available from your Vision Distributor or directly from Vision. The quick lock vise is an optional accessory for the Vision VE810 - see the Optional Accessories section for details. - Page 51 Tighten the edge guide thumbscrews. This process should be repeated anytime materials of different thicknesses are to be engraved. On thicker materials, more than 0.10 inch (2.5 mm), the edge guides can remain in their uppermost position. © 2018 Vision Engraving & Routing Systems...

-

Page 52: Zeroing The Cutter

The spindle now acts as a normal top loaded spindle for ease of operation. The split collet can be reinstalled when required. © 2018 Vision Engraving & Routing Systems... -

Page 53: Proximity Sensor

“Non-nose-riding” - WITHOUT proximity sensor When setting a depth in the Vision software, the proximity sensor should be turned off in the Cut Toolbox (in the Vision software program before sending the job to the machine). Also, make sure that there is no “float”... - Page 54 For diamond drag engraving, the engraving motor is turned off and the cutter “drags” across the material. Down pressure against the material can be reduced or increased as necessary by following the steps in "Adjusting Spindle Pressure" section of this manual. © 2018 Vision Engraving & Routing Systems...

-

Page 55: Step By Step Operation

In the following sections, there are 4 example jobs the user can use to learn the different ways to use the Vision VE810. In the first section, the machine will be set up to perform a diamond drag operation on coated aluminum and a simple plate will be engraved. -

Page 56: Example Job 1 - Diamond Drag

In this first example, Diamond Drag engraving will be performed on a 3" x 2" plate. The material used for this example application is black painted aluminum. Starting with a new file in Vision software, the first step is to adjust the plate size to match the plate to be engraved. - Page 57 Step by Step Operation Click on the Plate Size icon. The Plate Size window will appear with either the last plate size used, or the default size for the Vision VE810 engraver. © 2018 Vision Engraving & Routing Systems...

- Page 58 Vision VE810 S5 User Manual Click on the Current Selection drop down list and select Custom. © 2018 Vision Engraving & Routing Systems...

- Page 59 Step by Step Operation Enter the plate size to be engraved - for this example 3" x 2". © 2018 Vision Engraving & Routing Systems...

- Page 60 Vision VE810 S5 User Manual To add text, click on the Text Tools icon. The flyout icons will appear, then select the Text Compose icon. © 2018 Vision Engraving & Routing Systems...

- Page 61 The user should become familiar with the various ways fonts can be formatted with the toolbar options. For this example, the only change was for the font height, which was set to 0.500". Begin typing text to be engraved. © 2018 Vision Engraving & Routing Systems...

- Page 62 The Break Text warning may appear. If so, select No. If Yes is chosen, and more than one line of text has been entered, each line will align on top of one another in the center of the plate. © 2018 Vision Engraving & Routing Systems...

- Page 63 Step by Step Operation At this point, the screen should appear as below. © 2018 Vision Engraving & Routing Systems...

- Page 64 (upper left corner of the engraving table). Note that the Multi Mat material has been placed on the t-slot table in order to hold the engraving material in place. Select the Engrave icon from the left toolbar. © 2018 Vision Engraving & Routing Systems...

- Page 65 The Cut Toolbox will appear and the options for engraving will appear on the top toolbar. Make sure the Device selected is for your machine, then select the material drop down. Select Metals (Diamond Drag). Press the Engrave button in the cut toolbox to send the job to the machine. © 2018 Vision Engraving & Routing Systems...

- Page 66 If the file and material appear to be positioned properly and you are ready to engrave, select the Engrave icon from the left toolbar, turn off the Dry Run option and check to make sure the Proximity. © 2018 Vision Engraving & Routing Systems...

- Page 67 Step by Step Operation The finished piece should appear as shown below. © 2018 Vision Engraving & Routing Systems...

