Table of Contents

Advertisement

Quick Links

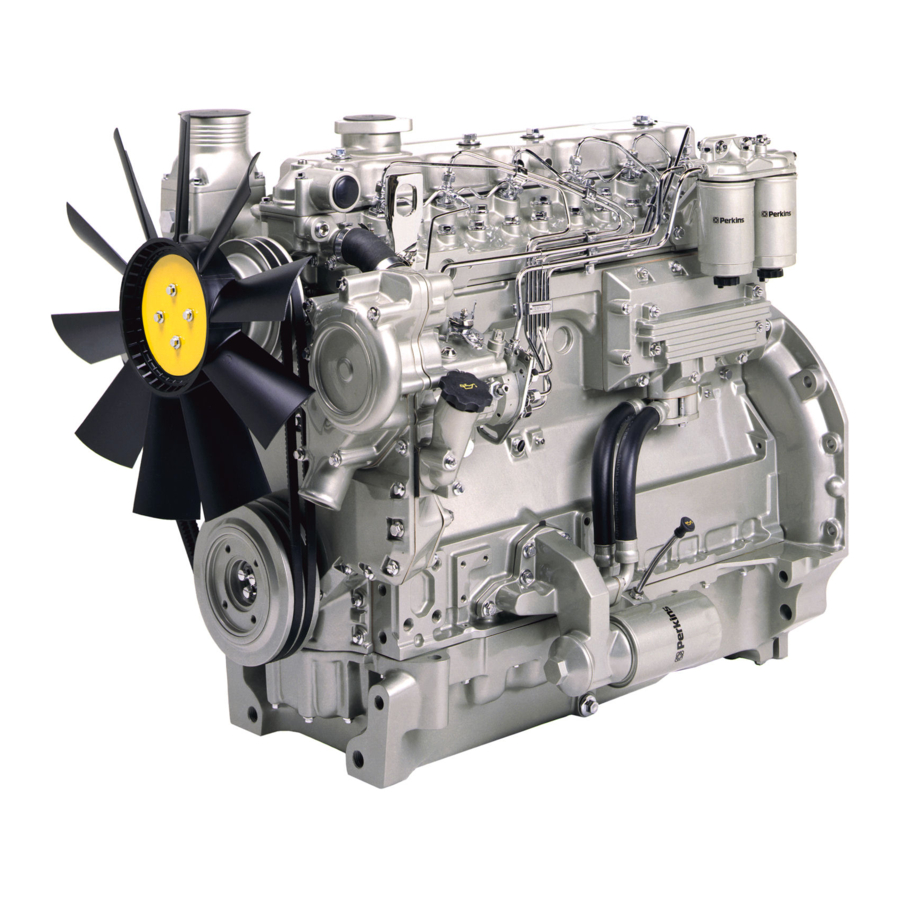

New 1000 Series

Perkins New 1000 Series

Models AJ to AS and YG to YK

WORKSHOP MANUAL

4 and 6 cylinder diesel engines for industrial and

agricultural applications

Publication TPD 1350E issue 3

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in March 2000 by Technical Publications.

Workshop Manual, TPD 1350, issue 3

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Perkins New 1000 Series

- Page 1 4 and 6 cylinder diesel engines for industrial and agricultural applications Publication TPD 1350E issue 3 © Proprietary information of Perkins Engines Company Limited, all rights reserved. The information is correct at the time of print. Published in March 2000 by Technical Publications.

- Page 2 New 1000 Series This publication is written in Perkins Approved Clear English Chapters 10 General information 11 Specifications 12 Cylinder head assembly 13 Piston and connecting rod assemblies 14 Crankshaft assembly 15 Timing case and drive assembly 16 Cylinder block assembly...

-

Page 3: Table Of Contents

New 1000 Series Contents 10 General information Introduction ..................15 Engine identification . - Page 4 New 1000 Series 12 Cylinder head assembly General description ................31 Rocker cover 12-1 To remove and to fit ...

- Page 5 New 1000 Series 13 Piston and connecting rod assemblies General description ................63 Big end bearing 13-1 To remove and to fit ..

- Page 6 New 1000 Series 14 Crankshaft assembly General description ................79 Crankshaft pulley 14-1 To remove and to fit - four cylinder engines ..

- Page 7 New 1000 Series 15 Timing case and drive assembly General description ................109 Timing case cover 15-1 To remove and to fit ..

- Page 8 New 1000 Series 16 Cylinder block assembly General description ................127 Cylinder block 16-1 To dismantle and to assemble ...

- Page 9 New 1000 Series Data and dimensions................158 19 Lubrication system General description ................159...

- Page 10 New 1000 Series Fuel system General description................181 Cold start advance unit ................ 183 Typical fuel system ...

- Page 11 New 1000 Series 21 Cooling system General description ................219 Thermostats 21-1 To remove, to fit and to test ..

- Page 12 New 1000 Series Intercooler 21-19 To remove and to fit ..............250 21-20 To clean and to inspect ...

- Page 13 New 1000 Series 23 Electrical equipment Alternators General description ................261 Precautions ..................261...

- Page 14 New 1000 Series 24 Auxiliary equipment Compressors General description ................275 Operation....

-

Page 15: General Information

Introduction This workshop manual has been written to provide Read and remember the "Safety precautions". assistance in the service and overhaul of Perkins New They are given for your protection and must be 1000 Series engines. For overhaul procedures the used at all times. - Page 16 New 1000 Series A0378N A0379 Workshop Manual, TPD 1350, issue 3...

-

Page 17: Engine Identification

AK80920*U510256B* If you need parts, service or information for your engine, you must give the complete engine number to your Perkins distributor. If there is a number in the area of the label marked TPL N , then this number must also be given to your Perkins distributor. -

Page 18: General Safety Precautions

Fit only genuine Perkins parts. dangerous hot coolant can be discharged. Do not use salt water or any other coolant which can cause corrosion in the closed circuit of the cooling system. -

Page 19: Engine Lift Equipment

New 1000 Series Engine lift equipment The maximum weight of the engine without coolant, lubricant or a gearbox fitted will vary for different applications. It is recommended that lift equipment of the minimum capacity listed below is used: Four cylinder engines ..500 kg (1100 lbs) Six cylinder engines. -

Page 20: Viton Seals

New 1000 Series Viton seals Some seals used in engines and in components fitted to engines are made of Viton. Viton is used by many manufacturers and is a safe material under normal conditions of operation. If Viton is burned, a product of this burnt material is an acid which is extremely dangerous. -

Page 21: Powerpart Recommended Consumable Products

POWERPART Studlock consumable products To permanently retain large fasteners and studs. Currently Loctite 270. Part number 21820270. Perkins have made available the products recommended below in order to assist in the correct POWERPART Nutlock operation, service and maintenance of your engine To retain and seal threaded fasteners and cup plugs and your machine. - Page 22 New 1000 Series POWERPART Compound To seal the outer diameter of seals. Currently Loctite Forma Gasket No 2. Part number 1861147. POWERPART Platelock For tight fitted metal surfaces. Suitable for metal plated surfaces and stainless steel, Currently Loctite 243. Part number 21826039.

-

Page 23: Specifications

New 1000 Series Specifications Basic engine data Number of cylinders: AJ, AK, AM, AP, AQ, AR, AS ............. 4 YG, YH, YK . -

Page 24: Thread Sealant

New 1000 Series Thread sealant When setscrews or studs are fitted into holes which are tapped through the cylinder block, a suitable sealant must be used to prevent leakage. Micro encapsulated anaerobic sealant (M.E.A.S) fasteners have been introduced instead of jointing compounds or other sealants when the fasteners are fitted in through holes into oil or coolant passages. -

Page 25: Standard Torque Tensions

New 1000 Series Standard torque tensions Most of the torque tensions on the engine are standard. Special torque tensions are listed in the separate special torque tables. The standard torque tensions listed in the tables below can be used when a special torque is not necessary. -

Page 26: Specific Torque Tensions

New 1000 Series Specific torque tensions The torque tensions below apply to components lubricated lightly with clean engine oil before they are fitted. Special torques for setscrews and nuts Torque Thread Description lbf ft kgf m size Cylinder head assembly... -

Page 27: Timing Case And Drive Assembly

New 1000 Series Special torques for setscrews and nuts Torque Thread Description lbf ft kgf m size Timing case and drive assembly Setscrews, timing case to cylinder block Setscrews, timing case to cylinder block Setscrews, hub of idler gear Setscrew, camshaft gear... -

Page 28: Flywheel And Housing

New 1000 Series Special torques for setscrews and nuts Torque Thread Description lbf ft kgf m size Flywheel and housing Setscrews, flywheel to crankshaft 1/2 UNF 10,7 Setscrews, cast iron flywheel housing to cylinder block - Head stamped 8.8 - Head stamped 10.9 - Head stamped 10.9... -

Page 29: Compression Test Data

New 1000 Series Compression test data Tests have shown that many factors affect compression pressures. Battery and starter motor condition, ambient conditions and the type of gauge used can give a wide variation of results for a given engine. It is not possible to give accurate data for... - Page 30 This page is intentionally blank...

