Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Felder Hammer HNC 47.82

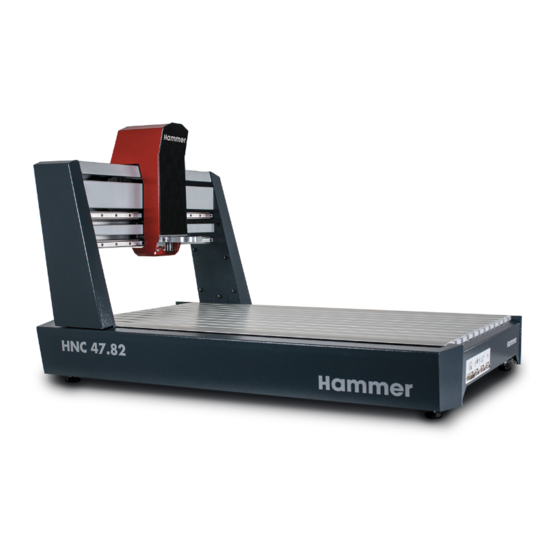

- Page 1 HNC 47.82 CNC portal machine Keep this manual to hand and in good condition for future reference! Please read this operating manual carefully before using the machine! Translation of the original operating instructions Version 2 25.3.2021 HNC_02, 5, en_GB...

- Page 2 Felder KG KR-Felder Straße 1 6060 Hall in Tirol +43 (0) 5223 / 5850 0 info@felder-group.com www.felder-group.com © 2021...

-

Page 3: Table Of Contents

HNC 47.82 Table of contents Table of contents Instructions..............Symbol legend. - Page 4 Table of contents Electrical connection..........30 Software.

-

Page 5: Instructions

HNC 47.82 Instructions Instructions Symbol legend Safety instructions Safety instructions in this manual are indicated with symbols. The safety instruc- tions are introduced by key words which state in words the extent of the hazard. Comply with safety instructions under all circumstances, and act with care in order to avoid accidents, personal injury, or material damage. -

Page 6: Liability And Warranty

The guarantee period is in accordance with national guidelines. Details may be found on our website, www.felder-group.com. Spare parts NOTICE Wrong or faulty spare parts Material damage, malfunction, machine failure −... -

Page 7: Safety

HNC 47.82 Safety Safety At the time of its development and production, the machine was built in accord- ance with prevailing technological regulations and therefore conforms to industry safety standards. However, hazards may arise should the machine be operated by untrained personnel, used improperly or employed for purposes other than those it was designed for. -

Page 8: Responsibilities Of The Operator

Safety Responsibilities of the operator This manual must be kept in the immediate vicinity of the machine. The manual must be accessible at all times to all persons working on or with the machine. The machine may only be operated if it is in proper working order and in safe condi- tion. -

Page 9: Personal Protective Equipment

HNC 47.82 Safety Personal protective equipment 3.7.1 Prohibitions When working on or with the machine, the following must be strictly observed: NOTE Wear a hair net. With long hair and beards a hair net must be worn. 3.7.2 Mandatory safety equipment When working on or with the machine, the following must always be worn by per- sonnel: Protective clothes:... -

Page 10: Other Risks

Safety Other risks Even if the safety measures are complied with, there are still certain associated risks that must be considered when working on the machine: ● Injuries when changing the tool: cutting injuries and crush risk ● Injury when coming into contact with rotating parts ●... - Page 11 HNC 47.82 Safety During all maintenance work on the aggregate: ● Service work carried out by untrained or unauthorised personnel. ● Non-observance of the maintenance guidelines. ● Non-observance of usage and damage tracks.

-

Page 12: Declaration Of Conformity

The signatory of this statement is the appointed agent for the compilation of the technical informa- tion. Prof. h.c. Ing. Johann Georg Felder CEO Felder KG KR-Felder-Straße 1, A-6060 HALL in Tirol... -

Page 13: Technology Data

HNC 47.82 Technology Data Technology Data All technical information is for the standard equipment without spindle and extrac- tion hood. Machine: Dimensions and weight Data Value Total length 1111 mm Total width 762 mm Total height 682 mm Weight approx. 81 kg Packaging incl. - Page 14 Technology Data Inner dimensions of the portal & other dimensions Data Value Clearance width 625 mm Clearance height 160 mm Table surface 1005 mm x 574 mm T grooves in the table 17.5mm x 7.5 mm for M8 Tool chucks (standard) Ø...

- Page 15 HNC 47.82 Technology Data Electrical connections Fig. 2: Machine connections at the rear Main switch Mains connection C14 Rotation speed control (0-10 volts) (not with HF motors) Connection for the machine head (not with HF motors) Extraction/cable guides...

