Rotax 914 series Installation Manual

914 series

Hide thumbs

Also See for 914 series:

- Maintenance manual (184 pages) ,

- Operator's manual (92 pages) ,

- Service bulletin (35 pages)

Summary of Contents for Rotax 914 series

- Page 1 �������� ������� INSTALLATION MANUAL FOR ROTAX® ENGINE TYPE 914 SERIES Ref. No.: IM-914 ROTAX ® 914 UL 3 WITH OPTIONS part no.: 897817...

- Page 2 GmbH&CO. KG and must not be reproduced, neither entirely nor partially, and passed on to third parties without previous consent in writing by BRP-Rotax GmbH&CO. KG. This text must be written on every complete or partial reproduction. The Manual must remain with the engine/aircraft in case of sale.

-

Page 3: Table Of Contents

2) Index ........................7 3) Preface ........................9 3.1) Remarks ........................9 3.2) Engine serial number ....................9 3.3) ROTAX Authorized Distributors for Aircraft Engines ............ 9 4) Safety ........................11 4.1) Repeating symbols ....................11 4.2) Safety information ..................... 11 4.3) Instruction ......................... - Page 4 14.4) Connecting dimensions, location of joints and directives for installation ....87 14.4.1) Electric fuel pump ....................87 14.4.2) Check valve ......................89 14.4.3) Fuel pressure control ................... 89 14.5) Notes on checking of fuel pressure ................90 Effectivity: 914 Series page 4 Edition 2 / Rev. 0 July 01/2008...

- Page 5 19.4.13) Connection of the electric rev-counter (tachometer) .......... 125 19.4.14) Battery ......................... 126 19.4.15) Relay ........................126 19.5) Internal consumer of electric power ................ 126 20) Propeller drive ....................127 20.1) Technical data ......................127 Effectivity: 914 Series page 5 Edition 2 / Rev. 0 July 01/2008...

- Page 6 23.4) Mechanical rev-counter (tach drive) ................ 136 23.5) Monitoring of the intake manifold pressure ............. 137 23.6) Air temperature in the airbox (optional) ..............138 24) Preparations for trial run of engine ..............139 Effectivity: 914 Series page 6 Edition 2 / Rev. 0 July 01/2008...

-

Page 7: Index

Engine speed 27 Propeller drive 127 Engine suspension 33, 38 Protective covering 32 Engine views 24 Exhaust gas temperature 40 Exhaust system 39 Expansion tank 51 External alternator 123 Effectivity: 914 Series page 7 Edition 2 / Rev. 0 July 01/2008... - Page 8 Turbo charger 98 Turbo Control Unit (TCU) 111, 119 Vacuum pump 129 Venting line of oil tank 67 Warning light 122 Water inlet bend 53 Wiring diagram (electric) 109 Effectivity: 914 Series page 8 Edition 2 / Rev. 0 July 01/2008...

-

Page 9: Preface

BRP-Rotax INSTALLATION MANUAL 3) Preface In this Manual the installation of all ROTAX 914 Series engines is described. ◆ NOTE: ROTAX 914 Series includes 914 F and 914 UL. Before starting with the engine installation, read this Installation Manual carefully. The Manual will provide you with basic information on correct engine installation, a requirement for safe engine operation. - Page 10 BRP-Rotax INSTALLATION MANUAL NOTES Effectivity: 914 Series page 10 Edition 2 / Rev. 0 July 01/2008...

-

Page 11: Safety

The information and components-/system descriptions contained in this Installation Manual are correct at the time of publication. BRP-Rotax, however, maintains a policy of continuous improvement of its products without imposing upon itself any obligation to install them on its products previously manufactured. - Page 12 Due to the varying designs, equipment and types of aircraft, BRP-Rotax makes no warranty or representation on the suitability of its engine’s use on any particular aircraft.

-

Page 13: Instruction

All technical directives relevant for safety are especially emphasized. Pass on safety instructions to other users, without fail. This engine must only be operated with accessories supplied, recommended and released by BRP-Rotax. Modifications are only allowed after consent by the engine manufacturer. ■ CAUTION: Spare parts must meet with the requirements defined by the engine manufacturer. -

Page 14: Technical Documentation

Therefore deduction of dimensions or other details from illustra- tions is not permitted. Some measurements are given in the drawings, these are manufacturing dimensions and are subject to corresponding tolerances. Effectivity: 914 Series page 14 Edition 2 / Rev. 0 July 01/2008... - Page 15 This No. (e.g. 00277) does not have any meaning concerning the content! All necessary documentation is available from the BRP-Rotax Distribution and Service Center. Installation drawings and a DMU-model for (virtual) installation analysis are available from the ROTAX Authorized Distributors or their Service Centers. Fig.1 09199 08404 Effectivity: 914 Series page 15 Edition 2 / Rev.

- Page 16 BRP-Rotax INSTALLATION MANUAL NOTES Effectivity: 914 Series page 16 Edition 2 / Rev. 0 July 01/2008...

-

Page 17: List Of The Effective

07 01 2008 07 01 2008 07 01 2008 07 01 2008 07 01 2008 07 01 2008 07 01 2008 07 01 2008 07 01 2008 07 01 2008 Effectivity: 914 Series page 17 Edition 2 / Rev. 0 July 01/2008... - Page 18 BRP-Rotax INSTALLATION MANUAL NOTES Effectivity: 914 Series page 18 Edition 2 / Rev. 0 July 01/2008...

