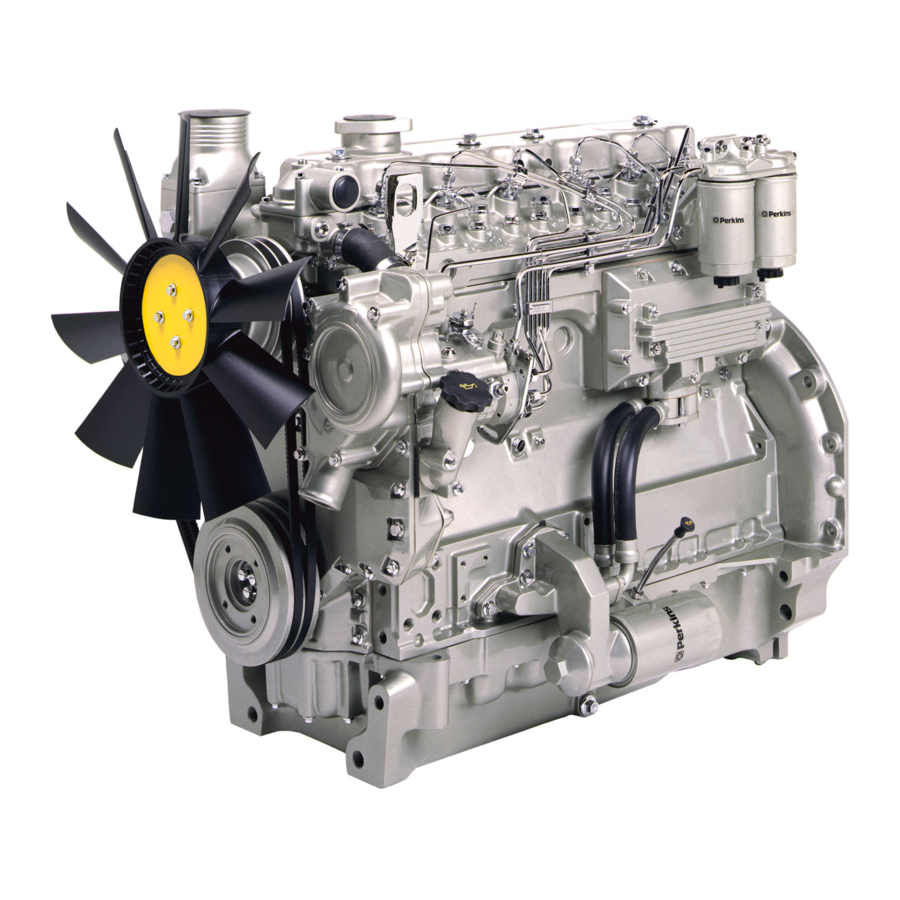

Perkins New 1000 Series Manuals

Manuals and User Guides for Perkins New 1000 Series. We have 2 Perkins New 1000 Series manuals available for free PDF download: Workshop Manual

Perkins New 1000 Series Workshop Manual (370 pages)

4 and 6 cylinder diesel engines for industrial and agricultural applications

Table of Contents

-

Introduction

15 -

Engine Views

16 -

Viton Seals

20 -

Rocker Cover

56 -

Manifolds

64 -

Valve Guides

81 -

Piston Rings

97 -

Connecting Rod

103 -

Thrust Washers

119 -

Main Bearings

122 -

Crankshaft

124 -

Balancer Unit

128 -

Front Oil Seal

141 -

Fuel Pump Gear

151 -

Camshaft Gear

155 -

Crankshaft Gear

156 -

Timing Case

157 -

Cylinder Block

164 -

Cylinder Liner

169 -

8 Engine Timing

179 -

Turbocharger

187 -

Filter Canister

205 -

Filter Head

206 -

Sump

207 -

Relief Valve

217 -

11 Fuel System

223 -

Fuel Filters

230 -

Atomisers

234 -

Fuel Lift Pump

238

Advertisement

Perkins New 1000 Series Workshop Manual (290 pages)

Models AJ to AS and YG to YK

Table of Contents

-

Introduction

15 -

Viton Seals

20 -

Rocker Cover

32 -

Valve Guides

51 -

Piston Rings

71 -

-

To Inspect74

-

-

-

To Inspect75

-

-

Crankshaft

91 -

Front Oil Seal

111 -

Fuel Pump Gear

118 -

Camshaft Gear

120 -

Crankshaft Gear

121 -

Timing Case

122 -

Cylinder Liner

130 -

Engine Timing

144 -

Engine Breather

156 -

-

Fuel System181

-

-

Fuel Filters

187 -

Fuel Lift Pump

193-

To Test195

-

-

Intercooler

254 -

Flywheel

258 -

Ring Gear

258 -

Drive Belts

262 -

Alternator

263-

To Maintain263

-

-

Fault Diagnosis

264-

Starter Motor268

-

Starter Motor

269 -

Starting Aid

273 -

Operation

280