Summary of Contents for Bomar Workline 410.280 DG

- Page 1 Series Workline Workline 410.280 DG Operating instructions Before transporting and using the machine, please read the instructions thoroughly! Seriové číslo / Serien Nummer / Serial Number ___________________ ...

- Page 2 Czech Republic, EU www: http://www.bomar.cz We are available: Mondays to Fridays – 16 Version: 1.02 / Nov. 2011 rev. 1 BOMAR, spol. s r.o. © – Subject to modifications and amendments. Manual version: 1.02 / Nov. 2011 Manual rev.:...

- Page 3 ...

- Page 4 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 5: Table Of Contents

Content 1. SAFETY NOTES ................ 7 1.1. Machine determination ................................9 1.2. Protective suit and personal safety ..........................9 1.3. Safety notes for machine operator ..........................10 1.4. Safety notes for the servicing and repairs ....................... 10 ... - Page 6 ASSEMBLIES FOR SPARE PARTS ORDER ........69 7.1. Workline 410.280 DG ................................70 7.2. Kusovník / Stückliste / Piece list – Workline 410.280 DG ................71 7.3. Rameno / Sägerahmen / Saw arm ..........................72 7.4.

-

Page 7: Safety Notes

Safety notes ... - Page 8 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 9: Machine Determination

Keep the operating instructions in good condition! 1.1. Machine determination The band saw Workline 410.280 DG is determined for cutting and shortening of rolled bars and drawn bars and profiles from steels, stainless steels, non-ferrous metals and plastics with cutting angle from -60° to 60°. -

Page 10: Safety Notes For Machine Operator

1.3. Safety notes for machine operator Attention! Machine can be operated by person older than 18 years! Machine can be operated only person physically and mentally fit for this activity Machine can be operated only by one person. Machine operator is responsible for presence of other persons by the machine. -

Page 11: Safety Notes For The Servicing And Repairs On Hydraulic Unit

Do not remove or do not lock the limit switches or safety equipments! Any use of the saw, accessories or machine parts other than that intended by the BOMAR, spol. s r.o. company is not permitted. The guarantee on this product will be afterward lost and BOMAR, spol. -

Page 12: Band Saw Cover

The device contains limit switch. Check the stretching carefully and periodically – eventually adjust. 1.6.4. Band saw cover It covers the visible area of the saw band from left guiding cube to the frame. Never switch on the saw band drive if this cover is not mounted! 1.6.5. -

Page 13: Instructions For First Help

1.7.1. Instructions for first help Pull off and safely remove polluted, soaked clothing. For breathing, go out in the fresh air or look for first aid treatment. Wash with water or use crèmes for contact with the skin. Flush with water for eyes and look for first aid treatment. For swallowing, drink a lot of water and induce vomiting. -

Page 14: Umístění Bezpečnostních Značek / Verteilung Der Sicherheitszeichen / Position Of Safety Symbols

1.9. Umístění bezpečnostních značek / Verteilung der Sicherheitszeichen / Position of safety symbols Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 15: Machine Documentation

Machine documentation ... - Page 16 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 17: Technická Data / Technische Daten / Technical Data

• IP 54 Krytí / Schutzart / Protection Akustický tlak / Schalldruckpegel / Acoustic pressure: • = 76,3 dB Workline 410.280 DG Aeqv Pohon / Atrieb / Drive: TM90 4X B14-FT115 • Typ / Typ / Type ~3 x 400V, 50Hz •... -

Page 18: Rozměrové Schéma / Aufstellzeichnung / Installation Diagram

2.2. Rozměrové schéma / Aufstellzeichnung / Installation diagram Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 19: Popis / Beschreibung / Description

2.3. Popis / Beschreibung / Description ... -

Page 20: Transportation And Stocking

2.4. Transportation and stocking 2.4.1. Conditions for transportation and stocking Keep recommendations for the manufacturers for transportation and stocking! If the recommendations are not kept, damage can occur to the machine. • Don’t use a forklift truck for handling the machine, if you do not have license for it! •... -

Page 21: Transportní Schéma / Transport Schema / Transport Scheme

2.4.4. Transportní schéma / Transport schema / Transport scheme ... -

Page 22: Activation

Check the floor supporting capacity before machine installing. If the floor capacity does not agree with requirements, you must prepare the necessary base for the machine. Minimal requirement: machine weight – Workline 410.280 DG – 530 kg + weight of accessories + maximum weight of material •... -

