Summary of Contents for Inficon ELT3000 PLUS

- Page 1 Translation of the original operating instructions ELT3000 PLUS Battery Leak Detector Catalog No. 600-201, 600-202 From software version V1.41 (Device operation) minc95en1-01-(2304)

- Page 2 INFICON GmbH Bonner Strasse 498 50968 Cologne, Germany...

-

Page 3: Table Of Contents

5.3 Design of device............................. 28 5.3.1 Connect devices ......................... 29 5.3.1.1 Requirements of a test chamber.................. 32 5.4 Connecting to the power supply system .................... 34 5.5 Interfaces ............................... 35 5.5.1 Configure barcode scanner...................... 35 6 Operation .............................. 36 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) - Page 4 6.7.3 Delete measurement data...................... 52 6.7.4 Bringing up device information.................... 52 6.7.5 Bringing up log .......................... 53 6.8 Updating the software .......................... 53 6.8.1 Updating the software of the operating unit ................ 53 6.8.2 Updating the software of the basic unit.................. 54 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 5 10.2 Operate leak detector via web browser (LAN) .................. 90 10.2.1 Configure the LAN connection of the leak detector .............. 90 10.2.2 Setting the LAN connection in the PC or Tablet ................. 91 10.2.3 Allow client access........................ 91 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 6 Table of contents INFICON 10.3 Data request or control via network ....................... 92 10.3.1 Export measurement data...................... 93 10.4 CE Declaration of Conformity......................... 94 10.5 UKCA .............................. 94 10.6 RoHS.............................. 94 Index ................................ 95 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 7: About This Manual

The minimum detectable leak rate that can be detected by the leak detector under ideal conditions (< 1 x 10 mbar l/s*). Helium equivalent leakage rate at a pressure difference of 1000 mbar versus 0 mbar for 100% DMC (dimethyl carbonate). Gas Control Unit (basic unit, operating unit) ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 7 / 98... - Page 8 1 | About this manual INFICON Gas Detection Unit Dimethyl carbonate, typical solvent in battery electrolyte. CAS No. 616-38-6 MSDS Material Safety Data Sheet 8 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 9: Safety

• Using the device in potentially explosive atmospheres • Use of the device in dry environments (relative humidity <30%) without consulting INFICON. • Using the device with chambers that do not participate in the equipotential bonding ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 9 / 98... - Page 10 2 | Safety INFICON • Connection of hazardous electrical voltages to the device interfaces (except mains connection). • Operation in the living area 10 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 11: Duties Of The Operator

Danger due to • Only use the device away from areas with a risk of explosions. chemical substances ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 11 / 98... - Page 12 • The device must not be shaken during operation and at least five minutes after being switched off. Escaping electrolyte can accumulate in the measuring chamber. Danger due to escaping electrolyte after the measurement. 12 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 13: Scope Of Delivery, Transport, Storage

Exhaust air hose Ø 10 mm, length 3 m (GCU, exhaust outlet for the exhaust system) RS232 connection cable Angle clip OD 6 mm Angle clip OD 8 mm Exhaust connection nut (Exhaust GCU) Replacement air filter ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 13 / 98... - Page 14 Power cable Scope of delivery Gas Detection Unit (GDU) Quantity package 2 Gas Detection Unit (GDU) Power cable for GDU Unpacking instructions ► Check the scope of delivery of the product for completeness after receipt. 14 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 15 ► Only transport the device in its original packaging. ► Remove the transport protection before startup. Storage Always store the device in compliance with the technical data, see “Technical data [} 22]“. See also 2 Transport protection [} 26] ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 15 / 98...

