Summary of Contents for Inficon ELT3000

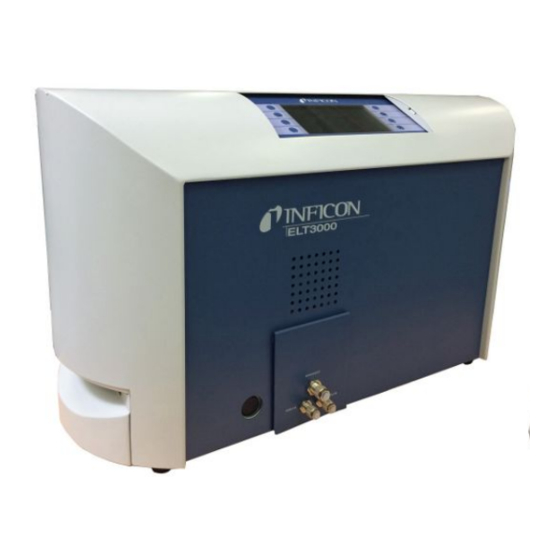

- Page 1 Translation of the original operating instructions ELT3000 Battery Leak Detector Catalog No. 600-001, 600-002 From software version mina95en1-10-(2007) 1.11.00 (Device operation)

- Page 2 INFICON GmbH Bonner Strasse 498 50968 Cologne, Germany...

-

Page 3: Table Of Contents

5.2 Setup .............................. 23 5.3 Design of device ............................. 24 5.3.1 Connect devices ......................... 26 5.3.1.1 Connection scheme for a test chamber ................ 29 5.4 Connecting to the power supply system .................... 33 5.5 Interfaces .............................. 34 6 Operation................................ 35 6.1 Switch on and login.......................... 36 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) - Page 4 6.7.3 Updating the software of the Gas Detection Unit................ 48 6.8 Calibrate device ............................ 49 6.8.1 Calibration........................... 49 6.8.2 Calibration equipment ......................... 50 6.9 Restoring factory defaults ........................ 50 6.10 Advanced settings .......................... 50 6.11 Bringing up active errors and warnings .................... 50 6.12 Logging off from the device ........................ 51 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

- Page 5 8.4 Gas Control Unit: Replacing filter mat on bottom of device .............. 65 8.5 Gas Detection Unit: Replacing the air filter of the basic unit.............. 66 9 Decommissioning ............................ 67 9.1 Return shipment of battery leak tester.................... 67 10 CE Declaration of Conformity ......................... 69 11 Accessories .............................. 70 Index................................ 71 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

-

Page 6: About This Manual

Imminent hazard resulting in death or serious injuries WARNING Hazardous situation resulting in potential death or serious injuries CAUTION Hazardous situation resulting in minor injuries NOTICE Hazardous situation resulting in damage to property or the environment 6 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 7: Definition Of Terms

* Helium equivalent leak rate at a pressure difference of 1000 mbar to 0 mbar. Gas Control Unit (basic unit, operating unit) Gas Detection Unit Dimethyl carbonate, typical solvent in battery electrolyte. CAS Nr. 616-38-6 MSDS Material Safety Data Sheet ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 7 / 74... -

Page 8: Safety

• Testing of wet or damp test objects • Use outside the technical specifications, see "Technical Specifications" • Using the device with detectable defects or defective power switch • Using the device in potentially explosive atmospheres 8 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 9: Duties Of The Operator

• Only instructed personnel should be permitted to work with and on the device. The instructed personnel must have received training on the device. • Make sure that authorized personnel have read and understood the instruction manual and all other applicable documents. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 9 / 74... -

Page 10: Dangers1

• Place the battery leak detector only on surfaces that are not tilted. slipping off or falling • Do not lift or carry the battery leak detector by yourself. down Escaping electrolyte can accumulate in the measuring chamber. Danger due to escaping electrolyte during the measurement. 10 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 11: Scope Of Delivery, Transport, Storage

Angle clip OD 6 mm Angle clip OD 8 mm Exhaust connection nut (Exhaust) Replacement air filter Electrical fuses (GCU) Electrical fuses (GDU) ► Check the scope of delivery for completeness using the following figure. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 11 / 74... - Page 12 Power cable Replacement air filter Scope of delivery package 2 Quantity Gas Detection Unit (GDU) Power cable for GDU Unpacking instructions ► Check the scope of delivery of the product for completeness after receipt. 12 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

- Page 13 If packed in unsuitable packaging, the battery leak detector may be damaged during transport. ► Keep the original packaging. ► Only transport the battery leak detector in its original packaging. ► Remove the transport protection before startup Transport protection [} 23]. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 13 / 74...