-

Page 31: Cylinder Head Assembly

New 1000 Series Cylinder head assembly General description In a diesel engine there is little carbon deposit and for this reason the number of hours run is no indication of when to overhaul a cylinder head assembly. The factors which indicate when an overhaul is necessary are how easily the engine starts and its general performance. -

Page 32: Rocker Cover

New 1000 Series Rocker cover To remove and to fit 12-1 Engines are supplied with rocker covers (A) made of a plastic material or aluminum. To remove 1 Disconnect the breather pipe. 2 Remove the cap nuts and rubber seal (A1) from the top of the rocker cover and remove the heat shield, if one is fitted. -

Page 33: Rocker Assembly

New 1000 Series Rocker assembly To remove and to fit 12-2 To remove 1 Remove the rocker cover, see operation 12-1. 2 Release evenly and gradually the fasteners of the rocker shaft brackets; begin with the end brackets and move toward the centre. Remove the fasteners and lift off the rocker assembly. -

Page 34: To Dismantle And To Assemble

New 1000 Series To dismantle and to assemble 12-3 3 Ream the bush in the rocker lever to give a clearance on the rocker shaft of 0,03/0,09 mm (0.001/ 0.004 in). Clean thoroughly the bush and check that To dismantle the oil hole is free from debris. -

Page 35: Valve Tip Clearances

New 1000 Series Valve tip clearances To check and to adjust 12-5 Notes: The valve tip clearance is measured between the top of the valve stem and the rocker lever (A). With the engine hot or cold, the correct clearances are 0,20 mm (0.008 in) for the inlet valves and 0,45... - Page 36 New 1000 Series Six cylinder engines 1 Rotate the crankshaft in the normal direction of rotation until the inlet valve (A11) of number 6 cylinder has just opened and the exhaust valve (A12) of the same cylinder has not closed completely. Check the clearances of the valves (A1 and A2) of number 1 cylinder and adjust them, if necessary.

-

Page 37: Valve Springs

New 1000 Series Valve springs To change the valve springs (with cylinder head fitted) 12-6 Special tools Valve spring compressor, PD.6118B Stud adaptor used with PD.6118B, PD.6118-7 Setscrew adaptor used with PD.6118B, PD.6118-8 A0051 Note: Paragraphs 1 to 12 refer to a change of valve springs for a single cylinder. - Page 38 New 1000 Series 9 Fit the valve spring caps. Caution: Ensure that the valve spring is compressed squarely or damage can occur to the valve stem. 10 Fit the valve spring compressor, compress the valve spring and fit the collets. Remove the valve spring compressor.

-

Page 39: Cylinder Head Assembly

New 1000 Series Cylinder head assembly (Engine types AJ to AS and YG to YK) To remove and to fit 12-7 To remove 1 Drain the cooling system. 2 Disconnect the battery terminals. 3 Remove the air filter/cleaner hose at the induction manifold. - Page 40 New 1000 Series 12 Remove the atomiser leak-off pipe. 13 Remove the atomisers, see operation 20-3. Fit suitable covers to the nozzles and the open connections. 14 If a compressor is fitted: Remove the coolant pipe which is fitted between the cylinder head and the compressor.

- Page 41 New 1000 Series To fit (Engine types AJ to AQ and YG to YK) page 45 for AR and AS engine types Special tools: Angle gauge, to tighten cylinder head setscrews, MS.1531 1 Clean the bottom face of the cylinder head and the top face of the cylinder block.

- Page 42 New 1000 Series 7 Tighten the setscrews, in the correct sequence, a further part of a turn according to the length of the setscrews (page 40/A or B). Short setscrews (S) must be turned a further 150° (2.5 flats). Medium length setscrews (M) must be turned a further 180°...

- Page 43 New 1000 Series 17 Fit the induction and exhaust manifolds: Note: The manifold joints are fitted without jointing compound. For four cylinder engines: Ensure that the two inlet and exhaust manifold joints (A1) and (A2) are fitted correctly, the rear joint (A1) must be fitted with the two location tabs (A3) towards the sump.

- Page 44 New 1000 Series 20 For engines fitted with turbochargers: Fit the turbocharger, see operation 18-1. 21 Fit the fuel pipe between the fuel filter and the fuel lift pump. 22 Fit the fuel pipe between the fuel filter and the fuelled starting aid in the induction manifold.

- Page 45 New 1000 Series To fit (Engine types AR and AS) page 41 for AJ to AQ and YG to YK engine types Special tools: Angle gauge, to tighten cylinder head setscrews, MS.1531 1 Clean the bottom face of the cylinder head and the top face of the cylinder block.

- Page 46 New 1000 Series 9 Tighten the M10 setscrews, in the correct sequence, a further part of a turn according to the length of the setscrews, see (A) and (C). Short setscrews (S) must be turned a further 120° (2 flats).

- Page 47 New 1000 Series 19 Fit the induction and exhaust manifolds: Note: The manifold joints are fitted without jointing compound. Ensure that the two inlet and exhaust manifold joints (A1) and (A2) are fitted correctly, the rear joint (A1) must be fitted with the two location tabs (A3) towards the sump.

- Page 48 New 1000 Series 22 The top half of the induction manifold (A1) is sealed to the bottom half (A2) with a liquid joint and fastened together by six cap screws. The top half of the manifold must be removed to obtain access to four of the manifold fasteners (A3) inside the manifold.

-

Page 49: Valves And Valve Springs

New 1000 Series Valves and valve springs To remove and to fit 12-8 Special tools: Valve spring compressor, PD.6118B Stud adaptor, PD.6118-7 Setscrew adaptor, PD.6118-8 To remove Warning! Wear eye protection during this operation. 1 Remove the cylinder head, see operation 12-7. -

Page 50: To Inspect And To Correct

New 1000 Series To inspect and to correct 12-9 Special tools: Gauge, valve depth, PD.41D Dial gauge for use with PD.41D, PD.208 1 Check the depth of the valves below the face of the cylinder head before the valve springs are removed. -

Page 51: Valve Guides

New 1000 Series Valve guides To inspect 12-10 To check the valve guides for wear: The maximum permissible clearance (A5) with a valve lift of 15,0 mm (0.6 in), between the valve stem and the bore of the guide is 0,100 mm (0.008 in) for inlet valves and 0,121 mm (0.011 in) for exhaust valves. -

Page 52: 12-11To Remove And To Fit

New 1000 Series To remove and to fit 12-11 Special tools: Remover/replacer for valve guides (main tool), PD.1D Adaptor PD.1D-13 used with PD.1D, PD.1C-6 and PD.248 Distance piece, inlet guide, PD.1C-6 used with PD.1D and PD.1D-13 Distance piece, exhaust guide, PD.248 used with PD.1D and PD.1D-13... - Page 53 New 1000 Series To fit 1 Clean the parent bore in the cylinder head for the valve guide. 2 Lubricate the outer surface of the new valve guide (A6) with clean engine lubricating oil. 3 Fit the adaptor (A5) into the remover/replacer tool (A3).

-

Page 54: Cylinder Head

New 1000 Series Cylinder head To inspect and to correct 12-12 1 Remove the cylinder head assembly, see operation 12-7. 2 Remove the thermostat housing. 3 Inspect the cylinder head for signs of gas or coolant leakage. 4 Remove the valve springs and the... -

Page 55: To Correct A Valve Seat With A Valve Seat Cutter

New 1000 Series To correct a valve seat with a valve seat cutter 12-13 Special tools: Cutter (31° or 46°) for inlet and exhaust valve seats and valve guides reamer PD.242. Caution: Valves must not be lapped. The valve seats are cut and the valve guides are reamed in one operation with a special tool (A). -

Page 56: To Fit Valve Seat Inserts

New 1000 Series To fit valve seat inserts 12-14 1 Remove the valve guide and clean the bore into which the guide is to be fitted. 2 Fit new partially finished valve guides, see operation 12-11. 3 With the bore of the new partially finished valve... -

Page 57: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 58 New 1000 Series Exhaust valves Diameter of valve stem ........8,938/8,960 mm (0.3519/0.3528 in) Clearance in valve guide .

- Page 59 New 1000 Series Maximum permissible distortion of cylinder head Four cylinder engines A1 . . . 0,08 mm (0.003 in) A2 . . . 0,15 mm (0.006 in) A3 . . . 0,15 mm (0.006 in) Six cylinder engines A1 . . . 0,13 mm (0.005 in) A2 .

- Page 60 New 1000 Series Valve seat insert tool (A) Inlet (for 45° valves and 30° valves), engine types AJ to AQ and YG to YK A1..1,5 mm (0.06 in) A2..20 mm (0.800 in) A3.

- Page 61 New 1000 Series Valve guides Inside diameter of partially finished guide ......8,600/8,700 mm (0.3386/0.3425 in) Inside diameter of finished guide.