Page 23: First Run Of The Power Pack

2.6.3. First run of the power pack Before the first run check: • The direction of the Pump, while run the power pack for max. 2seconds. • The cooling fan of the motor has to rotate in the same direction as the arrow on the top of the motor cowling indicates. -

Page 24: Kotevní Plan / Verankerungsplan / Grounding Plan

2.6.5. Kotevní plan / Verankerungsplan / Grounding plan Přívod elektrické energie• Enrgiezuleitung• Power supply Kotvící materiál / Verankerungsm aterial / Grouding material • 4× Hmoždina / Dübel / Plug – ø12 mm • Vrtáno do hloub ky / In die Tiefe gebohrt / Drilled to – 95 mm •... -

Page 25: Electrical Connection

2.7. Electrical connection Attention! Only a qualified professional must carry out the servicing and repairs of the electric equipment! Take special care during work with electrical equipment. High voltage shock can have fatal consequences! Always keep notes about work safety. Electrical parameters of the machine: •... -

Page 26: Filling Of The Cooling System

Constant tooth system – the saw band has parallel tooth pitch all over length. This way is suitable for cutting of solid material. BOMAR recommended Variable tooth system for band saw. Variable tooth system – tooth pitch is variable. Variable tooth system is used for profiled materials and bundle cutting. -

Page 27: Saw Band Running-In

Footnotes: Z – teeth number on one inch S – tooth with zero angle of the teeth K – tooth with positive angle of the teeth Examples of the tooth system marking: 32 S – number „32“ means 32 teeth on one inch (that means constant tooth system), letter „S“... -

Page 28: Tables For Teeth Selection

Tables for teeth selection SHAPED MATERIAL (D , S = mm) Note: Table shows tooth system selection for cutting one piece of the profile. For cutting of more pieces of the profiles (bundle), you must think of the size of the wall as double size of the wall of one profile (that means, size „S“ equates to 2×S). In table, there are tooth systems constant and variable. Tooth system (Z Size of the Outer diameter of the profile D... -

Page 29: Machine Control

Machine control ... - Page 30 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 31: Starting The Band Saw

3.1. Starting the band saw » Switch on the main switch of the band saw. The main switch is situated on the the switchboard. ... -

Page 32: Control Panel

3.2. Control panel Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 33: Machine Control

TOTAL – STOP button In emergency causes the machine must be immediately switched off. Machine Turn ON/OFF Switch into position 1 to turn ON the machine or into position 0 to OFF. Cooling system selection You can select from three possibilities: Cooling with Microniser (optional accessories) Cooling is switched on when the drive is running. -

Page 34: Cycle Breaking

3.3.1. Cycle breaking • » STOP button Semi-automatic cycle is interrupted by pressing button 5 – STOP of the cycle The arm stops fall into cut and saw blade is stoped. By pressing button 4 – START of the working cycle, you can start the cycle. •... -

Page 35: Adjusting Band Guides

3.4.2. Adjusting band guides If you want to achieve a smooth and precise cut, it is helpful to position the guide cube as close as possible to the material. Release the stopping lever of the listel. Move the left part of the guide so that the left edge of the guide blocks is as close as possible cutted material. -

Page 36: Adjustment Of Pressure To The Cut

3.4.5. Adjustment of pressure to the cut For cutting extremely hard materials operator can add strength to the cut by the M16 nut on spring holder. 3.4.6. Speed adjustment of the arm lowering Speed of the arm lowering is adjusted by regulation valve on control panel – pos. 8. •... -

Page 37: Material Insertion

If you cut long pieces of the material (for example rod, tube), you must use the roller conveyors for material shifting to the band saw. Contact Bomar for more information about roller conveyors Make sure the conveyor is long enough and the material cannot tip off the conveyor. - Page 38 Attention: Not all material shapes are suitable for bundle cuts. Keep the recommendation of your supplier of the saw bands for material insertion to the bundle. Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 39: Machine Service

Machine service ... - Page 40 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 41: Saw Band Dismantling

4.1. Saw band dismantling During the dismantling, take care that you do not damage the limit switch if the saw band stretching. Lift the saw frame to the top position. Stop the saw frame in top position by control valve. Dismantle yellow protective cover of the saw band. -