-

Page 19: Table Of Amendments

DOA Nr. EASA.21J.048. 00568 chapter page date of remark for date of approval date of signature change approval from authorities inclusion 0 to 24 07 01 2008 DOA* ––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– Effectivity: 914 Series page 19 Edition 2 / Rev. 0 July 01/2008... - Page 20 BRP-Rotax INSTALLATION MANUAL NOTES Effectivity: 914 Series page 20 Edition 2 / Rev. 0 July 01/2008...

-

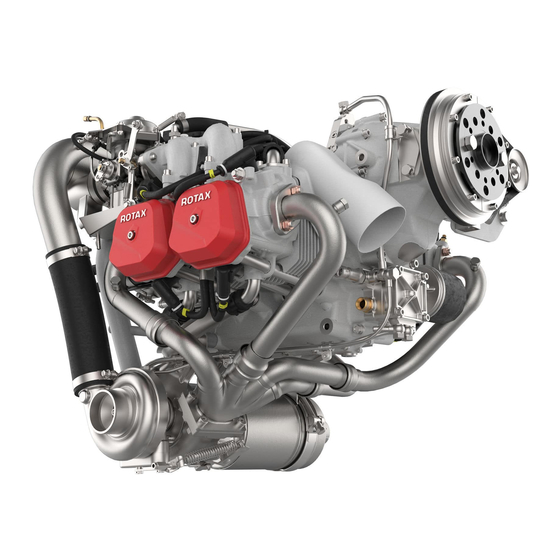

Page 21: Description Of Design

3 for version 4 ◆ NOTE: Conversion of the version 2/4 to version 3 and vice versa may be accomplished by BRP-Rotax Authorized Distributors or their Service Center. 7.2) Standard engine design 4 stroke, 4 cyl. horizontally opposed, spark ignition engine with turbo charger, single... -

Page 22: Auxiliary Equipment

Components especially developed and tested for this engine are readily available at BRP-Rotax. Following auxiliary equipment has been tested on ROTAX engine type 914 for safety and durability to the standards of aviation. The furnishing of proof in accordance to the latest FAR or EASA has to be conducted by the aircraft manufacturer. - Page 23 The furnishing of proof in accordance to the latest FAR or EASA has to be conducted by the aircraft manufacturer. intake filter Flydat mechanical tachometer electric tachometer shock mount oil hose Effectivity: 914 Series page 23 Edition 2 / Rev. 0 July 01/2008...

-

Page 24: Engine Components, Engine Views, Definition Of Main Axes

30 sensor for cylinder head temperature 39 external alternator 21 connection for oil return 31 2x pressure sensor 40 enrichment jet line (engine) 32 connection for mechanical tachom- eter Effectivity: 914 Series page 24 Edition 2 / Rev. 0 July 01/2008... - Page 25 BRP-Rotax INSTALLATION MANUAL Fig. 3 08418 Fig. 5 00123 Cyl. 4 Cyl. 3 Cyl. 2 Cyl. 1 Fig. 6 00124 00122 Fig. 4 Effectivity: 914 Series page 25 Edition 2 / Rev. 0 July 01/2008...

- Page 26 BRP-Rotax INSTALLATION MANUAL NOTES Effectivity: 914 Series page 26 Edition 2 / Rev. 0 July 01/2008...

-

Page 27: Technical Data

2. Manifold pressure:....see Operators Manual 914 Series, sec. 10.1. 3. Acceleration: ......see Operators Manual 914 Series, sec. 10.1. 4. Critical flight level ....see Operators Manual 914 Series, sec. 10.1. 5. Oil pressure: ......see Operators Manual 914 Series, sec. 10.1. -

Page 28: Installation Dimensions (All Dimensions In Mm)

Engine dry from serial production with int. alternator, with overload clutch, without fuel pumps (see section Description of design) ROTAX 914 F, 914 UL Engine weight ..configuration 2 and 4: ......71,7 kg (158 lb) configuration 3: ........74,4 kg (164 lb) auxiliary equipment: Weight of .... -

Page 29: Centre Of Gravity Of Engine And Standard Equipment

24 560 25 450 axis y1 - y1 (kg cm²) moment of inertia around 26 520 27 480 axis z1 - z1 (kg cm²) 04860 Effectivity: 914 Series page 29 Edition 2 / Rev. 0 July 01/2008... - Page 30 BRP-Rotax INSTALLATION MANUAL NOTES Effectivity: 914 Series page 30 Edition 2 / Rev. 0 July 01/2008...

-

Page 31: Preparations For Engine Installation

12 month after date of delivery from BRP-Rotax. This warranty is subject to the following conditions: the engine has to be stored in the packing as supplied by BRP-Rotax. the covers on various openings must not be removed (see section of protective covering) engine has to be stored in a suitable place (at min. -

Page 32: Protective Covering

3: ......1x disk plug or cap airbox: ............2x cap ▲ WARNING: Protective covering to be utilized for transport and at engine installation only. Before engine operation remove these protections. Effectivity: 914 Series page 32 Edition 2 / Rev. 0 July 01/2008... -

Page 33: Engine Suspension And Position

▲ WARNING: If the engine suspension frame supplied by BRP-Rotax is not used or if modified, certification to the latest requirements such as FAR or EASA has to be conducted by the aircraft manufacturer. -

Page 34: Definition Of Attachment Points

▲ WARNING: The engine suspension to be designed by the aircraft or fuselage manufacturer such that it will carry safely the maximum occurring operational loads without exceeding the max. allowable-forces and moments on the engine attachment points. page 34 Effectivity: 914 Series July 01/2008 Edition 2 / Rev. 0... -

Page 35: Permissible Fitting Positions

6° decline of propeller shaft axis after longer periods of downtime. See FAR, § 33.17. page 35 Effectivity: 914 Series July 01/2008 Edition 2 / Rev. 0... - Page 36 The centres of attachment points L1 und R1 must be on an axis y2 parallel to y- axis. 5° 5° Fig. 10 02454 Tolerated roll deviation of parallelism: ......± 5°. (See Fig. 10) page 36 Effectivity: 914 Series July 01/2008 Edition 2 / Rev. 0...

