Summary of Contents for Ametek mocon AQUATRAN 3/40

- Page 1 AQUATRAN ® Model 3/40 Operator’s Manual Revision D Lauper Instruments AG Gas-Detection Irisweg 16B CH-3280 Murten Tel. +41 26 672 30 50 info@lauper-instruments.ch www.lauper-instruments.ch Part Number 143-217...

- Page 2 Trademarks & Patents MOCON, COULOX, and AQUATRAN are registered trademarks of Mocon, Inc. For information on applicable patents see: https://www.ametekmocon.com/aboutus/legal/intellectualproperty Copyright© 2021 MOCON, Inc. All rights reserved.

- Page 3 AQUATRAN Model 3/40 Operator’s Manual About This Manual About This Manual This manual explains how to set up and use the AQUATRAN Model 3/40 Water Vapor Transmission Rate System. This manual is designed for viewing electronically. Most references to other sections or chapters in this document are hyperlinks which can be used to navigate to the referenced section.

-

Page 4: Safety Information

Safety Information AQUATRAN Model 3/40 Operator’s Manual Safety Information Be sure to read and understand this section and all other applicable chapters of the Operator's Manual and all on-product safety signs before setting up, operating, and maintaining this analyzer. Safety signs appear in this manual and on the analyzer. All safety signs are identified by the words WARNING and CAUTION. -

Page 5: Table Of Contents

AQUATRAN Model 3/40 Operator’s Manual Table of Contents Table of Contents About This Manual ............................iii Safety Information ............................iv Chapter 1: Introduction..........................1-1 Features ............................... 1-2 Measuring a Water Vapor Transmission Rate ..................1-3 Permeation Test Overview ........................1-6 Individual Zero Phase ........................ - Page 6 Table of Contents AQUATRAN Model 3/40 Operator’s Manual Filling the Test Gas Water Reservoir ....................3-7 Loading and Unloading a Test Cartridge ..................3-8 Chapter 4: Using the Instrument Software....................4-1 Software Features ..........................4-1 Instrument Software Structure and Organization .................. 4-2 Chapter 5: Permeant Sensor Calibration ....................

- Page 7 AQUATRAN Model 3/40 Operator’s Manual Table of Contents Electrical Requirements ........................10-1 Physical Specifications ........................10-1 Chamber Specifications ........................10-2 Gas Supply Requirements ......................... 10-2 Sample Conditioning Capabilities ....................... 10-2 Transmission Rate Measurement Capabilities ................... 10-4 Appendix A: Site Preparation Instructions ....................A-1 Appendix B: Spare Parts ..........................

- Page 8 Table of Contents AQUATRAN Model 3/40 Operator’s Manual Figures Figure 1-1: AQUATRAN Model 3/40 System ..................... 1-1 Figure 1-2: An AQUATRAN Model 3/40 Permeation Cell ................1-3 Figure 1-3: Large Tray Cartridge ....................... 1-4 Figure 1-4: Package Adapter Cartridge ..................... 1-4 Figure 1-5: Bottle &...

-

Page 9: Chapter 1: Introduction

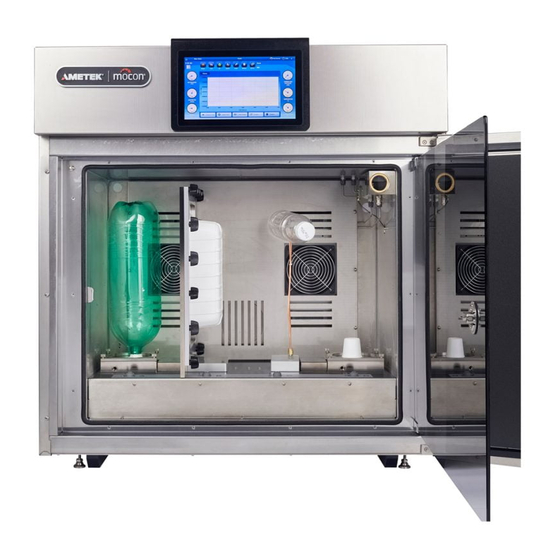

AQUATRAN Model 3/40 Operator’s Manual Introduction Chapter 1: Introduction This chapter provides a brief overview of the AQUATRAN Model 3/40 Water Vapor Transmission Rate System. Read this chapter to get an overview of: • The features of the AQUATRAN Model 3/40 system •... -