- Page 16 Technology Data Fig. 3: Electrical control box HF Mains connection C14 Main switch Data Value Connection point on the machine C14 device plug Input voltage machine 88-264 V AC 50/60 Hz Power consumption of the machine / 460 W / 2300W incl.

- Page 17 HNC 47.82 Technology Data Tool Fig. 4: Clamping height Tool holder Tool Clamping height Data Value Clamping height HFM 1000* 85 mm Clamping height HF motor* 105 mm Ø tool max. 36 mm Ø shaft max. HFM 1000 8 mm Ø...

- Page 18 Technology Data ● Router tools with a diameter ≥ 16 mm must adhere to the standards DIN EN 847-1:2018-01 and DIN EN 847-2:2018-01. ● Follow the operating instructions of the tool manufacturer. ● Select the correct tool and use the recommended rotation speed for the respective material.

-

Page 19: Noise Level

HNC 47.82 Technology Data Reference point Fig. 5: Reference point X-axis Y-axis Machine zero point Reference point Front of the machine The machine zero point is situated at the rear, left hand corner (connections for PC, emergency stop, etc. are at the front). The reference point is at X: 798 mm and Y: 449 mm X-axis Y-axis... - Page 20 Technology Data The specified values are emission values and therefore do not represent certain workplace values. Although there is a correlation between emission and immis- sion levels, it is not possible to state whether increased safety measures are required. Factors which can considerably influence the present immission level at the workplace include the duration of exposure, the character of the working area and other influences in the neighbouring area.

-

Page 21: Machine Assembly

Workpiece support Mains connection & main switch Portal with machine head Clamping of the router Connections Machine data plate A-6060 HALL in Tirol, KR-Felder-Straße 1 Austria, Tel. +43 (0) 5223 58500 Fax +43 (0) 5223 56130, info@hammer.at www.hammer.at TYPE: HNC 47.82 Nr.:... -

Page 22: Safety Devices

Machine assembly Safety devices ● The machine is equipped with an emergency stop button. This must be con- nected to the machine. See ⮫ ‘Connection emergency stop’ on page 32 ● The use of an extraction protection hood is compulsory when using rotating tools. -

Page 23: Transport, Packaging And Storage

HNC 47.82 Transport, packaging and storage Transport, packaging and storage Safety instructions NOTICE Transport damage The machine can be damaged or destroyed if it is subjected to improper handling during transport. − Always move the machine with the utmost care and caution. −... -

Page 24: Transport

Transport, packaging and storage Transport Fig. 8: Packaging The machine is transported equipped with the transport locks. It is recommended to store the packaging and transport locks, once removed. If, due to any defects, the machine has to be returned to the manufacturer then the original packaging and transport locks should be used. -

Page 25: Storage

HNC 47.82 Transport, packaging and storage Environmental protection Packaging materials are valuable raw materials and in many cases they can be used again, reprocessed or recycled. ENVIRONMENT Dispose of the packaging in an environmentally friendly manner − Dispose of the packaging materials in an environmentally friendly way and always in accordance with local waste dis- posal regulations. -

Page 26: Setup And Installation

Setup and installation Setup and installation Safety instructions WARNING Improper setup and installation Severe injuries and damage to property − Work may only be carried out by authorised, trained per- sonnel who are familiar with how to operate the machine and are in strict observance of all safety instructions. -

Page 27: Remove Transport Locking Devices

HNC 47.82 Setup and installation Remove transport locking devices It is recommended to store the packaging and transport locks, once removed. If, due to any defects, the machine has to be returned to the manufacturer then the original packaging and transport locks should be used. -

Page 28: Attach The Mounting Plate For The Router Motor Using Screws

Setup and installation ● Provide sufficient light at the workstation. ● Sufficient clearance or screening from neighbouring workstations. ● Set the levelling feet and then check that the machine is level using a spirit level. All 4 of the adjustable feet must sit flush to the floor. Fig. -

Page 29: Mount The Extraction Hood

HNC 47.82 Setup and installation Mount the extraction hood Fig. 11: Mount the extraction hood Extraction hood Height adjustment screw Mount for the height adjustment screw Magnetic dust brush Mount the extraction hood to the machine head using the height adjustment screws. -

Page 30: Electrical Connection

Setup and installation Electrical connection WARNING Electric current! Serious injury or death − The work to be performed may only be carried out by a trained electrician. Before connecting the machine to the power supply, compare the information on the nameplate with those of the power supply. Only connect the machine if the two sets of data correspond to each other. - Page 31 HNC 47.82 Setup and installation Fig. 13: Machine connections at the rear Main switch Mains connection C14 Rotation speed control (0-10 volts) (not with HF motors) Connection for the machine head (not with HF motors) Extraction/cable guides Mains connection machine Connect the machine using the C13 plug at the rear of the machine to the power supply.