- Page 37 Vertical axis: y-axis must be square to the longitudinal axis of the aircraft. 10° Fig. 11 10° 02455 Tolerated roll deviation of Yaw tolerance: ± 10° (See Fig. 11) Effectivity: 914 Series page 37 Edition 2 / Rev. 0 July 01/2008...

-

Page 38: General Directives For Engine Suspension

The engine suspension has to be designed to prevent any excessive engine movement and to minimize noise emission and vibration on air frame side. See also SL-912-010 "Identifying abnormal vibrations on aircrafts", latest issue. page 38 Effectivity: 914 Series July 01/2008 Edition 2 / Rev. 0... -

Page 39: Exhaust System

The complete exhaust system is in the volume of supply and is certified together with the engine. ▲ WARNING: If the ROTAX exhaust system is not employed or if modified, certification to the latest requirements such as FAR or EASA has to be conducted by the aircraft manufacturer. -

Page 40: Operating Limits

Reading of the exhaust gas temperature has to be taken for certification to the latest requirements such as FAR or EASA has to be conducted by the aircraft manufacturer. Fig. 13/2 07131 ~100 mm (3.94 in.) page 40 Effectivity: 914 Series July 01/2008 Edition 2 / Rev. 0... -

Page 41: General Notes Concerning The Exhaust System

ANTISEIZE) to avoid jams and locks of the ball joint. ■ CAUTION: Vibrations due to improper installation and maintenance are a common source for errors of the exhaust system. page 41 Effectivity: 914 Series July 01/2008 Edition 2 / Rev. 0... - Page 42 BRP-Rotax INSTALLATION MANUAL NOTES page 42 Effectivity: 914 Series July 01/2008 Edition 2 / Rev. 0...

-

Page 43: Cooling System

12.1) Description of the system See Fig. 14. The cooling system of the ROTAX 914 is designed for liquid cooling of the cylinder heads and ram-air cooling of the cylinders. The cooling system of the cylinder heads is a closed circuit with an expansion tank and overflow bottle. -

Page 44: Operating Limits

(cowling or free installation, tractor or pusher, flight speed, etc.). Effectivity: 914 Series page 44 Edition 2 / Rev. 0 July 01/2008... -

Page 45: Coolant Types

5-10 °C (41-50 °F) higher with waterless coolant. Permanent monitoring of cylinder head temperature is necessary. Additional monitoring of the actual coolant temperature is possible, but not required. Effectivity: 914 Series page 45 Edition 2 / Rev. 0... -

Page 46: Check Cooling System - Efficiency Of The Cooling System

During flight test the place with the highest cylinder head temperature must be found, this can vary with different engine installation (cowling or free installation, tractor or pusher, fight speed etc.). Effectivity: 914 Series page 46 Edition 2 / Rev. 0... - Page 47 If fluid volume is lost and the probe is not fully submerged in the fluid the display could show a lower temperature than actual (measuring air temperature instead of fluid temperature). Effectivity: 914 Series page 47 Edition 2 / Rev. 0 July 01/2008...

-

Page 48: Determination Of Operating Limits, Coolant And Necessary Modification On Radiator Installation

This is possible by calculating the difference between the head material and the coolant temperature. This is done by following the flight test procedure on page 47. Effectivity: 914 Series page 48 Edition 2 / Rev. 0 July 01/2008... - Page 49 128 °C (262 °F). ■ CAUTION: The design of the radiator installation must be changed (example: cowl modifications), such that the operating temperature will not exceed the specified limits. Effectivity: 914 Series page 49 Edition 2 / Rev. 0 July 01/2008...

-

Page 50: Requirements On The Cooling System

▲ WARNING: The size and layout of the cooling system must be designed to keep the heat of the operating temperatures within the specified limits. To minimize flow resistance employ a radiator with low flow resistance and parallel flow as realized on the original BRP-Rotax radiator and use short hoses and pipelines. Coolant hoses: temperature durability: min. -

Page 51: Size And Position Of Connections

The aircraft manufacturer has to carry out the check of coolant level in the expansion tank and note it in the daily inspection section of his flight manual according latest issue of Operators Manual ROTAX 914. It is recommended to make adequate precautions for accomplishment of these inspections, e.g. - Page 52 200± 10 mm 252± 5 mm Fig.19 07136 ◆ NOTE: The picture shows ROTAX 912 Series, but the location of the expan- sion tank is identical as on ROTAX 914 Series. Effectivity: 914 Series page 52 Edition 2 / Rev. 0...