Page 10: Features

Introduction AQUATRAN Model 3/40 Operator’s Manual Features The following features of the AQUATRAN Model 3/40 Water Vapor Transmission Rate System make it very versatile and easy to use: Fully automatic (Hands Off) testing. • Four Test Cells to provide increased test capacity. •... -

Page 11: Measuring A Water Vapor Transmission Rate

AQUATRAN Model 3/40 Operator’s Manual Introduction Measuring a Water Vapor Transmission Rate To make an accurate transmission rate measurement a known concentration Test Gas is applied to one side of the barrier material to be tested and the other side is swept with a water vapor free Carrier Gas (nitrogen). -

Page 12: Figure 1-3: Large Tray Cartridge

Introduction AQUATRAN Model 3/40 Operator’s Manual Testing Packages and Films To test packages (or films) the sample must be mounted in a Diffusion Cell. A Diffusion Cell exposes one side of the sample barrier to a Test Gas and the other side to a Carrier Gas. The gases supplied to the cell can be dry or at a specified RH. -

Page 13: Figure 1-5: Bottle & Cup Cartridge

AQUATRAN Model 3/40 Operator’s Manual Introduction Figure 1-5: Bottle & Cup Cartridge Figure 1-6: Film Test Cartridges MOCON, Inc. Revision D... -

Page 14: Permeation Test Overview

Introduction AQUATRAN Model 3/40 Operator’s Manual Permeation Test Overview A “Permeation Test” consists of up to two phases that are performed using a Test Cell. The “Cell” may contain a package cartridge or a film cartridge. The Test Phase (always present) is used to measure the transmission rate of the test sample. -

Page 15: Chapter 2: Setting Up

AQUATRAN Model 3/40 Operator’s Manual Setting Up Chapter 2: Setting Up This chapter provides information on how to set up an AQUATRAN Model 3/40 and prepare it for use. Read this chapter to learn about: Unpacking the System • • Preparing for System Installation •... -

Page 16: Front Panel Parts And Controls

Setting Up AQUATRAN Model 3/40 Operator’s Manual Front Panel Parts and Controls The names and locations of the parts and controls located on the front of the instrument are shown in Figure 2-1, and 2.1. Figure 2-1: Front Panel Parts and Controls Item Name Description USB Ports... -

Page 17: Back Panel Parts And Controls

AQUATRAN Model 3/40 Operator’s Manual Setting Up Back Panel Parts and Controls The names and locations of the parts and controls located on the back of the instrument are shown in Figure 2-2 and Table 2.2. Figure 2-2: Back Panel Connections and Controls Item Name Description The switch that is used to turn the instrument on and off. -

Page 18: Table 2.2: Back Panel Controls And Connections

Setting Up AQUATRAN Model 3/40 Operator’s Manual Water Supply Inlet Port The fitting that connects the Test Gas water supply to the instrument. Compressed Air Inlet Port The fitting that connects the Compressed Air supply to the instrument. Carrier Gas Inlet Port The fitting that connects the Carrier Gas supply to the instrument. -

Page 19: Inner Chamber Parts And Controls

AQUATRAN Model 3/40 Operator’s Manual Setting Up Inner Chamber Parts and Controls Figure 2-3: Test Cell Details Item Name Description Test Cell Gas Ports The Test Cell Inlet, Outlet and True Seal gas ports. Test Cartridge Clamp Bar The device used to clamp a Test Cartridge to the Test Cell gas ports. Test Cell Clamp\Unclamp Button The button used to clamp and unclamp a Test Cartridge. -

Page 20: Carrier Gas (Nitrogen)

Setting Up AQUATRAN Model 3/40 Operator’s Manual Carrier Gas (Nitrogen) The AQUATRAN Model 3/40 requires a Carrier Gas that is 99.7% nitrogen. Compressed Air Supply The AQUATRAN Model 3/40 requires a supply of clean, dry compressed air for chamber RH generator that provide moisture as test gas. -