-

Page 16: Description

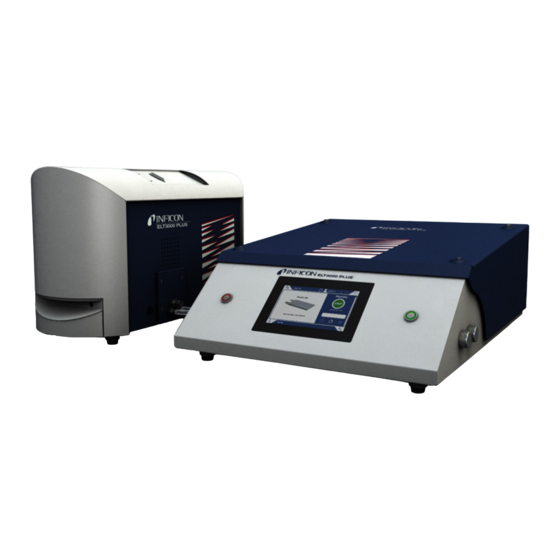

4 Description 4.1 Function The ELT3000 Plus can be operated as "stand-alone" or "integrated" in a plant. This device is a battery leak detector that allows you to non-destructively check for leaks, both on hard battery cells and pouch cells. - Page 17 The integrated pump is used to evacuate the measuring chamber to the desired target pressure. A valve control system adapted to the measurement sequence allows the analysis gas to be fed to the Gas Detection Unit. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 17 / 98...

-

Page 18: Display

Navigation button settings Optional input field Product name Navigation diagnostic button Time Calibrate Access control Measure User name ZERO Previous page Setpoint Next page Name of current window Navigation operation button Information navigation button Start button 18 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) - Page 19 Call up help for the current function Confirm entry or selection Load Analysis Save Edit Copy Delete Page forward Page back The measurement result is displayed in the measurement window on the left. For more information, see Result display [} 20]. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 19 / 98...

-

Page 20: Result Display

If the leak rate is below the setpoint, the measurement result is shown on a green Leaktight background. Setpoint Leak Measurement result: If the leak rate is above the setpoint for leaks, the measurement result is shown on a Leaking red background. Leak Setpoint Leak 20 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) - Page 21 If the leak rate is above the setpoint for warning but still below the setpoint for leaks, Warning the measurement result is shown on an orange background. The specification of a setpoint for a warning is optional. Leak Warning Setpoint Leak ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 21 / 98...

-

Page 22: Technical Data

Max. relative humidity above 40°C 50 % Relative humidity during storage and Minimum 10% Maximum 90% transport Degree of contamination Max. altitude above sea level 2000 m * Use of the ELT3000 PLUS only after consultation with INFICON GmbH. 22 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 23: Electrical Data

EN 60529 IP20 UL 50E type 1 Overvoltage category Fuses Gas detection unit 2 × 4 A slow-acting 250 V Gas Control Unit 2 × 3.15 A slow- acting 250 V Power connection lines 2.5 m each ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 23 / 98... -

Page 24: Physical Data

1000 mbar versus 0 mbar for 100% DMC (dimethyl carbonate)) Measurement range 3 decades Detectable masses 2 to 200 amu Mass spectrometer Quadrupole mass spectrometer Ion source 2 cathodes Time until ready for operation < 3 min 24 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 25: Factory Settings

Warning threshold value 8.00E-6 mbar*l/s Automatic start of measurement Volume Optional input field Pre-LD 2 seconds 4 seconds Chamber purging time 5 seconds Chamber vent time 4 seconds Chamber vacuum limit 4.5 mbar Evacuation timeout 120 seconds ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 25 / 98... -

Page 26: Installation

► Only operate the battery leak detector in a dry environment. ► Operate the battery leak detector away from sources of liquid and moisture. 26 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) - Page 27 Unit, a Gas Control Unit and an optional vacuum chamber. The installation, connection and commissioning of the battery leak detector may only be carried out by INFICON trained and instructed employees. • In order not to distort the measurement results, select a location where the possible room temperature for the device is constant.