-

Page 68: Rotary Engraving

5.4.2 Rotary Engraving In this section, we will set up to engrave with a rotating cutter. The figure below shows the Vision VE810 spindle with a rotary cutter. NOTE: It is recommended to use a vacuum chip removal system which removes the debris while engraving. -

Page 69: Example Job 2 - Rotary Engraving

The Vacuum Chip Removal System significantly reduces these problems and provides for a cleaner work area. © 2018 Vision Engraving & Routing Systems... - Page 70 Vision VE810 S5 User Manual As with Example Job 1, the first step is to set the plate size in the Vision software. Then, we will enter the text using the Frame Text Compose tool as shown below. With this tool selected, text will automatically be centered and have automatic Kerning. In the below example, the font was changed to Casual1, with a height of 1.250 inches and a slant of 19 degrees.

- Page 71 Cut Toolbox shows that the Vacuum, Prox, Dry Run, and Spindle are all enabled. Since this is the second example job, sending a Dry Run job to the engraver is suggested. © 2018 Vision Engraving & Routing Systems...

- Page 72 (when using the proximity sensor function) and causing the engraver to not engrave to the proper depth. © 2018 Vision Engraving & Routing Systems...

-

Page 73: Burnishing

5.4.3 Burnishing In this section, we will set up to engrave with a burnishing cutter. The figure below shows the Vision VE810 spindle with a burnishing cutter and an optional EZ Rider burnishing adapter. The Vision VE810 spindle with burnishing cutter... - Page 74 Next, insert the cutter through the EZ Rider and spindle so that the cutter sticks out below the nose cone approximately 1/4 inch (6 mm). Tighten the set screw in the EZ Rider to hold the cutter in place. © 2018 Vision Engraving & Routing Systems...

- Page 75 Move the Z down approximately 0.03 – 0.05 inches (0.5 – 1.0mm) to preload the EZ Rider spring. Select the set surface button. The Spindle will rise to confirm the surface has been set. Select the go to home button. © 2018 Vision Engraving & Routing Systems...

-

Page 76: Example Job 3 - Burnishing

Vision software will automatically format the imported text. Begin by selecting the Plate Size Icon and setting the engraving area to the standard Vision VE810 8 x 6 inch area... - Page 77 0.250 inches as shown, then click on Apply. Note that the page margins on the toolbar are located such that the top field is for the top margin, the left field is the left margin, etc. © 2018 Vision Engraving & Routing Systems...

- Page 78 Vision VE810 S5 User Manual The screen should then appear as below. Select the Text Compose Icon. © 2018 Vision Engraving & Routing Systems...

- Page 79 Enter any text in the format you wish to use. In this example, two lines of text are entered as variables (it does not matter what you type. The text entered is only for formatting and will be replaced with the text imported from the .txt file). © 2018 Vision Engraving & Routing Systems...

- Page 80 Change the settings to Always compress or expand text to fit width, Method: Width compress/expand, and Apply to: Each Line Individually. Deselect Word Wrap, then select OK. For a detailed description of all the font modifications possible, refer to the Vision software help or user manual.

- Page 81 In this example, a text file was created in order to copy and paste the variables into the Vision software. Highlight the text and select copy from the edit menu (or right click and select copy). Note that in this example, the two variables are entered as subsequent lines in the text file and that there may be difficulties when importing from other file formats.

- Page 82 Vision VE810 S5 User Manual To insert the copied text, select Layout Plate Object Paste Clipboard Into Plate. Click in the center of the plate. © 2018 Vision Engraving & Routing Systems...

- Page 83 Also, if there are more variables than can be fit into one plate in the Vision software, multiple plates (or pages) are automatically generated for individual output to the engraver. The lower right corner of the Vision software screen allows the user to view the individual pages.

- Page 84 Metals(Burnishing) as the material and click on OK. If you choose to run a Dry Run (as shown) to make sure the setup is correct, proceed as in prior sections to send the file to the engraver. © 2018 Vision Engraving & Routing Systems...

- Page 85 Step by Step Operation Note – In this example a toolpath was added to the plate objects to show where the name badges will be cut. (plate objects are shown in image below) © 2018 Vision Engraving & Routing Systems...

