Novexx Solutions ALX 73 Series Service Manual

Hide thumbs

Also See for ALX 73 Series:

- User manual (135 pages) ,

- Operating manual (43 pages) ,

- Service manual (30 pages)

Table of Contents

Advertisement

Quick Links

04/13 Rev. 5.08-02

Installation/Deinstallation

Defining the operating position ..................... 2

Space requirement .................................... 2

Admissible operation positions .................. 2

Top labelling .............................................. 3

Side labelling ............................................. 5

Unpacking and assembling the machine ...... 7

Transportation ........................................... 7

Unpacking the machine ............................. 7

Mounting the unwinder ............................ 13

Mounting the holding plate ...................... 15

Mounting the dispensing edge holder ..... 19

Mounting the dispensing edge ................ 20

Mounting the dancer arm unit ................. 21

Connecting remote operation panels .......... 22

Important notes ....................................... 22

Connecting .............................................. 22

Wall mounting ......................................... 22

Connecting to the mains power supply ....... 23

Producing the power cable ...................... 24

Connecting the sensors .............................. 25

Label sensor ............................................ 25

Alternative label sensor ........................... 27

Product sensor ........................................ 32

External OD sensor ................................. 34

Internal OD sensors ................................ 37

Rotary encoder ........................................ 38

SERVICE MANUAL

ALX 73x

Installing APSF ............................................40

Principle of operation ...............................40

Mounting the rotary encoder ....................41

wheel .......................................................42

Entering the rotary encoder type .............43

Input of encoder data ...............................43

Calibrating the belt speed ........................44

dispensing speed adjustment ..................44

Mounting of options .....................................47

Applicators ...............................................47

Adjustable dispensing edge holders ........48

Dancer arm unit with double roller ...........50

Take the machine out of operation ..........51

Dismantling the machine .........................51

Machine disposal .....................................52

Appendix .....................................................53

edge holder ..............................................53

deflection roller) .......................................54

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Novexx Solutions ALX 73 Series

-

Page 1: Table Of Contents

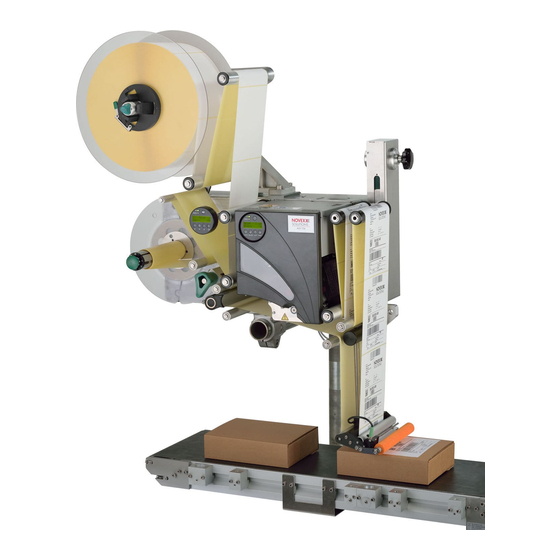

04/13 Rev. 5.08-02 SERVICE MANUAL ALX 73x Installation/Deinstallation Defining the operating position ..... 2 Installing APSF ..........40 Space requirement ........2 Principle of operation .......40 Admissible operation positions ....2 Mounting the rotary encoder ....41 Top labelling ..........3 Entering the rotary encoder resolution ..42 Side labelling .......... -

Page 2: Defining The Operating Position

04/13 Rev. 5.08-01 SERVICE MANUAL Defining the operating position ALX 73x Defining the operating position Space requirement For machine dimensions read topic section Technical Data > „Entire unit“ > „Dimensions“. On the machine side facing the operator must be left at least 1 m free space for loading and changing of sup- plies. -

Page 3: Top Labelling

04/13 Rev. 5.08-01 SERVICE MANUAL Defining the operating position ALX 73x Top labelling Horizontal operating position [2] Horizontal position for top labelling with two unwinders. [4] Horizontal position for top labelling with one unwinder on top. [3] Horizontal position for top labelling with one unwinder left. - Page 4 04/13 Rev. 5.08-01 SERVICE MANUAL Defining the operating position ALX 73x Vertical operating position [5] Vertical operating position for top labelling with one side [6] Vertical operating position for top labelling with one top mounted unwinder. mounted unwinder.

-

Page 5: Side Labelling

04/13 Rev. 5.08-01 SERVICE MANUAL Defining the operating position ALX 73x Side labelling Horizontal operating position [7] Horizontal operating position for side labelling with two [9] Horizontal operating position for side labelling with one top mounted unwinder. unwinders. [8] Horizontal operating position for side labelling with one side mounted unwinder. - Page 6 04/13 Rev. 5.08-01 SERVICE MANUAL Defining the operating position ALX 73x Vertical operating position [10] Vertical operating position for side labelling with one side [11] Vertical operating position for side labelling with one top mount- ed unwinder. mounted unwinder.