-

Page 14: Description

Gas detection unit The display of the gas detection unit can fail due to electrostatic charge. ► You can continue operating the ELT3000 without limitation. ► The display can be reactivated by restarting the unit. Display... - Page 15 • electrical and electronic sub-assemblies for the electrical power supply and signal processing. Gas Control Unit "STOP" button Button for stopping the measurement Touchscreen "START" button Button for starting the measurement USB 2.0 interface USB 2.0 interface ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 15 / 74...

-

Page 16: Display

INFICON 4.2 Display 4.2.1 Design of touchscreen Settings Optional input field Product name Diagnosis Time Calibration Access control Measure User name Purge Page back Setpoint Page forward Name of current window Operation Information Start button 16 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) - Page 17 Call up help for the current function Confirm entry or selection Load Analysis Save Edit Copy Delete Page forward Page back The measurement result is displayed in the measurement window on the left. For more information, see Result display [} 18]. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 17 / 74...

-

Page 18: Result Display

If the leak rate is below the setpoint, the measurement result is shown on a green Leaktight background. Setpoint Leak Measurement result: If the leak rate is above the setpoint for leaks, the measurement result is shown on a Leaking red background. Leak Setpoint Leak 18 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 19: Technical Specifications

Dimensions (W x H x D) 700 mm x 540 mm x 250 mm Weight 32 kg Gas detection unit Mechanical data Dimensions (W x H x D) 610 mm x 300 mm x 380 mm Weight 33 kg ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 19 / 74... -

Page 20: Ambient Conditions

240 VA Protection class IP 20 Overvoltage category Fuses Gas detection unit 2 × 4 A slow-acting 250 V Gas Control Unit 2 × 3.15 A slow- acting 250 V Power connection lines 2.5 m each 20 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 21: Physical Data

1000 mbar to 0 mbar) Measurement range 3 decades Detectable masses 2 to 200 amu Mass spectrometer Quadrupole mass spectrometer Ion source 2 cathodes Time until ready for operation < 3 min ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 21 / 74... -

Page 22: Factory Settings

Automatic start of measurement Volume Optional input field Pre-ZERO 2 seconds ZERO 4 seconds Pre-LD 2 seconds 2 seconds Chamber purging time 5 seconds Chamber vent time 4 seconds Chamber vacuum limit 4.5 mbar Evacuation timeout 120 seconds 22 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 23: Installation

► Only operate the battery leak detector in a dry environment. ► Operate the battery leak detector away from sources of liquid and moisture. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 23 / 74... -

Page 24: Design Of Device

Operation of the battery leak detector may produce hazardous vapors. ► Connect the Gas Detection Unit and the Gas Control Unit to an exhaust line. ► Do not inhale harmful gases or vapors. ► Ensure sufficient ventilation at the installation location. 24 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) - Page 25 The Gas Detection Unit and Gas Control Unit subcomponents of the battery leak detector are heavy and can slip from the hands. ► Only lift and transport the Gas Detection Unit and the Gas Control Unit using two people. Overview Gas detection unit Gas Control Unit ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 25 / 74...

-

Page 26: Connect Devices

Connect the Exhaust connection of the GDU to the exhaust system via the Ø 8 mm connecting hose. Connect the vacuum control unit (GCU) to the gas detection system (GDU) using the RS232 signal cable. Use the enclosed angle clips to lay the hoses without kinks. 26 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) - Page 27 5 Power switch 13 PURGE, fresh air connection, Ø 6 6 Power cable connection 14 VENT (chamber connection ventilation) 7 Fuses behind cover 15 GDU B, Ø 6 mm 8 RS232 signal connection to the gas detection system ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 27 / 74...

- Page 28 RS232 interface Power supply 1. Headphone port: Not used in this case. 2. I/O port, inputs/outputs: Not used in this case. 3. RS232 interface: Gas Detection Unit connection to Gas Control Unit. 4. Power switch: 28 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

-

Page 29: Connection Scheme For A Test Chamber

Example of an individually manufactured test chamber Fig. 1: Example of test chamber Venting test chamber connection Rubber feet (4x) Exhaust air test chamber Cover handle connection Liquid separator Red LED indicator Test chamber housing Green LED indicator ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 29 / 74... - Page 30 Observe the following table when constructing an individually manufactured test chamber. If you have any questions about constructing or using an individually manufactured test chamber, please contact INFICON Service. Table of requirements Designation Recommendation...

- Page 31 Cover opening angle 100-110° Opening aid For heavy covers e.g. with gas-operated springs Lock for cover For heavy covers Avoid risk of crushing and cutting injuries through design! Equipment feet Rubber feet Use anti-slip rubber feet! ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 31 / 74...