-

Page 86: Profile Cutting

In this section, we will set up to engrave with a standard engraving cutter and cut completely through engraver's plastic with a cutter/beveler. The cutter/beveler is used to create a contrast on the edge of the cut material. The figure below shows the Vision VE810 spindle with a rotary cutter/beveler. © 2018 Vision Engraving & Routing Systems... -

Page 87: Example Job 4 - Profile Cutting

First, we draw a rectangle using the shape tools Size the rectangle to be 3” X 1”. Set the X bounds to .25 and the Y to .25 to position the badge .25 inches away from the edge guides. © 2018 Vision Engraving & Routing Systems... - Page 88 Now we round the corners by selecting the rectangle and pressing the round corners icon. In the text box put in .100 and click apply. Use the Frame Text Compose Tool to add text to the badge. © 2018 Vision Engraving & Routing Systems...

- Page 89 Now make a male tool path by clicking on name badge and then pressing on the male toolpath icon. In the Tool Path screen select the profile cutter you are using the depth, and the color you would like to use for your cut path. (Here we use Red) Press Ok. © 2018 Vision Engraving & Routing Systems...

- Page 90 1. Adjust the cutter to cut through the material PLUS 0.001 - 0.003 inches (0.0250 - 0.075 mm). This method will produce a clean cut of the parts and lightly cut into the sacrificial material underneath, or © 2018 Vision Engraving & Routing Systems...

- Page 91 Go to the software and click on the red toolpath. Press the engrave icon and change the material settings to Engravers plastic (Cutter/Bevler). Now press the engrave icon to send the job to the machine. © 2018 Vision Engraving & Routing Systems...

- Page 92 Vision VE810 S5 User Manual Press the magnifying glass on the touchscreen to preview the engraving area. When ready press the play button to start the profile cut. © 2018 Vision Engraving & Routing Systems...

-

Page 93: Vectorizing Bitmaps And Creating Vector Fills

It is often required that a scanned image or a bitmap file is requested to be engraved. Since the Vision engraver is vector based and requires vector lines in order to follow a path for engraving, these bitmaps will need to be converted to vector images before being sent to the engraver. - Page 94 The next screen has only one adjustment - Alignment Bitmap Density. There is a slider bar for darkening or lightening the image to show more or less detail. The default slider position is recommended. Select OK and the bitmap will be automatically converted to a vector outline for engraving. © 2018 Vision Engraving & Routing Systems...

-

Page 95: Vector Hatch Fills

When an outline of an object needs to have the interior, or sections of the interior engraved, the Hatch Fill tool is used. As an example, if a simple circle is drawn in the Vision software, but the user wants to engrave the entire circle, not just the outline, a hatch fill is used to create the vector fill path for the engraver to follow. - Page 96 Vision VE810 S5 User Manual Filling a simple object After creating a new file in the Vision Click, hold and drag a circle, then select the Hatch software, draw a circle using the Circle icon Fill icon from the Stroke and Fill Tools flyout menu.

- Page 97 Hatch fills can be applied to outline text, but not single line text. In the below example, Arial text was used by selecting the Frame Text Compose icon and clicking in the middle of the plate to create the text as shown. © 2018 Vision Engraving & Routing Systems...

- Page 98 As with the previous example, the hatch fill is applied. Adjust the Tool width, Tool angle, Tool style and color as desired, then select Close. The file is ready to be sent to the engraver. © 2018 Vision Engraving & Routing Systems...

- Page 99 Break Path icon to separate the individual outlines. Next, we will need to create a path. The Vision Express software has an intelligent path tool that will automatically detect portions of the graphic that are within outside vector lines and will create a hatch fill with the center portions left as unfilled.

- Page 100 Then click and hold on the node in the center of the graphic. The automatic detection will display the areas that can be hatch filled. If this looks correct, select the Hatch Fill icon. © 2018 Vision Engraving & Routing Systems...

- Page 101 Step by Step Operation The hatch fill will be applied. Adjust the tool options as desired and select Close from the toolbar menu. The file is ready to be sent to the engraver. © 2018 Vision Engraving & Routing Systems...

