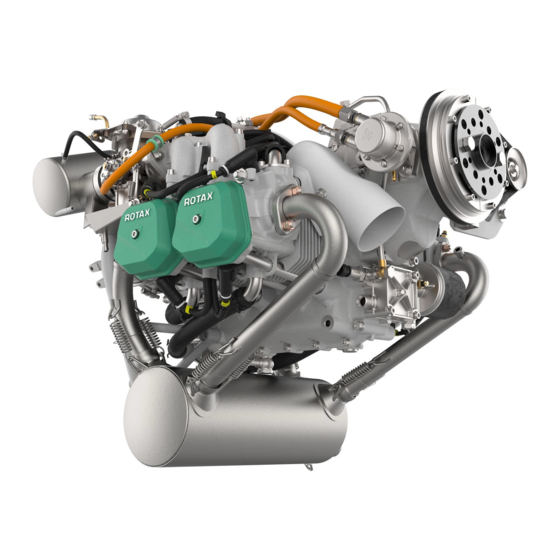

Rotax 912 Series Operator's Manual

Hide thumbs

Also See for 912 Series:

- User manual ,

- Maintenance manual (456 pages) ,

- Installation manual (199 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Rotax 912 Series

- Page 2 GmbH&Co KG, Austria, acc, BGBI 1984 no. 448, and shall not, without prior written permission of BRP-Rotax GmbH&Co KG, be disclosed in whole or in part to third parties. This legend shall be included on any reproduction of these data, in whole or in part.

- Page 3 4 – Abnormal operation Chapter 5 – Performance and Fuel consumption Chapter 6 – Weights Chapter 7 – System Description Chapter 8 – Preservation and storage Chapter 9 – Supplement Effectivity: 912 Serie BRP-Rotax Page Content-1 Edition 4 / Rev. 0 November 01/2016...

- Page 4 NOTES Page Notes-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 5 The structure of the Manual follows whenever it is possible the structure of the „GAMA Specification #1 for Pilot’s Operating Handbook“. Foreword BRP-Rotax GmbH & Co KG (hereinafter “BRP-Rotax”) provides “Instructions of Continued Airworthiness”, which are based on the design, the tests and certification of the engine and its components.

- Page 6 NOTES Page Notes-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 7 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Effectivity: 912 Serie BRP-Rotax Page LEP-1 Edition 4 / Rev. 0 November 01/2016...

- Page 8 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 Nov. 01 2016 rear Nov. 01 2016 page Nov. 01 2016 Page LEP-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 9 INTRO Nov. 01 2016 DOA* Nov. 01 2016 DOA* Nov. 01 2016 DOA* 1 up to 9 Nov. 01 2016 DOA* Effectivity: 912 Serie BRP-Rotax Page TOA-1 Edition 4 / Rev. 0 November 01/2016...

- Page 10 Summary of the relevant amendments in this context, but without any claim to completeness. page current no. chapter date of comments change 1 up to 9 Nov. 01 2016 new layout and change of company name Page TOA-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 11 If any passages of the Manual are not clearly understood or in case of any questions, please contact an ROTAX® authorized aircraft engines distributors or their independent service center. BRP-Rotax wishes you much pleasure and satisfaction flying your aircraft powered by this ROTAX®-aircraft engine.

- Page 12 For additional information on engines, maintenance or parts, you can also contact your nearest ROTAX® authorized aircraft engines distributor or their independent service center. Engine serial When making inquiries or ordering parts, always indicate the...

- Page 13 Air Transport Association American Wire Gauge Control Area Network Coil 1–4 Ignition coils 1–4 CPS 1+2 Crankshaft Position Sensor 1+2 Constant Speed Actuator Cooling Temperature Sensor clockwise counter-clockwise Effectivity: 912 Serie BRP-Rotax Page 1-3 Edition 4 / Rev. 0 November 01/2016...

- Page 14 HIC B Harness Interface Connector B Instrument Flight Rules INJ 1–8 Injector 1–8 Illustrated Parts Catalog inch per second iRMT independent ROTAX Maintenance Technician Table of content International Standard Atmosphere Kilograms KNOCK Knock sensor MAPS 1+2 Manifold Air Pressure Sensor 1+2...