- Page 32 Setup and installation Mains connection HF spindle (optional) Fig. 14: Electrical control box HF Mains connection C14 Main switch The HF spindle is premounted and connected to the machine. The frequency inverter must be placed on a flat, stable surface and connected to the mains supply (⮫...

-

Page 33: Software

HNC 47.82 Setup and installation Software Download / Installation Download the Eding CNC Software and instruction manual from the manu- facturer (⮫ https://www.edingcnc.com/). Install the Eding CNC software on to the PC following the manufacturers instruction manual. Download configuration file (⮫ http://fg.am/hncini). Extract Zip folder. -

Page 34: Adjustments And Tool Changes

Adjustments and tool changes Adjustments and tool changes Safety instructions WARNING Improper adjustment and setup Serious physical injury or material damage. − Adjustment and setup may only be carried out by authorised, trained personnel who are familiar with how to operate the machine and are in strict observance of all safety instructions. -

Page 35: Tighten The Router Motor In Place

HNC 47.82 Adjustments and tool changes Tighten the router motor in place Fig. 17: Tighten the router motor in place Fixation of the router motor Mains connection router motor (rear side) Extraction/cable guides Place the router motor in to the 43 mm collar and clamp using the nut (10-11 Nm). -

Page 36: Tighten The Router Tool In Place

Adjustments and tool changes Tighten the router tool in place 9.3.1 Protective housing NOTICE Tool breakage Damage to tools and machine − Adhere to the rotation and feed speed defined on the tool. − Each time before the machine is started, check that all of the locking nuts and locking devices are secured with the right torque setting. -

Page 37: Hf-Motor (Optional)

HNC 47.82 Adjustments and tool changes Dimensions Length 1500 mm Width 1000 mm Height 800 mm Material MDF, 19 mm 9.3.2 HF-motor (optional) WARNING Collision danger and risk of cutting Severe injuries caused by rotating tools − Adjustments to the machine or changing the tools may only be done once the machine has stopped. -

Page 38: Router Motor Hfm 1000

Adjustments and tool changes Fig. 19: HF spindle: Clamp tool in place Fix the spindle Sleeve nut Tighten the router tool in place Tool: ●Router tooling ●Spanner 22 mm ●Collet chuck key Insert the collet chuck into the sleeve nut. Insert the router tool and move it until it reaches the stop in the tool socket. -

Page 39: Dust Extraction

HNC 47.82 Adjustments and tool changes Dust extraction Fig. 20: Dust extraction Connection for dust extractor (Ø 32 mm) Height adjustment extraction Extraction/cable guides CAUTION Breathing in dust Risk of damage to health from dust − The machine may only be used in combination with a func- tioning extraction system. - Page 40 Adjustments and tool changes Fix the extraction hose to the guide on the machine head (using a cable tie or similar).

-

Page 41: Operation

HNC 47.82 Operation 10 Operation WARNING Insufficient preparation Severe injuries and damage to property − It is only permitted to switch on the machine if, for the work at hand, the required preconditions are fulfilled and any prelimi- nary work is completed. −... -

Page 42: Preparation

Operation ● Injuries from flying workpieces (e.g. offcuts). ● Offcuts or other parts of the workpiece should not be removed from the cut- ting area whilst the machine is still running. ● Only remove chips when the machine is at a standstill. No program may be loaded / executed. -

Page 43: Warm Up Hf-Spindle

HNC 47.82 Operation WARNING Flying pieces Severe injuries and damage to property − Use appropriate clamping devices to fasten the workpieces to the machine table. Tip: Bridging for nesting applications When nesting is being carried out, it is recommended to leave material bridges between smaller components. -

Page 44: Tool

Operation Fig. 21: Workpiece bow 10.4.2 Tool The length, number of edges, cutting angle and diameter of the tool influence the working accuracy that is achievable. The tools differ greatly from manufacturer to manufacturer. Tip: Use sharp tools High accuracy can only be achieved with sharp tools. NOTICE Feed rate too high Material damage... -

Page 45: Maintenance

HNC 47.82 Maintenance 11 Maintenance 11.1 Safety instructions WARNING Improper maintenance Severe injuries and damage to property − Maintenance work may only be carried out by authorised, trained personnel who are familiar with how to operate the machine and are in strict observance of all safety instructions. WARNING Electric current! Serious injuries... -

Page 46: Maintenance Schedule

Maintenance ● Constant visual contact between operator and maintenance technician to ensure fast and unambiguous communication. ● Instructions from maintenance personnel must be repeated and confirmed by the operator before they are carried out. ● Before switching on a stationary element, maintenance technicians must move to a safe position and approach the moving elements again only after the instructions they have given have been correctly carried out by the oper- ator. - Page 47 HNC 47.82 Maintenance Y-axis Fig. 22: Screws for the side cover Screws for the side cover...