- Page 62 This page is intentionally blank...

-

Page 63: Piston And Connecting Rod Assemblies

Piston and connecting rod assemblies General description The pistons used in the New 1000 Series engines have a "Fastram" combustion chamber in the top of the piston (A). The piston (B) for engine types AR and AS has two recesses in the top face for the valves. - Page 64 New 1000 Series Notes: If the crankshaft or the cylinder block is to be renewed, it may be necessary to change the grade of the connecting rods, see operation 13-10. This will occur if the correct piston height above the...

-

Page 65: Big End Bearing

New 1000 Series Big end bearing To remove and to fit 13-1 There are location thimbles (B1) fitted to the latest bolts used with connecting rods that have serrated faces. The location thimbles are used in the factory to prevent movement of the bolts when the nuts for the big end cap are tightened by automatic equipment. -

Page 66: To Inspect

New 1000 Series To fit 1 Clean the bearing faces of the connecting rod and the crank pin. 2 Ensure that the protrusion for the location dowels is 3,0/4,5 mm (0.12/0.18 in) above the cap faces. Clean the complete bearing and lubricate the bearing surface and the crank pin with clean engine lubricating oil. -

Page 67: Piston And Connecting Rod

New 1000 Series Piston and connecting rod To remove and to fit 13-3 To remove 1 Drain the lubricating oil and the cooling system. 2 Remove the cylinder head assembly, see operation 12-7. 3 Remove all carbon from the top of the bores of the cylinder liners. - Page 68 New 1000 Series To fit Special tools: Piston replacer tool, PD.206 1 Ensure that the piston, the cylinder bore, the crank pin and the big end of the connecting rod are clean. Lubricate the piston and the cylinder liner with clean engine lubricating oil.

- Page 69 New 1000 Series 7 Clean the connecting rod cap and the lower half of the shell bearings. Fit the bearing to the cap; ensure that the location tag is fitted correctly in its recess. Lubricate the bearing with clean engine lubricating oil.

-

Page 70: To Check The Piston Height Above The Cylinder Block

New 1000 Series To check the piston height above the cylinder block 13-4 Special tools: Piston height tool, PD.41D Dial gauge for use with PD.41D, PD.208 Caution: If the correct piston height above the cylinder block is not obtained, damage to the engine can occur. -

Page 71: Piston Rings

New 1000 Series Piston rings To remove and to fit 13-5 The pistons have two compression rings and an oil control ring. All the piston rings are above the gudgeon pin. To ensure that the correct type is obtained always use the engine identification number to order new parts. -

Page 72: Piston And Connecting Rod Assembly

New 1000 Series engines have six connecting rod length grades, if a new connecting rod is fitted, ensure that it is of the correct length... -

Page 73: To Check The Length Of A Connecting Rod

New 1000 Series To check the length of a connecting rod 13-7 A partially finished small end bush, which can be fitted to the original connecting rod and machined to obtain the correct length grade is available, see operation 13-10. Specialist equipment and personnel with the correct training are needed to machine the partially finished small end bush. -

Page 74: Piston And Piston Rings

New 1000 Series Piston and piston rings To inspect 13-8 1 Check the piston for wear and other damage. 2 Check that the piston rings are free to move in their grooves and that the the rings are not broken. -

Page 75: Connecting Rod

Caution: Do not use a reamer, specialist equipment and personnel with the correct training are needed to machine the partially finished small end bush. For further information refer to your nearest Perkins distributor. 4 Machine the partially finished bush. To obtain the... -

Page 76: Piston Cooling Jets

New 1000 Series Piston cooling jets To remove and to fit 13-11 To remove Release the valve assembly and remove the piston cooling jet assembly (A). Notes: The crankshaft is removed in (A) to show clearly the piston cooling jet. -

Page 77: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 78 New 1000 Series Connecting rods Type ............'H' section, wedge shape small end Location of cap to connecting rod .

-

Page 79: Crankshaft Assembly

New 1000 Series Crankshaft assembly General description The crankshaft is a chrome-molybdenum forging which has five main journals for four cylinder engines and seven main journals for six cylinder engines. End-float is controlled by thrust washers on both sides of the centre main bearing. -

Page 80: Crankshaft Pulley

New 1000 Series Crankshaft pulley To remove and to fit - four cylinder engines 14-1 To remove 1 Remove the drive belt(s), see operation 23-3. 2 Release the three setscrews (A2 which hold the pulley and remove the setscrews), the thrust block (A1) and the pulley (A3). -

Page 81: Crankshaft Pulley And Damper

New 1000 Series Crankshaft pulley and damper To remove and to fit - six cylinder engines 14-2 Consumable products: POWERPART Retainer (oil tolerant) Caution: A viscous damper (C1) should be renewed if there is impact damage to the outer casing or if... - Page 82 New 1000 Series To fit 1 If the damper is fitted to the rear face of the pulley, fit the damper to the pulley with its inner flange against the rear face of the pulley. If a viscous damper is fitted, put the damper in position on the face of the pulley (A1).

-

Page 83: To Inspect

New 1000 Series To inspect 14-3 1 When an integral pulley and damper (A) is fitted, the assembly should be renewed if: The rubber insert (A1) between the hub and the outer ring is split. The rubber insert is damaged by oil or solvents There is movement of the pulley or outer ring on the hub. -

Page 84: Rear Oil Seal Assembly

New 1000 Series Rear oil seal assembly To remove and to fit 14-4 Special tools: Replacer tool for rear oil seal, PD.145D Consumable products: POWERPART Threadlock POWERPART Silicone rubber sealant A0098 1 Remove the drive components from the rear end of the engine. -

Page 85: To Renew The Rear Oil Seal

New 1000 Series To renew the rear oil seal 14-5 Special tools: Replacer tool for rear oil seal, PD.145D There are three positions in which the seal can be fitted in the housing (A). 4,6mm (0.18in) Position "1" (A1) is used when a new seal is first fitted in service. -

Page 86: Thrust Washers

New 1000 Series Thrust washers To check crankshaft end-float 14-6 The axial movement of the crankshaft is controlled by thrust washers fitted both sides of the centre main bearing (A). The end-float can be checked with a feeler gauge between a thrust washer and the crankshaft (B), or with a dial test indicator on one end of the crankshaft to check the movement (C). -

Page 87: To Remove And To Fit

New 1000 Series To remove and to fit 14-7 To remove 1 Drain the lubricating oil and remove the lubricating oil sump, see operation 19-3. 2 If necessary, remove the balancer unit, see operation 14-12. 3 If necessary, remove the lubricating oil strainer and suction pipe, see operation 19-4. - Page 88 New 1000 Series 6 Fit the cap with the location tags of both halves of the shell bearings to the same side (A1). Tighten the main bearing setscrews gradually and evenly to 265 Nm (196 lbf ft) 27,0 kgf m.

-

Page 89: Main Bearings

New 1000 Series Main bearings To remove and to fit (with the crankshaft in position) 14-8 If the rear main bearing is to be removed with the crankshaft in position, the flywheel, the flywheel housing, the rear oil seal housing and the bridge piece will have to be removed. -

Page 90: To Inspect

New 1000 Series To fit 1 Clean the upper half of the shell bearing and lubricate the bearing surface with clean engine lubricating oil. Caution: Only the upper half of the bearing has lubrication holes and must be fitted to the cylinder block. -

Page 91: Crankshaft

New 1000 Series Crankshaft 13 Remove the bridge piece. Warning! The engine should be upside down before the fasteners for the crankshaft are removed. If the engine cannot be turned upside down support the To remove and to fit 14-10 crankshaft before the fasteners are removed. - Page 92 New 1000 Series To fit 1 Ensure that all lubricating oil passages are clean and free from restriction. 2 Clean the main bearing housings and the upper half of the bearings. Fit the shell bearings with the location tags fitted correctly in their recesses. Lubricate the bearings with clean engine lubricating oil.

- Page 93 New 1000 Series 8 Fit the setscrews to the main bearing caps and tighten them gradually and evenly to 265 Nm (196 lbf ft) 27,0 kgf m. 9 Clean the bridge piece and the location areas for the bridge piece in the cylinder block. Use a straight edge (A2) to ensure that the bridge piece is in line with the rear face of the cylinder block.

-

Page 94: To Inspect

New 1000 Series To inspect 14-11 Check the crankshaft for wear and other damage. The maximum permissible wear and ovality on the crankshaft journals and crank pins is 0,04 mm (0.0016 in). The main journals and the crank pins of standard size crank shafts can be machined to 0,25mm (0.010 in),... -

Page 95: Balancer Unit

New 1000 Series Balancer unit To remove and to fit 14-12 To remove 1 Drain the lubricating oil from the sump and remove the sump, see operation 19-3. Warning! The weight of the unit is approximately 25 kg (55 lb). -

Page 96: To Dismantle And To Assemble

New 1000 Series To dismantle and to assemble 14-13 4 Release the setscrews which hold the lubricating oil pump and the suction pipe (A10 and A9) to the balancer frame and remove the lubricating oil pump Consumable products: and the suction pipe. - Page 97 New 1000 Series Notes: The latest oil transfer plate is fitted without a joint or sealant; always give the correct engine number when parts are needed. There are two plugs in the balancer frame, a short tapered plug with a hexagonal socket head and a long plug with a square socket head.

