Hyundai N700E Instruction Manual

Hide thumbs

Also See for N700E:

- Instruction manual (115 pages) ,

- Instruction manual (103 pages) ,

- Instruction manual (174 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Hyundai N700E

- Page 1 DOC.NO. HHIS-WZ-PE-081(08) N700E INSTRUCTION MANUAL N700E INSTRUCTION MANUAL...

- Page 2 N700E INSTRUCTION MANUAL CAUTION FOR UL/cUL REQUIREMENTS - THE HYUNDAI HEAVY INDUSTRY N700E INVERTER UL FILE NUMBER IS E205705. CONFIRMATION OF UL LISTING CAN BE FOUND ON THE UL WEB SITE : www.ul.com - DO NOT CONNECT OR DISCONNECT WIRING, OR PERFORM SIGNAL CHECKS WHILE THE POWER SUPPLY IS TURNED ON.

- Page 3 N700E INSTRUCTION MANUAL SAFETY FOR THE BEST RESULTS WITH N700E SERIES INVERTER, READ THIS MANUAL AND ALL OF THE WARNING SIGN ATTACHED TO THE INVERTER CAREFULLY BEFORE INSTALLING AND OPERATING IT, AND FOLLOW THE INSTRUCTION EXACTLY. KEEP THIS MANUAL HANDY FOR YOUR QUICK REFERENCE.

- Page 4 PROVIDED BY HYUNDAI. CAUTION : BE SURE TO CONNECT A MOTOR THERMAL SWITCH OR OVERLOAD DEVICES TO THE N700E SERIES CONTROLLER TO ASSURE THAT INVERTER WILL SHUT DOWN IN THE EVENT OF AN OVERLOAD OR AN OVERHEATED MOTOR CAUTION: ROTATING SHAFTS AND ABOVE GROUND ELECTRICAL POTENTIALS CAN BE HAZARDOUS.

- Page 5 N700E INSTRUCTION MANUAL NOTE : POLLUTION DEGREE 2 THE INVERTER MUST BE USED IN THE ENVIRONMENT OF THE POLLUTION DEGREE 2. TYPICAL CONSTRUCTIONS THAT REDUCE THE POSSIBILITY OF CONDUCTIVE POLLUTION ARE, 1) THE USE OF AN UNVENTILATED ENCLOSURE. 2) THE USE OF A FILTERED VENTILATED ENCLOSURE WHEN THE VENTILATION IS FAN FORCED THAT IS, VENTILATION IS ACCOMPLISHED BY ONE MORE BLOWERS WITHIN THE ENCLOSURE THAT PROVIDE A POSITIVE INTAKE AND EXHAUST.

- Page 6 FAMILIAR WITH CONSTRUCTION AND OPERATION OF THE EQUIPMENT AND THE HAZARDS INVOLVED. FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY INJURY. 1. THE POWER SUPPLY TO N700E INVERTER MUST MEET THESE SPECIFICATIONS a. VOLTAGE FLUCTUATION ±10% OR LESS. b. VOLTAGE IMBALANCE ±3% OR LESS.

- Page 7 N700E INSTRUCTION MANUAL CONFORMITY TO THE LOW VOLTAGE DIRECTIVE (LVD) THE PROTECTIVE ENCLOSURE MUST CONFORM TO THE LOW VOLTAGE DIRECTIVE. THE INVERTER CAN CONFORM TO THE LVD BY MOUNTING INTO A CABINET OR BY ADDING COVERS AS FOLLOWS. 1. CABINET AND COVER THE INVERTER MUST BE INSTALLED INTO A CABINET WHICH HAS THE PROTECTION DEGREE OF TYPE IP2X.

- Page 8 N700E INSTRUCTION MANUAL UL WARNINGS AND CAUTIONS MANUAL FOR N700E SERIES THIS AUXILIARY INSTRUCTION MANUAL SHOULD BE DELIVERED TO THE END USER. 1. WIRING MARKING FOR ELECTRICAL PRACTICE AND WIRE SPECIFICATIONS “USE COPPER CONDUCTOR ONLY, 75℃ WITH A TORQUE RATING.

- Page 9 N700E INSTRUCTION MANUAL 3. FUSE SIZE DISTRIBUTION FUSE SIZE MARKING IS INCLUDED IN THE MANUAL TO INDICATE THAT THE UNIT SHALL BE CONNECTED WITH AN UL LISTED INVERSE TIME, RATED 600V WITH THE CURRENT RATINGS OR AN UL LISTED FUSE AS SHOWN IN THE TABLE BELOW.

- Page 10 N700E INSTRUCTION MANUAL General Safety Information 1. Installation CAUTION Be sure to install the unit on flame resistant material such as metal. Otherwise, there is a danger of fire. Be sure not to place anything highly flammable in the vicinity.