-

Page 28: Design Of Device

The Gas Detection Unit and Gas Control Unit subcomponents of the battery leak detector are heavy and can slip from the hands. ► Only lift and transport the Gas Detection Unit and the Gas Control Unit using two people. 28 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 29: Connect Devices

Connect the Exhaust connection of the GDU to the exhaust system via the Ø 8 mm connecting hose. Connect the Gas Control Unit (GCU) to the Gas Detection Unit (GDU) using the RS232 signal cable. Use the enclosed angle clips to lay the hoses without kinks. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 29 / 98... - Page 30 13 PURGE, fresh air connection, Ø 6 6 Power cable connection 14 VENT (test chamber air connection ventilation Ø 8 mm) 7 Fuses behind cover 15 GDU B, Ø 6 mm 8 RS232 signal connection to the Gas Detection Unit 30 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 31 GDU B, Ø 6 mm Back view Headphone jack (not used) Power switch I/O port, inputs/outputs (not used) 5 Electrical fuses behind cover RS232 interface (connection of Power supply Gas Detection Unit to Gas Control Unit.) ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 31 / 98...

-

Page 32: Requirements Of A Test Chamber

Observe the following table when constructing an individually manufactured test chamber. If you have any questions about constructing or using an individually manufactured test chamber, please contact INFICON Service. Table of requirements Designation Recommendation... - Page 33 Opening angle Cover opening angle 100-110 ° Opening aid For heavy covers e.g. with gas-operated springs Lock for cover For heavy covers Avoid crushing and cutting hazards. Equipment feet Rubber feet Use anti-slip rubber feet! ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 33 / 98...

-

Page 34: Connecting To The Power Supply System

Metal parts of the implant can trigger an alarm. ► As a wearer of such devices, keep at least 10 cm distance between the leak detector and the implant. ► Furthermore, take into account distances specified by the manufacturer of the implant. 34 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 35: Interfaces

Language selection: “English US“ ð The leak detector requires an English (US) keyboard layout. To test the configuration of the scanner, connect it to a PC and use a text editor to check the output of the scanner. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 35 / 98... -

Page 36: Operation

• Operating instructions bus module BM1000 • Interface Protocols ELT3000 PLUS The paths given in the following sections refer to the operation of the ELT3000 PLUS. If the bus module or the I/O module is used, the actions must be implemented within the scope of the protocol that is used. -

Page 37: Switch On And Login

Operation | 6 The path information for the control unit always starts in the main menu. NOTICE For operation in inline mode, please contact INFICON Service. 6.1 Switch on and login Device setting only via Gas Control Unit (GCU) You can only make settings on the Gas Control Unit (GCU). -

Page 38: Select, Modify, Create User Profile

The window "User settings" will open. , to delete a user profile. A confirmation prompt appears. After selecting the settings, the "User settings" window opens. In this case, enter a user name, change it or keep it as required. 38 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 39: Modify Personal Settings

As per factory settings, after switching on the device the user "Supervisor" automatically logs in and the measurement screen is brought up. This default user also has the permissions of the group "Supervisor". Without changing this setting, any user can operate all functions without restriction. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 39 / 98... -

Page 40: Switch On Automatic Login

Enter the name of the user in the "Name" window. The input is case-sensitive. Enter the current PIN of the user profile in the "PIN" window. Activate the option "Active" in the window "Auto Login". Save 40 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 41: Changing The Volume

"Autostart" option on or off. ü Operator or Supervisor rights > Device Adjust. Save ð If the automatic measurement start is OFF, press the "START" button on the touchscreen or on the housing to start the measurement. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 41 / 98... -

Page 42: Lighting On Or Off

Operator or Supervisor rights > Device Adjust. Save 6.2.9 Select test chamber (optionally available) INFICON offers different measuring chambers: - TC3000S (small rigid test chamber) - TC3000L (large rigid test chamber) - FTC3000 (flexible test chamber) 6.2.9.1 Select test chamber... -

Page 43: Configure Test Chamber

INFICON Operation | 6 6.2.10 Configure test chamber Customer-specific test chambers only These settings are only made for customer-specific test chambers. If you have any questions about possible settings, please contact INFICON Service. Universal Supervisor Chamber vacuum limit Evacuation timeout... -

Page 44: Operating Mode

The desired operating mode is selected via the HMI or via the interface to the ELT3000 PLUS. You can communicate with the ELT3000 PLUS either via a serial protocol or via a field bus. Please refer to the document "ELT3000-Protocol-Descriptions-iira95en1". - Page 45 If your image is not stored on the device, expand the image database. After pressing you can transfer images (JPG, PNG; max. 400 x 400 px) from a USB flash drive (FAT32 format) to the image database. Save ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 45 / 98...