-

Page 53: Water Inlet Bend

M6x20 and lock washers. Tighten screws to 10 Nm (90 in.lb.). ■ CAUTION: Utilize total slip-on length for hose connection. Secure hoses with suitable spring type clamp or screw clamp. Effectivity: 914 Series page 53 Edition 2 / Rev. 0 July 01/2008... -

Page 54: Requirements, Feasible Location And Fitting Position Concerning Radiator/ Expansion Tank/Overflow Bottle

Additionally the system needs an overflow bottle (7) where surplus coolant is collected and returned back into the circuit at the cooling down period. Effectivity: 914 Series page 54 Edition 2 / Rev. 0 July 01/2008... -

Page 55: Overflow Bottle

Protection by insulation, or routing in a hose with hot air flow or by furnishing the vent line with a bypass opening (slot) (6) before passing through cowling (7). See Fig. 23 to Fig. 27. 09132 Fig. 23 Effectivity: 914 Series page 55 Edition 2 / Rev. 0 July 01/2008... - Page 56 Make sure the hose (5) has no kinks. Route it overboard and secure. LOCTITE Ø 6mm (0. 236 in) ® 05294 Fig. 24 05295 Fig. 25 11,5mm (0.453 in) 05033 05039 Fig. 26 Fig. 27 Effectivity: 914 Series page 56 Edition 2 / Rev. 0 July 01/2008...

-

Page 57: General Directives For The Cooling System

INSTALLATION MANUAL 12.9) General directives for the cooling system See Fig. 28. BRP-Rotax offers essential parts of the cooling system for this engine such as radiator, etc.. ▲ WARNING: Certification to the latest requirements to FAR or EASA has to be conducted by the aircraft manufacturer. - Page 58 Install the radiator without distortion or stressand free of vibrations (rubber mounts are recommended). At installation of a non-original ROTAX radiator take care of sufficient cooling capacity. See section 12.7 To achieve the best possible cooling effect via the venting of the cooler it is recommended to install a proper elastic sealing as a link to the cowling or to an air duct.

-

Page 59: Coolant Capacity

This must also be warranted at "hot day conditions"! Max. permissible cylinder wall temperature on cylinder 2 ..... 200 °C (392 °F) (see Fig. 29) Schraube / screw M5 02050 Fig. 29 Effectivity: 914 Series page 59 Edition 2 / Rev. 0 July 01/2008... -

Page 60: 1)General Directives For Ducting Of The Cooling Air

In special cases a separate cold air supply to the air intake filters has to be provided. BRP-Rotax has developed especially for this application a non-certified cooling air ducting. to be conducted by the aircraft manufacturer. -

Page 61: Data For Optional Components Of Cooling System

15 (0.59 in) (-11.81 in) (-1.18 in) (-0.55 in) engagement (mm) 12.12)Data for optional components of cooling system overflow bottle See Fig. 30. 09148 Fig. 30 Effectivity: 914 Series page 61 Edition 2 / Rev. 0 July 01/2008... - Page 62 See Fig. 32. weight: see section 8. 09165 Fig. 32 ◆ NOTE: The gap between cowling and radiator should be covered by appropriate sealing lips for better efficiency of cooling. Effectivity: 914 Series page 62 Edition 2 / Rev. 0 July 01/2008...

-

Page 63: Lubrication System

13) Lubrication system 13.1) Description of the system See Fig. 33. The ROTAX 914 engine is provided with a dry sump forced lubrication system with a main oil pump with integrated pressure regulator and an additional suction pump. ◆ NOTE: The oil pumps are driven by the camshaft. -

Page 64: Limits Of Operation

Advantages: safe oil pressure after cold start, prevention of fuel and water accumulation in the oil. See therefore SL-914-009 "Use of an oil thermostat", latest issue. Effectivity: 914 Series page 64 Edition 2 / Rev. 0 July 01/2008... -

Page 65: Checking Of The Lubrication System

◆ NOTE: The required pressure gauges and connection parts are not included in the ROTAX engine delivery. 13.3.1) Measuring of the vacuum Measuring of vacuum in the oil suction line (1) (line from oil tank to oil pump via oil cooler) at a max. -

Page 66: 2) Measuring Of The Pressure In The Crankcase

(contamination, restrictions of cross-section etc.) is too high. This condition is unsafe and must be rectified without delay. max. 0,45 bar above atmospheric pressure Fig. 35 08324 Effectivity: 914 Series page 66 Edition 2 / Rev. 0 July 01/2008... -

Page 67: Requirements On The Oil- And Venting Lines

Protection by insulation, or routing in a hose with hot air flow or by furnishing vent line with a bypass opening (1) before passing through cowling (2). See Fig. 36. Effectivity: 914 Series page 67 Edition 2 / Rev. 0... -

Page 68: Connecting Dimensions And Location Of Connections

Tightening torque:..... 25 Nm (18.5 ft.lb) Fig. 37 02468 Oil pump inlet nipple (2): outside dia ..13,2 mm (0.52 in.) slip-on length ..max. 21 mm (0.83 in.) Fig. 38 00226 Effectivity: 914 Series page 68 Edition 2 / Rev. 0 July 01/2008... - Page 69 BRP-Rotax INSTALLATION MANUAL Ölpumpe (inlet) (3): thread 3/4-16 UNF (AN-8) Tightening torque of the inlet line:..25 Nm (18.5 ft.lb) Fig. 39 02468 Effectivity: 914 Series page 69 Edition 2 / Rev. 0 July 01/2008...

- Page 70 Tightening torque of banjo bolt (3) M16x1,5x28: ..35 Nm (25.8 ft.lb) connection with screw connection (2) (optional): thread ........3/4-16 UNF (AN-8) Tightening torque of oil return line: ....25 Nm (18.5 ft.lb) Fig. 40 09175 Effectivity: 914 Series page 70 Edition 2 / Rev. 0 July 01/2008...