-

Page 102: Advanced Operation

Vision VE810 S5 User Manual Advanced Operation The following sections are for users that have progressed through the step-by-step operation of the Vision VE810 and want to know how to get the most out of their engraver. It can be challenging to correctly position text and/or graphics. Odd shaped items, which are difficult to measure or locate on the engraving table, pose the biggest problem to most users. - Page 103 The software defaults to offset #1 (top left corner of engraving table) so we will need to tell it to use this custom home in the software. Go to the Vision 10 software, click on the tool path to be engraved and press the engrave icon.

-

Page 104: Using The Measure Feature

Now press the Tool Setup button 5.6.2 Using the Measure Feature The Measure Feature allows the user to jog to the material and set plate size using the laser feature of the machine. © 2018 Vision Engraving & Routing Systems... - Page 105 Step by Step Operation Open up the vision software and press the plate size icon Now press the measure button. Use the touch panel on the machine to Jog to the top left of the area to be engraved. Press the yellow select button in the middle of the screen, and the yellow background will disappear.

- Page 106 Vision VE810 S5 User Manual The touchscreen will now show a magnifying glass in the center. Press this to preview the new plate size engraving area using the machines laser. © 2018 Vision Engraving & Routing Systems...

-

Page 107: Using The Red Dot Laser Pointer For Positioning

A common and easy way to position text and graphics is to use the Red Dot Laser Pointer along with an outline of the area to be engraved in the Vision 10 Software. The Following example will walk the user through the process. - Page 108 X and Y readouts for the upper left and the lower right corners of your engraving area. In the Vision 10 software we will now draw guidelines using the measurements we wrote down. To add a guideline, click with the right mouse button anywhere within the plate area. Now select Edit Guides.

- Page 109 Click Ok when finished. You should now have 4 guidelines as shown here. (Your items engraving area and locations will differ from those shown in this example) Select the shape tools icon from the left toolbar, and then select the circle tool (or rectangle tool for a rectangle). © 2018 Vision Engraving & Routing Systems...

-

Page 110: Creating A Center Driver

Creating a Center Driver In this section, a custom driver will be created based on the VE810 S5 Vise driver that will allow the user to set a home position in the center of an engraving area. The Vision 10 software will automatically position the job based on this center location. - Page 111 Step by Step Operation First, we need to create and save a custom Center driver. Open up the Vision 10 software and select Engrave, then Engraving Defaults from the top menu bar. © 2018 Vision Engraving & Routing Systems...

- Page 112 Vision VE810 S5 User Manual The Plot widow will appear and from the Selected Driver drop down list, select the VE810 S5 Vise driver. If this driver has not been installed, refer to the section - Installing Additional Drivers. Select Setup.

- Page 113 Step by Step Operation Under the Installed Drivers section, make sure the VE810 S5 Vise driver is selected, then select Create custom copy of selected driver. Type in VE810 Center Driver, then click on OK. © 2018 Vision Engraving & Routing Systems...

- Page 114 Select the VE810 Center Driver we just created from the Selected Driver drop down list. Change the settings in the Move fields to 0 for both X and Y move, click on Apply and then click on Close. © 2018 Vision Engraving & Routing Systems...

- Page 115 Set the plate size to match the engraving area you determined for your item. In this example, a 1.75" x 0.75" size was entered. Make sure the Selected Driver is the VE810 Center Driver, then click on OK. © 2018 Vision Engraving & Routing Systems...

- Page 116 In this case, it is the center of the 3.0" piece of acrylic. Press the Set Offset button on the engraver. This is now the center of the engraving area for our job. The below picture shows the spindle positioned over the center of the engraving area. © 2018 Vision Engraving & Routing Systems...

- Page 117 Select the Engrave icon from the left side toolbar. Double check to make sure that the Device is set to the VE810 S5 Center Driver (on the top toolbar). Choose your material from the Material Setting drop down list on the top toolbar.

-

Page 118: Adjusting Spindle Pressure

(when viewed from the top of the machine). In order to access this knob and turn it, turn the machine off, then turn the knob clockwise to increase pressure and counterclockwise to decrease pressure. © 2018 Vision Engraving & Routing Systems... - Page 119 Step by Step Operation © 2018 Vision Engraving & Routing Systems...