Page 21: Connecting The Gas Lines

AQUATRAN Model 3/40 Operator’s Manual Setting Up Connecting the Gas Lines The AQUATRAN Model 3/40 has a gas inlet for connection of the Carrier Gas (nitrogen) supply. This compression fitting is intended for use with 1/8” copper tubing. Refer to Figure 2-4 for the location of the fitting and an example of plumbing system diagram. -

Page 22: Connecting The Compressed Air Supply

Setting Up AQUATRAN Model 3/40 Operator’s Manual Connect the inlet fitting on the regulator tee to the output fitting on the Desiccant Tower using the tubing a nuts and a ferrule. Make sure the tube is inserted all the way into the fitting on the Desiccant Tower before tightening the knurled nut. -

Page 23: Setting The Gas Supply Pressures

AQUATRAN Model 3/40 Operator’s Manual Setting Up Remove the cover from the reservoir. If necessary, remove the supply line and filter from the inside the reservoir. Insert the end of the supply line (without the filter) through the opening in the cover with the filter on the inside surface of the cover. -

Page 24: System Outgassing

Setting Up AQUATRAN Model 3/40 Operator’s Manual Set the pressure on the Carrier Gas regulator-tee so that the gauge reads 25 psi. Caution: The maximum Carrier Gas pressure to the instrument must not exceed 29 psi. Input pressures greater than 32 psi (2.2 bar) will damage the system. Caution: The maximum Compressed Air pressure to the instrument must not exceed 100 psi. -

Page 25: Chapter 3: Preparing For A Test

AQUATRAN Model 3/40 Operator’s Manual Preparing for a Test Chapter 3: Preparing for a Test This chapter provides information on how to prepare for a permeation test. Read this chapter to learn about: Testing Basics • • How Barrier Properties Affect Testing Developing Test Methods for Films and Packages •... -

Page 26: Testing Mixed Barriers

Preparing for a Test AQUATRAN Model 3/40 Operator’s Manual Testing Mixed Barriers Simultaneously testing barriers with widely divergent transmission rates is not recommended. The data for some or all of the individual samples may not be accurate when there is a large difference in the transmission rates between samples. -

Page 27: Individual Zero Processing

AQUATRAN Model 3/40 Operator’s Manual Preparing for a Test Individual Zero Processing Adjusting the ReZero frequency will compensate for small shifts in the baseline zero. It may also be necessary to compensate for individual variations such as seal permeation and leakage in the Test Cartridge. - Page 28 Preparing for a Test AQUATRAN Model 3/40 Operator’s Manual Whenever you use the Advanced Test method to test a sample that may take more time to safely purge than is provided by the initial ReZero state, consider using a Purge state. The settings for the High Purge mode fields are explained below.

-

Page 29: Conditioning The Sample

AQUATRAN Model 3/40 Operator’s Manual Preparing for a Test Conditioning the Sample Sample Conditioning is a test state that allows the sample barrier to acclimate to the specified test conditions. When you condition a sample, it is exposed to carrier gas and test gas in the same manner as during normal testing. -

Page 30: Using The Reference Check Function

Preparing for a Test AQUATRAN Model 3/40 Operator’s Manual Using the Reference Check Function The AQUATRAN Model 3/40 contains a dedicated “Reference” cell that can be used to track instrument performance. When the “Reference Check” function is enabled a “Reference Test” will be performed whenever a test is started, and all Test Cells were previously idle. -

Page 31: Saved Test Methods

AQUATRAN Model 3/40 Operator’s Manual Preparing for a Test The Advanced Test Method allows the user to specify all of the parameters and conditions used to perform a permeation test. An Advanced Test Method allows the most flexibility in determining how a permeation test will be executed. -

Page 32: Loading And Unloading A Test Cartridge

Preparing for a Test AQUATRAN Model 3/40 Operator’s Manual Adjust the tubing as required to ensure the filter is resting on the bottom of the reservoir. Make sure the reclaiming tube is put back into the headspace of the reservoir (tank). Loading and Unloading a Test Cartridge The AQUATRAN Model 3/40 uses a pneumatic system to clamp and unclamp a Test Cartridge. -

