Kyocera KM-2035 Service Manual

Hide thumbs

Also See for KM-2035:

- Specifications (42 pages) ,

- Operation manual (150 pages) ,

- Service manual (14 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Kyocera KM-2035

-

Page 1: Service Manual

KM-2035 KM-1635 SERVICE MANUAL Published in October 2005 842HB110 First Edition... - Page 2 CAUTION Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions. CAUTION Double-pole/neutral fusing.

- Page 3 Revision history Revision Date Replaced pages Remarks...

- Page 4 This page is intentionally left blank.

-

Page 5: Safety Precautions

Safety precautions This booklet provides safety warnings and precautions for our service personnel to ensure the safety of their customers, their machines as well as themselves during maintenance activities. Service personnel are advised to read this booklet carefully to familiarize themselves with the warnings and precautions described here before engaging in maintenance activities. - Page 6 Safety warnings and precautions Various symbols are used to protect our service personnel and customers from physical danger and to prevent damage to their property. These symbols are described below: DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect compliance with warning messages using this symbol.

-

Page 7: Installation Precautions

1.Installation Precautions WARNING • Do not use a power supply with a voltage other than that specified. Avoid multiple connections to one outlet: they may cause fire or electric shock. When using an extension cable, always check that it is adequate for the rated current....................•... -

Page 8: Specifications 1

2.Precautions for Maintenance WARNING • Always remove the power plug from the wall outlet before starting machine disassembly....• Always follow the procedures for maintenance described in the service manual and other related brochures............................• Under no circumstances attempt to bypass or disable safety features including safety mechanisms and protective circuits. - Page 9 • Do not remove the ozone filter, if any, from the copier except for routine replacement..... • Do not pull on the AC power cord or connector wires on high-voltage components when removing them; always hold the plug itself...................... •...

- Page 10 This page is intentionally left blank.

-

Page 11: Table Of Contents

2HA/2HB CONTENTS 1-1 Specifications 1-1-1 Specifications............................1-1-1 1-1-2 Parts names............................1-1-3 (1) Copier..............................1-1-3 (2) Operation panel..........................1-1-4 1-1-3 Machine cross section ..........................1-1-5 1-2 Installation 1-2-1 Installation environment ..........................1-2-1 1-2-2 Unpacking and installation ........................1-2-2 (1) Installation procedure ........................1-2-2 1-2-3 Setting initial copy modes ........................1-2-6 1-2-4 Installing the drawer heater (option) .......................1-2-7 1-2-5 Installing the key counter (option) ......................1-2-10 1-3 Maintenance Mode... - Page 12 2HA/2HB 1-5 Assembly and Disassembly 1-5-1 Precautions for assembly and disassembly....................1-5-1 (1) Precautions ............................1-5-1 (2) Drum..............................1-5-1 (3) Toner ..............................1-5-1 (4) Running a maintenance item......................1-5-2 1-5-2 Paper feed section ..........................1-5-3 (1) Detaching and refitting the separation pulley ..................1-5-3 (2) Detaching and refitting the forwarding pulley and paper feed pulley..........1-5-5 (3) Detaching and refitting the paper conveying unit ................1-5-7 (4) Detaching and refitting the MP paper feed pulley and MP separation pad ........1-5-9 (5) Detaching and refitting the registration left roller................1-5-11...

- Page 13 2HA/2HB 2-2 Electrical Parts Layout 2-2-1 Electrical parts layout..........................2-2-1 (1) PWBs ..............................2-2-1 (2) Switches and sensors ........................2-2-2 (3) Motors ...............................2-2-3 (4) Other electrical components......................2-2-4 2-3 Operation of the PWBs 2-3-1 Power source PWB..........................2-3-1 2-3-2 Main PWB ...............................2-3-4 2-3-3 Engine PWB............................2-3-8 2-3-4 Operation unit PWB ..........................2-3-14 2-3-5 CCD PWB .............................2-3-17 2-4 Appendixes...

- Page 14 2HA/2HB This page is intentionally left blank. 1-4-30...

-

Page 15: Specifications

2HA/2HB 1-1 Specifications 1-1-1 Specifications Type ..........Desktop Copying system ......Indirect electrostatic system Originals.......... Sheets, books and 3-dimensional objects (Maximum original size: A3/Ledger) Original feed system ....... Fixed Copy paper ........Paper weights Drawer: 64 to 105 g/m Duplex unit: 64 to 90 g/m MP tray: 45 to 160 g/m Paper type Drawer: Standard paper, recycled paper and color paper... - Page 16 2HA/2HB Standard memory ......Bitmap memory: 18 MB Image storage memory: 14 MB Resolution........Reading: 600 x 600 dpi Writing: 600 x 600 dpi Light source ........Rare gas lamp Dimensions ........574 (W) x 552 (D) x 502 (H) mm "...

-

Page 17: Parts Names

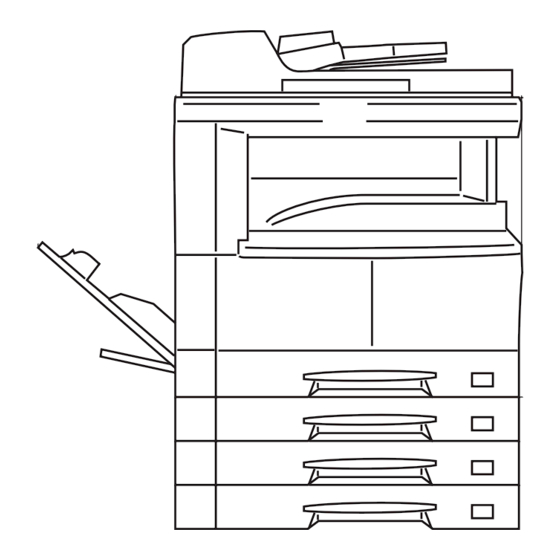

2HA/2HB 1-1-2 Parts names (1) Copier Figure 1-1-2 Original cover 11. Contact glass Output tray 12. Original size indicator plate Operation panel 13. Left cover Drawer 14. Waste toner box Width guide 15. Toner container release lever Length guide 16. Toner container Left cover handle 17. - Page 18 2HA/2HB (2) Operation panel Metric Inch Figure 1-1-3 Start key (Indicator) 20. EcoPrint key Stop/Clear key 21. Auto Exposure key Reset key 22. Exposure adjustment keys (Indicators) Energy Saver key 23. Attention indicator Numeric keys 24. Memory overflow indicator Interrupt key 25.

-

Page 19: Machine Cross Section

2HA/2HB 1-1-3 Machine cross section Light path Paper path Figure 1-1-4 Machine cross section Paper feed section Optical section Drum section Developing section Transfer and separation section Fuser section Exit and switchback section Duplex section 1-1-5... - Page 20 2HA/2HB This page is intentionally left blank. 1-4-30...

-

Page 21: Installation Environment

2HA/2HB 1-2 Installation 1-2-1 Installation environment ° ° Temperature: 10 to 32.5 C/50 to 90.5 Humidity: 15 to 80%RH Power supply: 120 V AC, 9.0 A / 220 to 240 V AC, 5.0 A ± ± Power source frequency: 50 Hz 0.3%/60 Hz 0.3% Installation location... -

Page 22: Unpacking And Installation

2HA/2HB 1-2-2 Unpacking and installation (1) Installation procedure Start Unpacking. Installing the toner (maintenance item U130). Install the optional paper feeder. Load paper. Remove the tapes and pins. Output an own-status report Install the original cover or the optional DP. (maintenance item U000). - Page 23 2HA/2HB Unpacking. Figure 1-2-2 Unpacking Copier 10. Left spacer 19. Original holder (Asia and Power cord 11. Rear spacer Oceania) Toner container 12. Rear pad 20. Operation guide Outer case 13. Skid Cassette size sheet Lower left pad 14. Belt Paper protection bag Lower right pad 15.

- Page 24 2HA/2HB Install the optional paper feeder. 1. Install the optional paper feeder as necessary . Remove the tapes and pins. 1. Remove the eleven tapes. Tapes Tapes Tape Tapes Tape Tapes Figure 1-2-3 2. Remove the two pins for light source unit. Pins Figure 1-2-4 Install the original cover or the optional DP.

- Page 25 2HA/2HB Install the toner container. 1. Hold the new toner container vertically and tap the upper part five times or more. 2. Turn the toner container upside down and tap the upper part five times or more. 3. Shake the toner container up and down five times or more.

-

Page 26: Setting Initial Copy Modes

2HA/2HB Connect the power cord. 1. Connect the power cord to the connector on the copier. 2. Insert the power plug into the wall outlet and turn the power switch on. Installing the toner (maintenance item U130). 1. Enter the maintenance mode by entering "10871087" using the numeric keys. 2. -

Page 27: Installing The Drawer Heater (Option)

2HA/2HB 1-2-4 Installing the drawer heater (option) Drawer heater installation requires the following parts: Drawer heater (P/N 120 V specifications: 2C960030, 220-240 V specifications: 2C960040) One (1) M4 x 10 tap-tight S binding screw (P/N BAB54100) <Procedure> 1. Remove the right cover. 2. - Page 28 2HA/2HB 4. Insert the cassette heater from the bottom of the machine and attach it to the copier. 1) Pass the connector of the cassette heater through the hole located in the right frame of the machine to pull it out. 2) Insert the projections at the rear side of the cassette heater mounting plate into the two holes in the rear frame of the machine.