-

Page 120: Installing Additional Drivers

Installing Additional Drivers If you need to install additional drivers, such as the VE810 S5 Vise driver or for another machine, in the Vision 10 software, select File from the top menu bar, then select Install and click on Cutting Devices. - Page 121 Step by Step Operation © 2018 Vision Engraving & Routing Systems...

- Page 122 If you wish to uninstall driver(s), simply follow the above procedure, and deselect the drivers by removing the check mark to the left of the machines you want to uninstall from the Manufacturer section of the Driver Installation Wizard window, then click on Next to remove those drivers. © 2018 Vision Engraving & Routing Systems...

-

Page 123: Part Vi Maintenance

Step by Step Operation Maintenance Vision strives for the highest quality in their manufacturing process to provide you with the most cost effective, reliable engraving machine in use today. Please remember that proper maintenance and care is necessary to achieve maximum product life expectancy. - Page 124 Re-install the new filter bag into the top cap of unit and fasten to bottom casing. If proper suction doesn't return after replacing the filter bag, then the HEPA filter needs to be replaced. © 2018 Vision Engraving & Routing Systems...

-

Page 125: Motion System Cleaning & Lubrication

Spindle, press on the top of the Spindle to move the Spindle down and press on the bottom of the Spindle to move it up. Cover Removal Top Cover Screws Remove the two top cover screws (shown below). © 2018 Vision Engraving & Routing Systems... - Page 126 11/32" nut driver to hold the nut and remove the screw with a Phillips screwdriver from the back of the machine. Spindle Cover To remove the spindle cover, slide the cover up. Squeezing the sides of the cover will facilitate removal. © 2018 Vision Engraving & Routing Systems...

- Page 127 Apply isopropyl alcohol to a paper towel and wipe down the X-Axis (carriage) leadscrew and the stainless steel rails for the carriage. Move the carriage by hand to access all areas of the leadscrew and rails. © 2018 Vision Engraving & Routing Systems...

- Page 128 Raise and lower the spindle to access the upper and lower sections of the spindle rail. The rail is located behind the spindle. Apply isopropyl alcohol to a paper towel and wipe down the sides and front of the spindle rail. © 2018 Vision Engraving & Routing Systems...

- Page 129 Only use Teflon-free silicone spray on the leadscrews. DO NOT use any lubricant other than Teflon-free silicone spray, as it may attract debris and create a buildup that can cause mechanical failure. © 2018 Vision Engraving & Routing Systems...

-

Page 130: Changing The Motor Belt

When this happens, the motor belt generally needs to be changed. The following explains the procedure for changing the motor belt. Cover Removal Top Cover Screws Remove the two top cover screws (shown below). © 2018 Vision Engraving & Routing Systems... - Page 131 11/32" nut driver to hold the nut and remove the screw with a Phillips screwdriver from the back of the machine. Spindle Cover To remove the spindle cover, slide the cover up. Squeezing the sides of the cover will facilitate removal. © 2018 Vision Engraving & Routing Systems...

- Page 132 Vision VE810 S5 User Manual © 2018 Vision Engraving & Routing Systems...

- Page 133 To replace the belt, align the belt in the motor pulley and pull the belt forward and roll it down over the front edge of the lip on the top of the spindle. Do not excessively stretch the belt when replacing © 2018 Vision Engraving & Routing Systems...