-

Page 46: Select Product

Select > Empty the measuring chamber. Start the ZERO measurement. ð The result is displayed in green and the values are applied. In the event of an error, the result is displayed in red. 46 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 47: Set Coarse Leakage Detection (Optional)

INFICON Operation | 6 6.4.4 Set coarse leakage detection (optional) The coarse leak detection serves in particular to protect the ELT3000 PLUS from contamination with the test gas. Setting the operation mode Set the threshold value for the coarse leak detection To do this, select a factor to the default threshold from the offered factors. -

Page 48: Checking The Operation Of The Device

"Result display”. 6.5 Measure For stand-alone operation only. for operation in integrated mode, contact the INFICON service CAUTION Warning about hand injuries ► Only open and close the test chamber when your fingers are outside the test chamber halves and outside the pivoting range of the test chamber. - Page 49 "Measurement" window on the left side. In addition, the word "OK", "Leak Warning" or "Leak" is displayed, see "Result display [} 20]". After completion of the measurement you can remove the object and measure additional test objects. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 49 / 98...

- Page 50 6 | Operation INFICON If you repeat the measurements with the same test object, the measurement results may differ. This is usually due to a reduced amount of solvent caused by the previous measurement. 50 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 51: Purge Device

FAT32 formatting to any of the USB ports of the device. > Measurements Save ð All measurement data are transferred. There is an indication when the export is completed. The measurement data remain saved on the device. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 51 / 98... -

Page 52: Transferring Analysis Data

The device records data in the internal memory for every measurement and in the event of error. You can either send this file to INFICON via email or request an upload link from support. How to provide INFICON with this data Connect a FAT32 formatted USB flash drive to the control unit Navigate to the "Diagnosis... -

Page 53: Bringing Up Log

In order to load the new software version, press on the button "Update". ð After completion there is an automatic restart of the operating unit. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 53 / 98... -

Page 54: Updating The Software Of The Basic Unit

If this is the same as the version already installed the background is green, otherwise it is red. In order to load the new software version, press on the button "Update". ð After completion there is an automatic restart of the system. 54 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 55: Updating The Software Of The Gas Detection Unit

If this is the same as the version already installed the background is green, otherwise it is red. In order to load the new software version, press on the button "Update". ð After completion there is an automatic restart of the system. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 55 / 98... -

Page 56: Update The Software In Expert Mode

ð After completion there is an automatic restart of the system. 6.9 Calibrate device For stand-alone operation only for integrated operation, contact INFICON Service. 6.9.1 Calibration General calibration Calibration is required in the following cases,: • Operational needs require a daily calibration. -

Page 57: Calibration Equipment

ð You will now be prompted to perform a ZERO measurement and then to measure the calibration leak. ð After calibration the determined calibration factor is displayed in the window "Calibration". 6.10 Restoring factory defaults You can restore the device to factory settings. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 57 / 98... -

Page 58: Advanced Settings

► > Measurement Improper changes can result in faulty measurements. ► Only make changes to the settings on this page after consultation with INFICON. 6.12 Bringing up active errors and warnings Active errors Errors or warnings are displayed on the active user interface. In addition, the diagnosis symbol changes color >... -

Page 59: Warning And Error Messages

• Contact customer service • Confirm the warning message • Turn the power off to the device and check if the message appears again when you turn on the power • Replace the internal I/O module ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 59 / 98... - Page 60 • Replace the internal I/O module E107 Internal IIC communication Internal IIC • Contact customer service error communication error • Replace the internal I/O module 60 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 61 • Contact customer service on the device defective • Replace the internal I/O module W127 Wrong bootloader version The bootloader is not • Contact customer service compatible with • Replace the internal I/O module application ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 61 / 98...

- Page 62 GDU software is obsolete A more up-to-date • Contact customer service to get an GDU software exists. updated GDU software For trouble-free • Install the latest GDU software operation, it is recommended to update the GDU software. 62 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 63 • Confirm the error Leak between GCU • Check the hose connections between the and GDU GDU and GCU • Contact customer service • Check the hose connections between the GDU and GCU and replace them if necessary ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 63 / 98...