Page 33: Chapter 4: Using The Instrument Software

AQUATRAN Model 3/40 Operator’s Manual Using the Instrument Software Chapter 4: Using the Instrument Software This chapter provides an overview of the software system used to operate the AQUATRAN Model 3/40. Detailed information on how to use the instrument software can be found in the Instrument Help System. Read this chapter to learn about: •... -

Page 34: Instrument Software Structure And Organization

Using the Instrument Software AQUATRAN Model 3/40 Operator’s Manual Instrument Software Structure and Organization All of the User Interface and Instrument Control functions of your permeation system are accessed through the Instrument Software. The User Interface consists of a Title bar, an Icon bar, and the Workspace. The “Title”... - Page 35 AQUATRAN Model 3/40 Operator’s Manual Using the Instrument Software Figure 4-1: Software Home Screen of AQUATRAN 3/40 MOCON, Inc. Revision D...

-

Page 36: Chapter 5: Permeant Sensor Calibration

Using the Instrument Software AQUATRAN Model 3/40 Operator’s Manual Chapter 5: Permeant Sensor Calibration You will need to calibrate the system to ensure accuracy in determining water vapor transmission rates. Calibration also ensures proper automatic compensation in the transmission rates when environmental and other factors cause the system to drift. -

Page 37: Permeant Sensor Calibration Test Setup

AQUATRAN Model 3/40 Operator’s Manual Using the Instrument Software Permeant Sensor Calibration Test Setup To calibrate an instrument to a standard reference film or a certified film use the following procedure: Mocon has available Certified NIST Films that cover the usual testing range. Call MOCON in NOTE: the USA for more information at (763) 493-6370. - Page 38 Using the Instrument Software AQUATRAN Model 3/40 Operator’s Manual 8. Verify the following Cell Level parameters have been correctly assigned: Area/Cell: Verify the area is set correctly if not using a Certified film. Package/Film selection: Verify that Package is selected if using a Certified film. If using another film, set the Package/Film buttons to the appropriate selection for the method used to establish the reference transmission rate.

-

Page 39: Chapter 6: Testing Packages

AQUATRAN Model 3/40 Operator’s Manual Testing Packages Chapter 6: Testing Packages This chapter contains information on how to test packages. Suggestions on how to maximize the accuracy of your results and procedures describing how prepare for and perform a package test are discussed. Read this chapter to learn about: •... -

Page 40: Package Mounting Methods

Testing Packages AQUATRAN Model 3/40 Operator’s Manual Package Mounting Methods There are many different types of packages and most of them can be tested on the AQUATRAN Model 3/40. To test packages a Diffusion Cell must be created to provide the required difference in permeant concentration across the barrier material. -

Page 41: Mounting Flexible Packages

AQUATRAN Model 3/40 Operator’s Manual Testing Packages opening is cut in the foil to allow the carrier gas to sweep the inside of the package. The foil containing the package is then mounted in the Test Cartridge. More detailed information on using a Rigid Package Test Cartridge is provided in the “User Guide” included with each Test Cartridge. -

Page 42: Mounting Packages Using A Package Adapter Cartridge

Testing Packages AQUATRAN Model 3/40 Operator’s Manual Mounting Packages using a Package Adapter Cartridge Not all packages are compatible with the standard Test Cartridges which are designed for testing the most common types of rigid and flexible packages. These types of packages can be tested using a Package Adapter Cartridge. -

Page 43: Use 100%Rh Package Test Cartridge

AQUATRAN Model 3/40 Operator’s Manual Testing Packages Use 100%RH Package Test Cartridge For package samples requiring 100%RH test, a specially designed 100%RH Package Test Cartridge (P/N 054-269) is needed. Refer to the its User Guide for details. Figure 6-4: 100%RH Package Test Cartridge Package Purging The amount of time required to properly purge a package can be unpredictable. -

Page 44: Monitoring And Controlling A Package Test

Testing Packages AQUATRAN Model 3/40 Operator’s Manual There are two basic types of test methods that can be used to start a test: an “Auto Test” method or an “Advanced Test” method. The “Auto Test” method attempts to automatically optimize some of the test parameters while the test is executing. -

Page 45: Chapter 7: Testing Flat Film Samples

AQUATRAN Model 3/40 Operator’s Manual Testing Flat Film Samples Chapter 7: Testing Flat Film Samples This chapter contains information on how to test flat film samples. Suggestions on how to maximize the accuracy of your results and procedures describing how to perform the test are discussed. Read this chapter to learn about: •... -