-

Page 7: Unpacking And Assembling The Machine

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Unpacking and assembling the machine WARNING! Acute risk of injury and long-term bodily inju- ry from working with heavy loads! Lift or carry the machine with a minimum ... -

Page 8: Mounting The Machine On A Support Stand

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting the machine on a support stand WARNING! Risk of injury from a tipping over support stand. When installing the machine on a support stand, make sure that it can not tip over. ... - Page 9 04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Rear side mounting Prerequisites: • Support stand with a tube end providing the follow- ing measures: – Outer-Ø: 60 mm – Wall thickness: minimum 5 mm • Adjustable head joint [19] (article number A9773) [15] Mounting the machine side bracket.

- Page 10 04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x 9. Incline the machine to the required angle by turning the adjustment screw [20A]. Turn in = Inclination upwards +4° Turn out = Inclination downwards -4° [20] Setting the declination.

- Page 11 04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting at the machines outer side Prerequisites: • Support stand with a tube end providing the follow- ing measures: – Outer-Ø: 60 mm – Wall thickness: minimum 5 mm •...

- Page 12 04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting with adjustable head joint at the machines outer side To attach the machine inclinable at its outer side, the flange plate can be combined with the adjustable head joint.

-

Page 13: Mounting The Unwinder

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting the unwinder Mounting notes • RH unwinder: For mounting the unwinder on top right or at the right side, a RH model must be used, see rating plate [25 circle]. •... - Page 14 04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting the unwinder to the unwinder holder 1. Push the unwinder onto the unwinder holder. Abwickler [31A] auf den Abwicklerhalter [31B] stecken. Top mounting: The stud at the unwinder holder must engage in the centre hole [31C][29] at the un- winder.

-

Page 15: Mounting The Holding Plate

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting the holding plate Tool 8 mm hex socket screwdriver Mounting Attach the dispensing edge holding plate [32A] with 4 screws to the frontal housing flange. The 2 studs [32B] in the holding plate must rest on the flange edge [32C]. -

Page 16: Configuring The Dispensing Edge Holder

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Configuring the dispensing edge holder An ALX 73x with standard dispensing edge holder and fixed L-shape dispensing edge can print labels up to a length of 225 mm without having to modify the length of the dispensing edge holder. - Page 17 04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x [34] Diagram for finding out the optimum length of the dispensing edge holder (linear dancer lever with single deflection roller). Reading example: Starting with a label length of 330 mm [34A], the dia- gram shows a length range for the rods of 145 mm [34B] to 255 mm [34C] (dotted lines).

- Page 18 04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x An additional length area results, if the vertical line is elongated until it cuts the second coloured area. The examle shows here an admissible rod lengthof 475 to 511 mm (dashed lines).

-

Page 19: Mounting The Dispensing Edge Holder

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting the dispensing edge holder The dispensing edge holder is required for mounting L-shape dispensing edges. Both, the dispensing edge holder [35A] and the mount- ing flange [35B] on the holding plate have two concen- tric rings of holes on the connecting surfaces. -

Page 20: Mounting The Dispensing Edge

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting the dispensing edge Mounting a L-shape dispensing edge Prerequisite: Dispensing edge holder is mounted. Tool Hex socket screwdriver, 8 mm Mounting: 1. Fit the dispensing edge [36A] as pictured. ... -

Page 21: Mounting The Dancer Arm Unit

04/13 Rev. 5.08-02 SERVICE MANUAL Unpacking and assembling the machine ALX 73x Mounting the dancer arm unit Tools • Allen keys, 2/4 mm • Spanner, SW 13 Mounting 1. Remove the deflection roller [39A]. To do so, un- screw the axle using the spanner. 2. -

Page 22: Connecting Remote Operation Panels

04/13 Rev. 5.08-02 SERVICE MANUAL Connecting remote operation panels ALX 73x Connecting remote operation panels Important notes Remote operation panels are necessary, if the machine is installed at an inaccessible place, where the stand- ard operation panels can not be reached. Printer and dispenser each require a separate operation panel. -

Page 23: Connecting To The Mains Power Supply

04/13 Rev. 5.08-02 SERVICE MANUAL Connecting to the mains power supply ALX 73x Connecting to the mains power supply WARNING! The machine is connected with the mains supply! Contact with energised components can result in life-endangering currents through the body as well as burns. The mains connection may only be performed by authorised specialists who are ... -

Page 24: Producing The Power Cable

04/13 Rev. 5.08-02 SERVICE MANUAL Connecting to the mains power supply ALX 73x Producing the power cable Connecting to the machine The ALX 73x comes with a loose machine connector [44]. Article number: A9546 Tool: Screwdriver size 2 [44] Machine connector of the power cable. Connecting: 1. -

Page 25: Connecting The Sensors

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Connecting the sensors Label sensor Permitted sensor type: NPN The label sensor is included in the dispensing edge scope of delivery [47] (order no. A6589) Connecting the sensor [47] Recommended label sensor ... - Page 26 04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Adjusting the label sensor automatically Only works up to max. 120 mm label length (includ- ing the gap). (LMA) Call up MACHINE SETUP > Auto Sensor Adj. The label material is fed slowly until the next gap between labels (punch) is reached.