-

Page 134: Changing The Motor Brushes

Use a flat blade screwdriver to loosen the motor brush caps. Inspect the motor brush for length. If the length is under 1/8th inch (3.2 mm), the motor brush needs to be replaced. © 2018 Vision Engraving & Routing Systems... -

Page 135: Cleaning The Fan

2. Remove the filter guard by using a small flat blade screwdriver to pop the guard open. 3. Remove the filter and blow out the filter with low-pressure compressed air. 4. Replace the filter and filter guard by snapping it back in place. Cooling Fan Filter and Cover © 2018 Vision Engraving & Routing Systems... -

Page 136: Part Vii Troubleshooting

7. The nose cone or vacuum nose is loose. Problem: ”Shadowing“ occurs while engraving certain materials. Possible solutions: 1. Leave the protective film on the engraving material during engraving. 2. Use a plastic nose cone instead of a metal one. © 2018 Vision Engraving & Routing Systems... - Page 137 2. When diamond drag engraving, there may be too much down pressure. Check the grain of the material; it should be left to right. 3. The cutter may be dull or worn. 4. The material is not securely fastened to the table. © 2018 Vision Engraving & Routing Systems...

- Page 138 3. Increase the pre-load of the burnishing adapter. 4. Try other materials. Same reasons as above. Some materials are too tough to engrave. © 2018 Vision Engraving & Routing Systems...

-

Page 139: Mechanical Problems

The noise may be caused by the bearings. Problem: Spindle is hot. Possible solutions: 1. Ensure that the nose cone area is free of debris. Check the vacuum system (if used) for clogging. © 2018 Vision Engraving & Routing Systems... - Page 140 Problem: Spindle motor will not turn on. Possible solutions: 1. Check motor brushes. Problem: Motor belt will not stay on pulley. Possible solutions: 1. Motor belt is probably worn and needs to be replaced. © 2018 Vision Engraving & Routing Systems...

-

Page 141: Part Viii Optional Accessories

The system allows prompt removal of chips and dust created in the engraving process, reducing contamination and overheating in the spindle area. Chip removal also prevents the cutter from skipping over letters due to stray particles. This vacuum chip removal system is available with or without a Vision vacuum nose cone. -

Page 142: Quick Lock Vise

This will keep the material from bowing in the center. The quick lock vise will only work on square or rectangular material. To hold down irregular shaped objects, you must use some other method. Ask your Vision Distributor or Vision if you need more information on this feature. -

Page 143: Hold Down Clamps

The downward clamping force eliminates bowing. This clamp can be used with material up to 1/4” thick. Push Down Clamps This double-sided clamp secures items from the edge. It is ideal for heavy-duty items that are being cut, contoured or engraved. © 2018 Vision Engraving & Routing Systems... - Page 144 This clamp is designed to hold down square or rectangular plates. By lining up the “V” cut-out of the clamp with the corner of the plate, the engraver is allowed maximum engraving space. It will hold material as thin as 1/32”. © 2018 Vision Engraving & Routing Systems...

-

Page 145: Fixtures

Available for the Versa Vise, T-slot table, and Self-Centering Vise. Also usable with other computerized engravers and Pantographs. These fixtures enable engraving on uniquely shaped items such as pens, lighters, knives, keychains, and more. © 2018 Vision Engraving & Routing Systems... - Page 146 T-slot system. Seal Fixture The Seal Fixture enables engraving on notary seals, medallions, coasters, paperweights, dog tags, and other round objects. Usable with the Quick-Lock or Versa Vise. © 2018 Vision Engraving & Routing Systems...

- Page 147 This is a double-sided fixture that, when turned in one direction, accommodates a pen, and when turned in the other direction, accommodates a medallion, seal, or other circular item. With a space for the “eye” of the medallion, this fixture is usable with the Versa Vise or Quick-Lock Vise. © 2018 Vision Engraving & Routing Systems...

-

Page 148: Clamping Vises

This vise is supplied with a removable front clamping plate which allows for the holding of thicker items. Self-Centering Deep Vise This self-centering vise allows for easy setup of odd-shaped items up to 3 1/4” deep. © 2018 Vision Engraving & Routing Systems... - Page 149 Small Self-Centering Vise This fixture allows you to hold various small items such as nameplates, signs and placards. Dowel pin settings allow this item to work with most Vision fixtures for even more versatility. © 2018 Vision Engraving & Routing Systems...

- Page 150 Vision VE810 S5 User Manual © 2018 Vision Engraving & Routing Systems...

Need help?

Do you have a question about the VE810 S5 and is the answer not in the manual?

Questions and answers