- Page 29 2HA/2HB 5. Remove the two screws and open the power Wire of the drawer heater source PWB in the direction indicated by the arrow. Take care not to open the power source PWB too much. 6. Fit the wire of the drawer heater into the groove of the frame and put it inside the power source PWB.

-

Page 30: Installing The Key Counter (Option)

2HA/2HB 1-2-5 Installing the key counter (option) Key counter installation requires the following parts: Key counter cover (P/N 2A360010) Key counter retainer (P/N 66060030) Key counter mount (P/N 66060040) Key counter assembly (P/N 3029236241) Four (4) M4 x 6 bronze TP-A screws (P/N B4A04060) One (1) M4 x 40 round head screw (P/N B1B54400) Two (2) M3 x 6 bronze flat-head screws (P/N 7BB003306H) One (1) M3 bronze nut (P/N 7BC1003055++H01) - Page 31 2HA/2HB 3. Remove the rear cover. Aperture 4. Cut out the aperture plate on the right cover 4-pin connector using nippers. 7-pin connector 5. Connect the 4-pin connector of the key counter wire (located at a longer distance from the tube) to YC13 on the engine PWB, Clamp pass the wire through the two clamps, and pull the other 4-pin connector out from the...

-

Page 32: Maintenance Mode

2HA/2HB 8. Connect the 4-pin connector of the key counter to the key counter wire. 9. Engage the projection of the key counter mounting plate with the aperture of the right cover. 10. Secure the key counter cover and the key counter mounting plate together with the copier using a M4 x 40 screw. -

Page 33: Maintenance Mode

2HA/2HB 1-3 Maintenance Mode 1-3-1 Maintenance mode The copier is equipped with a maintenance function which can be used to maintain and service the machine. (1) Executing a maintenance item Start Enter “10871087” using Maintenance mode is entered. the numeric keys. Enter the maintenance item number using the zoom The maintenance item is... -

Page 34: Maintenance Mode Item List

2HA/2HB (2) Maintenance mode item list Item Initial Section Content of maintenance item setting* General U000 Outputting an own-status report U001 Exiting the maintenance mode U002 Setting the factory default data U004 Checking the machine number U005 Copying without paper U019 Displaying the ROM version Initialization... - Page 35 2HA/2HB Item Initial Section Content of maintenance item setting* High voltage U100 Setting the main high voltage Grid control voltage Copy interval Copy quantity Correction amount U101 Setting the other high voltages 27/45/22/45/166/177/37/35 1/35/42 U110 Checking/clearing the drum count Developing U130 Initial setting for the developing unit U144...

- Page 36 2HA/2HB Item Initial Section Content of maintenance item setting* Mode setting U342 Setting the ejection restriction U343 Switching between duplex/simplex copy mode Simplex copy U344 Setting preheat/energy saver mode ENERGY STAR U345 Setting the value for maintenance due indication Image U402 Adjusting margins of image printing 3.0/3.0/4.0...

-

Page 37: Contents Of Maintenance Mode Items

2HA/2HB (3) Contents of maintenance mode items Maintenance Description item No. Outputting an own-status report U000 Description Outputs lists of the current settings of the maintenance items, and paper jam and service call occurrences. Purpose To check the current setting of the maintenance items, or paper jam or service call occurrences. Before initial- izing the backup RAM, output a list of the current settings of the maintenance items to reenter the settings after initialization or replacement. - Page 38 2HA/2HB Maintenance Description item No. Checking the machine number U004 Description Displays the machine number. Purpose To check the machine number. Method 1. Press the start key. 2. Change the indication of the copy quantity display using the exposure adjustment keys. Exposure indicator Copy quantity display Exp.

- Page 39 2HA/2HB Maintenance Description item No. Copying without paper U005 Description Simulates the copy operation without paper feed. Purpose To check the overall operation of the machine. Method 1. Press the start key. 2. Select the item to be operated using the exposure adjustment keys. Display Operation Only the copier operates.

- Page 40 2HA/2HB Maintenance Description item No. Displaying the ROM version U019 Description Displays the part number of the ROM fitted to each board. Purpose To check the part number or to decide if the ROM version is new from the last digit of the number. Method 1.

- Page 41 2HA/2HB Maintenance Description item No. Initializing all data U020 Description Initializes all the backup RAM on the main board to return to the original settings. Purpose Run as needed. Method 1. Press the start key. 2. Select "on" using the zoom +/- keys. Display Operation - - -...

- Page 42 2HA/2HB Maintenance Description item No. Checking motor operation U030 Description Drives each motor. Purpose To check the operation of each motor. Method 1. Press the start key. 2. Select the motor to be operated using the exposure adjustment keys. Display Motor Drive motor (DM) Registration motor (RM)

- Page 43 2HA/2HB Maintenance Description item No. Checking clutch operation U032 Description Turns each clutch on. Purpose To check the operation of each clutch. Method 1. Press the start key. 2. Select the clutch or solenoid to be operated using the exposure adjustment keys. 3.

- Page 44 2HA/2HB Maintenance Description item No. Adjusting the print start timing U034 Description Adjusts the leading edge registration, center line or trailing edge margin. Purpose Make the adjustment if there is a regular error between the leading edges of the copy image and original. Make the adjustment if there is a regular error between the center lines of the copy image and original.

- Page 45 2HA/2HB Maintenance Description item No. Caution U034 Check the copy image after the adjustment. If the image is still incorrect, perform the following adjustments in (cont.) maintenance mode. U066 U071 U034 (P.1-3-19) (P.1-3-22) Adjustment: center line adjustment 1. Select group 2 using the image mode selection key. 2.

- Page 46 2HA/2HB Maintenance Description item No. Adjustment: trailing edge margin adjustment U034 1. Select group 3 using the image mode selection key. (cont.) Description Setting Initial Change in range setting value per step Trailing edge margin adjustment -4.0 to 10.0 1.0 mm 2.

- Page 47 2HA/2HB Maintenance Description item No. Adjusting the amount of slack in the paper U051 Description Adjusts the amount of slack in the paper at the registration roller. Purpose Make the adjustment if the leading edge of the copy image is missing or varies randomly, or if the copy paper is Z-folded.

- Page 48 2HA/2HB Maintenance Description item No. Performing fine adjustment of the motor speed U053 Description Performs fine adjustment of the speeds of the motors. Purpose Used to adjust the speed of the respective motors when the magnification is not correct. Also speed adjust- ment for each paper source can be performed in group 2.

- Page 49 2HA/2HB Maintenance Description item No. Adjusting the scanner input properties U060 Description Adjusts the image scanning density. Purpose Used when the entire image appears too dark or light. Method Press the start key. Setting 1. Change the setting using the zoom +/- keys. Description Setting range Initial setting...

- Page 50 2HA/2HB Maintenance Description item No. Adjusting the scanner magnification U065 Description Adjusts the magnification of the original scanning. Purpose Make the adjustment if the magnification in the main scanning direction is incorrect. Make the adjustment if the magnification in the auxiliary scanning direction is incorrect. Caution Adjust the magnification of the scanner in the following order.

- Page 51 2HA/2HB Maintenance Description item No. Adjusting the scanner leading edge registration U066 Description Adjusts the scanner leading edge registration of the original scanning. Purpose Make the adjustment if there is a regular error between the leading edges of the copy image and original. Caution Before making this adjustment, ensure that the following adjustments have been made in maintenance mode U034...

- Page 52 2HA/2HB Maintenance Description item No. Adjusting the scanner center line U067 Description Adjusts the scanner center line of the original scanning. Purpose Make the adjustment if there is a regular error between the center lines of the copy image and original. Caution Before making this adjustment, ensure that the following adjustments have been made in maintenance mode U034...

- Page 53 2HA/2HB Maintenance Description item No. Adjusting the DP magnification U070 Description Adjusts the DP original scanning speed. Purpose Make the adjustment if the magnification is incorrect in the auxiliary scanning direction when the optional DP is used. Caution Before making this adjustment, ensure that the following adjustments have been made in maintenance mode U053 U065 U070...

- Page 54 2HA/2HB Maintenance Description item No. Adjusting the DP scanning timing U071 Description Adjusts the DP original scanning timing. Purpose Make the adjustment if there is a regular error between the leading or trailing edges of the original and the copy image when the optional DP is used. Caution Before making this adjustment, ensure that the following adjustments have been made in maintenance mode U034...

- Page 55 2HA/2HB Maintenance Description item No. Adjusting the DP center line U072 Description Adjusts the scanning start position for the DP original. Purpose Make the adjustment if there is a regular error between the centers of the original and the copy image when the optional DP is used.

- Page 56 2HA/2HB Maintenance Description item No. Checking scanner operation U073 Description Simulates the scanner operation under arbitrary conditions. Purpose To check scanner operation. Method 1. Press the start key. 2. Select the item to be changed using the exposure adjustment keys. 3.

- Page 57 2HA/2HB Maintenance Description item No. Adjusting the DP automatically U076 Description Uses a specified original and automatically adjusts the following items in the DP scanning section. Adjusting the DP magnification (U070) Adjusting the DP scanning timing (U071) Adjusting the DP center line (U072) When this maintenance item is performed, the settings in U070, U071 and U072 are also changed.