- Page 11 N700E INSTRUCTION MANUAL General Safety Information 2. Wiring WARNING Be sure to ground the unit. Otherwise, there is a danger of electric shock and/or fire. Wiring work should be carried out by qualified electricians. Otherwise, there is a danger of electric shock and/or fire.

- Page 12 N700E INSTRUCTION MANUAL General Safety Information 3. Control and operation WARNING Be sure to turn on the power supply with the front case is closed. While the inverter is energized, be sure not to open the front case. Otherwise, there is a danger of electric shock.

- Page 13 N700E INSTRUCTION MANUAL General Safety Information CAUTION The cooling fins will have a high temperature. Be sure not to touch them. Otherwise, there is a danger of getting burned. Low to high speed operation of the inverter can be easily set. Be sure to operate it after checking the tolerance of the motor and machine.

-

Page 14: Table Of Contents

N700E INSTRUCTION MANUAL CONTENTS 1. GENERAL DESCRIPTION ................1-1 Inspection upon Unpacking ..................... 1-1 Inspection of the unit ....................1-1 1.1.1 Instruction manual ......................1-1 1.1.2 Questions and Warranty of the Unit ..................1-2 Questions on Unit ......................1-2 1.2.1 Warranty for the unit ..................... - Page 15 N700E INSTRUCTION MANUAL Auto-tuning ........................... 5-29 6. Protective function ..................... 6-1 7. Troubleshooting Tips ..................7-1 8. Maintenance and Inspection ................8-1 General Precautions and Notes ....................8-1 Inspection Items ........................8-1 General Inverter Electrical Measurements ................8-4 9. RS485 Communication MODBUS ..............9-1 10.

-

Page 16: General Description

Inspection of the unit Please open the package, remove the inverter, please check the following items. If you discover any unknown parts or the unit is damaged, please contact HYUNDAI. (1) Make sure that the package contains one operation manual for the inverter. -

Page 17: Questions And Warranty Of The Unit

If you have any questions regarding the warranty, please contact either your Local HYUNDAI Branch. -

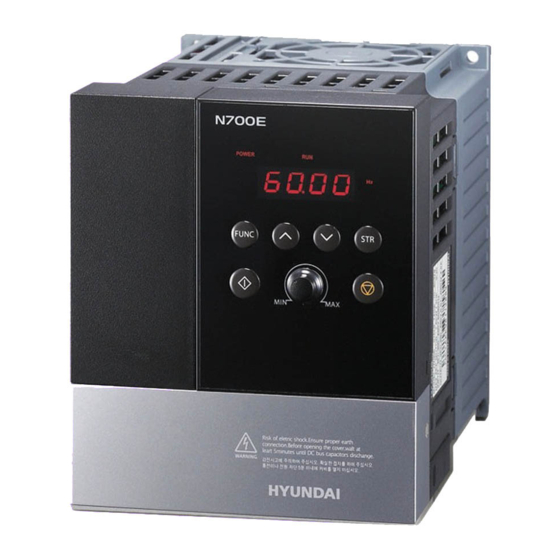

Page 18: Appearance

N700E INSTRUCTION MANUAL Appearance Operator Cover(Open/Close) Front Cover Control circuit terminals Main circuit terminals Fig1-3 Outlook of N700E Inverter (1frame) Fig1-4 Outlook of N700E Inverter (2frame) - Page 19 N700E INSTRUCTION MANUAL Fig1-5 Outlook of N700E Inverter (3frame)

-

Page 20: Terminal Block Cover Opening Method

N700E INSTRUCTION MANUAL Terminal block cover opening method Please open up the Terminal block cover... - Page 21 N700E INSTRUCTION MANUAL Fig1-6 Terminal block cover opening method of N700E Inverter (3frame...

-

Page 22: Installation And Wiring

N700E INSTRUCTION MANUAL 2. Installation and Wiring Installation CAUTION Be sure to install the unit on flame resistant material such as metal. Otherwise, there is a danger of fire. Be sure not to place anything flammable in the vicinity. -

Page 23: Installation

N700E INSTRUCTION MANUAL 2.1.1 Installation (1) Transportation This inverter has plastic parts. So handle with care. Do not over tighten the wall mounting fixings as the mountings may crack, causing is a risk of falling. Do not install or operate the inverter if there appears to be damaged or parts missing. -

Page 24: Wiring

N700E INSTRUCTION MANUAL Wiring WARNING Be sure to ground the unit. Otherwise, there is a danger of electric shock and/or fire. Wiring work should be carried out by qualified electricians. Otherwise, there is a danger of electric shock and/or fire. -

Page 25: Terminal Connection Diagram (Sink Type)

N700E INSTRUCTION MANUAL 2.2.1 Terminal Connection Diagram (sink type) N700E Power Supply 3 Phase 200V : 200 ~ 240V Rectifier Inverter 400V : 380 ~ 480V (50/60Hz ±10%) Power Circuit Signals Control Circuit Control Braking Resistor (Option) P24V * BRD circuit is installed... - Page 26 N700E INSTRUCTION MANUAL (1) Explanation of main circuit Terminals Symbol Terminal Name Explanation of contents R,S,T (R,S) Main power Connect alternating power supply. U,V,W Inverter output Connect three-phase motor. P, RB External braking resistor Connect optional External braking resistor. Inverter earth terminals Grounding terminal.