- Page 15 Production Organisation Approval PTFE Polytetrafluoroethylene Power Take Off Rev. Revision ROTAX® is a trademark of BRP-Rotax GmbH & Co KG Research Octane Number s.v. still valid (only Illustrated Parts Catalog) Serial Number Society of Automotive Engineers Service Bulletin Service Instruction...

- Page 16 Visual Flight Rules List of Effective Pages Maintenance Manual shows the serial component number Page 1-6 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 17 The information and descriptions of components and systems contained in this Manual are correct at the time of publication. BRP-Rotax maintains a policy of continuous improvement of its products without imposing upon itself any obligation to retrofit products previously manufactured.

- Page 18 ENVIRONMENT NOTE Environmental notes give you tips on environmental protection. A revision bar outside the page margin indicates a change to text or graphic. Page 1-8 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 19 • Due to the varying designs, equipment and types of aircraft, BRP-Rotax grants no warranty on the suitability of its engines use on any particular aircraft. Further, BRP-Rotax grants no warranty on this engines suitability with any other part, com- ponents or system which may be selected by the aircraft manufacturer, assembler or user for aircraft application.

- Page 20 Instrumentation • Select and use proper aircraft instrumentation. This instru- mentation is not included in the ROTAX® engine package. Verification to the latest regulations such as FAR or EASA has to be conducted by the aircraft manufacturer.

- Page 21 • This engine may be equipped with a vacuum pump. The safety warning accompanying the vacuum pump must be giv- en to the owner/operator of the aircraft into which the vacuum pump is installed. Effectivity: 912 Serie BRP-Rotax Page 1-11 Edition 4 / Rev. 0 November 01/2016...

- Page 22 Reference Any reference to a document refers to the latest edition issued by BRP-Rotax if not stated otherwise. Illustrations The illustrations in this Manual are merely sketches and show typical arrangements.

- Page 23 The Illustrations in this Manual are stored in a graphic data base system and are provided with a consecutive irrelevant number. This number (e.g. AE 5iS001) is of no significance for the content. Effectivity: 912 Serie BRP-Rotax Page 1-13 Edition 4 / Rev. 0 November 01/2016...

- Page 24 Components especially developed and tested for this engine are readily available at BRP-Rotax. Auxiliary equip- The following auxiliary equipment has been developed and ment certified tested for this engine.

- Page 25 The following auxiliary equipment has not been developed and ment not certified tested for this engine. • Exhaust system • Intake filter • Mechanical rev counter • Shock mount Effectivity: 912 Serie BRP-Rotax Page 1-15 Edition 4 / Rev. 0 November 01/2016...

- Page 26 2 for configura- tion 3 NOTE Conversion of the configuration 2 to configuration 3 may be ac- complished by ROTAX® authorized aircraft engines distributors or their Independent service centers. Page 1-16 BRP-Rotax Effectivity: 912 Serie November 01/2016...

- Page 27 Cyl.1 Cyl.3 Top view Cyl.2 Cyl.4 Figure .3: Top view engine Engine serial number CD carburetor Expansion tank with excess Electric starter pressure valve Exhaust flange External alternator Effectivity: 912 Serie BRP-Rotax Page 1-17 Edition 4 / Rev. 0 November 01/2016...

- Page 28 At 75 % continuous 16.2 l/h (4.3 gal/h) 18.5 l/h (4.9 gal/h) performance Specific consumption 285 g/kWh (0.47 lb/ 285 g/kWh (0.47 lb/ at max. continuous hph) hph) performance Page 1-18 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 29 1.11) Direction of rotation Direction of Direction of rotation on propeller shaft: counter clockwise, rotation viewed from the front. Figure .5: Normal direction of propeller rotation (engine) Effectivity: 912 Serie BRP-Rotax Page 1-19 Edition 4 / Rev. 0 November 01/2016...

- Page 30 NOTES Page Notes-20 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 31 912 A JAR 22 (TC No. EASA.E.121), 912 F/S FAR 33 (TC No. E00051 EN), JAR-E (TC No. EASA.E. 121). This chapter of the Operators Manual contains the operating limits that must be observed to ensure the ROTAX® aircraft engine and standard systems operate safely. Effectivity: 912 Serie...