- Page 58 2HA/2HB Maintenance Description item No. Turning the DP scanning position adjust mode on/off U087 Description Turns on or off the DP scanning position adjust mode, in which the DP original scanning position is adjusted automatically by determining the presence or absence of dust on the slit glass. Also changes the reference data for identifying dust.

- Page 59 2HA/2HB Maintenance Description item No. Setting the input filter (moire reduction mode) U088 Description Turns moire reduction mode on and off by switching the input filter on and off. Purpose Used to prevent regular density unevenness (moiré) on halftone image areas of the copy image in text mode and text and photo mode.

- Page 60 2HA/2HB Maintenance Description item No. Adjusting the scanner automatically U092 Description Makes auto scanner adjustments in the order below using the specified original. Adjusting the scanner center line (U067) Adjusting the scanner leading edge registration (U066) Adjusting scanner magnification in the auxiliary direction (U065) When this maintenance item is performed, the settings in U065, U066 and U067 are also changed.

- Page 61 2HA/2HB Maintenance Description item No. Setting the exposure density gradient U093 Description Changes the exposure density gradient in manual density mode, depending on respective image modes (text, text and photo, photo). Purpose To set how the image density is altered by a change of one step in the manual density adjustment. Also used to make copy image darker or lighter.

- Page 62 2HA/2HB Maintenance Description item No. Checking the original size detection U099 Description Displays the original width detection data and sets the original width detection threshold. Purpose To check the original width detection. Also to change the original size detection threshold if the size of the orig- inal on the contact glass is detected incorrectly.

- Page 63 2HA/2HB Maintenance Description item No. Method to set or check the original size detection threshold U099 1. Place an original on the contact glass and turn the original detection switch on. The original size detec- (cont.) tion starts and detection data is displayed. 2.

- Page 64 2HA/2HB Maintenance Description item No. Setting the main charging copy quantity correction U100 1. Change the setting using the zoom +/- keys. (cont.) Display Setting Setting range Initial setting Exp. 4 (lit) Copy interval 1 to 255 (minute) Exp. 5 (lit) Copy quantity 1 to 255 (10 sheets) Exp.

- Page 65 2HA/2HB Maintenance Description item No. Checking/clearing the drum count U110 Description Displays the drum counts for checking, clearing or changing a figure. Purpose To check the drum status. Also used to clear the count after replacing the drum during regular maintenance. Since the count was cleared before shipping, do not clear it when installing.

- Page 66 2HA/2HB Maintenance Description item No. Setting toner loading operation U144 Description Sets toner loading operation. Purpose To run when drum filming (background blur in paper edge section) occurs. Method Press the start key. Setting 1. Select either "on" or "oFF" using the zoom +/- keys. Display Description Toner loaded...

- Page 67 2HA/2HB Maintenance Description item No. Checking the developing count U158 Description Displays the developing count. Purpose To check the developing count. Method 1. Press the start key. 2. Select the item using the exposure adjustment keys. Exposure indicator Copy quantity display Exp.

- Page 68 2HA/2HB Maintenance Description item No. Stabilizing fuser forcibly U162 Description Stops the stabilization fuser drive forcibly, regardless of fuser temperature. Purpose To forcibly stabilize the machine before the fuser section reaches stabilization temperature. Method 1. Press the start key. "on" appears. 2.

- Page 69 2HA/2HB Maintenance Description item No. Setting the fuser phase control U198 Description Sets the use of fuser phase control to reduce electrical noise generated by the copier. Purpose Normally no change is necessary. If electrical noise generated by the copier causes flickering of the lights around the copier, select fuser phase control to reduces the noise.

- Page 70 2HA/2HB Maintenance Description item No. Operating DP separately U203 Description Simulates the original conveying operation separately in the DP. Purpose To check the DP. Method 1. Press the start key. 2. Place an original on the DP if running this simulation with paper. 3.

- Page 71 2HA/2HB Maintenance Description item No. Checking the operation of the DP motors and solenoids U243 Description Turns the motors and solenoids in the optional DP on. Purpose To check the operation of the DP motors and solenoids. Method 1. Press the start key. 2.

- Page 72 2HA/2HB Maintenance Description item No. Checking/clearing the maintenance count U251 Description Displays, clears and changes the maintenance count. Purpose To check the maintenance count. Also to clear the count during maintenance service. Method 1. Press the start key. 2. Select the item using the exposure adjustment keys. Exposure indicator Description Setting range...

- Page 73 2HA/2HB Maintenance Description item No. Switching between double and single counts U253 Description Switches the count system for the total counter and other counters. Purpose According to user (copy service provider) request, select if A3/11" x 17" paper is to be counted as one sheet (single count) or two sheets (double count).

- Page 74 2HA/2HB Maintenance Description item No. Changing the copy count timing U260 Description Changes the copy count timing for the total counter and other counters. Purpose To be set according to user (copy service provider) request. If a paper jam occurs frequently in the eject sec- tion when the number of copies is counted at the time of paper ejection, copies are provided without copy counts.

- Page 75 2HA/2HB Maintenance Description item No. Setting the size conversion factor U332 Description Sets the coefficient of nonstandard sizes in relation to the A4/11" x 8 " size. The coefficient set here is used to convert the black ratio in relation to the A4/11" x 8 "...

- Page 76 2HA/2HB Maintenance Description item No. Switching between duplex/simplex copy mode U343 Description Switches the Initial setting between duplex and simplex copy. Purpose To be set, according to frequency of use, to the more frequently used mode. Method Press the start key. Setting 1.

- Page 77 2HA/2HB Maintenance Description item No. Adjusting margins of image printing U402 Description Adjusts margins for image printing. Purpose Make the adjustment if margins are incorrect. Adjustment 1. Press the start key. 2. Select the item using the exposure adjustment keys. Exposure Setting Initial...

- Page 78 2HA/2HB Maintenance Description item No. Adjusting margins for scanning an original on the contact glass U403 Description Adjusts margins for scanning the original on the contact glass. Purpose Make the adjustment if margins are incorrect. Caution Before making this adjustment, ensure that the following adjustments have been made in maintenance mode U402 U404 U403...

- Page 79 2HA/2HB Maintenance Description item No. Adjusting margins for scanning an original from the DP U404 Description Adjusts margins for scanning the original from the DP. Purpose Make the adjustment if margins are incorrect when the optional DP is used. Caution Before making this adjustment, ensure that the following adjustments have been made in maintenance mode U402 U403...

- Page 80 2HA/2HB Maintenance Description item No. Adjusting the leading edge registration for memory image printing U407 Description Adjusts the leading edge registration during memory copying. Purpose Make the adjustment if there is a regular error between the leading edges of the copy image and original dur- ing memory copying.

- Page 81 2HA/2HB Maintenance Description item No. Checking/clearing copy counts by paper feed locations U901 Description Displays or clears copy counts by paper feed locations. Purpose To check the time to replace consumable parts. Also to clear the counts after replacing the consumable parts. Method 1.

- Page 82 2HA/2HB Maintenance Description item No. Checking/clearing the paper jam counts U903 Description Displays or clears the jam counts by jam locations. Purpose To check the paper jam status. Also to clear the jam counts after replacing consumable parts. Method 1. Press the start key. 2.

- Page 83 2HA/2HB Maintenance Description item No. Checking/clearing counts by the DP U905 Description Displays or clears the counts of the optional DP. Purpose To check the use of the DP. Also to clear the counts after replacing consumable parts. Method 1. Press the start key. 2.

- Page 84 2HA/2HB Maintenance Description item No. Checking the total count U908 Description Display the total count value. Purpose To check the total count value. Method 1. Press the start key. 2. Select the item using the exposure adjustment keys. Exposure indicator Copy quantity display (count value) Exp.

- Page 85 2HA/2HB Maintenance Description item No. Checking/clearing copy counts by paper size U911 Description Displays or clears the paper feed count value by paper size. Purpose To check the time to replace consumable parts. Also to clear the counts after replacing the consumable parts. Method 1.

- Page 86 2HA/2HB Maintenance Description item No. U911 (cont.) Image mode LED Exposure Copy quantity display (count value) (group No.) indicator Exp. 1 (lit) “-Lt” display the Letter size Exp. 2 (lit) First 3 digits of Letter size copy count Exp. 3 (lit) Last 3 digits of Letter size copy count Exp.

- Page 87 2HA/2HB Maintenance Description item No. Clearing the all accounting counts and machine life counter U927 Description Clears the total count and the scanner count. The counts, however, can be cleared only one time. If either of the total count or the scanner count exceeds 1,000, this mode cannot be run. Purpose To start the counters with value 0 when installing the machine.

- Page 88 2HA/2HB Maintenance Description item No. Setting of amount of slack for feeding from DP U942 Description Adjusts the amount of slack generated when the optional DP is used. Purpose Use this mode if an original non-feed jam, oblique feed or wrinkling of original occurs when the DP is used. Method Press the start key.

- Page 89 2HA/2HB Maintenance Description item No. Setting operation panel type U955 Description Sets the type of operation panel and LCD device. Purpose To set the type of operation panel and LCD device when the setting value is initialized by U020 on the machine with the operation panel for Taiwan or the LCD that displays Kanji.

- Page 90 2HA/2HB Maintenance Description item No. Checking/clearing the time for the exposure lamp to light U990 Description Displays or clears the accumulated time for the exposure lamp to light. Purpose To check duration of use of the exposure lamp. Also to clear the accumulated time for the lamp after replace- ment.