- Page 64 24 V power supply too high Malfunction of 24V • Contact customer service power supply unit • Check the connection between 24V power supply unit and internal I/O module • Replace 24V power supply unit 64 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 65 OPTION output is too low W305 GDU - Voltage U5_I_Sniffer Problem in GDU • Contact customer service is too low W306 GDU - Voltage U5_II_Leak Problem in GDU • Contact customer service is too low ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 65 / 98...

- Page 66 • Change or clean the air filters One fan of the GDU • Check whether a fan current is noticeable defective from the outside • Contact customer service • Check whether a fan current is noticeable from the outside 66 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 67 • Check whether a fan current is noticeable from the outside W343 GDU - Transpector limit Problem in GDU • Contact customer service value exceeded W344 GDU - No communication Problem in GDU • Contact customer service with Transpector ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 67 / 98...

- Page 68 Problem in GDU • Contact customer service parameters initializing W362 GDU - EEPROM Problem in GDU • Contact customer service parameters lost W363 GDU - TSP parameters Problem in GDU • Contact customer service inconsistent 68 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 69 Problem in GDU • Contact customer service range W384 GDU - Calibration leak Problem in GDU • Contact customer service signal too small W385 GDU - Problem during peak Problem in GDU • Contact customer service finding ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 69 / 98...

- Page 70 • Replace pressure sensor cable • Replace pressure sensor Internal I/O module • Contact customer service defective • Replace the internal I/O module Pressure sensor p1 • Contact customer service defective • Replace pressure sensor 70 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 71 • Replace the internal I/O module Pressure sensor p3 • Restart the device and check the function defective • Contact customer service • Restart the device and check the function • Replace pressure sensor ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 71 / 98...

- Page 72 • Let the device warm up for a few hours time The settings value for • Check and, if necessary, increase the the max. evacuation maximum evacuation time time until measurement • Check and, if necessary, increase the is too low maximum evacuation time 72 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 73 • Use another calibration leakContact leak too small customer service • Use another calibration leak W630 Calibration request Operating parameters • Perform a calibration or the measuring mass • Perform a calibration have been changed ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 73 / 98...

- Page 74 W903 Maintenance: Calibration Maintenance interval • Contact customer service leak expired for calibration leak • Perform the maintenance for the exceeded calibration leak • Reset the maintenance counter for the calibration leak 74 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

- Page 75 • Reset the maintenance counter for the exhaust filter W925 Maintenance: Air filter Maintenance interval • Contact customer service for air filter exceeded • Perform the maintenance for the air filter • Reset the maintenance counter for the air filter ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 75 / 98...

-

Page 76: Cleaning And Maintenance

8.1 Maintenance operations of Gas Control Unit (GCU) 8.1.1 Gas Control Unit (GCU): Cleaning the housing The housing of the Gas Control Unit (GCU) consists of a painted metal housing and an optional aluminum measuring chamber. Only use water for moistening. 76 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 77: Gas Control Unit (Gcu): Replace Hoses

The function and measuring accuracy of the leak detector can be impaired by contaminated filters. Check the transparent filter elements (inline filter) regularly for the ingress of dust. 1 Union nuts (metal) 2 Filter element (transparent) ► Replace the filter elements if they are clearly dirty. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 77 / 98... -

Page 78: Gas Control Unit (Gcu): Replacing Filter Mat On Bottom Of Device

Remove the plastic grille. It is only attached by catch tabs. Remove the used air filter from the plastic grille and insert a new one. Refit the plastic grille together with the new air filter. 78 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 79: Maintenance Operations Of Gas Detection Unit (Gdu)

► Allow the turbo molecular pump to power down before any maintenance work is performed or before moving the device. • Place the Gas Detection Unit (GDU) with the front panel on a soft surface ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 79 / 98... -

Page 80: Replace Oil Wick Cartridge

The oil wick cartridge has a limited service life and storage period; see the maintenance schedule. Procedure • Place the Gas Detection Unit with the front panel on a soft surface. Pay attention to the connections on the front panel. 80 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) - Page 81 INFICON Cleaning and maintenance | 8 • Unscrew the plastic screw with a 19 mm box wrench. • Lever out the aluminum plug with one or two narrow screw drivers. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 81 / 98...