- Page 32 5 | Installation INFICON Example Test chamber Gas Control unit RJ45 Gas Detection unit Fig. 2: ELT3000 connection Exhaust GCU Ø 10 mm INLET (test chamber connection fresh Ø 8 mm air) VENT (test chamber connection exhaust Ø 8 mm air)

-

Page 33: Connecting To The Power Supply System

If the individual devices are connected to different power supply networks, current flows may occur in the RS232 data line. Malfunctions and undesired operating states of the device are possible. ► Always connect the individual devices to the same supply network. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 33 / 74... -

Page 34: Interfaces

You can connect a barcode scanner or a USB flash drive via the two USB 2.0 interfaces. RS232 interface Communications between the Gas Detection Unit and the Gas Control Unit RJ45 network interface Interface for connection to an internal company network 34 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 35: Operation

20 cm on the sides, at least 10 cm at the front and rear. ► Keep heat sources away from the battery leak detector. ► Do not expose the battery leak detector to direct sunlight. ► Please note the technical specifications. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 35 / 74... -

Page 36: Switch On And Login

6.2.1 Setting the language You can set the language in the user settings, see Select, modify, create user profile [} 37]. 6.2.2 Setting date, time and time zone ü Supervisor rights > Date and time Adjust. Save 36 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 37: User Profile Settings

The window "User settings" will open. Otherwise, press a previously created user name and choose the following from the displayed tool bar: , to load a user profile. The login window opens. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 37 / 74... -

Page 38: Modify Personal Settings

Access to the entire user profile is not necessary. Press on your name, which appears on the top right of the display. ð The "User options" window opens. Select either the button "Change PIN" or "Change language" as required. 38 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 39: Switch Off Automatic Login

"Select, modify or create product (measurement settings)". ü Supervisor rights > User accounts > Manage Automatic Login Deactivate the option "Active" in the window "Auto Login". Save ð After restarting the device, the current settings are applied. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 39 / 74... -

Page 40: Switch On Automatic Login

The device can emit sounds up to a level of 100 dB (A) at the highest volume setting. ► Set the volume up to a maximum of "10". ► Use suitable hearing protection at volume settings above "5". ü Operator or Supervisor rights > Audio Adjust. Save 40 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 41: Switching Automatic Measurement Start On Or Off

Select > Empty the measuring chamber. Start the ZERO measurement. ð The result is displayed in green and the values are applied. In the event of an error, the result is displayed in red. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 41 / 74... -

Page 42: Using The Input Field In The Measurement Window

► Comply with all safety instructions from the battery manufacturer. CAUTION Warning about hand injuries ► Only open and close the test chamber when your fingers are outside the test chamber halves and outside the pivoting range of the test chamber. 42 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) - Page 43 "Measurement" window on the left side. In addition, the word "OK", "Leak Warning" or "Leak" is displayed, see "Result display [} 18]". After completion of the measurement you can remove the test object and measure additional test objects. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 43 / 74...

-

Page 44: Purge Device

All measurement data are transferred. There is an indication when the export is completed. The measurement data remain saved on the device. 6.6.2.1 Transferring analysis data The device records data in the internal memory for every measurement and in the event of error. 44 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 45: Delete Measurement Data

INFICON Operation | 6 You can either send this file to INFICON via email or request an upload link from support. How to provide INFICON with this data Connect a FAT32 formatted USB flash drive to the control unit Navigate to the "Diagnosis →... -

Page 46: Bringing Up Log

In order to load the new software version, press on the button "Update". ð After completion there is an automatic restart of the operating unit. 46 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 47: Updating The Software Of The Basic Unit

If this is the same as the version already installed the background is green, otherwise it is red. In order to load the new software version, press on the button "Update". ð After completion there is an automatic restart of the system. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 47 / 74... -

Page 48: Updating The Software Of The Gas Detection Unit

If this is the same as the version already installed the background is green, otherwise it is red. In order to load the new software version, press on the button "Update". ð After completion there is an automatic restart of the system. 48 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 49: Calibrate Device

ü The vacuum chamber is closed. ► Start the measurement. ð The second measurement, with E-Check (DMC), is completed. At the end of the measurement of the E-Check (DMC), the new calibration factor is determined and displayed by the device. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 49 / 74... -

Page 50: Calibration Equipment

► > Measurement Improper changes can result in faulty measurements. ► Only make changes to the settings on this page after consultation with INFICON. 6.11 Bringing up active errors and warnings Active errors Errors or warnings are displayed on the active user interface. In addition, the diagnosis symbol changes color >... -

Page 51: Logging Off From The Device

ð The login window opens. 6.13 Switching off the device You can turn off the Gas Detection Unit and Gas Control Unit at any time with the corresponding power switch. The parameters set in the device remain saved. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 51 / 74... -

Page 52: Warning And Error Messages

The EEPROM in the • Confirm the warning message internal IO module is • Check if the message occurs each time defective when you restart the device • Contact customer service 52 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) - Page 53 • Check the connection to the bus module module module interrupted • Replace the connection cable to the bus module Bus module defective • Replace the bus module Bus module connection • Contact customer service on the device defective ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 53 / 74...