Page 46: Preparing For A Film Test

Testing Flat Film Samples AQUATRAN Model 3/40 Operator’s Manual Preparing for a Film Test Before a test can be conducted there are a number of tasks that must be performed: The samples to be tested must be prepared. The samples must be mounted in a Film Test Cartridge and Loaded into the instrument. -

Page 47: Orienting The Sample

AQUATRAN Model 3/40 Operator’s Manual Testing Flat Film Samples If your sample is thin (less than 5 mils), you need only mask one side. Mount the sample in the test cell with the film side facing up. If your sample is thicker than 5 mils, mask both sides. Be sure the mask apertures are accurately aligned and the edges around the foil aperture are tight against the film. -

Page 48: Using 100%Rh Film Test Cartridge

Testing Flat Film Samples AQUATRAN Model 3/40 Operator’s Manual Replace the top of the Test Cartridge and tighten the screws securely. Install the Film Cartridge in one of the four test stations and clamp it into place. Figure 7-1: Mounting a Film Sample for Testing With Chamber RH Using 100%RH Film Test Cartridge For testing NIST films or other film samples with 100%RH, use the specially designed Film Test Cartridge (P/N 054-271). -

Page 49: Sample Purging

AQUATRAN Model 3/40 Operator’s Manual Testing Flat Film Samples 10. Replace the top of the Test Cartridge and tighten the screws securely. 11. Install the Film Cartridge in one of the four test stations and clamp it into place. Figure 7-2: 100%RH Film Test Cartridge Sample Purging The Film Test Cartridge does not normally need to be purged after mounting a sample. -

Page 50: Monitoring And Controlling A Film Test

Testing Flat Film Samples AQUATRAN Model 3/40 Operator’s Manual methodology when the properties of the barrier material are not known. An “Auto Test” is started by selecting the “Test” icon and filling out the fields displayed on the “Cell” and “Instrument” screens. An “Advanced Test”... -

Page 51: Chapter 8: Maintenance

AQUATRAN Model 3/40 Operator’s Manual Maintenance Chapter 8: Maintenance This contains information on how to clean and maintain the AQUATRAN Model 3/40. Read this chapter to learn about: Cleaning the Instrument • • Maintaining the Test Cells • Maintaining the Water vapor (Coulox) Sensor •... -

Page 52: Maintaining The Test Cells

Maintenance AQUATRAN Model 3/40 Operator’s Manual Maintaining the Test Cells Periodically the test cell gas ports should be examined, and any excess buildup of grease should be removed. Alcohol can be used to remove any residue from the grease. Inspect the gas ports and True Seal flush port and remove any grease that could obstruct the flow of gas. -

Page 53: Drying Out The Steam Generator Of Test Gas Before Shipping

AQUATRAN Model 3/40 Operator’s Manual Maintenance Item Quantity Part Number Description True Seal flush gas supply port 052-595 O-Ring, 1.024 ID X 0.047 CS, Buna N 033-340 O-Ring, 0.187 ID X 0.050 CS, Buna N Test Cell Clamp Bar Table 8.1: Test Station Replacement Components Drying Out the Steam Generator of Test Gas Before Shipping Before shutting down the instrument for long term storage or repair the Steam Generator must be ….. - Page 54 Maintenance AQUATRAN Model 3/40 Operator’s Manual Turn off the nitrogen tank gas flow by turning the knob all the way clockwise. Detach the gas lines (copper tubing) from each end of the desiccant chamber. Remove the cover end of the chamber. The cover end is the end connected to the nitrogen supply.