-

Page 71: 2) Oil Circuit (Turbo Charger)

....... 8 mm (.31 in) slip-on length ......max. 20 mm (.79 in) Tightening torque of banjo bolt (5) M10x1x19: ..15 Nm (133 in.lb) Fig. 41 02468 Effectivity: 914 Series page 71 Edition 2 / Rev. 0 July 01/2008... -

Page 72: 3) Oil Tank

(13). This screw plug has to be removed and is replaced by the hose nipple (10), sealing ring (14) 10x14 DIN 7603 and banjo bolt (11). Effectivity: 914 Series page 72 Edition 2 / Rev. 0 July 01/2008... -

Page 73: Effectivity: 914 Series Page

BRP-Rotax INSTALLATION MANUAL to oil cooler -> to oil pump (engine) ø165 from oil pump (turbolcharger) 02470 Fig. 42 ø139,2 from engine 02469 Fig.43 08397 08399 Fig. 43/1 Effectivity: 914 Series page 73 Edition 2 / Rev. 0 July 01/2008... -

Page 74: Feasible Position And Location Of The Oil Tank

Install the oil tank free of vibrations and not directly to the engine. Oil tank cover (3) and oil drain screw (4) to be easily accessible. Fig. 44 08410 Effectivity: 914 Series page 74 Edition 2 / Rev. 0 July 01/2008... -

Page 75: Feasible Position And Location Of The Oil Cooler

If need be, take appropriate measures like changing size of cooler, partial covering of cooler etc. 13.8) General notes on oil cooler BRP-Rotax offers for this engine an oil cooler (see Illustrated Parts Catalog, latest issue). ▲ WARNING: Certification of this cooler to the latest requirements such as FAR or EASA has to be conducted by the aircraft manufacturer. -

Page 76: Venting (Purging Or Priming) Of Lubrication System

60 turns. ■ CAUTION: Do not use starter for this purpose. Fit propeller and use it to turn engine. Release the pressure from the oil tank. Effectivity: 914 Series page 76 Edition 2 / Rev. 0 July 01/2008... -

Page 77: 1)Venting (Purging Or Priming) Of Turbocharger Lubrication System

Operators Manual (or SI-27-1997 Oil level check for ROTAX engine type 912 and 914 (Series), current issue). Add oil to engine oil tank to bring the oil level up to the full mark on the dipstick. -

Page 78: Inspection For Correct Venting (Priming) Of Hydraulic Valve Tappets

5 min. at 3500 rpm after refitting the valve covers is necessary. To get the hydraulic valve tappets primed, this process can be repeated another 2 times. Effectivity: 914 Series page 78 Edition 2 / Rev. 0... -

Page 79: Replacement Of Components

08413 Fig. 45 pressure..max. 1 bar (15 psi) max. 0,5 mm (0,02 in.) to oil pump (1) 05446 Fig. 46 back from engine (2) 05448 Effectivity: 914 Series page 79 Edition 2 / Rev. 0 July 01/2008... -

Page 80: Data For Optional Components Of Oil System

(6) (straight socket): outside dia ........ 12 mm (0.47 in.) slip-on length ......max. 24 mm (max. 0.94 in) Tightening torque:..... 25 Nm (18.5 ft.lb) Effectivity: 914 Series page 80 Edition 2 / Rev. 0 July 01/2008... - Page 81 BRP-Rotax INSTALLATION MANUAL 04910 Fig. 47 B: LOCTITE 243 Effectivity: 914 Series page 81 Edition 2 / Rev. 0 July 01/2008...

- Page 82 BRP-Rotax INSTALLATION MANUAL NOTES Effectivity: 914 Series page 82 Edition 2 / Rev. 0 July 01/2008...

-

Page 83: Fuel System

The fuel system includes the following items: tank coarse filter fine filter/watertrap fuel shut off valve 2 electric fuel pumps as well as the required fuel lines and connections Effectivity: 914 Series page 83 Edition 2 / Rev. 0 July 01/2008... - Page 84 Feeding lines to suction side of the electric fuel pumps (2) Lines from pressure side of the electric fuel pump to inlet of fuel pressure control (3) Returnline from fuel pressure control to fuel tank Effectivity: 914 Series page 84 Edition 2 / Rev. 0...

-

Page 85: Operating Limits

▲ WARNING: Fuel pressure in excess of stated limit can lead to an override of the float valve with subsequent engine stop. ◆ NOTE: On the standard engine no connection is provided for measuring the fuel pressure. See section 14.5. Effectivity: 914 Series page 85 Edition 2 / Rev. 0 July 01/2008... -

Page 86: Requirements Of The Fuel System

If you should encounter problems in this respect during the test period, than the affected components such as the supply line to the fuel pumps have to be cooled. Effectivity: 914 Series page 86 Edition 2 / Rev. 0... -

Page 87: Connecting Dimensions, Location Of Joints And Directives For Installation

ø 8 running-in period approx. 30 min. ø0,32 in. ◆ NOTE: A capacity increase of approx. 20% is feasible by running- ø 9 ø0,35 in. in process. Effectivity: 914 Series page 87 Edition 2 / Rev. 0 July 01/2008... - Page 88 BRP-Rotax INSTALLATION MANUAL ■ CAUTION: Employ GENUINE-ROTAX fuel pumps only. Non-compliance will release BRP-Rotax from any liability. Place of installation: Installation of the fuel pumps principally near the fuel tank to gain advantage of a cool location, especially important at tendency of vapour locks.