- Page 91 2HA/2HB Maintenance Description item No. Outputting a VTC-PG pattern U993 Description Selects and outputs a VTC-PG pattern created in the copier. Purpose When performing respective image printing adjustments, used to check the machine status apart from that of the scanner with a non-scanned output VTC-PG pattern. Method 1.

-

Page 92: Copier Management

2HA/2HB 1-3-2 Copier management In addition to a maintenance function for service, the copier is equipped with a management function which can be oper- ated by users (mainly by the copier administrator). In this copier management mode, settings such as default settings can be changed. -

Page 93: Job Accounting

2HA/2HB (2) Job accounting (3) Default setting Job accounting on/off setting User status report 1. Select [01.JobAccounting] and press the OK key. Prints the details of the default settings. 2. Select [ON] or [OFF] and press the OK key. 1. Select [01.Copy Status] and press the OK key. If A4/11"... - Page 94 2HA/2HB Photo exposure adjustment Selected cassette Adjusts the exposure to be used when photo original is Selects the cassette that is to be automatically be selected for the image mode. given priority for use. 1. Select [09.Photo Density] and press the OK key. 1.

- Page 95 2HA/2HB MP tray paper size Sets the paper size for the MP tray so that it will be Auto detect originals automatically selected. Predetermines what paper size is selected for printing 1. Select [23.MPTray Config] and press the OK key. when copying an original document of non-standard 2.

- Page 96 2HA/2HB Combine mode borderline Alarm Selects the type of borderline to be used in the layout The alarm can be set to sound when errors occur. mode. 1. Select [55.Alarm] and press the OK key. 1. Select [46.Combine Border] and press the OK key. 2.

-

Page 97: Paper Misfeed Detection

2HA/2HB 1-4 Troubleshooting 1-4-1 Paper misfeed detection (1) Paper misfeed indication When a paper misfeed occurs, the copier immediately stops copying and displays the jam location on the operation panel. Paper misfeed counts sorted by the detection condition can be checked in maintenance item U903. To remove paper jammed in the copier, open the front cover, left cover, or pull the drawer out. -

Page 98: Paper Misfeed Detection Conditions

2HA/2HB (2) Paper misfeed detection conditions OCM OFM OSBSW DPTSW FSSW DUPPCSW DUPFCL PFCL MPPFCL DPFCL1 DFSW1 DPFCL2 DFSW2 DPFCL3 Figure 1-4-2 1-4-2... - Page 99 2HA/2HB Section Jam code Description Conditions System No paper feed When the power switch is turned on, the machine detects acti- vation of the registration switch (RSW), the exit switch (ESW) or the feedshift switch (FSSW). Cover open JAM A cover open state is detected during copying. Secondary paper feed tim- When the machine waits for secondary paper feed, 30 s or eout...

- Page 100 2HA/2HB Section Jam code Description Conditions Paper con- Multiple sheets in the The drawer feed switch 1 (DFSW1)* does not turn off within veying sec- drawer 3* (second paper 6320 ms of drawer feed switch 1 (DFSW1)* turning on. tion feeder) The drawer feed switch 1 (DFSW1)* does not turn off within 2560 ms of drawer paper feed clutch 2 (DPFCL2)* turning on.

- Page 101 2HA/2HB Section Jam code Description Conditions Feedshift Misfeed in the feedshift The feedshift switch (FSSW) does not turn off within 6320 ms section section* (paper feed from of feedshift switch (FSSW) turning on. first paper feeder) The feedshift switch (FSSW) does not turn off within 1530 ms of paper switchback.

-

Page 102: Paper Misfeeds

2HA/2HB (3) Paper misfeeds Copier Problem Causes/check procedures Corrective measures A piece of paper torn from Check visually and remove it, if any. A paper jam in the copy paper is caught paper feed, paper around registration switch, conveying or exit exit switch or feedshift section is indicated switch. - Page 103 2HA/2HB Problem Causes/check procedures Corrective measures Paper in the first paper Change the paper. A paper jam in the feeder is extremely curled. paper feed section is Check if the paper feed pul- Check visually and replace any deformed pulley. indicated during ley, separation pulley or for- copying (no paper...

- Page 104 2HA/2HB Problem Causes/check procedures Corrective measures Broken registration switch Check visually and replace registration switch if its actuator is bro- A paper jam in the actuator. ken. paper feed section is Defective registration Run maintenance item U031 and turn registration switch on and indicated during switch.

- Page 105 2HA/2HB Problem Causes/check procedures Corrective measures (10) Deformed guides along the Repair or replace if necessary. A paper jam in the paper conveying path. paper conveying sec- Broken registration switch Check visually and replace registration switch if its actuator is bro- tion is indicated dur- actuator.

- Page 106 2HA/2HB Problem Causes/check procedures Corrective measures (13) Deformed guides along the Repair or replace if necessary. A paper jam in the paper conveying path. paper conveying sec- Broken drawer feed switch Check visually and replace drawer feed switch 2 if its actuator is tion is indicated dur- 2 actuator.

- Page 107 2HA/2HB Problem Causes/check procedures Corrective measures (16) Broken registration switch Check visually and replace the registration switch or exit switch if A paper jam in the or exit switch actuator. its actuator is broken. exit section is indi- Defective registration Run maintenance item U031 and turn each switch on and off cated during copying switch or exit switch.

- Page 108 2HA/2HB Problem Causes/check procedures Corrective measures (19) Broken duplex paper con- Check visually and replace the duplex paper conveying switch if A paper jam in the veying switch actuator. its actuator is broken. duplex section is indi- Defective duplex paper con- Run maintenance item U031 and turn duplex paper conveying cated during copying veying switch.

- Page 109 2HA/2HB Problem Causes/check procedures Corrective measures A piece of paper torn from Check visually and remove it, if any. An original jams an original is caught around when the power the DP timing switch or switch is turned on. original switchback switch. Defective DP timing switch Run maintenance item U244 and turn each switch on and off or original switchback...

- Page 110 2HA/2HB Problem Causes/check procedures Corrective measures Broken DP timing switch Check visually and replace DP timing switch if its actuator is bro- An original jams in actuator. ken. the original convey- Defective DP timing switch. Run maintenance item U244 and turn DP timing switch on and off ing section is indi- manually.

-

Page 111: Self-Diagnosis

2HA/2HB 1-4-2 Self-diagnosis (1) Self-diagnostic function This unit is equipped with a self-diagnostic function. When a problem is detected, copying is disabled. "C" and a number between 0100 and 7810 altenates, indicating the nature of the problem. After removing the problem, the self-diagnostic function can be reset by opening and closing the front cover to turn safety switch off and on or power switch turns off and (2) Self diagnostic codes Remarks... - Page 112 2HA/2HB Remarks Code Contents Causes Check procedures/corrective measures C0410 Optional DP communication problem DP installed incor- Check the installation state of the DP and Communication fails five times succes- rectly. adjust it if it is not properly installed. sively. Defective main Replace the main PWB or DP driver PWB PWB or DP driver and check for correct operation.

- Page 113 2HA/2HB Remarks Code Contents Causes Check procedures/corrective measures C3100 Scanner carriage problem Poor contact of the Reinsert the connector. Also check for conti- The home position is not correct when connector termi- nuity within the connector cable. If none, the power is turned on or copying the nals.

- Page 114 2HA/2HB Remarks Code Contents Causes Check procedures/corrective measures C4200 BD steady-state problem Defective laser Replace the LSU. The MIC detects a BD error for 600 ms diode. after the polygon motor rotation has Defective polygon Replace the LSU. been stabilized. motor.

- Page 115 2HA/2HB Remarks Code Contents Causes Check procedures/corrective measures C6400 Zero-crossing signal problem Poor contact in the Reinsert the connector. Also check for conti- The engine PWB does not detect the connector termi- nuity within the connector cable. If none, zero-crossing signal for the time speci- nals.

-

Page 116: Image Formation Problems

2HA/2HB 1-4-3 Image formation problems (1)No image appears (2)No image appears (3)Image is too light. (4)Background is visi- (5)A white line (entirely white). (entirely black). ble. appears longitudi- nally. See page 1-4-21. See page 1-4-21. See page 1-4-22. See page 1-4-22. See page 1-4-22. -

Page 117: No Image Appears (Entirely Black)

2HA/2HB (1) No image appears (entirely white). Copy example Causes Check procedures/corrective measures No trans- The connector terminals Reinsert the connector. Also check for continuity within the fer charg- of the high-voltage PWB connector cable. If none, remedy or replace the cable. ing. -

Page 118: Image Is Too Light

2HA/2HB (3) Image is too light. Copy example Causes Check procedures/corrective measures Insufficient toner. If the add toner indicator lights, replace the toner container. The transfer voltage is not output Clean or check the transfer roller (see page 1-5-27). properly. Dirty main charger wire. -

Page 119: A Black Line Appears Laterally

2HA/2HB (7) A black line appears laterally. Copy example Causes Check procedures/corrective measures Dirty contact glass. Clean the contact glass. Dirty or flawed drum. Clean the drum or, if it is flawed, replace it (see page 1-5-23). Dirty scanner mirror. Clean the scanner mirror. -

Page 120: The Leading Edge Of The Image Is Consistently Misaligned With The Original

2HA/2HB (11) The leading edge of the image is consistently misaligned with the original. Copy example Causes Check procedures/corrective measures Misadjusted leading edge registration. Readjust the leading edge registration (see page 1-3-12). Misadjusted scanner leading edge Readjust the scanner leading edge registration (see page 1- registration. -

Page 121: Image Is Partly Missing

2HA/2HB (15) Image is partly missing. Copy example Causes Check procedures/corrective measures Paper damp. Check the paper storage conditions. Paper creased. Replace the paper. Dirty or flawed drum. Clean the drum or, if it is flawed, replace the drum unit (see page 1-5-23). -

Page 122: Electric Problems

2HA/2HB 1-4-4 Electric problems Problem Causes Check procedures/corrective measures No electricity at the power Measure the input voltage. The machine does outlet. not operate when the The power cord is not Check the contact between the power plug and the outlet. power switch is plugged in properly. - Page 123 2HA/2HB Problem Causes Check procedures/corrective measures Poor contact in the connec- Reinsert the connector. Also check for continuity within the con- The exposure lamp tor terminals. nector cable. If none, remedy or replace the cable. does not turn on or Defective inverter PWB.