- Page 32 90 to 110 °C (190-230 °F) 912 UL to S/N 4 402 387/912 A to S/N 4 410 266 /912 F to S/N 4 412 764 Page 2-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 33 912 A/F/UL Permanent monitoring of coolant temperature is necessary. Engine start, oper- ating temperature Max. 50 °C (120 °F) (ambient temperature) Min. -25 °C (-13 °F) (oil temperature) Effectivity: 912 Serie BRP-Rotax Page 2-3 Edition 4 / Rev. 0 November 01/2016...

- Page 34 Max. 40° NOTE Up to this value the dry sump lubrication system warrants lubri- cation in every flight situation. applicable only for fuel pump from S/N 11.0036 Page 2-4 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 35 Oil pressure max. for a short period admissible at cold start. Oil temperature Oil temperature Max. 130 °C (266 °F) Min. 50 °C (120 °F) normal operating temperature: approx. 90 to 110 °C (190-230 °F) Effectivity: 912 Serie BRP-Rotax Page 2-5 Edition 4 / Rev. 0 November 01/2016...

- Page 36 912 S/ULS Permanent monitoring of coolant temperature is necessary. Engine start, oper- ating temperature Max. 50 °C (120 °F) (ambient temperature) Min. -25 °C (-13 °F) (Oil temperature) Page 2-6 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 37 Max. 40° NOTE Up to this value the dry sump lubrication system warrants lubri- cation in every flight situation. applicable only for fuel pump from S/N 11.0036 Effectivity: 912 Serie BRP-Rotax Page 2-7 Edition 4 / Rev. 0 November 01/2016...

- Page 38 Applicable for engine S/N with Suffix -01. Mixture ratio % Designation Concentrate Water conventional e.g. BASF Glysantine anticorrosion * coolant component can be increased up to max. 65 %. Page 2-8 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 39 AVGAS 100LL places greater stress on the valve seats due to its high lead content and forms increased deposits in the com- bustion chamber and lead sediments in the oil system. Anti Knock Index (RON+MON)/2 Effectivity: 912 Serie BRP-Rotax Page 2-9 Edition 4 / Rev. 0 November 01/2016...

- Page 40 Since the temperature range of neighboring SAE grades over- lubrication lap, there is no need for change of oil viscosity at short duration of ambient temperature fluctuations. Page 2-10 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 41 Figure .1: Temperature range Effectivity: 912 Serie BRP-Rotax Page 2-11 Edition 4 / Rev. 0 November 01/2016...

- Page 42 NOTES Page Notes-12 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 43 The following description of procedures depends on the respective type of installation in the aircraft and shall therefore only be seen functionally. Effectivity: 912 Serie BRP-Rotax Page 3-1 Edition 4 / Rev. 0 November 01/2016...

- Page 44 The coolant level must be between max. and min. mark. ENVIRONMENT NOTE Protect the environmental! Never spill any coolant. Dispose of the coolant in an environmentally sound way! Page 3-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 45 Expansion tank Figure .1: Expansion tank Radiator cap Expansion tank Overflow bottle coolant Figure .2: Overflow bottle Overflow bottle Coolant Effectivity: 912 Serie BRP-Rotax Page 3-3 Edition 4 / Rev. 0 November 01/2016...

- Page 46 Verify free movement of throttle cable and starting car- buretor over the complete range. Check from the cockpit. Exhaust system Step Procedure Inspect for damages, leakage and general condition. Page 3-4 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 47 This process is finished when air is returning back to the oil tank and can be noticed by a gurgle from the open oil tank. Check oil level and add oil if necessary. Install bayonet cap. Effectivity: 912 Serie BRP-Rotax Page 3-5 Edition 4 / Rev. 0 November 01/2016...

- Page 48 ATTENTION Do not actuate starter button (switch) as long as the engine is running. Wait until complete stop of engine! Step Designation Procedure Starter button actuate Page 3-6 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 49 For checking the two ignition circuits, only one circuit may be switched off and on at a time. Effectivity: 912 Serie BRP-Rotax Page 3-7 Edition 4 / Rev. 0 November 01/2016...

- Page 50 The propeller speed depends on the actual reduction ratio. Propeller Check of hydraulic propeller governor: governor Check control of the hydraulic propeller governor to specifica- tions of the manufacturer. Page 3-8 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 51 To evaporate possibly accumulated condensation water, at least once a day 100 °C (212 °F) oil temperature must be reached. Effectivity: 912 Serie BRP-Rotax Page 3-9 Edition 4 / Rev. 0 November 01/2016...