-

Page 89: 2) Check Valve

Any arrows shown on top of the fuel pressure control are of no significance for this application. carburetor to tank from fuel pump carburetor Fig. 51 05740 Effectivity: 914 Series page 89 Edition 2 / Rev. 0 July 01/2008... -

Page 90: Notes On Checking Of Fuel Pressure

1/3 (1). This ring hose nipple may be also fitted on the fuel line 2/4 (7), but not on the outlet (5) and inlet (6). All the necessary items are available as spare parts. 02476 Fig. 52 Effectivity: 914 Series page 90 Edition 2 / Rev. 0 July 01/2008... -

Page 91: Carburetor

If necessary install additional insulation or heat shields. Certification to the latest requirements such as FAR or EASA has to be conducted by the aircraft manufacturer. Effectivity: 914 Series page 91 Edition 2 / Rev. 0 July 01/2008... -

Page 92: 1) Drainage Pipelines To Airbox And Trip Tray

RISK OF FIRE! Connecting nipple (2) and (P2) for leakage line outside dia. ø 6 mm (1/4") slip on length max. 17 mm (11/16") 08415 Fig. 54 Effectivity: 914 Series page 92 Edition 2 / Rev. 0 July 01/2008... -

Page 93: Connections For Bowden-Cable Actuation And Limit Load

Directive for choke actuation The choke shaft (3) is marked (4). This mark has to point towards cable engagement (5). 0,09 in. 0,21 in. 05089 Fig. 56 Fig. 55 08415 Effectivity: 914 Series page 93 Edition 2 / Rev. 0 July 01/2008... -

Page 94: Requirements On Cable Actuation

(1) or fit a stronger return spring, (2) or a cable with pull-push action would have to be used. Secure the bowden cable sleeves (3) in the adjustment screws (4) (e.g. safety wire) Effectivity: 914 Series page 94 Edition 2 / Rev. 0 July 01/2008... -

Page 95: Requirements On The Throttle Lever

Adjustable positive stops for idle- and full throttle position are of course required. These stops have to be designed such to render adjustibility and to prevent overload of the idle stop on the carburetor. Effectivity: 914 Series page 95 Edition 2 / Rev. 0 July 01/2008... -

Page 96: Location And Determination Of The Throttle Position For Max. Continuous Power

The exact determination is achieved electronically by a PC program especially developed for this engine. For further details refer to the corresponding Maintenance Manual, section "Control system of the turbo charger". Effectivity: 914 Series page 96 Edition 2 / Rev. 0 July 01/2008... -

Page 97: Air Intake System

In the course of certification the fuel mixture process must be proofed by a CO-measurement. Effectivity: 914 Series page 97 Edition 2 / Rev. 0... -

Page 98: Requirements On The Air Intake System

Air temperature above the limit will automatically reduce boost pressure with consequent performance loss. The automatic back off on boost pressure will protect the engine against damage from overstressing. Effectivity: 914 Series page 98 Edition 2 / Rev. 0 July 01/2008... -

Page 99: 2) Requirements On The Intercooler

No additional forces or moments are allowed on turbo charger or airbox, therefore the intercooler has be supported inde- pendent and free of vibrations. Ladeluftkühler (Intercooler) 08416 Fig. 59 Effectivity: 914 Series page 99 Edition 2 / Rev. 0 July 01/2008... -

Page 100: 3) Airfilter

▲ WARNING: Use only filter elements which will not tend to restrict the flow when in contact with water. BRP-Rotax offers an air filter as described below. ▲ WARNING: The certification to the latest requirement such as FAR and EASA has to be conducted by the aircraft manufacturer. - Page 101 Location of connecting nipple P2: axis 04878 connecting x-axis y-axis z-axis nipple cylinder side 1/3 -568 -180 Fig. 61 cylinder side 2/4 -590 08415 Effectivity: 914 Series page 101 Edition 2 / Rev. 0 July 01/2008...

-

Page 102: Additional Notes Concerning Air Intake System

BRP-Rotax INSTALLATION MANUAL 16.3) Additional notes concerning air intake system Air filter See Fig. 62. - Weight: see sec. 8 09149 Fig. 62 Effectivity: 914 Series page 102 Edition 2 / Rev. 0 July 01/2008... -

Page 103: Pressure Sensors

To avoid any mix-up of pressure sensor wiring, plug connections are colour coded. grey plug connection (2) ➪ static pressure sensor black plug connection (3) ➪ airbox pressure sensor Fig. 64 08417 Effectivity: 914 Series page 103 Edition 2 / Rev. 0 July 01/2008... -

Page 104: Static Pressure Sensor

Location of installation is limited by the length of the wiring harness. length of cable assy.: approx. 250 mm (10 in.) from TCU. ø3 ø0,12 in. ø4,7 ø0,19 in. 60° 60° 0,95 in. Fig. 65 05091 0,83 in. Effectivity: 914 Series page 104 Edition 2 / Rev. 0 July 01/2008... -

Page 105: Servo Motor/Servo Cable

INSTALLATION MANUAL 18) Servo motor/Servo cable See Fig. 66/67. The correct adjustment of the servo cable (1) and consequently the waste gate (2) was made already on the course of the testrun at BRP-Rotax. Fig. 66 04853 18.1) Servo motor Prior to engine operation check the position of the waste gate as follows: ▲... -