- Page 27 N700E INSTRUCTION MANUAL Terminal Signal Terminal name Terminal function Symbol No.1 RJ-45 connector no.3 pin channel Basic RS-485 communication Communication terminal Terminal (RJ-45 RJ-45 connector no.6 pin terminal) Safety signal input common terminal Safety signal Safety signal input normally close (NC) input terminal...

-

Page 28: Main Circuit Wiring

When an EMC filter is to be installed, please contact your local HYUNDAI branch. Recommended Cable length between Driver and Motor... - Page 29 N700E INSTRUCTION MANUAL ④ Earth Ground (G) Make sure that you securely ground the inverter and motor for prevention of electric shock. The inverter and motor must be connected to an appropriate safety earth ground and follow all local electrical codes.

- Page 30 N700E INSTRUCTION MANUAL (2) Wiring of main circuit terminals The wiring of main circuit terminals for the inverter are in the following pictures. Width Screw Wiring of terminals Corresponding type Size (㎜) (L1) (L2) N700E-004SF 7.62 N700E-007SF N700E-004LF (L1) (L2)

- Page 31 N700E INSTRUCTION MANUAL (3) Applicable Tools Note1 : The applicable equipment is for HYUNDAI standard four poles squirrel cage motor. Power Supply 3 Phase Note2 : Be sure to consider the capacity of the circuit breaker to be used. Note3 : Be sure to use larger wire for power lines if the distance exceeds 20m.

- Page 32 (N•m) Leak breaker model U,V,W, P and (HP) (600V rated) (MCCB) Terminal (AWG) N700E-004SF N700E-004LF N700E-007SF N700E-007LF 220V N700E-015SF Class N700E-015LF N700E-022SF N700E-022LF N700E-037LF N700E-004HF N700E-007HF 380V N700E-015HF Class N700E-022HF N700E-037HF Table 2-6 Common applicable tools for N700E inverters 2-11...

-

Page 33: Terminal Connection Diagram

N700E INSTRUCTION MANUAL 2.2.3 Terminal connection diagram (1) Terminal connection diagram ① The control circuit terminal of inverters is connected with the control board in unit. Fig 2-4 Terminal connection diagram (2) Example of Main PCB terminal’s wire Frequency Signal 1kΩ~2kΩ... - Page 34 N700E INSTRUCTION MANUAL (3) Wiring ① Both the CM1 and L terminals are insulated to both the common terminal of the input and output signals. These terminals are common, DO NOT short or connect to ground. ② Use twisted screened cable, for the input and output wires of the control circuit terminals.

- Page 35 N700E INSTRUCTION MANUAL (4) Change of input logic type Inverter control board Sink/Source Connection control Switch Default : Sink Type (NPN) SINK TYPE : SOURCE TYPE : Inverter control board No.2 channel 485 communication option Terminating resistance selection switch (option)

- Page 36 N700E INSTRUCTION MANUAL • Selection switch ① SINK/SOURCE TYPE - SINK/SOURCE TYPE selection switch. • SINK TYPE (NPN Type) : • SOURCE TYPE (PNP Type): ② The connection to the input programmable logic controller Using internal power Using external power...

-

Page 37: Operation

N700E INSTRUCTION MANUAL 3. Operation WARNING Be sure not to touch the main terminal or to check the signal add or remove wires and/or connectors. Otherwise, there is a danger of electric shock. Be sure not to turn the input power supply on until after front case is closed. - Page 38 N700E INSTRUCTION MANUAL CAUTION The cooling fins will have high temperature. Be sure not to touch them. Otherwise, there is a danger of getting burned. Low to high speed operation of the inverter can be easily set. Be sure to operate it ...

-

Page 39: Operating

N700E INSTRUCTION MANUAL Operating This inverter requires two different signals in order for the inverter to operate correctly. The inverter requires both an operation setting and a frequency setting signal. The following indicates the details of each method of operation and necessary instructions for operation. -

Page 40: Control Settings

N700E INSTRUCTION MANUAL Control Settings This is an example of a common connection. Please refer to Digital Operator, for the detailed use of the digital operator. 3.2.1 To input the operation setting and the frequency setting from the terminal control... -

Page 41: Operation Setting And The Frequency Setting From The Digital Operator

N700E INSTRUCTION MANUAL 3.2.2 Operation setting and the frequency setting from the digital operator (Remote operator is also same use.) N700E Power Supply 3 Phase 200V : 200 ~ 240V 400V : 380 ~ 480V (50/60Hz ±10%) Power Circuit Control Circuit... -

Page 42: Parameter Code List

N700E INSTRUCTION MANUAL 4. Parameter Code List About Digital Operator 4.1.1 Name and contents of each part of Standard-type digital operator (1) Part name UP/DOWN Key PRG LED RUN LED This key is used to change data and This LED is on when the... - Page 43 N700E INSTRUCTION MANUAL (2) Operation procedure ① Key Description in RPM...