- Page 124 2HA/2HB Problem Causes Check procedures/corrective measures (11) Original is not placed cor- Check the original and correct if necessary. The original size is rectly. not detected cor- Poor contact in the original Reinsert the connector. Also check for continuity within the con- rectly.

-

Page 125: Mechanical Problems

2HA/2HB 1-4-5 Mechanical problems Problem Causes/check procedures Corrective measures Check if the surfaces of the following rollers or Clean with isopropyl alcohol. No primary paper feed. pulleys are dirty with paper powder: forward- ing pulley, paper feed pulley, separation pul- ley, registration rollers, MP paper feed pulley and MP separation pad. - Page 126 2HA/2HB This page is intentionally left blank. 1-4-30...

-

Page 127: Precautions For Assembly And Disassembly

2HA/2HB 1-5 Assembly and Disassembly 1-5-1 Precautions for assembly and disassembly (1) Precautions Be sure to turn the power switch off and disconnect the power plug before starting disassembly. When handling PWBs, do not touch connectors with bare hands or damage the board. Do not touch any PWB containing ICs with bare hands or any object prone to static charge. -

Page 128: Running A Maintenance Item

2HA/2HB (4) Running a maintenance item Start Enter “10871087” using Maintenance mode is entered. the numeric keys. Enter the maintenance item number using the zoom The maintenance item is +/- keys or numeric keys. selected. Press the start key. The selected maintenance item is run. Press the stop/clear key. -

Page 129: Paper Feed Section

2HA/2HB 1-5-2 Paper feed section (1) Detaching and refitting the separation pulley Follow the procedure below to replace the separation pulley. Procedure 1. Open the front cover and left cover. Remove the waste toner box. 2. Pull out the drawer. Drawer Figure 1-5-1 3. - Page 130 2HA/2HB 5. Remove the separation pulley unit from the lower paper feed unit. 6. Remove the separation pulley from the sep- aration pulley unit. 7. Replace the separation pulley and refit all the removed parts. Separation pulley Separation pulley unit Lower paper feed unit Figure 1-5-4 1-5-4...

-

Page 131: Detaching And Refitting The Forwarding Pulley And Paper Feed Pulley

2HA/2HB (2) Detaching and refitting the forwarding pulley and paper feed pulley Follow the procedure below to replace the forwarding pulley and paper feed pulley. Procedure 1. Remove the lower paper feed unit (see page 1-5-3). 2. Remove the drum unit (see page 1-5-23). 3. - Page 132 2HA/2HB 7. Remove the springs, stop ring and bushing and then the shaft holder from the upper Shaft holder Spring paper feed unit. Spring Stop ring Upper paper feed unit Bushing Figure 1-5-8 8. Remove the forwarding pulley from the Paper feed pulley upper paper feed unit.

-

Page 133: Detaching And Refitting The Paper Conveying Unit

2HA/2HB (3) Detaching and refitting the paper conveying unit Follow the procedure below to maintenance of the paper feed section. Procedure 1. Remove the drum unit (see page 1-5-23). 2. Remove the stop ring and strap from the rear side. Restore the paper conveying unit. Remove the pin and plate, and then remove the stopper from the front side. - Page 134 2HA/2HB 6. Push the fitting portions of the MP upper cover. Remove the MP upper cover from the MP unit. MP upper cover Figure 1-5-12 7. Detach the connector and remove the MP lower cover from the copier. Connector MP lower cover Figure 1-5-13 8.

-

Page 135: Detaching And Refitting The Mp Paper Feed Pulley And Mp Separation Pad

2HA/2HB (4) Detaching and refitting the MP paper feed pulley and MP separation pad Follow the procedure below to replace the MP paper feed pulley and MP separation pad. Procedure 1. Open the front cover and remove the waste toner box. Pull out the drawer. 2. - Page 136 2HA/2HB 7. Temporarily push the MP paper feed pulley MP paper feed pulley unit unit into the rear side to unlock the front side and then remove it from the copier. Figure 1-5-18 8. Remove the MP paper feed pulley from the MP paper feed pulley shaft.

-

Page 137: Detaching And Refitting The Registration Left Roller

2HA/2HB (5) Detaching and refitting the registration left roller Follow the procedure below to replace the registration left roller. Procedure Stopper 1. Remove the paper conveying unit (see page 1-5-7). Paper conveying unit 2. Remove the transfer roller (see page 1-5- 27). -

Page 138: Optical Section

2HA/2HB 1-5-3 Optical section (1) Detaching and refitting the exposure lamp Take the following procedure when the exposure lamp is to be replaced. Procedure Contact glass 1. Remove the original cover or the DP. 2. Remove the two screws holding the upper right cover and then the cover. -

Page 139: Detaching And Refitting The Scanner Wires

2HA/2HB (2) Detaching and refitting the scanner wires Take the following procedure when the scanner wires are broken or to be replaced. (2-1) Detaching the scanner wires Procedure Uppeer rear cover 1. Remove the exposure lamp (see page 1-5- 12). 2. - Page 140 2HA/2HB 5. Remove the screw holding each of the front and rear wire retainers and then remove the mirror 1 frame from the scanner unit. Mirror 1 frame Rear wire Front wire retainer retainer Figure 1-5-30 6. Unhook the round terminal of the scanner Round terminal wire from the scanner tension spring on the left side of the scanner unit.

-

Page 141: Fitting The Scanner Wires

2HA/2HB (2-2) Fitting the scanner wires Caution: When fitting the wires, be sure to use those specified below. Machine front: P/N 2C91236 (gray) Machine rear: P/N 2C91235 (black) Fitting requires the following tools: Two frame securing tools (P/N 302C968310) Two scanner wire stoppers (P/N 3596811) Procedure 1. - Page 142 2HA/2HB 4. Insert the locating ball on each of the scan- ner wires into the hole in the respective scanner wire drum and wind the scanner wire three turns inward and four turns out- ward. With the locating ball as the reference point, wind the shorter end of each of the wires outward.

- Page 143 2HA/2HB 8. Loop the outer ends of the scanner wires around the outer grooves in the pulleys on the mirror 2 frame, winding from below to above........................(1) 9. Hook the round terminals onto the catches inside the scanner unit............. (2) 10.

-

Page 144: Detaching And Refitting The Isu (Reference)

2HA/2HB (3) Detaching and refitting the ISU (reference) Take the following procedure when the ISU is to be replaced. Procedure Detaching the ISU ISU cover 1. Remove the contact glass (see page 1-5- 12). 2. Remove the four screws holding the ISU cover and then the cover. -

Page 145: Detaching And Refitting The Laser Scanner Unit

2HA/2HB (4) Detaching and refitting the laser scanner unit Take the following procedure when the laser scanner unit is to be replaced. Procedure 1. Remove the original cover or the DP. 2. Remove the upper right cover, contact glass, upper rear cover, middle left cover, upper left cover, slit glass and front scanner cover (see page 1-5-13). - Page 146 2HA/2HB 5. Remove the four pins holding the scanner unit and then the unit. Scanner unit Figure 1-5-43 6. Remove the screw holding the exit cover Inner rear cover Exit cover and then the cover. Remove the two screws holding the inner rear cover and then the cover.

- Page 147 2HA/2HB 8. Remove the two screws holding the exit unit and then pull out the unit a little. Exit unit Figure 1-5-46 9. Remove the exit tray. Exit tray Figure 1-5-47 10. Remove the four screws and detach the two Connector connector and then remove the laser scan- ner unit.