-

Page 55: System Standby

AQUATRAN Model 3/40 Operator’s Manual Maintenance Figure 8-2: The Desiccant Chamber System Standby When a test series is complete, the instrument sets the sensor to the Bypass state. In this position the sensor is isolated and protected from inadvertent exposure to large amounts of water vapor. If no testing will be performed for an extended period of time (overnight or weekend), leave a sample mounted and clamped in the test cells. -

Page 56: System Shutdown For Storage Or Repair

Maintenance AQUATRAN Model 3/40 Operator’s Manual System Shutdown for Storage or Repair When shutting down the instrument for relocation, long-term storage, or if the instrument is to be sent for factory repairs, follow these instructions: End all active tests and verify that the sensor is set to Bypass. Unclamp and remove any Test Cartridges in the chamber. -

Page 57: Chapter 9: Troubleshooting

AQUATRAN Model 3/40 Operator’s Manual Trouble Shooting Chapter 9: Troubleshooting This chapter contains information to assist you in solving problems that may occur during the operation of the instrument. Read this chapter to learn about: • Error Messages and Warnings •... -

Page 58: Recovering From A Sensor Over-Range Condition

Troubleshooting AQUATRAN Model 3/40 Operator’s Manual Symptom: Abrupt changes in display readings or long-term cyclic oscillations. Comment: Unwanted data fluctuations observed during a test cycle may be caused by abrupt changes in the carrier gas flow rate. Such a transient symptom can be produced by a temporary restriction in any gas line, or gas usage by another system. -

Page 59: Chapter 10 Specifications

AQUATRAN Model 3/40 Operator’s Manual Specifications Chapter 10 Specifications This chapter contains the specifications of the AQUATRAN Model 3/40. Read this chapter for details about: Environmental requirements • Electrical requirements • • Physical specifications • Gas Supply requirements • Operational capabilities Environmental Requirements Operation 22 °C ±... -

Page 60: Chamber Specifications

Specifications AQUATRAN Model 3/40 Operator’s Manual Chamber Specifications Height Width Depth Volume 17 inches 25.5 inches 12 inches 3 cubic feet Uncrated (43.2 cm) (64.8 cm) (30.5 cm) (85 Liters) Table 10.3: Chamber Specifications Gas Supply Requirements Gas Composition Nitrogen Supply Pressure, Nominal 25 PSI, (1.72 Bar), (172 kPa) Supply Pressure, Maximum... -

Page 61: Figure 10-1: Chamber Rh Working Range

AQUATRAN Model 3/40 Operator’s Manual Specifications Chamber RH Working Range Chamber Temperature Set-Point (C) Low range High Range Figure 10-1: Chamber RH Working Range MOCON, Inc. Revision D 10-3... -

Page 62: Transmission Rate Measurement Capabilities

Specifications AQUATRAN Model 3/40 Operator’s Manual Transmission Rate Measurement Capabilities Test Range, Package 0.000025 to 0.5 g/(pkg • day) Test Range, Film, 50 cm 0.005 to 100 g/(m • day) Resolution, Package 0.000001 g/(pkg • day) Resolution, Film 0.0002 g/( m •... -

Page 63: Appendix A: Site Preparation Instructions

AQUATRAN Model 3/40 Operator’s Manual Site Preparation Instructions : Site Preparation Instructions Part Number 140-220 (See next page) MOCON, Inc. Revision D... - Page 64 Site Preparation Instructions AQUATRAN Model 3/40 Operator’s Manual Part Number 140-220 Revision D 7500 Mendelssohn Avenue North Minneapolis, MN 55428 U.S.A. Telephone 763-493-6370 Web Site: www.ametekmocon.com SITE PREPARATION INSTRUCTIONS IMPORTANT! REQUIREMENTS FOR THE START-UP OF THE AQUATRAN Model 3/40 SYSTEM ®...

- Page 65 AQUATRAN Model 3/40 Operator’s Manual Site Preparation Instructions (104 cm) from the work surface to any overhead obstruction is required. A minimum clearance of 6 inches (15.2 cm) is required at the sides, back and top of the instrument. The surface upon which the instrument will be placed must safely support a minimum of 225 pounds (102 kilograms).

- Page 66 Site Preparation Instructions AQUATRAN Model 3/40 Operator’s Manual “RECOMMENDED ELECTRICAL INSTALLATION” Compressed Air - A supply of clean, dry compressed air is required for the test gas. The supply pressure must be between 72 and 100 psig (5 to 6.9 Bar) at a maximum flow rate of 0.88 CFM (25 LPM). The compressed air purity must meet or exceed ISO 8753-1:2010 [1:3:1].