- Page 44 N700E INSTRUCTION MANUAL ② Extended function mode navigation map ③ Example that the frequency is set from potentiometer to the standard operator and the equipment starts running) Submenu “d” – Display options Ability to display several performance values of the drive (Pages 4-6 and 4-7) Submenu “F”...

-

Page 45: Key Definition And Operation Of "Shift

N700E INSTRUCTION MANUAL Key Definition and Operation of “SHIFT” 4.1.2 Definition : The “SHIFT” function is enable to press both up and down key simultaneously. The left most 7- segment digit is blinked and if press store key, the blinked segment moves to the right digit. When the ‘store’... -

Page 46: Function List

N700E INSTRUCTION MANUAL Function List 4.2.1 Monitor Mode (d-group) Display Func- Name Description code Real-time display of output frequency to Output frequency monitor motor, from 0.00 to 400.0 Hz, "Hz" LED ON Real-time display of output current to motor, Output current monitor from 0.0 to 999.9A, "A"... -

Page 47: Trip & Warning Monitor Mode Of D Group

N700E INSTRUCTION MANUAL 4.2.2 Trip & Warning monitor mode of D Group Func- Name Description code Displays the current trip event ·Display method Alarm reason ↓ press the UP key Output frequency at alarm event ↓ press the UP/DOWN key... -

Page 48: Basic Function Mode Of F Group

N700E INSTRUCTION MANUAL 4.2.3 Basic Function Mode of F Group Run- Func- Name time Description Defaults code Edit Standard default target frequency that determines constant motor that deter-mines constant motor speed. units of 0.01Hz setting range is volume Output frequency setting setting 0.00 to 400.0Hz. -

Page 49: Expanded Function Mode Of A Group

N700E INSTRUCTION MANUAL 4.2.4 Expanded Function Mode of A Group Run- Func- Name time Description Defaults code Edit Basic parameter settings Four options: select codes: 0..Keypad potentiometer Frequency command 1..Control terminal input (Multi-speed command 2..Standard operator method) 3.. - Page 50 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Two options: select codes: Frquency (A06) (A09=0) External frequency start (A05) pattern setting (A09=1) (A07) (A08) Analog input 20mA 0--- start at start frequency 1--- start at 0Hz Range n = 1 to 8, where n = number of samples for...

- Page 51 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Sets the frequency of the V/F breakpoint Manual torque boost 100.0% frequency setting A in graph for torque boost. Two available V/F curves: three select codes: 0... Constant torque 004LF/HF 1...

- Page 52 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Frequency-related Functions Sets a limit on output frequency less than the maximum frequency(A04). Range is 0.00 to 400.0Hz in units of 0.01Hz. Upper limit (A38) Frequency upper limit 0.00Hz...

- Page 53 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Automatic Voltage Regulation (AVR) Function Automatic (output) voltage regulation, selects from three type of AVR functions three option codes: 0... Constant ON AVR function selection 1... Constant OFF 2... OFF during deceleration...

- Page 54 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Set the characteristic curve of Acc1 and Acc2, two options:. 0 --- Linear 1 --- S-curve (max. acceleration time : 39.0sec) 2 --- U-curve (max. acceleration time : 29.0sec)

- Page 55 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit PID Control(Note1) Enables PID function and Feed Forward Function, three option codes: A70 PID Function selection 0..PID control disable 1..PID control enable 2..F/F control enable Displays the PID reference. If parameter A72 = 2, Used to adjust the PID reference from UP/DOWN ...

- Page 56 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Two options : select codes A80 PID Output reverse 0..PID output reverse disable 1..PID output reverse enable PID scale factor (multiplier), A81 PID scale factor 100.0% 0.1 to 1000% in units of 0.1% 0.0 to Max Frequency in units of 0.01Hz.

- Page 57 N700E INSTRUCTION MANUAL The figure below is a more detailed diagram of the PID control. Frequency Source Frequency Command 0 : Potentiometer 1 :Analog input 2 : Keypad C01~C06 : 23(PIDD) 3 : Remote PID Feed-back source CurFreq < PrePID Freq...

- Page 58 N700E INSTRUCTION MANUAL Note 2) Pre-PID The Pre PID function is activated in Function code A82 (Pre PID Frequency). When the run signal comes, the inverter operates in the form of Open loop. If the output frequency reaches the Pre PID Frequency, it operates in Closed loop (PID control).