- Page 52 Remedy • Intake air pre-heating is the only effective remedy. See Flight Manual supplied by the aircraft manufacturer Icing Icing due to water in fuel. Page 3-10 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 53 • Use non-contaminated fuel (filtered through suede) • Generously sized water separators • Fuel lines routing inclined • Prevent condensation of humidity, i. e avoid temperature dif- ferences between aircraft and fuel Effectivity: 912 Serie BRP-Rotax Page 3-11 Edition 4 / Rev. 0 November 01/2016...

- Page 54 NOTES Page Notes-12 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 55 4.4.2 Oil pressure above permitted range at low ambient temperatures....................5 4.5 Engine on fire or fire in the engine compartment ..................5 4.6 Trouble shooting ................... 6 Effectivity: 912 Serie BRP-Rotax Page 4-1 Edition 4 / Rev. 0 November 01/2016...

- Page 56 Further checks - see Maintenance Manual. The following description of procedures depends on the respective type of installation in the aircraft and shall therefore only be seen functionally. Page 4-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 57 • Carry out an unscheduled maintenance check according to Maintenance Manual Line chapter 05-50-00. Effectivity: 912 Serie BRP-Rotax Page 4-3 Edition 4 / Rev. 0 November 01/2016...

- Page 58 Reduce engine power setting to the minimum necessary and carry out precautionary landing. Oil pressure Oil pressure below minimum - during flight • Check oil system. • A maintenance inspection should be carried out. Page 4-4 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 59 (authorized by the Aviation Authorities). • An entry in the logbook must be made. • A maintenance inspection should be carried out. Effectivity: 912 Serie BRP-Rotax Page 4-5 Edition 4 / Rev. 0 November 01/2016...

- Page 60 Let engine cool down at idling at ap- prox. 2000 rpm. Knocking under load Possible cause Remedy Octane rating of fuel too Use fuel with higher octane rating. low. Page 4-6 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 61 Oil level is increasing Possible cause Remedy Oil too cold during engine Cover oil cooler surface, maintain the operation. oil temperature prescribed. Contamination with diesel Check fuel. fuel. Effectivity: 912 Serie BRP-Rotax Page 4-7 Edition 4 / Rev. 0 November 01/2016...

- Page 62 Oil pressure must be measured at idle at an oil temperature of minimum 50 °C (120 °F). Be sure the oil pressure does not go below minimum at idle. Page 4-8 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 63 Those values need to determined and provided by the aircraft manufacturer. Effectivity: 912 Serie BRP-Rotax Page 5-1 Edition 4 / Rev. 0 November 01/2016...

- Page 64 (Gal/h) in.Hg (7,93) (5,28) (2,64) 3000 4000 5000 5800 rpm Figure .2: Values along propeller curve manifold pressure fuel consumption Page 5-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 65 At deviation of temperature conditions from standard atmos- phere conditions the engine performance to be expected can be calculated from the performance indicated, multiplied by standard temperature, divided by actual temperature in K. Effectivity: 912 Serie BRP-Rotax Page 5-3 Edition 4 / Rev. 0 November 01/2016...

- Page 66 Figure .3: Performance graphs 912 A/F/UL Page 5-4 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 67 Benzinverbrauch fuel consumption 5800 2500 3000 3500 4000 4500 5000 5500 Drehzahl/Engine speed [1/min / rpm] Figure .5: Performance graphs Motor 912 S/ULS Effectivity: 912 Serie BRP-Rotax Page 5-5 Edition 4 / Rev. 0 November 01/2016...

- Page 68 44.6 / 60 88.7 / 65.42 55 % 4300 38.0 / 50 84.3 / 62.17 NOTE Further essential information regarding engine behavior see Service Letter SL-912-016, latest edition. Page 5-6 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 69 °K. Figure .6: Performance graph Effectivity: 912 Serie BRP-Rotax Page 5-7 Edition 4 / Rev. 0 November 01/2016...

- Page 70 NOTES Page Notes-8 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 71 0.8 kg (1.8 lb) Overload clutch 1.7 kg (3.7 lb) NOTE The overload clutch is installed on all certified aircraft engines and on non-certified aircraft engines of the configuration 3. Effectivity: 912 Serie BRP-Rotax Page 6-1 Edition 4 / Rev. 0 November 01/2016...