- Page 98 New 1000 Series To assemble 5 Ensure that the drive shaft turns freely. Check the end-float of the drive shaft with feeler gauges 1 Ensure that the location spigot (A8) on the rear face between the front face of the drive gear for the of the lubricating oil pump is clean.

- Page 99 New 1000 Series 6 Put the balancer frame upside down on the bench (A1). Turn the gear of the drive shaft (A3) until the larger of the two outer holes (A2) - in the front face of the drive gear - is in the position shown in (A). Ensure that the drive shaft will not move from this position.

- Page 100 New 1000 Series 9 If necessary, press a new bearing (A14) into the idler gear (A12). Lubricate the bearing with clean engine lubricating oil. Fit the hub (A13) into the bearing and fit the thrust washer (A15) onto the rear of the hub.

-

Page 101: To Inspect

New 1000 Series To inspect 14-14 1 Clean all the components before inspection. 2 Check the gear teeth and the splines of the drive shaft for wear or other damage. Renew the drive shaft if necessary. 3 Check the idler gear, needle roller bearing, hub and thrust washer for wear or other damage. -

Page 102: To Remove And To Fit The Needle Roller Bearings For The Drive Shaft

New 1000 Series To remove and to fit the needle roller bearings for the drive shaft 14-15 2,5/3,0 17,0/17,8 31,70 3,25/ 3,30 1 Press out the bearings with a suitable adaptor. 2 Clean the parent bores and lubricate them with... -

Page 103: To Remove And To Fit The Bushes For The Balance Weights

New 1000 Series To remove and to fit the bushes for the balance weights 14-16 2,5/3,0 17,0/17,8 31,70 3,25/ 3,30 1 Press the bushes out of the balancer frame and the rear cover with a suitable adaptor. 37,84 42 50,8... -

Page 104: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 105 New 1000 Series The finished sizes for crankshaft journals (A) which have been ground undersize are given in the table below: Item 0,25 mm (0.010 in) 0,51 mm (0.020 in) 0,76 mm (0.030 in) 75,905/75,926 mm 75,651/75,672 mm 75,397/75,418 mm (2.9884/2.9892 in)

- Page 106 New 1000 Series With the crankshaft on mountings at the front and rear journals, the maximum run-out (total indicator reading) at the journals must not be more than shown below: Journal 4 cylinder crankshafts 6 cylinder crankshafts Mounting Mounting 0,08 mm (0.003 in) 0,10 mm (0.004 in)

- Page 107 New 1000 Series Bearing clearance Four cylinder engines: All bearings ..........0,057/0,117 mm (0.0022/0.0046 in) Six cylinder engines: All other bearings.

- Page 108 This page is intentionally blank...

-

Page 109: Timing Case And Drive Assembly

New 1000 Series Timing case and drive assembly General description The timing case (A) is for engines fitted with a gear driven coolant pump. The timing case (B) is for engines fitted with a belt driven coolant pump. The timing case is made of either aluminium or cast iron. -

Page 110: Timing Case Cover

New 1000 Series Timing case cover To remove and to fit 15-1 To remove 1 Remove the fan, see operation 21-9. 2 Remove the alternator, see operation 23-4. 3 Remove the crankshaft pulley, see operation 14-1 operation 14-2. 4 Drain the coolant and remove the coolant pump, see section 21. -

Page 111: Front Oil Seal

Fastener plate for use with PD.170, PD.170-3 Adaptor for use with PD.170 A 0 12 7 (1) Refer to your nearest Perkins distributor. Fit a rod through the hole in the end of the threaded bar to prevent movement of the bar when the nut is To remove tightened. -

Page 112: To Fit Wear Sleeve

New 1000 Series To fit wear sleeve 15-3 To renew a worn crankshaft pulley, a wear sleeve (A2) is fitted over the spigot (A1). 1 Remove the crankshaft pulley, see operation 14-1 operation 14-2. Note: Full instructions and a special tool to fit the wear sleeve are in each service kit. -

Page 113: Idler Gear And Hub

New 1000 Series Idler gear and hub To remove and to fit 15-4 To remove 1 Remove the timing case cover, see operation 15-1. 2 Rotate the crankshaft until the marked teeth of the crankshaft gear and the camshaft gear and the fuel pump gear are all aligned with the marked teeth of the idler gear (A). - Page 114 New 1000 Series To fit 1 Use the three idler gear setscrews to ensure the correct position of the idler gear hub (A2) with the lubrication hole (A1) at the top. Push the hub into position and remove the setscrews.

- Page 115 New 1000 Series 4 Check the idler gear end-float (A) and the timing gear backlash (B). 5 Fit the timing case cover, see operation 15-1. 6 Fit the coolant pump, see operation 21-2. 7 Fit the crankshaft pulley, see operation 14-1 operation 14-2.

-

Page 116: Idler Gear And Hub For The Bendix Compressor

New 1000 Series Idler gear and hub for the Bendix compressor The latest compressor is made by Bendix and is driven directly from the engine timing case and does not have an auxiliary drive assembly. The engine idler gear (A12) drives the compressor gear (A4) through a separate idler gear (A11/B4) fitted onto a hub (A9). - Page 117 New 1000 Series To fit 1 Renew the "O" ring (A1). Lightly lubricate the components with clean lubricating oil before they are assembled onto the hub. Check that the four cap screws (B4) which secure the idler hub bracket (B2) to the timing case are tightened to the correct torque 35 Nm (26 lbf ft) 3,5 kgf m.

-

Page 118: Fuel Pump Gear

Stanadyne and Lucas fuel injection pump timing pin, pump gear. Special tools are needed to remove these PD.246 fasteners, refer to your Perkins distributor. 4 Inspect the gear for wear and other damage and 1 Remove the timing case cover, see operation 15-1. - Page 119 New 1000 Series To fit The fuel pump gear will only fit in one position. The gear is fitted with the letters C and M at the front. Caution: Check that the shaft of the fuel injection pump is released,...

-

Page 120: Camshaft Gear

New 1000 Series Camshaft gear To remove and to fit 15-7 To remove Special tools: Gear puller, PD.155C Adaptors for use with PD.155C, PD.155B-5 A0134A 1 Remove the timing case cover, see operation 15-1. 2 Rotate the crankshaft until the marked teeth of the crankshaft gear and the camshaft gear are in mesh with the idler gear. -

Page 121: Crankshaft Gear

New 1000 Series Crankshaft gear To remove and to fit 15-8 To remove 1 Remove the timing case cover, see operation 15-1. 2 Rotate the crankshaft until the marked teeth of the crankshaft gear and the camshaft gear are in mesh with the idler gear. -

Page 122: Timing Case

New 1000 Series Timing case To remove and to fit 15-9 Consumable products: POWERPART Jointing compound POWERPART Nutlock To remove 1 Remove the fan, see operation 21-9. 2 Remove the drive belts, see operation 23-3. 3 Remove the crankshaft pulley,... - Page 123 New 1000 Series To fit 1 Ensure that the sump joint is not damaged. If the joint is damaged, remove the sump and fit it with a new joint after the timing case has been fitted. The front section of the joint can be cut away and the front...

-

Page 124: Camshaft And Tappets

New 1000 Series Camshaft and tappets To remove and to fit 15-10 To remove 1 Before the engine is removed from the vehicle or the machine, drain the lubricating oil and the coolant. 2 Remove the timing case, see operation 15-9. -

Page 125: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 126 New 1000 Series Crankshaft gear Number of teeth ............... 28 Diameter of bore .

-

Page 127: Cylinder Block Assembly

Note: Short engines are also available. Your Perkins distributor has specialist equipment and personnel with the correct training to repair worn cylinder bores. Workshop Manual, TPD 1350, issue 3... -

Page 128: To Dismantle And To Assemble

New 1000 Series Cylinder block To dismantle and to assemble 16-1 Consumable products: POWERPART Nutlock Note: If the cylinder block is to be renewed, it may be necessary to change the grade connecting rods, operation 13-7. This will occur if the correct piston... -

Page 129: To Inspect

New 1000 Series To assemble To inspect 16-2 1 Clean thoroughly the new cylinder block. Ensure 1 Clean the passages for the coolant and for the oil. that all the oil passages are clean and free from debris. 2 Check the cylinder block for cracks and for other damage. -

Page 130: Cylinder Liner

New 1000 Series Cylinder liner To inspect 16-3 To ensure the best performance during the life of the engine it is important that worn or damaged cylinder liners are renewed. If a change of liner becomes necessary in service, transition fit liners and partially finished liners are available. -

Page 131: To Remove And To Fit

New 1000 Series To remove and to fit 16-4 Special tools: Remover/replacer for cylinder liner (main tool), PD.150B Adaptors for use with PD.150B, PD.150B-17A Depth gauge, liner flange, PD.41D Dial gauge for use with PD.41D, PD.208 Consumable products: (See Section... - Page 132 New 1000 Series To fit a service liner A service liner is a transition fit of +/- 0,03 mm (+/- 0.001 in) in the parent bore. A special tool will not be necessary to fit some liners, but where a liner is a tight fit, tool PD.150B can be used.