-

Page 59: Expanded Function Mode Of B Group

N700E INSTRUCTION MANUAL 4.2.5 Expanded function mode of b group Run- Func- Name time Description Defaults code Edit Restart Mode Select inverter restart method, four option codes: 0..Alarm output after trip, no automatic restart 1..Restart at 0Hz 2..Resume operation after frequency matching 3.. - Page 60 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Overload Restriction Select overload or overvoltage restriction modes 0..Overload, overvoltage restriction mode OFF Overload overvoltage 1..Only overload restriction mode ON Restriction mode selection 2..Only overvoltage restriction mode ON 3..

-

Page 61: Other Function

N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Other Function Start frequency Sets the starting frequency for the inverter output, range is 0.50Hz Adjustment 0.50 to 10.00Hz in units of 0.01Hz Sets the PWM carrier frequency, range is ... - Page 62 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Other Function In case of the lower starting current level during speed Voltage increase Level search motion on the basis of the motor rated current, 100% during Speed Search...

- Page 63 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Other Function This function detects communication time out in case of communication cut off. To set the detection time of time out, “code b28” is used. Communication time out ...

-

Page 64: Expanded Function Mode Of C Group

N700E INSTRUCTION MANUAL 4.2.6 Expanded Function Mode of C Group Run- Func- Name time Description Defaults code Edit Input Terminal Function Select function for terminal 1 <code> 0: Forward run command(FW) 1 : Reverse run command(RV) 2 : 1st multi-speed command(CF1) -

Page 65: Output Terminal Function

N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Input Terminal Status Select logic convention, two option codes: Input Terminal 1 a/b 0..a contact (normally open) [NO] contact setting (NO/NC) 1..b contact (normally close) [NC] Select logic convention, two option codes: Input Terminal 2 a/b 0.. - Page 66 N700E INSTRUCTION MANUAL Run- Func- Name time Description Defaults code Edit Output Terminal state setting Analog meter Range is 0 to 250, resolution is 1 100.0% gain adjustment Analog meter Range is -3.0 to 10.0% resolution is 0.1 0.0%...

-

Page 67: Expanded Function Mode Of H Group

N700E INSTRUCTION MANUAL 4.2.7 Expanded Function mode of H Group Run- Func- Name time Description Defaults code Edit Two States for auto-tuning function, option codes: Auto-tuning mode selection 0..Auto-tuning OFF 1..Auto-tuning ON Two selections, option codes: 0…Use standard motor data Motor data selection 1…Use auto-tuning data... -

Page 68: Using Intelligent Terminals

N700E INSTRUCTION MANUAL 5. Using intelligent terminals Intelligent terminal lists Terminal Terminal name Description symbol SWF switch Forward ON(closed) :Forward run Forward RUN/STOP OFF(open) : stop Reverse SWR switch Reverse ON(closed) :Reverse run RUN/STOP OFF(open) :stop 0-speed 3-speed 2-speed Multi-speed... - Page 69 N700E INSTRUCTION MANUAL Terminal Terminal name Description symbol External power supply terminal External power connection terminal for intelligent input terminals. for input When assign 13[AT signal] to code C01~C06 • AT signal OFF : Frequency command It is possible to command frequency using voltage signal...

-

Page 70: Monitor Terminal Function

N700E INSTRUCTION MANUAL Monitor terminal function Monitor terminal function [FM] (analog) • The inverter provides an analog output terminal primary for frequency monitoring on terminal [FW] (output frequency, Output current, and output voltage monitor signal). • Parameter C18 selects the output signal data. -

Page 71: Intelligent Input Terminal Function

N700E INSTRUCTION MANUAL Intelligent Input Terminal Function 5.3.1 Input Terminal Function Forward Run/Stop [FW] and Reverse Run/Stop Command [RV] • When you input the Run command via the terminal [FW], the inverter executes the Forward Run command (high) or Stop command(low) •... - Page 72 N700E INSTRUCTION MANUAL Multi-Speed Select [CF1][CF2][CF3][CF4] • The inverter provides storage parameters for up to 16 different target frequencies (speeds) that the motor output uses for steady-state run condition. These speeds are accessible through programming four of the intelligent terminals as binary-encoded inputs CF1 to CF4 per the table .

- Page 73 N700E INSTRUCTION MANUAL Speed 0 Speed 1 Speed 2 Speed 3 Speed 4 Speed 5 Speed 6 Speed 7 Speed 8 Speed 9 Speed 10 Speed 11 Speed 12 Speed 13 Speed 14 Speed 15 Control circuit terminal Multi-speed Set code...