-

Page 148: Adjusting The Longitudinal Squareness (Reference)

2HA/2HB (5) Adjusting the longitudinal squareness (reference) Perform the following adjustment if the copy image is longitudinally skewed (longitudinal squareness not obtained). Caution: Adjust the amount of slack in the paper (page 1-3-15) first. Check for the longitudinal squareness of the copy image, and if it is not obtained, perform the longitudinal squareness adjustment. -

Page 149: Drum Section

2HA/2HB 1-5-4 Drum section (1) Detaching and refitting the drum unit Follow the procedure below to replace the drum unit. Cautions: Avoid direct sunlight or strong light when detaching and refitting the drum unit. Never touch the drum surface when holding the drum unit. Procedure Inner cover 1. -

Page 150: Detaching And Refitting The Drum Separation Claws

2HA/2HB (2) Detaching and refitting the drum separation claws Follow the procedure below to replace the drum separation claws. Procedure 1. Remove the drum unit (see page 1-5-23). Drum unit 2. Push the drum separation claws with the minus driver from the top of the corner hole and remove the claws. -

Page 151: Detaching And Refitting The Main Charger Unit

2HA/2HB (3) Detaching and refitting the main charger unit Follow the procedure below to replace the main charger unit. Procedure 1. Open the front cover. Main charger 2. While lifting the main charger unit toward the release lever upper right, remove the unit from the copier. 3. -

Page 152: Developing Section

2HA/2HB 1-5-5 Developing section (1) Detaching and refitting the developing unit Follow the procedure below to replace the developing unit. Procedure 1. Remove the drum unit (see page 1-5-23). 2. While lifting the developing unit a little, remove the unit from the copier. 3. -

Page 153: Transfer Section

2HA/2HB 1-5-6 Transfer section (1) Detaching and refitting the transfer roller Follow the procedure below to replace the transfer roller. Procedure Rear release 1. Remove the paper conveying unit (see page lever stopper 1-5-7). Front release 2. Remove the screw holding each of the front lever stopper and rear release lever stoppers and then the stoppers from the release lever shaft. -

Page 154: Fuser Section

2HA/2HB 1-5-7 Fuser section (1) Detaching and refitting the fuser unit Follow the procedure below to replace the fuser unit. Procedure 1. Open the front cover and left cover and then remove the inner cover. 2. Insert a flat-blade screwdriver or the like through the groove at the left side of the machine and unlock the engaged portion of front left cover 1 to remove it. - Page 155 2HA/2HB 5. Remove the screw and detach the two con- nectors and then remove the fuser unit from copier. 6. Replace the fuser unit and refit all the removed parts. Connectors Fuser unit Figure 1-5-61 1-5-29...

-

Page 156: Detaching And Refitting The Press Roller

2HA/2HB (2) Detaching and refitting the press roller Follow the procedure below to replace the press roller. Procedure 1. Remove the fuser unit (see page 1-5-28). 2. Remove the two screws and then separate the fuser right unit and left unit. Fuser right unit Fuser left unit Figure 1-5-62... -

Page 157: Detaching And Refitting The Fuser Heater M And S

2HA/2HB (3) Detaching and refitting the fuser heater M and S Follow the procedure below to replace the fuser heater M and S. Procedure 1. Remove the fuser unit and separate the fuser right unit and left unit (see pages 1-5- 28, 30). -

Page 158: Detaching And Refitting The Heat Roller Separation Claws

2HA/2HB (4) Detaching and refitting the heat roller separation claws Follow the procedure below to replace the heat roller separation claws. Procedure 1. Remove the fuser unit and separate the fuser right unit and left unit (see page 1-5- Fuser left unit 28, 30). -

Page 159: Detaching And Refitting The Heat Roller

2HA/2HB (5) Detaching and refitting the heat roller Follow the procedure below to replace the heat roller. Procedure 1. Remove the fuser unit and separate the fuser right unit and left unit (see pages 1-5- 30). 2. Remove the heat roller separation claws. (see page 1-5-32). -

Page 160: Detaching And Refitting The Fuser Thermostat

2HA/2HB (6) Detaching and refitting the fuser thermostat Follow the procedure below to replace the fuser thermostat. Procedure Fuser thermostat 1. Remove the fuser unit and separate the fuser right unit and left unit (see page 1-5- 28, 30). 2. Remove the heat roller (see page 1-5-33). 3. -

Page 161: Adjusting The Fuser Unit Height (Adjusting Lateral Squareness)

2HA/2HB (8) Adjusting the fuser unit height (adjusting lateral squareness) Follow the procedure below if the drum is not parallel to the fuser unit and therefore paper is not fed straight to the fuser section and the trailing edge of image on either the front or rear side becomes longer. Procedure 1. - Page 162 2HA/2HB This page is intentionally left blank. 1-4-30...

-

Page 163: Upgrading The Firmware On The Main Pwb

2HA/2HB 1-6 Requirements on PWB Replacement 1-6-1 Upgrading the firmware on the main PWB Follow the procedure below to upgrade the firmware on the main PWB, engine PWB or language software. Firmware upgrading requires the following tools: Flash DIMM (P/N 2C968131) Procedure 1. -

Page 164: Adjustment-Free Variable Resistors (Vr)

2HA/2HB 1-6-2 Adjustment-free variable resistors (VR) The variable resistors listed below are set at the factory prior to shipping and cannot be adjusted in the field. High-voltage PWB: VR201, VR202, VR301 Drum unit zener PWB: VR1 1-6-3 Remarks on PWBs replacement Confirm the version of the firmware and upgrade the version in up-to-date state when replacing PWBs. -

Page 165: Paper Feed Section

2HA/2HB 2-1 Mechanical construction 2-1-1 Paper feed section The paper feed section conveys paper from the drawer or MP tray to the left and right registration rollers, at which point secondary feed takes place and the paper travels to the transfer section in sync with the printing timing. Drawer can hold up to 300 sheets of paper. - Page 166 2HA/2HB RMPWB EPWB YC2-1, 2, 4, 5 YC1-4 YC4-4 DPWB YC5-12 YC1-9 YC8-9 PFCL PFCL YC2-2 YC1-15 YC8-3 PFCL MPPFCL MPPFCL MPPFCL YC3-1 YC1-13 YC8-5 YC6-2 YC1-16 YC8-2 MPPWSW MPPWSW YC5-9 YC1-10 YC8-8 MPPWSW MPPSW MPPSW YC5-2 YC1-17 YC8-1 MPPSW PLSW YC22-1, 2, 4 PLSW...

-

Page 167: Optical Section

2HA/2HB 2-1-2 Optical section The optical section consists of the scanner, mirror frames and the image scanning unit for scanning and the laser scanner unit for printing. Figure 2-1-3 Optical section Mirror 1 frame Mirror 2 frame Exposure lamp (EL) Mirror 1 Mirror 2 Mirror 3... -

Page 168: Original Scanning

2HA/2HB (1) Original scanning The original image is illuminated by the exposure lamp (EL) and scanned by the CCD PWB (CCDPWB) in the image scan- ning unit via the three mirrors, the reflected light being converted to an electrical signal. The scanner and mirror frames travel to scan on the optical rails on the front and rear of the machine to scan from side to side. -

Page 169: Image Printing

2HA/2HB (2) Image printing The image data scanned by the CCD PWB (CCDPWB) is processed on the main PWB (MPWB) and transmitted as image printing data to the laser scanner unit . By repeatedly turning the laser on and off, the laser scanner unit forms a latent image on the drum surface. - Page 170 2HA/2HB The dimensions of the laser beam are as shown in Figure 2-1-6. Less than 100 m Less than 85 m Figure 2-1-6 Scanning in the main direction is provided by the rotating polygon mirror, while scanning in the auxiliary direction is pro- vided by the rotating drum, forming a static latent image on the drum.

-

Page 171: Drum Section

2HA/2HB 2-1-3 Drum section The drum section consists of the drum, main charger section, cleaning section and cleaning lamp. The main charger section consists of main charger wire, main charger grid and main charger shield, and the drum is charged by a high voltage applied to the main charger wire. In addition, this section is equipped with a manual main charger cleaner that is used for cleaning the main charger wire. -

Page 172: Developing Section

2HA/2HB 2-1-4 Developing section The developing section consists of the developing unit and the toner container. The developing unit consists of the developing roller where a magnetic brush is formed, the doctor blade and the develop- ing spirals that agitate the toner. Also, the toner container sensor (TCS) checks whether or not toner remains in the toner container. -

Page 173: Formation Of Magnetic Brush

2HA/2HB (1) Formation of magnetic brush The developing roller consists of a magnet roller with four poles and a sleeve roller. Rotation of the sleeve roller around the magnet roller entrains toner, which in turn forms a magnetic brush at pole N1 on the magnet roller. The height of the magnetic brush is regulated by the doctor blade;... -

Page 174: Single Component Developing System

2HA/2HB (2) Single component developing system This machine uses the single component developing system, and reversal processing is performed with a + charged drum and a + charged magnetic toner. With the single component developing system, toner is electrically charged by friction with the developing sleeve and + charged when it passes through the magnetic toner blade. -

Page 175: Transfer And Separation Sections

2HA/2HB 2-1-5 Transfer and separation sections The transfer and separation sections consists of the transfer roller, separation electrode and drum separation claws. A high voltage generated by the high-voltage PWB (HVTPWB) is applied to the transfer roller for transfer charging. Paper after transfer is separated from the drum by applying separation bias that is output from the high-voltage PWB (HVTPWB) to the separation electrode. -

Page 176: Fuser Section

2HA/2HB 2-1-6 Fuser section The fuser section consists of the parts shown in figure. When paper reaches the fuser section after the transfer process, it passes between the press roller and heat roller, which is heated by fuser heaters M or S (FH-M or FH-S). Pressure is applied by the fuser unit pressure springs so that the toner on the paper is melted, fused and fixed onto the paper. -

Page 177: Exit And Switchback Sections

2HA/2HB 2-1-7 Exit and switchback sections The exit and switchback sections exit paper on which fuser has ended with the exit roller that is rotated by forward rotation of the exit motor. In duplex copying, paper is turned over by reverse rotation of the exit motor. Figure 2-1-18 Exit and switchback sections Feedshift guide Exit roller... -

Page 178: Duplex Section

2HA/2HB 2-1-8 Duplex section In duplex mode, after copying on to the reverse face of the paper, the paper is reversed in the switchback section and con- veyed to the duplex unit. The paper is then conveyed to the copier paper feed section by the upper and lower duplex feed rollers. -

Page 179: Paper Conveying Operation In Duplex Copying

2HA/2HB (1) Paper conveying operation in duplex copying Paper of which copying onto the reverse side is complete is conveyed to the switchback section, the exit motor switches from forward rotation to reverse rotation to switch the exit roller to reverse rotation, and the paper conveying direction is reversed. - Page 180 2HA/2HB This page is intentionally left blank. 1-4-30...