Page 106: Servo Cable

140 °C (284 °F) ■ CAUTION: All temperature limits must be verified at the first time of installation of the ROTAX 914 into an airframe, or at any modification of the airframe as it may influence such temperatures. 65 mm 35 mm (2,6 in.) -

Page 107: Electric System

Optional extras - external alternator (as option if the output of the integrated generator is inadequate) - electric tachometer (accessory) - appliance (battery) not supplied by BRP-Rotax Effectivity: 914 Series page 107 Edition 2 / Rev. 0... -

Page 108: Requirements On Circuit Wiring

RT CA DO-160C, sections 18, 20-22 and IEC 801-2. The following EMC/EMI tests were performed: Radio frequency Susceptibility (conducted) Radio frequency Susceptibility (radiated) Audio Frequency Susceptibility Lightning Susceptibility Conducted RF Interference Radiated RF Interference Effectivity: 914 Series page 108 Edition 2 / Rev. 0 July 01/2008... -

Page 109: Wiring Diagram

Items 1-20, 52-54 are included in the standard volume of supply of the engine Items 21-25 are available as accessory Items 30-51 can't be supplied by BRP-Rotax ▲ WARNING: The certification of items/components which are not included in the standard volume of supply of engine has to be conducted by the aircraft manufacturer to the latest requirements such as FAR or EASA. - Page 110 BRP-Rotax INSTALLATION MANUAL Fig. 69 08317 Effectivity: 914 Series page 110 Edition 2 / Rev. 0 July 01/2008...

-

Page 111: Description Of The Turbo Control Unit (Tcu)

BRP-Rotax INSTALLATION MANUAL 19.3) Description of the Turbo Control Unit (TCU) See latest Operators Manual 914 Series, section 9.5. 19.4) Technical data and connection of the electric components 19.4.1) Integrated generator See Fig. 70 Feeding wires (1) from the generator to rectifier-regulator on left side of ignition housing (see Fig. -

Page 112: 2) Rectifier-Regulator

Description of connections: yellow - from generator red - to battery, positive terminal +B = battery positive terminal warning lamp circuit control or field circuit Fig. 71 09168 Effectivity: 914 Series page 112 Edition 2 / Rev. 0 July 01/2008... - Page 113 The graph current over engine speed has been determined and is valid only at the following conditions. ambient temperature: ..20 °C (68 °F) voltage: ......permanent 13,5 V tolerance: ......max ± 5% Effectivity: 914 Series page 113 Edition 2 / Rev. 0 July 01/2008...

-

Page 114: 3) Electronic Modules

3,96 mm. At the new version the cable grommet and fasten connector are integrated in the 6-pole connector housing. See also SI-914-016, latest issue. Effectivity: 914 Series page 114 Edition 2 / Rev. 0 July 01/2008... - Page 115 Check for tight fit. 08323 Fig. 74 ◆ NOTE: Faston connector and insulation sheath of the old version are available as spare part. See also SI-914-016, latest issue. Effectivity: 914 Series page 115 Edition 2 / Rev. 0 July 01/2008...

-

Page 116: 5) Electric Starter

Max. 80 °C (176 °F) temperature range by the electric starter housing. Activate starter for max. 10 sec. (without interruption), followed by a cooling period of 2 min! 02502 Fig.76 Effectivity: 914 Series page 116 Edition 2 / Rev. 0 July 01/2008... -

Page 117: 6) Starter Relay

■ CAUTION: Activation of start relay limited to short duration. Over a period of 4 min. operation, the duty cycle is 25%. Fig. 77 09169 Effectivity: 914 Series page 117 Edition 2 / Rev. 0 July 01/2008... -

Page 118: 7) Electric Fuel Pumps

Graph is effective on a seasoned pump only, running-in period approx. 30 min. Fuse: Each of the two fuel pumps has to be protected by y slow blowing 5A fuse in accordance with wiring diagram (Fig. 69). Effectivity: 914 Series page 118 Edition 2 / Rev. 0 July 01/2008... -

Page 119: 8) Turbo Control Unit (Tcu)

▲ WARNING: If the standard attachment should not be utilized or changed, certification to the latest requirements such as FAR or EASA has to be conducted by the aircraft manufacturer Effectivity: 914 Series page 119 Edition 2 / Rev. 0... - Page 120 ▲ WARNING: The TCU comprises electronic components and is therefore completely sealed. The TCU is allowed to be opened only by persons authorized by BRP-Rotax! connections:+ terminal: flexible cable 0,75 mm (18 AWG) white No. 1* - terminal:flexible cable 0,75 mm (18 AWG) white No.

-

Page 121: 9) Isolating Switch For Servo Motor

To avoid any mix-up of the polarity cut first one wire and connect on switch as per wiring diagram (Fig. 69). After first wire is connected sever second wire and connect also to switch. Effectivity: 914 Series page 121 Edition 2 / Rev. 0... -

Page 122: 10)Boost Lamp

(12 volt), each wire must be connected directly to the lamp. Use a two wire lamp; do not use a lamp that grounds through the base as this will defeat the warning system. Effectivity: 914 Series page 122 Edition 2 / Rev. 0 July 01/2008... -

Page 123: 12)External Alternator (Optional Extra)

(field circuit) (3) and warning lamp circuit (4): via supplied standard plug (Sumitomo 6111-2568) Fig. 81 03199 Cyl. 1 Cyl. 2 Cyl. 3 Cyl. 4 Fig. 82 04902 Effectivity: 914 Series page 123 Edition 2 / Rev. 0 July 01/2008... - Page 124 3 times the prop speed. 1/min. / rpm. n Propeller 1000 1500 2000 2500 rpm. propeller n Generator 2000 3000 4000 5000 6000 7000 8000 00547 rpm. alternator Fig. 83 Effectivity: 914 Series page 124 Edition 2 / Rev. 0 July 01/2008...