- Page 67 AQUATRAN Model 3/40 Operator’s Manual Site Preparation Instructions RECOMMENDED ELECTRICAL INSTALLATION NOTES The impedance of the equipment ground path from receptacle being utilized back to main service entrance where equipment ground and neutral are connected together must be one ohm or less. Machinery and air conditioners can generate a large amount of electrical interference on the AC power lines.

- Page 68 Site Preparation Instructions AQUATRAN Model 3/40 Operator’s Manual The MOCON AQUATRAN Model 3/40 system will provide years of useful life provided these requirements are observed. Please contact MOCON in the USA at (763) 493-6370 with any questions regarding these Site Preparation Instructions.

-

Page 69: Appendix B: Spare Parts

AQUATRAN Model 3/40 Operator’s Manual Spare Parts : Spare Parts The following is a list of the spare parts that are available for the AQUATRAN Model 3/40. To order, contact the MOCON in the USA at (763) 493-6370. Part Unit Of Description Quantity Number... - Page 70 Spare Parts AQUATRAN Model 3/40 Operator’s Manual Part Unit Of Description Quantity Number Measure 054-269 100%RH Package Test Cartridge 052-878 Assy, Filter, Water Tank 054-010 Coupling, Air Hose, 1/4 Sleeve Lock, 1/4 NPT Female 143-217 Manuscript, AQUATRAN, 3/40, On Flash Drive 210-017 Cord, Power, 125V, 18/3, SVT, IEC, Unshielded, 7 1/2 FT 310-027...

-

Page 71: Appendix C: Warranty And Service Policies

AQUATRAN Model 3/40 Operator’s Manual Warranty and Service Policies : Warranty and Service Policies Part Number: 032-846, Warranty Policy Part Number: 032-847, International Service Policy Part Number: 032-848, Domestic Service Policy (See next pages) MOCON, Inc. Revision D... - Page 72 Warranty and Service Policies AQUATRAN Model 3/40 Operator’s Manual Part Number 032-846 Revision G 7500 Mendelssohn Avenue North Minneapolis, MN 55428 USA Telephone 763-493-6370 Web Site: www.ametekmocon.com WARRANTY POLICY STATEMENT OF LIMITED WARRANTY MOCON, Inc. warrants that any part of any MOCON instrument or accessory ( “ I n s t r u m e n t ” ) which proves to be defective in material or workmanship during the warranty period will be repaired by MOCON "certified"...

- Page 73 AQUATRAN Model 3/40 Operator’s Manual Warranty and Service Policies This warranty covers normal use only. It does not cover damage that results from alteration, accident, misuse, abuse, neglect, or failure to follow assembly, installation, operational, or other MOCON instruction. All warranty repair items are to be shipped a t purchaser's expense, to and from MOCON MOCON software is provided "as is"...

- Page 74 Warranty and Service Policies AQUATRAN Model 3/40 Operator’s Manual Part Number 032-847 Revision D 7500 Mendelssohn Avenue North Minneapolis, MN 55428 USA Telephone 763-493-6370 Web Site: www.ametekmocon.com INTERNATIONAL SERVICE POLICY MOCON offers a complete range of service options to purchasers of MOCON instrumentation and systems. ♦♦♦SERVICE PERFORMED WITHIN THE WARRANTY PERIOD♦♦♦...

- Page 75 AQUATRAN Model 3/40 Operator’s Manual Warranty and Service Policies Part Number 032-848 Revision E 7500 Mendelssohn Avenue North Minneapolis, MN 55428 USA Telephone 763-493-6370 Web Site: www.ametekmocon.com DOMESTIC SERVICE POLICY MOCON offers a complete range of service options to purchasers of MOCON instrumentation and systems. ♦♦♦SERVICE PERFORMED WITHIN THE WARRANTY PERIOD♦♦♦...

- Page 76 Warranty and Service Policies AQUATRAN Model 3/40 Operator’s Manual Invoices are due NET 30 days (with approved credit) and are billed and payable in U.S. dollars. • • All parts are shipped EXW MOCON factory Minneapolis, Minnesota; freight and Insurance will be billed separately. MOCON insures all shipments unless advised otherwise.