-

Page 181: Electrical Parts Layout

2HA/2HB 2-2 Electrical Parts Layout 2-2-1 Electrical parts layout (1) PWBs Machine front Machine inside Machine rear Figure 2-2-1 PWBs Engine PWB (EPWB)........Controls the other PWBs, electrical components and optional devices. Main PWB (MPWB) ........Controls the operation panel and laser scanner unit. Power source PWB (PSPWB) ..... -

Page 182: Switches And Sensors

2HA/2HB (2) Switches and sensors Machine front Machine inside Machine rear Figure 2-2-2 Switches and sensors Power switch (MSW)........Turns the AC power on and off. Front cover safety switch (FCSSW)..... Breaks the safety circuit when the front cover is opened. Left cover safety switch (LCSSW) .... -

Page 183: Motors

2HA/2HB (3) Motors Machine front Machine inside Machine rear Figure 2-2-3 Motors Drive motor (DM) ......... Drives the machine. Scanner motor (SM)........Drives the optical system. Exit motor (EM) ..........Drives the exit section. Cooling fan motor 1 (CFM1) ......Cools the machine interior. Cooling fan motor 2 (CFM2) ...... -

Page 184: Other Electrical Components

2HA/2HB (4) Other electrical components Machine front Machine inside Machine rear Figure 2-2-4 Other electrical components Paper feed clutch (PFCL) ......Primary paper feed from the drawer. MP paper feed clutch (MPPFCL) ....Primary paper feed from the MP tray. Exposure lamp (EL) ........ -

Page 185: Power Source Pwb

2HA/2HB 2-3 Operation of the PWBs 2-3-1 Power source PWB Rectifier circuit IL001 ON/OFF +24V T001 SW001 F002 L004 D005 switch circuit L003 DC24V D101 output C008 circuit Q006 C102 INPUT D206 F201 DC5V F001 Switching output C204 circuit control circuit (IC001) F003 DC5V... - Page 186 2HA/2HB Q206 Q101 C104 PC005 C008 L102 PC004 D101 Q006 D005 YC3 YC5 C204 C006 F201 C301 L004 T001 C102 C017 TR001 TR002 IC301 C027 L003 L001 L012 F003 F002 C003 SW001 L013 F001 Figure 2-3-2 Power source PWB silk-screen diagram Connector Pin No.

- Page 187 2HA/2HB Connector Pin No. Signal Description +5 V1 5 V DC power supply for FCSSW Connected Not used to the front +5 V3 5 V DC power supply cover safety switch H.LIVE AC power supply for FH-M/S (LIVE) Connected MH.OUT AC power supply for FH-M to the fuser MH.OUT...

-

Page 188: Main Pwb

2HA/2HB 2-3-2 Main PWB CCDPWB MPWB EPWB 3.3V EGIRN 2.5V SBSY SDIR RSTN SCKN EGSI EGSO SCAN ASIC1 LEDON LCDD OPWB LCDRS LCDEN LCDR_W SBSY SDIR EGIRN RSTN EGSO SCKN EGSI SAMPLE VDATAN ASIC2 OVSYNK SAMPLE PDMASKN VDATAN OUTPEN SELECTOR PLGCLK OUTPEN PLGCLK... - Page 189 2HA/2HB U28 U34 Figure 2-3-4 Main PWB silk-screen diagram 2-3-5...

- Page 190 2HA/2HB Connector Pin No. Signal Description +5 V 5 V DC power supply for OPWB Connected BUZERDRN OPWB buzzer signal to the opera- SCAN7N Key switch scan signal 7 tion unit SCAN6N Key switch scan signal 6 SCAN5N Key switch scan signal 5 SCAN4N Key switch scan signal 4 SCAN3N...

- Page 191 2HA/2HB Connector Pin No. Signal Description SCKN Engine communication clock signal Connected EGSO Engine serial communication reception to the PLGCLK PM clock signal engine PWB SGND Ground OUTEPN Laser diode output signal +5 V 5 V DC power supply from EPWB +5 V 5 V DC power supply from EPWB +5 V...

-

Page 192: Engine Pwb

2HA/2HB 2-3-3 Engine PWB CFM1,2 PSPWB HVTPWB INPWB LAMPN DHVDR FAN1 24V1 ILOCKF THVDR FAN2 24V4 ILOCKL SHVDR SHVISEL SLEPN MHVISEL ORGTIM 24V1 DHVCLK ERASE1N DOPSEL,DOPRDY (DB) ERASE2N 24V4 DOPSI,DOPSO DHVIADJ DOPSCLK 24V1 THVIADJ TONEEPY TONEFUL Scanner unit OPSWN ORGLSWN HUMID TEMP HPSWN... - Page 193 2HA/2HB YC16 YC17 YC19 YC18 YC26 YC22 Figure 2-3-6 Engine PWB silk-screen diagram 2-3-9...

-

Page 194: Motor,

2HA/2HB Connector Pin No. Signal Description +12 V 12 V DC power supply for MPWB Connected OVSYNC Original scanning interval signal to the Main RSTN Reset signal EGRN Engine communication EGRN signal SDIR Engine communication SDIR signal SBSY Engine communication SBSY signal PDMASKN Printing image interval signal EGSI... - Page 195 2HA/2HB Connector Pin No. Signal Description +24V4 24 V DC power supply for DM Connected PGND Ground to the drive SGND Ground motor +5 V 5 V DC power supply for DM DM on/off DM rotation sync signal DM clock signal BPPESW MPPSW on/off Connected...

- Page 196 2HA/2HB Connector Pin No. Signal Description YC11 +24 V4 24 V DC power supply for CFM2 Connected FAN2DRN CFM on/off to the cool- ing fan motor 2 YC13 +24 V1 24 V DC power supply for key counter Connected KEYCN Key counter count signal to the key SGND...

- Page 197 2HA/2HB Connector Pin No. Signal Description YC21 MHEATN FH-M on/off Connected SHEATN FH-S on/off to the power SLEPN Power source sleep signal source PWB ZCROS O Zero-cross signal SGND Ground +24 V2 LCSSW on/off SGND Ground +5 V3 FCSSW on/off YC22 C1PLSW3N PLSW on/off...

-

Page 198: Operation Unit Pwb

2HA/2HB 2-3-4 Operation unit PWB BUZERDRN SCAN7N SCAN6N SCAN5N SCAN4N SCAN3N Dig1 SCAN2N Dig1 SCAN1N Dig2 SCAN0N Dig3 7 segment KEY4 KEY3 KEY2 KEY1 KEY0 LED12 LED11 LED10 LED9 LED8 LED7 LED6 LED5 LED4 LED3 LED2 LED1 LED0 Figure 2-3-7 Operation unit PWB block diagram The operation unit PWB (OPWB) consists of key switches, LEDs, 7 segment LED and buzzer. - Page 199 2HA/2HB Figure 2-3-8 Operation unit PWB silk-screen diagram 2-3-15...

- Page 200 2HA/2HB Connector Pin No. Signal Description SCAN0N Key switch scan signal 0 Connected SCAN1N Key switch scan signal 1 to the main SCAN2N Key switch scan signal 2 SCAN3N Key switch scan signal 3 SCAN4N Key switch scan signal 4 SCAN5N Key switch scan signal 5 SCAN6N...

-

Page 201: Ccd Pwb

2HA/2HB 2-3-5 CCD PWB CCDPWB Tr.AMP CCD sensor MPWB Driver Figure 2-3-9 CCD PWB block diagram Figure 2-3-10 CCD PWB silk-screen diagram 2-3-17... - Page 202 2HA/2HB Connector Pin No. Signal Description SGND Ground Connected MPWB SH signal to the main SGND Ground MPWB CP signal SGND Ground MPWB RS signal SGND Ground CCDCLKN CCDCLKN signal SGND Ground CCDCLK CCDCLK signal SGND Ground +12 V 12 V DC power supply from MPWB SGND Ground +5 V...

- Page 203 2HA/2HB 2-4-1...

- Page 204 2HA/2HB 2-4-2...

- Page 205 2HA/2HB 2-4-3...

- Page 206 2HA/2HB 2-4-4...

-

Page 207: Maintenance Parts List

2HA/2HB Maintenance parts list Maintenance part name Alternative Fig. Ref. Part No. part No. Name used in service manual Name used in parts list Paper feed pulley PULLEY, PAPER FEED 2AR07220 Separation pulley PULLEY, SEPARATION 2AR07230 Forwarding pulley PULLEY, LEADING FEED 2AR07240 MP paper feed pulley PARTS,BYPASS PULLEY,SP... -

Page 208: Periodic Maintenance Procedures

2HA/2HB Periodic maintenance procedures Maintenance Section Method Maintenance cycle Points and cautions Page part/location Test copy Perform at the maxi- Test copy Every service and test print mum copy size Maintenance Section Method Maintenance cycle Points and cautions Page part/location Paper feed Paper feed pulley Check or replace -... - Page 209 2HA/2HB Maintenance Section Method Maintenance cycle Points and cautions Page part/location Developing Developing unit Check or replace - Replace if the problem occurs. P.1-5-26 section Maintenance Section Method Maintenance cycle Points and cautions Page part/location Drum section Drum unit Check or replace Every 150,000 counts Replace if the problem occurs.