- Page 82 8 | Cleaning and maintenance INFICON • Hook something into the center bore of the plastic container and pull out the plastic container. 82 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 83: Replace Mains Fuses

The fuses are located behind a flap near the mains switch. They are in two slots. The mains fuses are available with order no. 200 000 914. Two identical fuses must be used at all times. ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 83 / 98... - Page 84 • Lever out the cover of the mains plug to the right with a screwdriver. • Pull out the two slots and replace the fuses. • Push the slots back in. Ensure that the arrows point up. • Close the flap. 84 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 85: Maintenance Plan

Explanation of maintenance levels: Maintenance level I: Customer without any technical training Maintenance level II: Customer with technical and INFICON training Maintenance level III: INFICON Service 8.4 Creating screenshots You can save the current screen contents of the device to an image file. You can use such a file for service communication, for example. -

Page 86: Have The Device Serviced Or Repaired

Maintenance inside the device should only be performed by the manufacturer. You can send in your device to INFICON so it can be maintained or repaired. For further details see "Send in battery leak detector for maintenance, repair or disposal [} 87]”. -

Page 87: Decommissioning

9 Decommissioning 9.1 Dispose of battery leak detector The battery leak detector can be disposed of by the operator or sent to INFICON. The battery leak detector consists of materials that can be recycled. This option should be exercised to prevent waste and also to protect the environment. - Page 88 9 | Decommissioning INFICON 88 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

-

Page 89: Appendix

Connection-KIT E_Check 600-106 Bus module BM1000 PROFIBUS 560-315 BM1000 ProfiNet 560-316 BM1000 DeviceNet 560-317 BM1000 EtherNet/IP 560-318 I/O1000 module 560-310 Data cable I/O1000 2m 560-332 Data cable I/O1000 5m 560-335 Data cable I/O1000 10m 560-340 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 89 / 98... -

Page 90: Operate Leak Detector Via Web Browser (Lan)

ð Static: The IP address, as well as the network mask and gateway have to be configured manually, so that the leak detector can be reached in the network. If necessary, contact a network administrator. Save See also 2 Setting the LAN connection in the PC or Tablet [} 91] 90 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 91: Setting The Lan Connection In The Pc Or Tablet

ü The network connection between the leak detector and one or more PCs or Tablets has been established, see “Setting the LAN connection in the PC or Tablet [} 91]”. ► > Network > Connected clients ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 91 / 98... -

Page 92: Data Request Or Control Via Network

A data interface was implemented for this purpose (REST interface). This interface responds to requests on port 3000 when valid parameters are transmitted with data in the requested format. 92 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) - Page 93 =4,6,7 products Separated by comma for several Messung ID Messungen nach ID ID's der mid=2, mid=4,6,7 abfragen Messungen datetime Time zone Lokale- oder UTC-Zeit local, utc Standard: datetime=local, mid=utc wählen local ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 93 / 98...

-

Page 94: Ce Declaration Of Conformity

10 | Appendix INFICON 10.4 CE Declaration of Conformity 10.5 UKCA 10.6 RoHS 94 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) -

Page 95: Index

Physical data 24 Entering a barcode 45 Product Errors and warnings (active) 58 Create 45 Delete 45 Load 44 Product settings Gas Control Unit 17 Copy 45 Gas detection unit 55 Edit 44 Proximity switch 41 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304) 95 / 98... - Page 96 85 Test chamber 42 Transfer the product image to the leak detector 45 Transport 15 Transport protection 26 User 37 User profile Create 38 Delete 38 Edit 38 Load 38 ZERO 46 ZERO measurement 46 96 / 98 ELT3000 PLUS-Operating-instructions-minc95en1-01-(2304)

Need help?

Do you have a question about the ELT3000 PLUS and is the answer not in the manual?

Questions and answers