-

Page 77: Appendix D: Theory Of Operation

AQUATRAN Model 3/40 Operator’s Manual Theory of Operation : Theory of Operation How the Water Vapor Transmission Rate is measured When a film is installed in a Test Cell, it is exposed to a continuous flow of dry nitrogen gas across the one side (the Carrier Gas side) and an RH on the other (the Test Gas side). -

Page 78: Factors That Affect The Transmission Rate Of A Barrier Material

Theory of Operation AQUATRAN Model 3/40 Operator’s Manual infrared sensor/amplifier produces a DC output proportional to the amount of water vapor. The DC output is converted to a value and transmitted to the computer. The computer subtracts the ReZero value from the DC output value. The result is converted to units of Water Vapor Transmission Rate (WVTR) using a scaling factor determined by the nitrogen gas flow rate. -

Page 79: Relative Humidity

AQUATRAN Model 3/40 Operator’s Manual Theory of Operation Relative Humidity The amount of water vapor that some materials (such as nylon, cellophane and ethyl vinyl alcohol) are exposed to significantly affects the water vapor transmission rate of the barrier. The barrier properties of some of these materials can be permanently affected by prolonged exposures to significant amounts of water vapor. -

Page 80: How The Automatic Purge Function Works

Theory of Operation AQUATRAN Model 3/40 Operator’s Manual How the Automatic Purge Function Works The Automatic Purge function determines an appropriate Purge Time by monitoring the amount of water vapor in the Carrier Gas exhaust of the Test Cell. The water vapor in the exhaust of each test cell is measured using dedicated Purge Down sensors. -

Page 81: How The Reference Check Function Works

AQUATRAN Model 3/40 Operator’s Manual Theory of Operation How the Reference Check Function Works The instrument contains a dedicated “Reference” cell that is used to track instrument performance over time. The Permeable barrier material used in the Reference Cell is located in the Test Chamber. The Reference Cell barrier is therefore exposed to the same test conditions as the samples mounted in the Test Cells. -

Page 82: How Sequential Testing Works

Theory of Operation AQUATRAN Model 3/40 Operator’s Manual “Historical” transmission rate. When the difference in the value of these variables is less than 1%, the sample is declared to be at equilibrium. The absolute magnitude of the measured transmission rate is used to determine if an Individual Zero Phase will be performed during the test. -

Page 83: Appendix E: Electrical And Plumbing Diagrams

AQUATRAN Model 3/40 Operator’s Manual Electrical and Plumbing Diagrams : Electrical and Plumbing Diagrams Title Part Number Electrical Diagram, AQUATRAN Model 3/40 054-004 Plumbing Diagram, AQUATRAN Model 3/40 054-005 MOCON, Inc. Revision D... - Page 84 Electrical and Plumbing Diagrams AQUATRAN Model 3/40 Operator’s Manual Figure 10-2: Electrical Diagram Page 1 Revision D MOCON, Inc.

- Page 85 AQUATRAN Model 3/40 Operator’s Manual Electrical and Plumbing Diagrams Figure 10-3: Electrical Diagram Page 2 MOCON, Inc. Revision D...

- Page 86 Electrical and Plumbing Diagrams AQUATRAN Model 3/40 Operator’s Manual Figure 10-4: Electrical Diagram Page 3 Revision D MOCON, Inc.

- Page 87 AQUATRAN Model 3/40 Operator’s Manual Electrical and Plumbing Diagrams Figure 10-5: Electrical Diagram Page 4 MOCON, Inc. Revision D...

- Page 88 Electrical and Plumbing Diagrams AQUATRAN Model 3/40 Operator’s Manual Figure 10-6: Electrical Diagram Page 5 Revision D MOCON, Inc.

- Page 89 AQUATRAN Model 3/40 Operator’s Manual Electrical and Plumbing Diagrams Figure 10-7: Plumbing Diagram Page 1 MOCON, Inc. Revision D...

- Page 90 Electrical and Plumbing Diagrams AQUATRAN Model 3/40 Operator’s Manual Figure 10-8: Plumbing Diagram Page 2 Revision D MOCON, Inc.

-

Page 91: Appendix G: Compliance

AQUATRAN Model 3/40 Operator’s Manual Compliance : Compliance MOCON, Inc. Revision D...

Need help?

Do you have a question about the mocon AQUATRAN 3/40 and is the answer not in the manual?

Questions and answers