- Page 74 N700E INSTRUCTION MANUAL Standard operator option code Set the parameter [ C01 ~ C06 ] to [ A11 ~ A25 ], F01 Option Terminal Function Name State Description Code Symbol Valid for inputs: C01,C02,C03,C04,C05,C06 Example: Required setting F01, A11 to A25 Notes : •...

- Page 75 N700E INSTRUCTION MANUAL Jogging Command [JG] [JG] Terminal • When the terminal [JG] is turned on and the Run command is issued, the inverter [FW,RV] outputs the programmed jog frequency to the motor. Use a switch between Moter terminals [CM1] and [P24] to activate Speed the JG frequency.

- Page 76 N700E INSTRUCTION MANUAL Two-stage Acceleration and Deceleration [2CH] [FW,RV] • When terminal [2CH] is turned on, the inverter changes the rate of acceleration [2CH] and deceleration from the initial settings F02 (acceleration time1) and F03(deceleration time1) to use the second set of acceleration / deceleration values.

- Page 77 N700E INSTRUCTION MANUAL Free-run stop [FRS] • When the terminal [FRS] is turned on, the inverter stops the output and the motor enters the free-run state (coasting). If terminal [FRS] is turned off, the output resumes sending power to the motor if the Run command is still active.

- Page 78 N700E INSTRUCTION MANUAL External Trip [EXT] • When the terminal [EXT] is turned on, the inverter enters the trip state, indicates error code, E12 and stop the output. This is a general purpose interrupt type feature, and the meaning of the error depends on what you connect to the [EXT] terminal.

- Page 79 N700E INSTRUCTION MANUAL Unattended Start Protection [USP] • If the Run command is already set when power is turned on, the inverter starts running immediately after power up. The Unattended Start Protection (USP) function prevents that automatic start up, so that the inverter will not run with-out outside intervention.

- Page 80 N700E INSTRUCTION MANUAL Software Lock [SFT] • When the terminal [SFT] is turned on, the data of all the parameters and functions except the output frequency is locked (prohibited from editing). When the data is locked, the keypad keys cannot edit inverter parameters.

- Page 81 N700E INSTRUCTION MANUAL Analog Input Current / Voltage Select [AT] • The [AT] terminal selects whether the inverter uses the voltage[O-L] or current [OI-L] input terminals for external frequency control. When the switch between the terminals [AT] and [CM1] is on, it is possible to set the output frequency by applying a current input signal at [OI]-[L].

- Page 82 N700E INSTRUCTION MANUAL Reset Inverter [RS] 12ms min • The [RS] terminal causes the inverter to execute the reset operation. If the inverter [RS]terminal is in Trip Mode, the reset cancels the Trip state. Approx.30ms When the switch between the set terminals...

- Page 83 N700E INSTRUCTION MANUAL 3-Wire input function [STA, STP, F/R] • This function is used when a momentary push start/stop control is required. • Set the operation command selection A02 to control terminal (1). • Assign 15 (STA), 16 (STP) and 17 (F/R) to three of the intelligent input terminals, and the operation becomes possible as follows.

- Page 84 N700E INSTRUCTION MANUAL UP/DOWN Function [UP, DOWN] • The Inverter output frequency can be changed with the UP and DOWN intelligent input terminals. • Assign 18 (UP) and 19(DN) to two of the intelligent input terminals 1~6 •This function will not operate when the external analog frequency command or the jogging operation is used.

- Page 85 N700E INSTRUCTION MANUAL Local Keypad Operation [O/R], Local Terminal Input Operation [T/R] • In case of operation by other than using keypad or terminal, it can be changed to local keypad operation (O/R function (20)) or local terminal input (T/R function (21)) by the multi-function input for the purpose of conducting manual operation method change.

- Page 86 N700E INSTRUCTION MANUAL PID Integral Reset [PIDIR] • When the terminal [PID Integral Reset] is turned on, the accumulated Integral term of the PID controller is reset. Option Terminal Input Function Name Description Code Symbol State The accumulated Integral term of the PID controller is reset to zero.

- Page 87 N700E INSTRUCTION MANUAL PID Disable [PIDD] • When the terminal [PID Disable] is turned on, the inverter operates without PID control. Setting the function code F01 can change the target frequency. When the terminal [PID Disable] is turned off, the inverter operates with PID control.

-

Page 88: Safety Function (Sc, S1, S2) - Option

N700E INSTRUCTION MANUAL 5.3.2 Safety Function (SC, S1, S2) - option • Protective Functions Ensure safety circuits are wired correctly and in the proper state before turning on the drive. Disconnect the wire jumper between S2-SC or connect the wire jumper between S1-SC when utilizing the safety disables inputs. -

Page 89: Intelligent Output Terminal Function

N700E INSTRUCTION MANUAL Intelligent Output Terminal Function Frequency Arrival Signal [FA1]/[FA2] Frequency Arrival [FA1] and [FA2] signals indicate when the output frequency accelerates or decelerates to arrive at a constant frequency. Refer to the figure below. Frequency Arrival [FA1](upper graph) turns on when the output frequency gets within 0.5Hz below or 1.5Hz above the target constant frequency. - Page 90 N700E INSTRUCTION MANUAL Run Signal [RUN] When the [RUN] signal is selected as an intelligent output terminal, the inverter outputs a signal on that terminal when it is in the Run Mode. The output logic is active low, and is the open collector type (switch to ground)

- Page 91 N700E INSTRUCTION MANUAL Overload Advance Notice Signal [OL] When the output current exceeds a preset value, the [OL] terminal signal turns on. The parameter C21 sets the overload threshold. The overload detection circuit operates during powered motor operation and during regenerative braking.