Page 42: Saw Band Stretching And Inspection

Insert new saw band in the guide cubes. Make sure the saw band runs between both guide rollers and it is pushed all the way to the top. Put the saw band on both guide wheels. Make sure that the saw band ridge fits tightly to the wheel rim. -

Page 43: Saw Band Setting

• The saw band runs on the wheel rim – The saw band and wheel rim can be damaged Start and stop saw band drive. Stop the main switch! Open rear cover of the saw frame. Check saw band placing on the wheels. •... -

Page 44: Limit Switch Of The Saw Frame Lower Position Adjustment

Lift the saw frame to the top position. Release the nut of the screw and set it to the desired value. Secure the screw with nut. Set the limit switch of the saw frame lower position. 4.6. Limit switch of the saw frame lower position adjustment If the lower stop of the saw frame was set, the limit switch must be set again. -

Page 45: Cooling Agents And Chips Disposal

4.7. Cooling agents and chips disposal The quality of the cooling If the solution is too weak: If the solution is too strong: agent will deteriorate due to: • • • use of contaminated water corrosion protection is the cooling ability is decreased diminished •... -

Page 46: Hydraulic, Greases And Oils

Use oils with specification DIN 51517 in the gearboxes. Select the viscosity grade ISO VG according to the original oil fill. Attention: When replacing, use oils recommended by BOMAR or oils, which has comparable parameters from the other manufacturers. Do not forget, that mineral and synthetic oils must not be... -

Page 47: Lubrication

Hydraulic oils quantity – see chapter Hydraulic oil level check. Note: When replacing, use oils recommended by BOMAR or oils, which has comparable parameters from the other manufacturers. Do not forget, that mineral and synthetic oils may not be mixed! - Page 48 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 49: Hydraulic Unit Service

4.8.5. Hydraulic unit service After 50 hours working time, or the latest 3 month after the first run, the first service should be carried out. This includes: • checking off all screws and connections, fixing points, tubes and hoses for leakage •... -

Page 50: Worn Pieces Replacement

4.10. Worn pieces replacement 4.10.1. Hard metal guides replacement If the hard metal guides cannot be adjusted, they have to be replaced. Dismantle the saw band. Remove the hosepipe leading the cooling agent. Dismantle guide cube of the saw band. Loosen the adjusting screws of the metal guide. -

Page 51: Saw Band Guiding Rollers Replacement

Release the nut of the brush, exchange old brush to new brush and screw on the nut of the brush. Set the brush to the saw band. 4.10.3. Saw band guiding rollers replacement If the saw band is not sufficiently guided by guiding pulleys or if the pulleys are obviously worn, the pulleys should be replaced. -

Page 52: Stretching Wheel Replacement

Change all bearings and other worn parts. Install eccentrics to the cubes. Install components on both eccentrics in given order. Put bearings by means of the preparation on eccentrics. ATTENTION! Do not replace the eccentrics placing in the cube Screw on nuts on both eccentrics and tighten them. - Page 53 Screw off the screw and take down the washer. Pull off the wheel from the shaft by means of the three-armed puller. If bearing stayed on the shaft, pull off it too Check score of the bearings of the stretching wheel and replace them for new. Clean the shaft and grease it with oil.

-

Page 54: Driving Wheel Replacement

Insert the bearing to the hole in the wheel and press it to the retaining ring. Put the wheel on the shaft and screw on the preparation to the wheel stretching to the hole in the shaft. 10. Pull on the wheel on the shaft. 11. -

Page 55: Cooling Pump Replacement

Pull off the wheel from the shaft by means of the three-armed puller. Install the wheel on the shaft. Insert the feather to the groove. Screw on the preparation to the wheel stretching to the hole in the shaft. Pull on the wheel on the shaft. - Page 56 Remove the cover of the pump terminal switchboard. Disconnect 4 terminal connectors of the input cables. Cables are identified according to the red clamps.. Loosen the bushing and pull the cable out from the pump. Dismantle new pump switchboard cover. Push the cable through the bushing and fasten it.