- Page 133 New 1000 Series 7 Lubricate the ratchet of the handle and the threaded rod with Shell Spirax oil or an equivalent oil. Operate the handle and press the liner into the parent bore to within 50 mm (2.0 in) of the fitted position.

- Page 134 New 1000 Series To fit a partially finished liner The liner is an interference fit in the parent bore. A special tool will be necessary to fit the liners, tool PD.150B can be used. If a liner is a very tight fit it may be necessary to use a hydraulic press.

- Page 135 New 1000 Series 10 Use tool PD.41D to check that the flange of the cylinder liner is between 0,10 mm (0.004 in) above to 0,10 mm (0.004 in) below the top face of the cylinder block (A). This measurement must be from the flange (A2) of the cylinder liner, not the top of the flame ring (A1).

- Page 136 New 1000 Series Cylinder bore, engine types AR and AS To inspect 16-5 To ensure the best performance during the life of the engine it is important that worn or damaged cylinder bores are corrected. The condition of a cylinder bore is decided by: The amount and location of any polished areas.

-

Page 137: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 138 Cylinder liner specifications Caution: Specialist training and equipment is needed to machine the finish of a partially finished liner. For further information contact your nearest Perkins Distributor. Partially finished liner Interference fit of liner in parent bore ....... 0,025/0,076 mm (0.003/0.001 in) Inside diameter of partially machined liner.

- Page 139 Note: Two oversize pistons are available in service:- 0,5 mm (0.020 in) and 1,0 mm (0.040 in). Caution: Specialist training and equipment is needed to machine the cylinder bore. For further information contact your nearest Perkins Distributor. Preliminary bore Final size of standard bore before it is honed ....102,873/102,924 mm (4.0501/4.0521 in) First oversize of bore before it is honed .

- Page 140 This page is intentionally blank...

-

Page 141: Engine Timing

New 1000 Series Engine timing General description To reach the accurate fuel injection needed for engines to conform to emissions legislation, the latest fuel injection pumps operate at a static timing very close to TDC. The timing gears are stamped with timing marks to ensure that they are assembled correctly (A). - Page 142 Special tools are needed to remove these fasteners, refer to your Perkins distributor. To remove the fuel injection pump from the engine it is only necessary to remove the four setscrews (B1)

- Page 143 New 1000 Series Engine timing To set number 1 piston to TDC on the compression stroke 17-1 Special tools: Valve spring compressor, PD.6118B Stud adaptor for use with PD.6118B, PD.6118B-7 Setscrew adaptor for use with PD.6118B, PD.6118B- A0173 1 Fasten a temporary pointer to the timing case cover with its tip near to the outer edge of the crankshaft pulley or damper (A1).

-

Page 144: Another Method To Set Number 1 Piston To Tdc On The Compression Stroke

New 1000 Series Another method to set number 1 piston to To check the valve timing 17-3 TDC on the compression stroke 17-2 1 Set the piston of number 1 cylinder to TDC on the 1 Fasten a temporary pointer to the timing case cover... -

Page 145: To Check The Timing Of The Fuel Injection Pump

A0374C specialist to correctly position the hub on the shaft with special test equipment available to Perkins distributors. 1 Set the piston of number 1 cylinder to TDC on the... -

Page 146: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. -

Page 147: Aspiration System

New 1000 Series Aspiration system General description Warning! Turbochargers operate at high speed and at high temperatures. Keep fingers, tools and debris away from the inlet and outlet ports of the turbocharger and prevent contact with hot surfaces. Continued Workshop Manual, TPD 1350, issue 3... - Page 148 New 1000 Series A turbocharger (A), is fitted between the exhaust and induction manifolds. The turbocharger is driven by exhaust gases and passes air to the engine at more than atmospheric pressure. It is lubricated by oil from the main gallery. The oil passes through the bearing housing of the turbocharger and returns to the lubricating oil sump;...

- Page 149 New 1000 Series Turbocharger To remove and to fit 18-1 Consumable products: POWERPART Threadlock (pipe) To remove 1 Thoroughly clean the turbocharger. 2 Remove the air cleaner hose at the compressor inlet. A0221 3 Remove or disconnect the support bracket for the turbocharger.

- Page 150 New 1000 Series To fit 1 Remove the covers from the pipes, manifolds and the turbocharger. 2 Check that the turbocharger inlets and outlets are clean and free from restriction and that the turbocharger shaft rotates freely. Also check that the open ports in the manifolds and the exhaust pipe are clean and free from restriction.

-

Page 151: To Clean The Impeller And The Compressor Casing

New 1000 Series To clean the impeller and the compressor casing 18-2 Generally, it is not necessary to remove the turbocharger to remove the compressor casing, except on some engines where the compressor casing is held by a circlip and access to the circlip is not always possible. - Page 152 New 1000 Series To remove and to fit the actuator assembly of the waste-gate unit 18-3 It is important that the waste-gate actuator setting is not altered. Do not remove the actuator or mounting bracket unless it is necessary to renew the actuator assembly.

-

Page 153: To Check And Adjust The Operation Of The Waste-Gate

New 1000 Series To check and adjust the operation of the waste-gate 18-4 If the waste-gate valve does not operate at the correct pressure, it can affect the engine performance. If the valve opens at a low pressure, this can cause black exhaust smoke and loss of power at lower engine speeds. -

Page 154: Turbocharger Faults

New 1000 Series Turbocharger faults The chart below is given to assist in the correct diagnosis of turbocharger faults. If the inside of the induction manifold is wet, check that there is not a fuel leak from the fuelled starting aid, if... - Page 155 New 1000 Series 1 Element of the air filter dirty. 2 Restricted crankcase breather. 3 Element of the air filter not fitted, or not sealing correctly. Loose connection to turbocharger. 4 Internal distortion or restriction in pipe from air filter to turbocharger.

-

Page 156: Engine Breather

New 1000 Series Engine breather Open breathers fitted to New 1000 Series engines have a pipe connected to the rocker cover which will allow any crankcase pressure to pass directly from the engine. A gauze strainer (A) may be fitted to remove any oil mist and return it to the rocker cover. -

Page 157: To Clean And To Renew

New 1000 Series Closed breather Closed breather systems fitted to New 1000 Series engines have an oil separator which is fastened to the crankcase and a breather valve is fitted between the oil separator and the induction manifold. Crankcase gases pass through the oil separator where oil from the gases is returned to the sump. -

Page 158: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. Turbocharger The make and type of turbocharger fitted is marked on the turbocharger identification plate; as a general guide the make and type of turbocharger fitted are as follows: 4 Cylinder engines . -

Page 159: Lubrication System

New 1000 Series Lubrication system General description Four cylinder engine lubrication system (page The lubricating oil passes from the filter to the 160/A) pressure rail which is drilled the complete length of the left side of the cylinder block. If the oil filter is on... - Page 160 New 1000 Series A0289 Workshop Manual, TPD 1350, issue 3...

- Page 161 New 1000 Series A0290 Workshop Manual, TPD 1350, issue 3...

- Page 162 New 1000 Series Six cylinder engine lubrication system (page The turbocharger is lubricated by oil after the filter. Oil 160/A) is supplied from a connection on the right side of the cylinder block through an external pipe to the The oil pump is similar to that used on four cylinder turbocharger.

- Page 163 Caution: The canister contains a valve and special tube to ensure that lubricating oil does not drain from the filter. Therefore, ensure that the correct Perkins POWERPART canister is used. The filter can have one or two canisters (B4) or (A1) A 0 22 3/1 fitted.

- Page 164 New 1000 Series Filter head To remove and to fit 19-2 Consumable products POWERPART nutlock 1 Put a tray under the filter head to contain spilt lubricating oil. 2 Remove the filter canister(s), see operation 19-1. 3 Remove the canister type oil cooler from the filter...

-

Page 165: To Remove And To Fit

New 1000 Series Sump To remove and to fit 19-3 Warning! Discard the used lubricating oil in a safe place and in accordance with local regulations. 1 Operate the engine until it is warm. 2 Stop the engine, remove the sump drain plug (B1) and its "O"... -

Page 166: To Inspect And To Correct

New 1000 Series 4 Loosely assemble the bracket of the suction pipe to the correct main bearing cap. Fit the suction pipe to the oil pump together with a new joint or an "O" ring. Tighten the setscrews. Tighten the setscrew of the suction pipe bracket. - Page 167 New 1000 Series Lubricating oil pump To remove and to fit 19-6 For four cylinder engines fitted with a balancer unit, the oil pump is integral with the balancer unit, section 14 for removal instructions. The lubricating oil pump has a channel (B1) in the body of the pump.