- Page 92 N700E INSTRUCTION MANUAL Output Deviation for PID Control [OD] The PID loop error is defined as the magnitude(absolute value) of the difference between the Set point (target value) and the process Variable (actual value). When the error magnitude exceeds the press value for C24, the [OD] terminal signal turns on.

- Page 93 N700E INSTRUCTION MANUAL Alarm Signal output [AL] The Inverter alarm signal is active when a fault has occurred and it is in the Trip Mode. When the fault is cleared the alarm signal becomes inactive. We must make a distinction between the alarm signal [AL] and the alarm relay contacts AL0, AL1.

- Page 94 N700E INSTRUCTION MANUAL Contact a (Initial setting) During normal running or power is turned off When an alarm occurs Contact Power Run State AL0-AL1 AL0-AL2 Normal Open Closed Contact a Trip Closed Open (initial Setting) Open Closed 5-27...

-

Page 95: Sensorless Vector Control

Function description The N700E inverter has a built-in auto-tuning algorithm. The N700E inverter is capable of preforming high-starting torque and high-precision operation. The required torque characteristic or speed control characteristic may not be maintained in case that the inverter capacity is move than twice the capacity of the motor in use . -

Page 96: Function Description

N700E INSTRUCTION MANUAL Auto-tuning Function description The auto-tuning procedure automatically sets the motor parameters related to sensorless vector control. Since sensorless vector control is dependent upon specific motor parameter, the standard motor parameters have been set at the factory. Therefore, to apply to a different motor, you must auto-tune with the new motor to achieve optimal... - Page 97 Auto-tuning process completed : Auto-tuning process failed : Note) The motor parameter of N700E is standard data of HYUNDAI standard 4-poles motor. At the sensorless vector control when using different poles motor, operates by using auto-tuning data as a motor parameter.

- Page 98 N700E INSTRUCTION MANUAL Setting Method (1)Digital panel Name Setting range Description Auto-tuning 0 : Auto-tuning OFF mode selection 1 : Auto-tuning ON 0 : Standard data Motor data setting 1 : Auto-tuning data 00.4L : 220V / 0.5HP 0.07L : 220V / 1.0HP 01.5L : 220V / 2.0HP...

- Page 99 N700E INSTRUCTION MANUAL Remark 1. If satisfactory performance through auto-tuning cannot be fully obtained, please adjust the motor constants for the observed symptoms according to the table below. Operation Symptom Adjustment Parameter status When low frequency Slowly increase the motor constant R1 in relation...

-

Page 100: Protective Function

N700E INSTRUCTION MANUAL 6. Protective function The various functions are provided for the protection of the inverter itself, but they may also protection function when the inverter breaks down. Error Name Cause(s) Code When the inverter output current exceeds the rated current by more than Over current approximately 200% during the motor locked or reduced in speed. - Page 101 N700E INSTRUCTION MANUAL Other display Contents Display It is displayed when initialization of data is processing (It is not displayed when initialization of history is processing.) There is no data available (Trip history, PID feedback data) The auto-tuning operation terminates normally.

-

Page 102: Troubleshooting Tips

N700E INSTRUCTION MANUAL 7. Troubleshooting Tips Symptom/condition Probable Cause Countermeasure • Is the frequency command source A01 • Make sure the parameter A01 parameter setting Correct? setting correct? •Is the Run command source A02 • Make sure the parameter A02... - Page 103 N700E INSTRUCTION MANUAL Symptom/condition Probable Cause Countermeasure • Was power turned off after a parameter • Edit the data and press the edit but before pressing the store key? store key once Inverter No down- •Edits to data are permanently stored at •...

-

Page 104: Maintenance And Inspection

N700E INSTRUCTION MANUAL 8. Maintenance and Inspection Please read following safety messages before troubleshooting or performing maintenance on the inverter and motor system. DANGER • Wait at least ten(10) minutes after turning off the input power supply before performing maintenance of an inspection. -

Page 105: Spare Parts

N700E INSTRUCTION MANUAL We recommend that you stock spare parts to reduce down time, which include Spare parts Quantity Part description Symbol Note Used Spare Cooling FAN Front case Case Main case Bottom cover... - Page 106 N700E INSTRUCTION MANUAL - Monthly and Yearly Inspection Chart Inspection Check for… Item Inspected Cycle Inspection Method Criteria Month Year Ambient temperature Extreme Ambient Thermometer, ∨ between -10 to 50℃, temperatures environment hygrometer non-condensing & humidity Abnormal Stable environment for ∨...