-

Page 57: Závady / Troubleshooting

Závady / Troubleshooting ... -

Page 58: Mechanical Problems

5.1. Mechanical problems Problem Possible causes Repair Wrongly adjusted hard metal guides. Set according to the chapter „Servicing and adjustment“ Worn hard metal guides. Replace to the chapter „Worn pieces replacement“ Wrongly adjusted cubes of the saw Set according to the chapter „Servicing and band guiding. - Page 59 Problem Possible causes Repair Worn saw band guide bearings. Check guiding bearings and if you notice some sort of excessive damage, replace them according to chapter„Worn pieces replacement“ Wrongly adjusted guiding cubes of the Set guiding cube according to chapter „Servicing saw band.

-

Page 60: Electric And Hydraulic Problems

Problem Possible causes Repair The brush position and the brush cover The brush cover must be posed, in order to the is adjusted wrong – with the brush brush can be turned. cannot be turned. Backslash in driving wheel lodgement Change the driving shaft for a long one, new 12. -

Page 61: Hydraulic Problems

5.3. Hydraulic problems Problem Possible causes Repair Hydrogenerator not • reverse rotation Check the connections of each phase. supplying oil Reconnect properly connection of the electrical phases. • shortage of oil in the tank Add hydraulic oil • Oil viscosity does not correspond Change hydraulic oil. - Page 62 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 63: Schémata / Schemas / Schematics

Schémata / Schemas / Schematics ... -

Page 64: Elektrické Schema / Elektroschema / Wiring Diagrams - 3×400 V, Tn-C-S

6.1. Elektrické schema / Elektroschema / Wiring diagrams – 3×400 V, TN-C-S Manual version: 1.02 / Nov. 2011 Manual rev.:... - Page 65 ...

- Page 66 Manual version: 1.02 / Nov. 2011 Manual rev.:...

- Page 67 ...

-

Page 68: Hydraulické Schéma / Hydraulikschema / Hydraulic Diagram

92.153.071 TOTALSTOP Rozváděč / Schaltschrank / Switchboard 24VDC Rapidmove Rozváděč / Schaltschrank / Switchboard 24VDC 0–360st Škrtící ventil / Drosselventil / Throttle-valve (0,1,2,…,7) Válec zvedací / Hebezylinder / Lifting cylinder BOMAR Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 69: Výkresy Sestav Pro Objednání Náhradních Dílů / Zeichnungen Für Bestellung Der Ersatzteile / Drawing Assemblies For Spare Parts Order

410.280 DG), Serien Nr. (z. B. 125) und Baujahr (z. B. 1999). • For spare parts order, you must always to allege: type of machine (for example Workline 410.280 DG), serial number (for example 125, see cover page) and year of construction (for example 1999). ... -

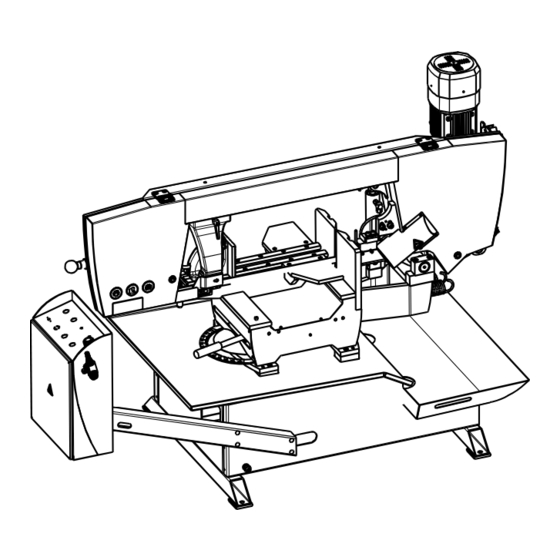

Page 70: Workline 410.280 Dg

7.1. Workline 410.280 DG Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 71: Kusovník / Stückliste / Piece List - Workline 410.280 Dg

7.2. Kusovník / Stückliste / Piece list – Workline 410.280 DG ... -

Page 72: Rameno / Sägerahmen / Saw Arm

7.3. Rameno / Sägerahmen / Saw arm Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 73: Kusovník / Stückliste / Piece List - Rameno / Sägerahmen / Saw Arm

7.4. Kusovník / Stückliste / Piece list – Rameno / Sägerahmen / Saw arm ... -

Page 74: Napínání / Spannung / Tensioning

7.5. Napínání / Spannung / Tensioning Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 75: Kusovník / Stückliste / Piece List - Napínání / Spannung / Tensioning