-

Page 125: 13)Connection Of The Electric Rev-Counter (Tachometer)

* from the 36 plug receptacle of TCU without plug connection length approx. 1000 mm (40 in) from TCU. ◆ NOTE: BRP-Rotax developed especially for this application a non- certified electric rev counter. Certification to the latest require- ments such as FAR or EASA has to be conducted by the aircraft manufacturer. -

Page 126: 14) Battery

A complete electrical load analysis covering all installed loads must be calculated by the aircraft manufacturer. Effectivity: 914 Series page 126 Edition 2 / Rev. 0 July 01/2008... -

Page 127: Propeller Drive

0,5 gm (.043 lb.in.) max. extension of the propeller shaft: 120 mm (4.72 in.) ■ CAUTION: No modification of propeller shaft is permitted. Effectivity: 914 Series page 127 Edition 2 / Rev. 0 July 01/2008... - Page 128 If there are no limits found in the technical literature, a max. of 0,1 IPS (inches per second) at 5000 rpm. can be assumed. 02581 120 mm (4.72 in.) Fig. 85 09193 02581 Effectivity: 914 Series page 128 Edition 2 / Rev. 0 July 01/2008...

-

Page 129: Vacuum Pump

0,54 of engine speed. ▲ WARNING: Certification to the latest requirements such as FAR or EASA has to be conducted by the aircraft manufacturer. 08322 Fig. 86 Effectivity: 914 Series page 129 Edition 2 / Rev. 0 July 01/2008... - Page 130 BRP-Rotax INSTALLATION MANUAL Fig. 87 08328 Effectivity: 914 Series page 130 Edition 2 / Rev. 0 July 01/2008...

-

Page 131: Hydraulic Governor For Constant Speed Propeller

22) Hydraulic governor for constant speed propeller 22.1) Technical data See Fig. 88 ◆ NOTE: See therefore also SB-914-035 "Installation/Use of governors for Rotax engine type 912 and 914", latest issue. drive via prop gear location of the necessary connection on the crankcase:... - Page 132 BRP-Rotax INSTALLATION MANUAL Fig. 88 08179 Effectivity: 914 Series page 132 Edition 2 / Rev. 0 July 01/2008...

-

Page 133: Connections For Instrumentation

(°C) ■ CAUTION: The graph resistance over temperature has been determined, and is effective at the following conditions only. ambient temperature: 20 °C (68 °F) tolerance: ± 10% Effectivity: 914 Series page 133 Edition 2 / Rev. 0 July 01/2008... -

Page 134: Sensor For Oil Temperature

20 °C (68 °F) tolerance: ± 15% BRP-Rotax offers a non-certified temperature indicating instrument. Refer to Illustrated Parts Catalog, latest issue. ▲ WARNING: Certification to the latest requirements such as FAR of EASA has to be conducted by the aircraft manufacturer. -

Page 135: Oil Pressure Sensor

12 V tolerance: ± 5% BRP-Rotax offers a non-certified pressure gauge. Refer to Illustrated Parts Catalog, latest issue. ▲ WARNING: Certification to the latest requirements such as FAR of EASA has to be conducted by the aircraft manufacturer. (Ω) Fig. -

Page 136: Mechanical Rev-Counter (Tach Drive)

-465 -160 M18x1, Fig. 96 05483 Fig. 95 00562 2,6 (0,102 in) installation dimensions: see Fig. reduction ratio: i = 4 i.e. 1/4 of engine speed Effectivity: 914 Series page 136 Edition 2 / Rev. 0 July 01/2008... -

Page 137: Monitoring Of The Intake Manifold Pressure

◆ NOTE: For in-flight variable pitch propellers and constant speed propellers a manifold pressure gauge must be fitted permanently in the cockpit. Effectivity: 914 Series page 137 Edition 2 / Rev. 0 July 01/2008... -

Page 138: Air Temperature In The Airbox (Optional)

To take air temperature readings in the airbox a connection is provided. This connection is closed on the standard engine by a plug screw. connection: tapping 1/8-27 NPT thread length approx. 9 mm (3/8") Fig. 98 05740 Effectivity: 914 Series page 138 Edition 2 / Rev. 0 July 01/2008... -

Page 139: Preparations For Trial Run Of Engine

- Check if other systems and instruments are installed appropriately - Check gauges for accuracy - Check wires routed properly and secured. - Check "P" leads are grounding when switched "OFF" (check with Ohmmeter) Effectivity: 914 Series page 139 Edition 2 / Rev. 0 July 01/2008... - Page 140 ■ CAUTION: Don't conduct any test flights before all faults have been traced and found. Make an entry of the details and test results into the engine log book. Effectivity: 914 Series page 140 Edition 2 / Rev. 0 July 01/2008...

- Page 142 Motornummer / Engine serial no. Flugzeugtype / Type of aircraft Flugzeugkennzeichen / Aircraft registration no. ROTAX® Vertriebspartner ROTAX® authorized distributor www.rotax-aircraft-engines.com ® and TM are trademarks of BRP-Rotax GmbH & Co. KG. © 2006 BRP-Rotax GmbH & Co. KG. All rights reserved.

Need help?

Do you have a question about the 914 series and is the answer not in the manual?

Questions and answers