-

Page 107: General Inverter Electrical Measurements

N700E INSTRUCTION MANUAL General Inverter Electrical Measurements The following table specifies how to measure key system electrical parameters. The diagrams on the next page show inverter-motor systems the location of measurement points for these parameters. Circuit location Reference Parameter Measuring instrument... -

Page 108: Rs485 Communication Modbus

N700E INSTRUCTION MANUAL 9. RS485 Communication MODBUS The communication between inverter and external controller can be done through RS-485 by use of the modular connector(RJ-45) or R+ and R- terminal(option) located in inverter control board. Function Initial Minimum Maximum Unit... - Page 109 N700E INSTRUCTION MANUAL Communication sequence The communication sequence is as follows External Frame 1 controller Frame 2 Inverter Wait time Frame start : Frame start is recognized by signal line data transmitted. Frame completion : Frame completion is recognized by no data during correspond 4, 5-character time.

- Page 110 N700E INSTRUCTION MANUAL External transmit frame Communication Order Parameter Data CRC Hi CRC Lo number Description Data size Specifications Target Inverter Communication Communication 1 byte 1~32 number number Command Frame type 1 byte 0x06 byte : Group Parameter Parameter 2 byte...

- Page 111 N700E INSTRUCTION MANUAL (Note1) Parameter setting Basic parameter byte : Each group is setting Group byte Group byte 0x01 0x05 0x02 0x06 0x03 0x04 byte : Parameter number setting. Ex) The case of A60 parameter reading or writing byte : 0x03...

- Page 112 N700E INSTRUCTION MANUAL (Note2) Data value setting Data value is transmitted except decimal point. Ex1) Output frequency Parameter value Communication data Conversion hexadecimal byte : 0x17 60.0Hz 6000 byte : 0x70 Ex2) acc/dec time Parameter value Communication data Conversion hexadecimal byte : 0x00 10.0sec...

- Page 113 N700E INSTRUCTION MANUAL 16bit CRC generation The step of CRC generation is as follows: 1. All of 16-bit register is 1.0xffff 2. The exclusive OR of 16-bit register and 8-bit register. 3. Shift right side 1bit 16-bit register 4. If the result of step 3 is 1, exclusive OR 16-bit register and 0xa001.

-

Page 114: Specification

N700E INSTRUCTION MANUAL 10. Specification 10.1 Standard specification list (1) 200V Class Specifications N700E- N700E- N700E- N700E- N700E- N700E- N700E- N700E- N700E- Inverter Model 004SF 007SF 015SF 022SF 004LF 007LF 015LF 022LF 037LF Max. Applicable motor (4P, HP) (Note1) Rated... - Page 115 N700E INSTRUCTION MANUAL (3) Common specification for 200V/400V class Inverter model Common specification for all model Control system(Note5) Space vector modulation PWM system Output frequency range 0.01∼400Hz (Note3) Digital command ±0.01% for Max. frequency, analog frequency ±0.1% Frequency accuracy (Note4) (25±10℃)

- Page 116 Braking resistor Footnotes for the preceding tables 1. The applicable motor refers to HYUNDAI standard 3-phase motor. To use other motors, care must be taken to prevent the rated motor current from exceeding the rated output current of the inverter.

-

Page 117: Dimension

N700E INSTRUCTION MANUAL 10.2 Dimension (1) N700E-004LF/004SF/007LF/007SF/015LF model external dimension.(mm) [W1] [H1] (2) N700E-015SF/004HF/007HF/015HF/022SF/022LF/022HF model external dimension.(mm) [H1] 10-4... - Page 118 N700E INSTRUCTION MANUAL (3) N700E-037LF/037HF model external dimension.(mm) [W1] [H1] Model W(Width) H(Height) D(Depth) Ø Weight [inch] [inch] [inch] [inch] [inch] [inch] [kG] N700E 004 SF 2.68 2.28 5.04 4.72 5.04 0.17 N700E 007 SF 2.68 2.28 5.04 4.72 5.04 0.17...

- Page 119 N700E INSTRUCTION MANUAL REVISION HISTORY TABLE ELECTRO ELECTRIC SYSTEMS The Data Revision contents Version No. of Issue First edition 11. 05. HHIS-WZ-PE-081(00) Function code default value (A31) Function code (C14) 11. 10. HHIS-WZ-PE-081(01) Function code description (F01, A04) Function code defalut value(C13) 11.

Need help?

Do you have a question about the N700E and is the answer not in the manual?

Questions and answers