- Page 48 Maintenance Fig. 23: Remove the Y-axis cover Clamping screw Coverage Switch off the machine at the main switch, disconnect the power supply. Remove the side cover screws (both sides of the portal). Loosen the clamping screw (both sides of the portal). Remove the cover.

- Page 49 HNC 47.82 Maintenance X-axis Fig. 24: Tilt the machine up in the direction of the machine head Fig. 25: Lubrication of the X axis Trapezoidal spindle Carry out reference run. Switch off the machine at the main switch, disconnect the power supply. Tilt the machine on the side on which the machine head is situated.

- Page 50 Maintenance Clean the trapezoidal spindle and nuts with a lint-free cloth. Remove excess grease. Apply Shell Gadus S3 V220 C2 evenly to the entire trapezoidal spindle with a brush. Switch machine on. Move several times over the entire length of the axle to distribute the grease.

- Page 51 HNC 47.82 Maintenance Z-axis Fig. 26: Remove the Z-axis cover Spindle holder Remove the cover screws Cable guide Z-axis cover...

- Page 52 Maintenance Fig. 27: Lubricate Z-axis Z-axis Move the Z-axis into the highest position. Switch off the machine at the main switch, disconnect the power supply. Remove the router motor and extraction. Unscrew the spindle holder. Loosen both cover screws. Loosen both cable guides which are on top of the machine head and remove the Z-axis cover.

-

Page 53: Check/Replace The Drive Belt

HNC 47.82 Maintenance Clean the trapezoidal spindle and nuts with a lint-free cloth. Remove excess grease. Apply Shell Gadus S3 V220 C2 evenly to the entire trapezoidal spindle with a brush. Move the Z-axis upwards on the drive wheel of the belt. Put everything back together in reverse order. - Page 54 Maintenance Z-axis Fig. 28: Changing the belt of the Z-axis. Belt Locking screws (4x) Switch off the machine at the main switch, disconnect the power supply. Remove the Z-axis cover. See ⮫ 11.3‘Grease trapezoidal spindles’⮫ ‘Z-axis’. Loosen the 4 motor fixing screws (do not remove them). Support the oppo- site side.

- Page 55 HNC 47.82 Maintenance Y-axis Fig. 29: Screws for the side cover Screws for the side cover...

- Page 56 Maintenance Fig. 30: Y-axis belt change Screws for the portal cover (both sides) Portal cover Locking screws (4x) Drive belt Switch off the machine at the main switch, disconnect the power supply. Remove the side cover screws (both sides of the portal). Unscrew the portal cover on both sides.

- Page 57 HNC 47.82 Maintenance X-axis Fig. 31: Underside of the HNC Remove the cover screws Wheels Belt tensioner Fig. 32: Remove the front and rear cover Cover screws...

-

Page 58: Check Protective Equipment

Maintenance Fig. 33: X-axis drive motor Drive motor Move the machine portal against the rear stop. Switch off the machine at the main switch, disconnect the power supply. Clamp the machine portal (using clamps). �� This will ensure that the portal remains parallel. Remove the cover screws ⮫... -

Page 59: Faults

HNC 47.82 Faults 12 Faults 12.1 Safety instructions WARNING Repairing faults incorrectly Severe injuries and damage to property. − Troubleshooting may only be carried out by authorised, trained personnel who are familiar with how to operate the machine and are in strict observance of all safety instructions. WARNING Electric current! Injury from electric shock. - Page 60 Faults Fault Cause Repair Emergency stop is not connected Connect emergency stop to the to the machine machine Axis are not moving, but the step The drive belt is broken. Replace the drive belt motor is running ● Axes movement incorrect Belt tension is too high or too low Check and set belt tension ●...

-

Page 61: Disposal

HNC 47.82 Disposal 13 Disposal Before disposing of the machine, contact the manufacturer. Should the machine be disposed of at the end of its operating life, all of the com- ponents need to be separated according to material class, to enable recycling or scrapping. - Page 63 Felder KG KR-Felder Straße 1 6060 Hall in Tirol +43 (0) 5223 / 5850 0 info@felder-group.com www.felder-group.com...

Need help?

Do you have a question about the Hammer HNC 47.82 and is the answer not in the manual?

Questions and answers