-

Page 27: Alternative Label Sensor

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Alternative label sensor Other suitable sensors can be used as an alternative to the throughbeam photoelectric sensor. Permitted sensor types: PNP or NPN Default setting: PNP Alternative label sensor and standard photoelectric sensor may both be connected at the same time. - Page 28 04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Connection Diagram +24V +24V NPN-Configuration 2,2k NPN-Signal 1,5k Signal Input Sensor connector PNP-Signal 2,2k PNP-Configuration Jumper (default: open) [52] Connection diagram alternative label sensor.

- Page 29 04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Example: capacitive label sensor Application: transparent Labels Order numbers: • A7775 (capacitive sensor including mounting mate- rial and connection cable) [53A] • A101452 (sensor only) www.di-soric.de Tools: Hexagon socket drivers 4/6 mm Installation: 1.

- Page 30 04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Leuze sensor setting: 1. Remove label material from the sensor fork. 2. Turn potentiometer [55B] to the right, until a light click is audible (= max. sensitivity). Turn the poten- tiometer ½...

-

Page 31: Position Sensor For Linear Dancer Arm

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Position sensor for linear dancer arm Connect cable [57] to the linear dancer unit [58A] and to the machines rear side [59A]. [57] Connection cable for the dancer arm position sensor (Article no.: A102508). -

Page 32: Product Sensor

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Product sensor • Permitted sensor types: PNP or NPN • Preset: PNP • Order no.: A7112 [60] Connecting the photoelectric sensor Plug the product sensor in to the connector shown [61A]. -

Page 33: Changing Light/Dark Switching At The Product Sensor Or The Alternative Label Sensor

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Changing light/dark switching at the product sensor or the alternative label sensor Basically, sensors can be assigned to three different groups regarding the function of pin 2: a) Pin 2 has no function b) Pin 2 = input, e.g. -

Page 34: External Od Sensor

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) External OD sensor [66] External OD sensor. The ALS30x can be equipped with an optional sensor [64] to check the outer diameter (OD sensor) of the label roll. The OD sensor triggers a display mes- sage and a signal at the signal interface, if less than a certain residual diameter is left on the label roll. - Page 35 04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Connecting Plug the roll diameter sensor in to the connector shown [67A]. Enabling (LMA) Set MASCHINE SETUP > OD sensor warn. to „Er- ror“ or „Warning“. MASCHINE SETUP > OD Sens.polarity ...

- Page 36 04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Setting the roll diameter Prerequisite: • OD sensor is installed an activated. • Label material roll with the required remaining di- ameter is prepared. Setting: 1. Measure the diameter of the prepared roll. 2.

-

Page 37: Internal Od Sensors

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Internal OD sensors The internal OD-sensors are integrated in the material unwinder. Precondition for activating the sensors is, that they are connected to the ALX 73x. Two unwinders can be connected overall. Each un- winder requires a cable kit. -

Page 38: Rotary Encoder

04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Rotary encoder For the labeller to be used with automatic speed adjust- ment, a rotary encoder must be connected. The rotary encoder communicates the conveyor belt speed to the label dispenser. - Page 39 04/13 Rev. 5.08-01 SERVICE MANUAL Connecting the sensors ALX 73x (LMA) Connecting the rotary encoder CAUTION! To avoid damage to the electronics: Switch the machine off before connecting the rotary encoder. Plug the rotary encoder in to the connector shown [75A].

-

Page 40: Installing Apsf

04/13 Rev. 5.07-00 SERVICE MANUAL Installing APSF ALX 73x Installing APSF Principle of operation APSF = Automatic Product Speed Following. [79] Rotary encoder (A) on the conveyor line (schematic). The automatic dispensing speed adjustment makes it possible to automatically adapt the dispensing speed to the speed of the conveyor belt. -

Page 41: Mounting The Rotary Encoder

04/13 Rev. 5.07-00 SERVICE MANUAL Installing APSF ALX 73x Mounting the rotary encoder Rotary encoder with measuring wheel at the conveyor belt [80] Mounting the rotary encoder with measurement wheel at the conveyor belt. D = Diameter of the measurement wheel. A measuring wheel translates the conveyor belt movement into rotation of the rotary encoder shaft. -