-

Page 210: Chart Of Image Adjustment Procedures

2HA/2HB Chart of image adjustment procedures Maintenance mode Adjusting Item Image Description Original Page Remarks order Item No. Exposure indicator Adjusting the magnification in the Polygon motor speed adjustment U053 Exp.2 (light) U053 test pattern P.1-3-16 main scanning direction (printing adjustment) Adjusting the magnification in the Drive motor speed adjustment... - Page 211 2HA/2HB Maintenance mode Adjusting Item Image Description Original Page Remarks order Item No. Exposure indicator Adjusting magnification of the Original scanning speed U065 Exp.2 (light) Test chart P.1-3-18 U065: For copying an original placed on scanner in the auxiliary scanning U070 P.1-3-21 the contact glass...

-

Page 212: General Wiring Diagram

2HA/2HB General wiring diagram 2-4-10... - Page 213 INSTALLATION GUIDE FOR THE 300-SHEET CASSETTE...

- Page 214 Procedure 1. Place the main body on the cassette A by Be sure to turn off the main switch of the main aligning the positioning insertion sections of body of the copier or MFP and disconnect the the main body with the positioning pins 1 at power plug of the main body from the wall the rear part of the cassette A.

-

Page 215: Load Paper In The Drawer

For stacking cassettes for use: 2. If a type of paper that is not included in the 3. Insert the main body power plug into the Stack a cassette on another cassette by specifications for the standard sheet wall outlet and turn the copier main switch aligning the positioning insertion sections of cassette size is used, replace the cassette the first cassette with the positioning pins 1 at... - Page 216 • If the operation panel is a 7-segment type: 2. a: Adequate image Adjusting the leading edge timing If a type b image is obtained, increase the 1. Run maintenance mode 034. adjustment value. Press the image quality mode key until "Text" is lit. (group 1) If a type c image is obtained, decrease the First optional cassette: Press the exposure key until "exp3"...

- Page 217 • If the operation panel is a 7-segment type: 2. a: Adequate image Adjusting the center line If a type b image is obtained, increase the 1. Run maintenance mode 034. adjustment value. Press the image quality mode key until "Text" and "Photo" are lit. (group 2) If a type c image is obtained, decrease the First optional cassette: Press the exposure key until "exp3"...

- Page 218 • If the operation panel is an LCD type: For models equipped with two standard If a type c image is obtained, decrease the Adjusting the leading edge timing cassettes, adjust only RCL T2 and RCL T3. adjustment value. 1. Run maintenance mode 034. Press the Interrupt key to output the test Setting range: -5.0 - +10.0 Select ADJ, RCL ON TIMING and press the...

- Page 219 • If the operation panel is an LCD type: For models equipped with two standard If a type c image is obtained, decrease the Adjusting the leading edge timing cassettes, adjust only LSU T2 and LSU T3. adjustment value. 1. Run maintenance mode 034. Press the Interrupt key to output the test Setting range: -7.0 - +10.0 Select ADJ, LSU OUT TIMING and press...

- Page 220 INSTALLATION GUIDE FOR THE DOCUMENT PROCESSOR...

- Page 221 Supplied parts Procedure A DP main body ........... 1 1. If the original holder is attached, remove it B Pin ............2 and remove the two screws 1 from the top C TP Taptite chromate screw M4 x 10 ..2 rear cover.

- Page 222 3. Place the DP A on the main body of the 4. Secure the DP A with the two TP Taptite 5. Close the DP A, fit the fixing fitting D from copier or MFP by fitting the pins B into the chromate screws M4 x 10 C and the two the rear side of the right hinge, and secure it holes 2 at the hinge sections of the DP A...

- Page 223 7. Remove the screw 4 from the rear cover 8. Clean the pasting position for the label in a and fit the connector protecting plate G to language F with alcohol. the rear cover using the screw 4. Paste the caution label F that corresponds The connector protecting plate G is not to the language according to the destination used for the MFP.

- Page 224 15mm 15mm 15mm 15mm [Operation check] 1. Prepare an original a on which 4 lines b are drawn 15 mm from the edges and the center line c is drawn. 2. Set the original a on the DP and make a test copy to check the copy image. At this time, set the paper guide for the original table and drawer to the paper size to be used.

- Page 225 • If the operation panel is a 7-segment type: Maintenance mode 070 (sub-scan line adjustment) Original a For copy example d: decrease the value. For copy example e: increase the value. Changing the value by one changes the sub-scan line by 0.1%. The larger the value, the larger the magnification of the sub-scan line of the copy image.

- Page 226 • If the operation panel is a 7-segment type: Maintenance mode 071 (leading edge timing adjustment) Original a For copy example f: increase the value. For copy example g: decrease the value. Changing the value by one moves the leading edge by 0.17 mm. The larger the value, the later the image scan start timing.

- Page 227 • If the operation panel is a 7-segment type: Maintenance mode 072 (center line adjustment) Original a For copy example h: increase the value. For copy example i: decrease the value. Changing the value by one moves the center line by 0.17 mm. The larger the value, the center of the image moves toward the right.

- Page 228 • If the operation panel is an LCD type: Maintenance mode 070 (sub-scan line adjustment) 1. Run maintenance mode 070. If an adequate image cannot be obtained, carry out the following adjustment. Select CONVEY SPEED1. 2. Original a (For adjustment of the back side in duplex copying, For copy example d: decrease the value.

- Page 229 • If the operation panel is an LCD type: Maintenance mode 071 (leading edge timing adjustment) 1. Run maintenance mode 071. 2. Original Select LEAD1. For copy example : increase the value. (For adjustment of the back side in duplex copying, For copy example g: decrease the value.

- Page 230 • If the operation panel is an LCD type: Maintenance mode 072 (center line adjustment) If an adequate image cannot be obtained, carry out the following adjustment. 1. Run maintenance mode 072. 2. Original a Select 1sided. For copy example h: increase the value. (For adjustment of the front side in duplex copying, For copy example i: decrease the value.

- Page 231 INSTALLATION GUIDE FOR THE DUPLEX UNIT...

- Page 232 Procedure 1. Open the left cover 1. Be sure to turn off the main switch of the main 2. Remove the stop ring 2 and the strap 3 body of the copier or MFP and disconnect the from the rear side. power plug of the main body from the wall 3.

- Page 233 6. Turn the wire guide section 4 of the duplex 7. Insert the axis sections 5 of the duplex unit 8. Press the duplex unit A in the direction unit A in the direction indicated by the A into the U-shape grooves of the indicated by the arrow to fit the claws 6 into arrow.

- Page 234 9. Hang the hook 7 of the plate lock C on the 10. Secure the duplex unit A with the two S 11. Open the conveyer unit and connect the conveying unit and then turn the plate lock Tite screws M3 x 06 B. connector 9 of the duplex unit A to the C to fit the hole 8 to the claw 9 of the main body.

- Page 235 • If the operation panel is a 7-segment type: 2. a: Adequate image Adjusting the leading edge timing If a type b image is obtained, increase the 1. Run maintenance mode 034. adjustment value. Press the image quality mode key until "Text" is lit. (group 1) If a type c image is obtained, decrease the Press the exposure key until "exp1"...

- Page 236 • If the operation panel is a 7-segment type: 2. a: Adequate image Adjusting the center line If a type b image is obtained, increase the 1. Run maintenance mode 034. adjustment value. Press the image quality mode key until "Text" and "Photo" are lit. (group 2) If a type c image is obtained, decrease the Press the exposure key until "exp1"...

- Page 237 • If the operation panel is an LCD type: If a type c image is obtained, decrease the Adjusting the leading edge timing adjustment value. 1. Run maintenance mode 034. Setting range: -5.0 - +10.0 Select ADJ, RCL ON TIMING and press the Start key. Changing the value by one moves the Select RCL DUP.

- Page 238 • If the operation panel is an LCD type: If a type c image is obtained, decrease the Adjusting the center line adjustment value. 1. Run maintenance mode 034. Setting range: -7.0 - +10.0 Select ADJ, LSU OUT TIMING and press the Start key. Changing the value by one moves the Select LSU DUP.

-

Page 239: Installation Guide

INSTALLATION GUIDE FOR THE Printing System (X) - Page 240 Supplied part Option Installing the printer board 2. Insert the printer board (A) all the way English into the slot and secure it with two screws A Printer board ........1 B USB interface IB-110 ......1 1. Remove two screws (1) and remove the INSTALLATION GUIDE FOR cover (2).

- Page 241 Installing IB-110 vertically: Installing IB-110 horizontally: 1. Connect the connector, which has a ferrite core, of the power cable (E) supplied with Note English IB-110 to the printer board, and connect the other side to IB-110. Attach the vertical stand (C) supplied with Attach the four rubber bases (D) supplied Be sure to use the supplied power cable and Installing the USB interface IB-110...

Need help?

Do you have a question about the KM-2035 and is the answer not in the manual?

Questions and answers