- Page 54 • Contact customer service E175 No communication with Problem in GDU • Contact customer service E176 GDU not in measuring mode Problem in GDU • Contact customer service W190 Detector contaminated Problem in GDU • Contact customer service 54 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

- Page 55 GDU - Input voltage 24V on Problem in GDU • Contact customer service the Transpector is too low E303 GDU - Input voltage 24V on Problem in GDU • Contact customer service the frequency converter is too low ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 55 / 74...

- Page 56 • Contact customer service frequency too high W324 GDU - Voltage Problem in GDU • Contact customer service U24_GB_EXT is too low E325 GDU - Internal photoelectric Problem in GDU • Contact customer service barrier 56 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

- Page 57 • Contact customer service cathode 1 E350 GDU - Turbo pump or Problem in GDU • Contact customer service electronics fault E351 GDU - No communication Problem in GDU • Contact customer service with the turbo controller ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 57 / 74...

- Page 58 • Contact customer service factor W378 GDU - Signal difference Problem in GDU • Contact customer service between test leak and air too small W379 GDU - Factor out of range Problem in GDU • Contact customer service 58 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

- Page 59 E397 GDU - TMP error 026 Error Problem in GDU • Contact customer service in temperature sensor in TC E398 GDU - TMP error 037 power Problem in GDU • Contact customer service failure ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 59 / 74...

- Page 60 • Use another test object, if possible The settings value for • Check and change the max. evacuation the max. evacuation time until measurement if necessary time until measurement is too low 60 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

- Page 61 E711 Maximum temperature of The ambient • Reduce the temperature in the basic unit exceeded temperature is too high environment where the device is located ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 61 / 74...

- Page 62 • Contact customer service for backing pump exceeded W920 Maintenance: Exhaust filter Maintenance interval • Contact customer service for exhaust filter exceeded W925 Maintenance: Air filter Maintenance interval • Contact customer service for air filter exceeded 62 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

-

Page 63: Cleaning And Maintenance

► Wear suitable protective clothing, especially gloves, apron and face protection. ► Observe the information in the respective MSDS. ► Rinse off electrolyte or acid splashes immediately with clean water. ► Consult a physician if necessary. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 63 / 74... -

Page 64: Gas Control Unit: Checking Inline Filter

The function and measuring accuracy of the leak detector can be impaired by contaminated filters. Check the transparent filter elements (inline filter) regularly for the ingress of dust. 1 Union nuts (blue) 2 Filter element (transparent) ► Replace the filter elements if they are clearly dirty. 64 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 65: Gas Control Unit: Replacing Filter Mat On Bottom Of Device

Remove the plastic grille. It is only attached by catch tabs. Remove the used air filter from the plastic grille and insert a new one. Refit the plastic grille together with the new air filter. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 65 / 74... -

Page 66: Gas Detection Unit: Replacing The Air Filter Of The Basic Unit

Loosen the screw of the cover plate until you can rotate the cover plate to the side. Fig. 3: Loosening the air filter cover Pull out the air filter and replace it with a new one. 66 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) -

Page 67: Decommissioning

Contact the manufacturer and send in a completed declaration of contamination before return shipment. ð You will then receive a return number. Use the original packaging when returning. Always include a copy of the completed contamination declaration before shipping the battery leak tester. See below. ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 67 / 74... - Page 68 9 | Decommissioning INFICON 68 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

-

Page 69: Ce Declaration Of Conformity

INFICON CE Declaration of Conformity | 10 10 CE Declaration of Conformity ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 69 / 74... -

Page 70: Accessories

11 | Accessories INFICON 11 Accessories Name Catalog number Leak detectors ELT3000 (Gas Detection Unit+Control Unit) 230V, 50Hz 600-001 ELT3000 (Gas Detection Unit+Control Unit) 110V, 60Hz 600-002 Test chambers TC3000S (Rigid chamber 180 mm × 180 mm × 27 mm) 600-100 TC3000L (Rigid chamber 400 mm ×... -

Page 71: Index

Errors and warnings (active) 50 Scope of delivery 11, 12 Setting the language 38 Setup 24 Function buttons 17 Software updates 46 Supervisor 37, 39 Switch off 51 Gas Control Unit 15 Switching on 36 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007) 71 / 74... - Page 72 Index INFICON Transport 13 Transport protection 23 User 37 User profile Create 37 Delete 38 Edit 38 Load 37 ZERO 41 ZERO measurement 41 72 / 74 ELT3000-Battery Leak-Detector-Operating-instructions-mina95en1-10-(2007)

Need help?

Do you have a question about the ELT3000 and is the answer not in the manual?

Questions and answers