- Page 168 New 1000 Series To fit 1 Fill the oil pump with clean engine lubricating oil. Fit the oil pump to the main bearing cap and tighten the setscrews to 22 Nm (16 lbf ft) 2,2 kgf m. 2 Check the idler gear and the bush for wear and other damage.

-

Page 169: To Renew The Shaft For The Idler Gear

New 1000 Series To renew the shaft for the idler gear 19-7 Consumable products: POWERPART Retainer (oil tolerant) The idler shaft for the lubricating oil pump fitted in the front main bearing cap of six cylinder engines is retained by a pin and POWERPART Retainer (oil tolerant). - Page 170 New 1000 Series Caution: Do not use excessive torque. 5 Hold the spacer in position and engage the setscrew fully into the threads in the pin. 6 Put the spacer into position centrally over the pin and tighten the nut onto the spacer. Continue to tighten the nut and pull the pin through the spacer.

- Page 171 New 1000 Series To fit the idler shaft 1 Check that the new idler shaft, part number 3271H002 or 3271H004 and the hole for the idler shaft in the bearing cap are clean and free from oil or grease. Remove any rough edges from the hole of the bearing cap.

- Page 172 New 1000 Series To fit the idler shaft (where a pin was not fitted) 1 Follow the procedure to fit the idler shaft, paragraphs 1 and 2 above. 2 Put the drill guide (A1) into position in the right hand (seen from the front face of the bearing cap) setscrew hole of the bearing cap.

-

Page 173: To Inspect

New 1000 Series To inspect 19-8 If any part is worn enough to have an effect on the performance of the oil pump, the complete oil pump must be renewed. 1 Release the setscrews and remove the cover of the oil pump. - Page 174 New 1000 Series Relief valve To remove and to fit 19-9 Four cylinder engines that have a balancer unit have a relief valve fitted inside the balancer frame. The relief valve of these engines cannot be removed as an assembly.

-

Page 175: To Dismantle And To Assemble

New 1000 Series To dismantle and to assemble 19-10 If necessary, the relief valve can be dismantled and assembled while it is fitted to the engine. 1 Apply pressure to the end plate (A4 or B5) of the spring assembly; release the circlip (A5) or remove... - Page 176 New 1000 Series Flexible oil pipes The oil cooler pipes fitted to 6 cylinder New 1000 Series engines do not have metal braid and are separate pipes. The part number of the pipes is stamped on a clip which is fastened to one end of each pipe.

- Page 177 New 1000 Series To fit the pipes - arrangement 2 1 Put a setscrew (A5) in position in the flange of the inner oil cooler pipe (A6), part number 2483A004. Put a new joint (A4) in position on the setscrew. Hold the flange and the joint in position and fit the centre setscrew (A8).

-

Page 178: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 179 New 1000 Series Oil pressure relief valve (standard) Diameter of bore for plunger ........18,24/18,27 mm (0.718/0.719 in) Outside diameter of plunger .

- Page 180 This page is intentionally blank...

-

Page 181: Fuel System

New 1000 Series engines are used for industrial and agricultural applications and use various fuel injection pumps. Either Bosch (A), Lucas (B) or Stanadyne (C) pumps may be fitted. - Page 182 New 1000 Series Bosch fuel injection pump The boost control fitted to the Bosch fuel pump is a diaphragm type (A1). A KSB type cold starting aid and a stop solenoid may also be fitted to these pumps. Lucas DP200 Series fuel injection pump...

-

Page 183: Cold Start Advance Unit

New 1000 Series Cold start advance unit Some Lucas, Bosch and Stanadyne rotary fuel injection pumps have a cold start advance unit that holds the timing of the pump in an advanced position when the engine is cold. Caution: It is important that the electrical connections to the sender unit are connected correctly. - Page 184 New 1000 Series Wiring diagrams for the cold start advance unit fitted to some Lucas DP200 Series, Bosch and Stanadyne fuel injection pumps are shown in the illustrations (A), (B) and (C) respectively. For easy identification the cables are shown in circles on the illustrations.

- Page 185 New 1000 Series Cold start advance unit (KSB) Bosch EPVE rotary fuel injection pump has a starting aid which holds the timing of the pump in an advanced position when cold. The device (A) is operated electrically and is connected by a shaft to the advance lever (A3) of the fuel injection pump.

-

Page 186: Typical Fuel System

New 1000 Series Typical fuel system The fuel injection pump increases the fuel pressure and injects high-pressure fuel at the correct time and six cylinder engines sequence through pipes to the atomisers (A11). A fuel Fuel systems vary from application to application, this leak-off rail is fitted to the top of each atomiser and information is provided for training purposes only. -

Page 187: Fuel Filters

New 1000 Series Fuel filters Cautions: It is important that only the genuine Perkins parts are used. The use of a wrong canister or element can damage the fuel injection pump. The pre-filter and main filter canisters must be renewed at the same time. - Page 188 Warning! Discard the used canister and fuel oil in a safe place and in accordance with local regulations. Cautions: It is important that only the genuine Perkins parts are used. The use of a wrong canister or element can damage the fuel injection pump.

- Page 189 Warning! Discard the used canister and fuel oil in a safe place and in accordance with local regulations. Cautions: It is important that only the genuine Perkins parts are used. The use of a wrong canister or element can damage the fuel injection pump.

- Page 190 Warning! Discard the used canister and fuel oil in a safe place and in accordance with local regulations. Cautions: It is important that only the genuine Perkins parts are used. The use of a wrong canister or element can damage the fuel injection pump.

-

Page 191: To Remove And To Fit

New 1000 Series Atomisers Atomiser fault 20-2 Regular maintenance of the atomisers is not necessary. The atomiser nozzles should be renewed and not cleaned, and renewed only if an atomiser fault occurs. The major problems that may indicate that new nozzles are needed are listed below:... - Page 192 New 1000 Series To fit 1 Thoroughly clean the threads of the gland nut (A3) and the cylinder head. Caution: Do not allow any thread sealant to get below the gland nut threads. 2 Ensure that the wire clip (A4) is in position. Put a 2 mm (0.08 in) bead of POWERPART atomiser thread...

-

Page 193: Fuel Lift Pump

New 1000 Series Fuel lift pump To remove and to fit 20-4 Consumable products: POWERPART nutlock 1 If a heat shield is fitted, remove it. Disconnect the fuel pipes from the fuel lift pump. 2 Release the setscrews, remove the fuel lift pump (A). -

Page 194: To Dismantle And To Assemble

New 1000 Series To dismantle and to assemble 20-5 To dismantle 1 Clean the outside surfaces of the fuel lift pump. 2 Make a mark across the flanges of the two halves of the pump to ensure correct relationship when the pump is assembled. -

Page 195: To Test

New 1000 Series 5 Put the diaphragm assembly in position over the lower half of the body with the blade of the pull rod aligned with the slot in the link arm. Press lightly down on the diaphragm until the notch in the pull rod is in the slot in the link arm and turn the diaphragm 90°... - Page 196 Special tools and personnel with the correct training are necessary to remove these fasteners, refer to your nearest Perkins distributor. Caution: A new fuel injection pump may be supplied with the pump shaft in the locked position. The drive...

- Page 197 If the hub is moved, the hub will need to be accurately fitted to the pump by use of special equipment available to Perkins distributors. 6 Remove the four fasteners (B4) and release the fuel pump gear from the hub of the fuel injection pump.

- Page 198 If the hub is moved, the hub will need to be accurately fitted to the pump by use of special equipment available to Perkins distributors. 6 Put the fuel pump gear onto the hub of the fuel pump.

- Page 199 New 1000 Series Caution: The fuel pump gear must be fitted to the engine before the crankshaft is rotated. 8 Carefully turn the gear counter-clockwise, by hand (A1), to remove the backlash between the idler gear and the fuel pump gear. Do not rotate the crankshaft or the fuel pump shaft.

-

Page 200: To Adjust

Normally the correct speed will be given in the manufacturer's handbook for the application. If it is not given, refer to your nearest Perkins distributor. Caution: The setting for the maximum no load speed can change for different applications. For the correct... -

Page 201: To Eliminate Air From The Fuel System

New 1000 Series To eliminate air from the fuel system 20-9 If air enters the fuel system, it must be removed before the engine can be started. Air can enter the system if: The fuel tank is drained during normal operation. - Page 202 New 1000 Series 5 Loosen the high-pressure connections at two of the atomisers (A1). Caution: Do not tighten the union nuts of the high- pressure pipes more than the recommended torque tension. If there is a leakage from the union nut, ensure that the pipe is correctly aligned with the atomiser inlet.

- Page 203 Note: On the latest engines with belt driven coolant pumps, four tamper proof fasteners retain the fuel pump gear. Special tools to remove these fasteners are available at your Perkins distributor. Caution: A new fuel injection pump may be supplied A 03 74 with the pump shaft in the locked position.