7.6. Kusovník / Stückliste / Piece list – Napínání / Spannung / Tensioning ... -

Page 76: Vedení Pásu / Sägebandführung / Belt Guide

7.7. Vedení pásu / Sägebandführung / Belt guide Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 77: Kusovník / Stückliste / Piece List - Vedení Pásu / Sägebandführung / Belt Guide

7.8. Kusovník / Stückliste / Piece list – Vedení pásu / Sägebandführung / Belt guide ... -

Page 78: Vodící Kostka / Führungsklotz / Guiding Cube - 1

7.9. Vodící kostka / Führungsklotz / Guiding cube - 1 Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 79: Kusovník / Stückliste / Piece List - Vodící Kostka / Führungsklotz / Guiding Cube - 1

7.10. Kusovník / Stückliste / Piece list – Vodící kostka / Führungsklotz / Guiding cube - 1 ... -

Page 80: Vodící Kostka / Führungsklotz / Guiding Cube - 2

7.11. Vodící kostka / Führungsklotz / Guiding cube - 2 Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 81: Kusovník / Stückliste / Piece List - Vodící Kostka / Führungsklotz / Guiding Cube - 2

7.12. Kusovník / Stückliste / Piece list – Vodící kostka / Führungsklotz / Guiding cube - 2 ... -

Page 82: Konzola Otočná / Drehkonsole / Turnable Console

7.13. Konzola otočná / Drehkonsole / Turnable console Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 83: Kusovník / Stückliste / Piece List - Konzola Otočná / Drehkonsole / Turnable Console

7.14. Kusovník / Stückliste / Piece list – Konzola otočná / Drehkonsole / Turnable console ... -

Page 84: Svěrák / Schraubstock / Vice - 1

7.15. Svěrák / Schraubstock / Vice – 1 Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 85: Kusovník / Stückliste / Piece List - Svěrák / Schraubstock / Vice - 1

7.16. Kusovník / Stückliste / Piece list – Svěrák / Schraubstock / Vice – 1 ... -

Page 86: Svěrák / Schraubstock / Vice - 3

7.17. Svěrák / Schraubstock / Vice – 2 Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 87: Kusovník / Stückliste / Piece List - Svěrák / Schraubstock / Vice - 2

7.18. Kusovník / Stückliste / Piece list – Svěrák / Schraubstock / Vice – 2 ... - Page 88 7.19. Svěrák / Schraubstock / Vice – 3 Manual version: 1.02 / Nov. 2011 Manual rev.:...

-

Page 89: Kusovník / Stückliste / Piece List - Svěrák / Schraubstock / Vice - 3

7.20. Kusovník / Stückliste / Piece list – Svěrák / Schraubstock / Vice – 3 ... -

Page 90: Podstavec / Untersatz / Base

7.21. Podstavec / Untersatz / Base Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 91: Kusovník / Stückliste / Piece List - Podstavec / Untersatz / Base

7.22. Kusovník / Stückliste / Piece list – Podstavec / Untersatz / Base ... -

Page 92: Podstavec / Untersatz / Base

7.23. Podstavec / Untersatz / Base Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 93: Kusovník / Stückliste / Piece List - Podstavec / Untersatz / Base

7.24. Kusovník / Stückliste / Piece list – Podstavec / Untersatz / Base ... -

Page 94: Brzda / Bremse / Brake

7.25. Brzda / Bremse / Brake Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 95: Odměřování / Gehrungmessung / Measuring

7.26. Odměřování / Gehrungmessung / Measuring ... -

Page 96: Doraz / Anschlag / Stop Piece

7.27. Doraz / Anschlag / Stop piece Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 97: Pohon / Antrieb / Drive

7.28. Pohon / Antrieb / Drive ... -

Page 98: Válec / Zylinder / Cylinder

7.29. Válec / Zylinder / Cylinder Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 99: Kusovník / Stückliste / Piece List - Válec / Zylinder / Cylinder

7.30. Kusovník / Stückliste / Piece list – Válec / Zylinder / Cylinder ... -

Page 100: Rozvaděč / Verteiler / Distributor

7.31. Rozvaděč / Verteiler / Distributor Manual version: 1.02 / Nov. 2011 Manual rev.:... -

Page 101: Kusovník / Stückliste / Piece List - Rozvaděč / Verteiler / Distributor

7.32. Kusovník / Stückliste / Piece list – Rozvaděč / Verteiler / Distributor ...

Need help?

Do you have a question about the Workline 410.280 DG and is the answer not in the manual?

Questions and answers