Page 42: Entering The Rotary Encoder Resolution

04/13 Rev. 5.07-00 SERVICE MANUAL Installing APSF ALX 73x The reduction ratio of the gear (motor axle rotates faster than drive axle) must be con- sidered, when entering the rotary encoder data. This can be done on two ways: D′ ... -

Page 43: Entering The Rotary Encoder Type

04/13 Rev. 5.07-00 SERVICE MANUAL Installing APSF ALX 73x Entering the rotary encoder type Depending on the features of rotary encoder and label dispenser, there are different ways to count the impulses generated by the rotary encoder: MACHINE SETUP > Encoder type. -

Page 44: Calibrating The Belt Speed

04/13 Rev. 5.07-00 SERVICE MANUAL Installing APSF ALX 73x Calibrating the belt speed MACHINEN SETUP > Encoder Diameter Aftercalling (LMA) the following is displayed: Encoder Diameter yy.y var • x.x = diameter of measuring wheel • yy.y = belt speed according to current measurement •... - Page 45 04/13 Rev. 5.07-00 SERVICE MANUAL Installing APSF ALX 73x Read the calculation results [84D]. In the rightmost column appear warning notes, if questionable values are entered [84E]. Inputs • p: sensor pulses: Number of pulses, which delivers the rotary encoder per rotation Typical values: 100 up to 5000 pulses/rotation •...

- Page 46 04/13 Rev. 5.07-00 SERVICE MANUAL Installing APSF ALX 73x Calculations Size Symbol Calculation Note π π d ⋅ 3 1415926 Wheel circumference 1000 -------- - -------- - ----------- - ⋅ Max. speed 1000 mm = 1 m; 60 s = 1 min ≤...

-

Page 47: Mounting Of Options

04/13 Rev. 5.08-01 SERVICE-MANUAL Installation / Deinstallation ALX 73x Mounting of options Mounting of options Applicators System requirements The following applicators can be operated at the ALX 73x: • LA-TO (tamp-on applicator) [1] • LA-BO (blow-on applicator) [2] Due to the danger of cuts and crush injuries, the LA-TO may only be operated with superior protective equipment installed (for details refer to the LA-TO... -

Page 48: Adjustable Dispensing Edge Holders

04/13 Rev. 5.08-01 SERVICE-MANUAL Installation / Deinstallation ALX 73x Mounting of options Adjustable dispensing edge holders Adjustable dispensing edge holder (simple version) Also read the notes about the standard dispensing edge holder in chapter Mounting the dispensing edge holder on page 19. - Page 49 04/13 Rev. 5.08-01 SERVICE-MANUAL Installation / Deinstallation ALX 73x Mounting of options Fine adjustable dispensing edge holder Also read the notes about the standard dispensing edge holder in chapter Mounting the dispensing edge holder on page 19. Setting range: A = 134 mm;...

-

Page 50: Dancer Arm Unit With Double Roller

04/13 Rev. 5.08-01 SERVICE-MANUAL Installation / Deinstallation ALX 73x Mounting of options Dancer arm unit with double roller Replacing the single by a double roller increases the la- bel amount that can be buffered in the loop. This is an advantage, if very long labels are processed. -

Page 51: Decommissioning, Dismantling, Disposal

04/13 Rev. 5.08-01 SERVICE-MANUAL Installation / Deinstallation ALX 73x Decommissioning, Dismantling, Disposal Decommissioning, Dismantling, Disposal Take the machine out of operation Disconnecting the machine from the compressed air supply (only machines with in- stalled applicator): 1. Switch off the compressed air supply of the applicator. 2. -

Page 52: Machine Disposal

04/13 Rev. 5.08-01 SERVICE-MANUAL Installation / Deinstallation ALX 73x Decommissioning, Dismantling, Disposal Machine disposal It is advisable to remove reusable machine components as long as the machine is firmly mounted. 1. Remove machine parts which can be reused (e. g. applicator, applicator interface, dispensing edge holder, dispensing edge). -

Page 53: Appendix

04/13 Rev. 5.08-01 SERVICE-MANUAL Installation/Deinstallation ALX 73x Appendix Appendix Length chart for adjustable dispensing edge holder Upper rods Meas. Article A5097 A5099 A5096 A5098 A5095 Length/ max. A5097 min. max. A5099 min. max. A5096 min. 1050 max. A5098 min. 1050 1133 max. -

Page 54: Diagram For Determining The Length Of The Dispensing Edge Holder (With Double Deflection Roller)

04/13 Rev. 5.08-01 SERVICE-MANUAL Installation/Deinstallation ALX 73x Appendix Diagram for determining the length of the dispensing edge holder (with double deflection roller) [2] Diagram for finding out the optimum length of the dispensing edge holder (linear dancer lever with dou- ble deflection roller).

Need help?

Do you have a question about the ALX 73 Series and is the answer not in the manual?

Questions and answers