- Page 204 New 1000 Series To remove Before the crankshaft is turned or the pump is fitted, put the spacer (A1) into position under the locking screw (A2) to ensure that the pump drive shaft is released. 1 Disconnect the battery before the fuel injection pump is removed from the engine.

- Page 205 New 1000 Series To fit Cautions: The engine must be set to TDC number 1 cylinder, compression stroke before the pump is fitted. If the crankshaft needs to be rotated, the pump must be fitted temporarily, or the loose gear could damage the timing case.

- Page 206 New 1000 Series Caution: The fuel pump gear must be fitted to the engine before the crankshaft is rotated. 8 Carefully turn the gear counter-clockwise, by hand (A1), to remove the backlash between the idler gear and the fuel pump gear. Do not rotate the crankshaft or the fuel pump shaft.

-

Page 207: To Adjust

Normally the correct speed will be given in the manufacturer's handbook for the application. If it is not given, refer to your nearest Perkins distributor. Caution: The setting for the maximum no load speed can change for different applications. For the correct... -

Page 208: To Eliminate Air From The Fuel System Lucas Dp200 Pump

New 1000 Series To eliminate air from the fuel system Lucas DP200 pump 20-12 Air will usually be removed from the fuel pump automatically when the engine is in operation. If the fuel pipes are disconnected or if the canister of the... - Page 209 New 1000 Series Caution: Damage to the fuel injection pump, battery and starter motor can occur if the starter motor is used excessively to eliminate air from the fuel system. 6 Put the electrical system switch to the "ON" position. Ensure that the manual stop control, if one is fitted, is in the "run"...

- Page 210 Special tools to remove these fasteners are available at your Perkins distributor. Fit a new joint (B1) to the timing case. Fit a new "O" ring (B2) to the fuel pump. DB4 fuel pumps are fitted with a rubber seal which has a square shape instead of an "O"...

- Page 211 New 1000 Series To remove 1 Disconnect the battery before the fuel injection pump is removed from the engine. 2 Set the engine to TDC on the number 1 cylinder on the compression stroke, see operation 17-1 or , operation 17-2.

- Page 212 New 1000 Series To fit Caution: The engine must be set to TDC number 1 cylinder, compression stroke before the pump is fitted. If the crankshaft needs to be rotated, the pump must be fitted temporarily, or the loose gear could damage the timing case.

- Page 213 New 1000 Series Caution: The fuel pump gear must be fitted to the engine before the crankshaft is rotated. 7 Carefully turn the gear counter-clockwise, by hand (A1), to remove the backlash between the idler gear and the fuel pump gear. Do not rotate the crankshaft or the fuel pump shaft.

-

Page 214: To Adjust

Specialist equipment, which is available at your Perkins distributor, is needed to adjust the idle or maximum speed settings. The warranty of the engine can be affected if the seals on the fuel injection pump... -

Page 215: To Eliminate Air From The Fuel System

New 1000 Series To eliminate air from the fuel system 20-15 If air enters the fuel system, it must be removed before the engine can be started. Air can enter the system if: The fuel tank is drained during normal operation. - Page 216 New 1000 Series Caution: Use a spanner to prevent movement of the fuelled starting aid (A1) when the union nut (A2) is loosened or tightened. 3 Loosen the union nut (A2) at the fuelled starting aid and operate the priming lever of the fuel lift pump until fuel, free of air, comes from the connection.

-

Page 217: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 218 New 1000 Series Atomiser service setting The code letters are stamped on the side of the atomiser body just below the connection for the nut of the high pressure pipe. Set and reset pressure Code Holder Nozzle (lbf/in 2645A308 2645A624...

-

Page 219: General Description

New 1000 Series Cooling system General description Coolant from the bottom of the radiator passes The coolant then passes from the rear of the cylinder through the centrifugal coolant pump, which is fitted block and into the cylinder head. The coolant leaves... - Page 220 New 1000 Series Thermostats Most engines are fitted with a single thermostat (A), some engines have twin thermostats fitted (B) Identification of the thermostat is by the nominal temperature which is stamped on the by-pass valve (A6) of the thermostat.

- Page 221 New 1000 Series Coolant pump - early gear driven pumps Identification of the coolant pump is by the last four digits of the part number, for example 4131E011, stamped on the front of the pump body. To remove and to fit...

- Page 222 New 1000 Series Coolant pump - latest gear driven pumps Caution: Do not remove the pressed steel cover. The latest coolant pump has a pressed steel cover (A2) of the impeller housing. Early gear driven pumps have a steel cover fastened by setscrews.

- Page 223 New 1000 Series To fit 1 Ensure that the joint faces on the pump body (A3) and on the cover of the timing case (A1) are clean. Check the joint faces for damage. Check that the spigot (A4) is clean.

- Page 224 New 1000 Series Coolant pump - belt driven To remove and to fit 21-4 Special tool: Gear puller, PD.155C Consumable products: POWERPART Retainer (oil tolerant) To remove A0311 1 Remove the fan, see operation 21-9. 2 Remove the fan belt, see operation 23-3.

- Page 225 New 1000 Series To fit Note: The joints are fitted without jointing compound. 1 If the rear body of the pump (A1) was removed from the cylinder block: Thoroughly clean the joint faces of the cylinder block and pump rear body. Fit a new joint (A2) between the rear body of the pump and the cylinder block.

- Page 226 New 1000 Series Coolant pump - belt driven high position Some engines are fitted with a coolant pump in a high position (A5), these are identified by the thermostat housing (A1) which is part of the pump rear body. The pump rear body has a connection (A4) to a coolant transfer plate (A3), which allows coolant from the pump impeller to pass into the cylinder block (A2).

- Page 227 New 1000 Series 7 Remove the four setscrews "D", in illustration (A), which secure the coolant pump to the rear body of the pump (A1). 8 Remove the coolant pump (B5) and discard the joint. 9 If it is necessary to remove the rear body of the pump from the cylinder block: Remove the setscrew for the alternator adjustment linkage and the spacer.

- Page 228 New 1000 Series To fit Note: The joints are fitted without jointing compound. 1 If the transfer plate (A4) was removed from the cylinder block: Thoroughly clean the joint faces of the cylinder block and transfer plate. Fit a new joint between the transfer plate and the cylinder block.

- Page 229 New 1000 Series Coolant pump - early gear driven pumps To dismantle and to assemble 21-6 To dismantle The coolant pump will need an overhaul if coolant leaks from the hole (A4) in the body of the pump. When this occurs coolant has passed through the coolant seal (A7) and has contaminated the bearings.

- Page 230 New 1000 Series To assemble Caution: It is important that all of the components in the coolant pump kit are used during the overhaul of the pump. Coolant pump kits include the latest components which may be of a different design to the original components fitted to the engine.

- Page 231 New 1000 Series 5 A tool (A) can be made to press the coolant seal into position. The tool should be made of a suitable material to the dimensions listed below: A 44,0 mm (1.73 in) B 40,0 mm (1.57 in) C 11,6 mm (0.46 in)

- Page 232 New 1000 Series Coolant pump - latest gear driven pumps The coolant pump will need an overhaul if coolant or engine lubricating oil leaks from the hole (A3) in the body of the pump. When this occurs coolant or lubricating oil has passed through the coolant seal (A4) or the oil seal (A2).

- Page 233 New 1000 Series Caution: Do not damage the sealing face of the oil seal housing during removal of the seal. 5 Drill a 3.175 mm (0.125 in ) hole through the top of the oil seal and fit a 25.4 mm (1.00 in ) self-tapping screw.

- Page 234 New 1000 Series To assemble Caution: It is important that all of the components in the kit for the coolant pump are used. The kit includes the latest components which may be of a different design to the original components fitted to the engine.

- Page 235 New 1000 Series 10 Lightly lubricate the oil seal (A2) with clean engine lubricating oil. Put the tapered tool PD.247 onto the drive shaft with the tapered end towards the bearing. The tapered tool ensures that the lip of the oil seal is correctly fitted when the seal is pressed into position.

- Page 236 New 1000 Series Caution: Do not lubricate the coolant seal (A4). It is important that it is not contaminated with oil or grease and, if it is held in the hand, it should be held by the edge of the outside flange. Do not damage the ring of green sealant applied to the body of the coolant seal just behind the flange.

- Page 237 New 1000 Series Coolant pump - belt driven The coolant pump will need an overhaul if coolant leaks from the hole (A9) in the body of the pump. When this occurs coolant has passed through the coolant seal (A2) and has contaminated the bearings.

- Page 238 New 1000 Series To assemble The service kit for the pump contains two bearings, the shaft, a circlip, a key, a joint and a coolant seal. Each bearing is filled with grease and sealed by the bearing manufacturer. The bearings will not need attention during service.

- Page 239 New 1000 Series Caution: Do not lubricate the seal. It is important that the seal is not contaminated by oil or grease and if it is held in the hand, it should be held by the edge of the flange. Do not damage the ring of green sealant applied to the body of the coolant seal just behind the flange of the seal.