- Page 72 NOTES Page Notes-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 73 The aircraft manufacturers Operators Manual is therefore definitive in terms of the operation of the engine, as it contains all the aircraft specific instructions. Effectivity: 912 Serie BRP-Rotax Page 7-1 Edition 4 / Rev. 0 November 01/2016...

- Page 74 Reading are taken on measuring point of the hottest cylinder ture measuring head, depending on engine installation. NOTE The temperature sensors are located in cylinder head 2 and 3. Page 7-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 75 Figure .1: Cooling system Expansion tank Pressure cap Radiator Overflow bottle Effectivity: 912 Serie BRP-Rotax Page 7-3 Edition 4 / Rev. 0 November 01/2016...

- Page 76 Electrical fuel pump Fuel pressure gauge 1x check valve Restrictor jet Carburetor Return line from engine to tank (with integrated adapter sleeve) Figure .2: Fuel system standard configuration Page 7-4 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 77 Figure .3: Lubrication system Pressure regulator Oil pressure sensor Oil pump Oil tank Oil radiator Oil filter Venting tube Oil temperature sensor (oil) Effectivity: 912 Serie BRP-Rotax Page 7-5 Edition 4 / Rev. 0 November 01/2016...

- Page 78 7.4) Electric system The ROTAX® 912 engine is equipped with a dual ignition unit of a breakeless, capacitor discharge design, with an integrated generator. The ignition unit needs no external power supply. Charging coils Two independent charging coils located on the generator stator supply one ignition circuit each.

- Page 79 3. Figure .5: Overload clutch Fig. shows a propeller gearbox of configuration 2 with the inte- grated overload clutch. Effectivity: 912 Serie BRP-Rotax Page 7-7 Edition 4 / Rev. 0 November 01/2016...

- Page 80 Alternatively either a vacuum pump or a hydraulic governor for hydraulic constant speed propeller can be used. The drive is in each case governor via the propeller reduction gear. Page 7-8 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 81 NOTE Other useful information for service and airworthiness of your engine you'll find on www.rotax-owner.com. ATTENTION Carry out all directives of Service Bulletins (SB), according to their priority.Observe according Service Instructions (SI) and Service Letter (SL).

- Page 82 Conduct checks on the cold engine only! Due to the special material of the cylinder wall, there is no need for extra protection against corrosion for the ROTAX® aircraft engines. At extreme climatic conditions and for long out of serv-...

- Page 83 For longer storage periods repeat preservation annually. Step Procedure Remove all plugs and caps. Clean spark plugs with plastic brush and solvent. Reinstall. Effectivity: 912 Serie BRP-Rotax Page 8-3 Edition 4 / Rev. 0 November 01/2016...

- Page 84 NOTES Page Notes-4 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 85 ROTAX® authorized aircraft engines distributor or their independent service center. NOTE The form is also available from the official ROTAX® AIRCRAFT ENGINES Website in electronic version. Authorized Overview of ROTAX® authorized aircraft engines distributor or Distributor their independent service center.

- Page 86 9.1) Form Figure .1: Form Page 9-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 87 Exceeding engine speed ....3 Exceeding of max. admissible coolant temperature .....4 Re-Start during flight ......3 Exceeding of max. admissible cooling system temperature ..3 Exceeding oil temperature ....4 Effectivity: 912 Serie BRP-Rotax Page Index-1 Edition 4 / Rev. 0 November 01/2016...

- Page 88 Safety notice ......7, 9 Terms ...........3 Standard version ......14 Trouble shooting ......6 Start..........9 Type description ......16 Table of amendments .....1 Weight, Accessories.......1 Take-off.........9 Weights, Engine, Accessories..1 Technical data ......18 Page Index-2 BRP-Rotax Effectivity: 912 Serie November 01/2016 Edition 4 / Rev. 0...

- Page 89 Figure .2: Fuel system (7).............4 Figure .3: Lubrication system (7)...........5 Figure .4: Ignition circuit (7) ............6 Figure .5: Overload clutch (7) ............7 Figure .1: Form (9)...............2 Effectivity: 912 Serie BRP-Rotax Page List of Figures-1 Edition 4 / Rev. 0 November 01/2016...

Need help?

Do you have a question about the 912 Series and is the answer not in the manual?

Questions and answers