-

Page 240: To Remove And To Fit

New 1000 Series To remove and to fit 21-9 To remove Release the setscrews and remove the fan. If necessary, fit the setscrews to retain the fan extension and the pulley to the hub. To fit Clean thoroughly the rear of the fan where it fits onto the fan extension. -

Page 241: Turbocharged Engines

New 1000 Series Lubricating oil cooler To remove and to fit - four cylinder turbocharged engines 21-11 To remove 1 Drain the cooling system. 2 Release the support bracket at the cooler (A3). 3 Release the setscrew and nut (A2) which fasten the low-pressure fuel pipes to the top of the cooler. -

Page 242: To Remove And To Fit - Six Cylinder Engines

New 1000 Series To remove and to fit - six cylinder engines 21-12 Some oil coolers fitted to six cylinder engines have a baffle (A3) to control coolant flow. The cooler element must be fitted with the baffle toward the front of the engine (A1). -

Page 243: To Remove And To Fit - Pressed Steel Cover Type

New 1000 Series To remove and to fit - pressed steel cover type 21-13 Some of the latest six cylinder engines are fitted with oil cooler with a pressed steel cover. To remove 1 Drain the cooling system, refer to the User's Handbook. - Page 244 New 1000 Series 5 Thoroughly clean the flange face of the cover and Caution: Do not remove the flanges (A7) and nuts of the cylinder block. (A9) from the studs (A8), before one of the oil pipes is fitted to the cover. This will ensure that the element is...

-

Page 245: To Remove And To Fit - Canister Type

New 1000 Series To remove and to fit - canister type 21-14 To remove 1 Drain the cooling system. 2 Release the hose clips of the coolant pipes at the oil cooler (A3). Release the threaded adaptor (A5) from the lubricating oil cooler and pull the oil cooler (A6) from the hose connections and the filter head (A1). -

Page 246: To Dismantle And To Assemble - Four Cylinder Turbocharged Engines

New 1000 Series To dismantle and to assemble - four cylinder turbocharged engines 21-15 To dismantle 1 Remove the oil cooler from the cylinder block, see operation 21-11. 2 Release the setscrews and remove the cover. 3 Release the self-locking nuts at the back of the oil cooler and remove the cooler element. -

Page 247: To Dismantle And To Assemble - Six Cylinder Turbocharged Engines

New 1000 Series To dismantle and to assemble - six cylinder turbocharged engines 21-16 Some oil coolers fitted to six cylinder engines have a baffle (A2) to control coolant flow. To dismantle 1 Remove the oil cooler, see operation 21-12. -

Page 248: To Dismantle And To Assemble Pressed Steel Cooler Type

New 1000 Series To dismantle and to assemble pressed steel cooler type 21-18 To dismantle 1 Remove the oil cooler from the cylinder block, see operation 21-13. 2 Put the oil cooler assembly (A5) on a clean work surface. Release the four nuts (A8) that retain the flanges for the lubricating oil pipes. - Page 249 New 1000 Series To assemble 1 Clean the seats of the three-piece "O" ring and renew the "O" rings (A3). 2 Clean the flange face (A1) for the three-piece "O" rings on the inside of the cover. 3 Fit the cover of the oil cooler to the element (A2).

-

Page 250: To Remove And To Fit

New 1000 Series Intercooler A water-to-air intercooler assembly is fitted to the induction manifold of some four and six cylinder high- rated engines to cool the air between the turbocharger and the combustion chamber. Hot air from the turbocharger passes through the casing of the intercooler and over the fins on the integral tube stack (A1) before it enters the combustion chamber. - Page 251 New 1000 Series To fit Adhesive sealing strips are fitted to the top cover and the induction manifold to seal the external surfaces of the tubestack. This is necessary to ensure that all of the air which enters the intercooler passes through the fins of the tubestack.

- Page 252 New 1000 Series Vertically mounted intercooler To remove 1 Release the hose clips (A7) which fasten the air hose from the turbocharger to the intercooler. Slide the hose away from the intercooler air inlet pipe. Warning! Do not drain the coolant while the engine is still hot and the system is under pressure because dangerous hot coolant can be discharged.

- Page 253 New 1000 Series To fit Adhesive sealing strips are fitted to the top cover and the induction manifold to seal the external surfaces of the tubestack. This is necessary to ensure that all of the air which enters the intercooler passes through the fins of the tubestack.

-

Page 254: To Clean And To Inspect

New 1000 Series To clean and to inspect 21-20 To clean 1 Thoroughly clean the flange face of the top cover and the induction manifold with an approved detergent solution. Warning! Do not allow compressed air to contact your skin, if compressed air enters your skin obtain medical help immediately. -

Page 255: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. - Page 256 New 1000 Series Thermostat Type: - Single............wax element, by-pass blanking - Twin .

-

Page 257: General Description

New 1000 Series Flywheel and housing General description The steel flywheel is fitted with a hardened starter ring. Generally the starter rings have 126 or 115 teeth. The flywheel housing is normally made of cast iron, but certain flywheel housings are made of aluminium alloy. -

Page 258: Ring Gear

New 1000 Series Flywheel To remove and to fit 22-1 Warning! The flywheel is heavy, use lift equipment or get help to assist with the lift operation before removal of the flywheel fasteners. To remove 1 Remove two opposite setscrews from the flywheel and fit temporarily two guide studs to ensure safety when the flywheel is removed and fitted. - Page 259 New 1000 Series Flywheel housing To remove and to fit 22-3 Warning! The flywheel housing is heavy, use lift equipment or get help to assist with the lift operation before removal of the flywheel housing fasteners. To remove 1 Remove the starter,...

-

Page 260: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. -

Page 261: General Description

New 1000 Series Electrical equipment Alternators General description The alternator is driven from the crankshaft pulley by single or double belt(s). The Lucas AC5RS, Magneti Marelli A127 and the Bosch KI 12 volt and NI 24 volt alternators have solid state regulators fitted at the rear. -

Page 262: To Adjust Tension

New 1000 Series Drive belts To check 23-1 1 Check the belt(s) for wear and damage and renew the belt(s), if necessary. If twin belts are fitted, they should both be renewed. 2 Check the belt tension. If twin belts are fitted, check/adjust the tension on the tighter belt. -

Page 263: To Maintain

New 1000 Series Alternator To remove and to fit 23-4 To remove 1 Disconnect the electrical connection. 2 Loosen the pivot fasteners of the alternator and the fasteners of the adjustment link. 3 Release all the belt tension and remove the belt(s). -

Page 264: Fault Diagnosis

New 1000 Series Fault diagnosis Any change in the above data can indicate a fault and the procedure that follows should be used before any The alternator is designed in such a way that a flow of components are disconnected. This procedure is not... - Page 265 New 1000 Series If the warning light is not illuminated when the switch is in the "on" position: Check the bulb. If no fault: Check all the connections at the regulator, at the alternator and at the battery. If no fault: Turn the switch to the "off"...

-

Page 266: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. -

Page 267: General Description

New 1000 Series Starter motors General description The Magneti Marelli M127 starter motor is operated by a solenoid and has a six roller clutch. The solenoid engages the starter drive in two operations to ensure that the motor gets its maximum torque only when the starter motor is engaged fully with the flywheel. -

Page 268: Starter Motor

New 1000 Series Starter motor To remove and to fit 23-6 Consumable products: POWERPART Hylosil Warning! Always disconnect the battery terminals before the removal of any component of the electrical system. To remove A0150 If the engine has a flywheel housing which is oil filled, drain the flywheel housing before the starter motor is removed. -

Page 269: To Maintain The Brush Gear And The Commutator

New 1000 Series To maintain the brush gear and the To test on the engine 23-8 commutator 23-7 Ensure that the battery is fully charged. S115 starter motors Turn on the lights and operate the starter switch. If no Inspect the brushes at intervals to ensure that they... -

Page 270: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. -

Page 271: General Description

New 1000 Series Starting aid General description There are two types of electrical starting aid in use: The fuelled starting aid and the port heater. The fuelled starting aid (B1) is a device which is operated electrically and ignites a controlled amount of diesel fuel in the induction manifold to heat the induction air. - Page 272 New 1000 Series Twin fuelled-starting-aid The correct procedure to remove and to fit twin fuelled starting aids is as follows: To remove 1 Disconnect the fuel connections and the electrical connections. 2 Remove the starting aids. To fit 1 Ensure that the seat faces of the manifold and the fuelled starting aids are free of dirt.

-

Page 273: To Remove And To Fit A Port Heater

New 1000 Series How to check the fuelled starting aid If the inside of the induction manifold is wet, check that there is not a fuel leak from the fuelled starting aid. 1 Disconnect the fuel pipe and the electrical connection at the starting aid. -

Page 274: Data And Dimensions

New 1000 Series Data and dimensions Note: This information is given as a guide for personnel engaged on engine overhauls. The dimensions which are shown are those which are mainly used in the factory. The information applies to all engines, unless an engine type code is shown. -

Page 275: General Description