Summary of Contents for Fuji Electric POD UG221H-LE4

- Page 1 FUJI UG SERIES PROGRAMMABLE OPERATION DISPLAY USER'S MANUAL <Simple POD Hardware> TYPE: UG221H-LE4 UG221H-LR4 UG221H-SR4 FEH382...

- Page 2 Preface Thank you for selecting the Fuji Programmable Operation Display, POD UG221H-LE4, LR4, SR4 (called as the Simple POD or POD hereafter). This User’s Manual <Simple POD Hardware> explains system configuration, specifications and handling of the Simple POD. To enable you to fully utilize the display, carefully read this User’s Manual.

- Page 3 Record of Revisions Reference numbers are shown at the bottom left corner on the back cover of each manual. Printing Date Reference No. Revised Contents July, 2004 FEH382 First edition...

- Page 4 Notes on Safe Use of POD In this manual, you will find various notes categorized under the following levels with the signal words “DANGER,” and “CAUTION.” Indicates an imminently hazardous situation which, if not avoided, will result in death or DANGER serious injury.

- Page 5 • Do not disassemble or modify POD. Otherwise, it may cause a malfunction. • Fuji Electric FA Components & Systems Co., Ltd. is not responsible for any damages resulting from repair, overhaul or modification of POD that was performed by an unauthorized person.

- Page 6 [General Notes] • Never bundle control cables and input/output cables with high-voltage and large-current carrying cables such as power supply cables. Keep these cables at least 200 mm away from the high-voltage and large-current carrying cables. Otherwise, malfunction may occur due to noise. •...

-

Page 7: Table Of Contents

Contents Preface Record of Revisions Notes on Safe Use of POD Chapter 1 Overview Features............................1-1 Models and Peripheral Equipment....................1-2 Simple POD Models ............................1-2 Peripheral Equipment............................1-3 System Composition ......................... 1-5 Chapter 2 Specifications Specifications ............................ 2-1 General Specifications ............................2-1 Display Specifications ............................2-2 Touch Switch Specifications ..........................2-2 Function Switch Specifications..........................2-2... - Page 8 Function Switches ..........................4-5 Types ..................................4-5 [SYSTEM] Switch..............................4-5 Chapter 5 Connections 1 : 1 Connection ..........................5-1 1 : n Connection (Multi-drop)......................5-2 n : 1 Connection (Multi-link 2) ......................5-3 n : 1 Connection (Multi-link) ......................5-4 Universal Serial Communications ..................... 5-5 UG-Link .............................

-

Page 9: Chapter 1 Overview

Overview Features Models and Peripheral Equipment System Composition... -

Page 10: Features

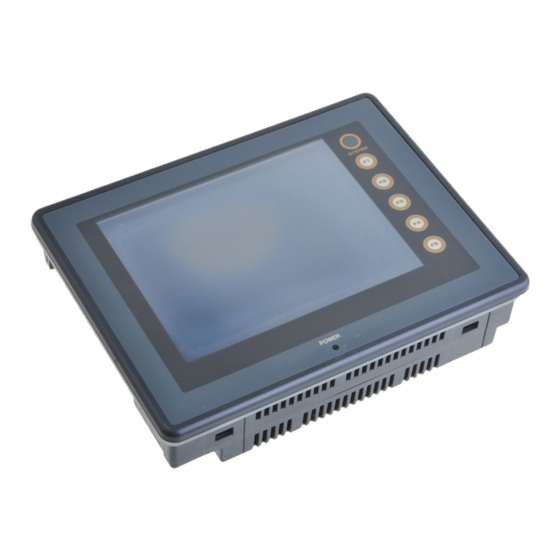

1. Features Features The Simple POD inherits and heightens the features of the UG20 Series as described below. 1. Low-cost Standard Model The Simple POD is a low-cost model adapted to provide the minimum necessary functions. This compact model, just 44.0 mm thick with a simple interface, is ideal for cost reduction. Two types with a 16-color display and an 8-step gradation white mode display are available. -

Page 11: Models And Peripheral Equipment

2. Models and Peripheral Equipment Models and Peripheral Equipment Simple POD Models The model name consists of the following information. UG221H- L E 4 Power supply specification 4: 24 VDC specification Memory specification E: Standard (UG221H-LE4 only) R: SRAM/built-in clock function Device specification S: 16-color STN color LCD L: 8-step gradation STN monochrome LCD... -

Page 12: Peripheral Equipment

2. Models and Peripheral Equipment Peripheral Equipment The following options are available for using the Simple POD more effectively. UG00S-CWV3 (configuration software: English/Japanese) Application software for editing display data for the POD. (Windows98/NT4.0/Me/2000/XP compatible) The Simple POD is supported with ver. 3.2.1.0 and later. UG00P-MR (card recorder) The card recorder creates a backup copy of screen data or works as an external memory storage system for memory manager and data logging functions. - Page 13 2. Models and Peripheral Equipment UG00C-B (barcode reader connection cable) 3 m Used for connection between the Simple POD and a barcode reader. UG00C-H (multi-link 2 master cable) Used for Multi-Link 2 connection between the Simple POD master station and the Simple POD slave station.

-

Page 14: System Composition

3. System Composition System Composition The following illustration shows possible system configurations using the Simple POD. UG Series configuration During operation software Transferring (Link communication) Simple POD screen data Creating RS-232C/RS-422 disc screens UG00C-T RESET UG00S-CWV3 Computer (PC) Link unit During operation (Universal serial communication) - Page 15 3. System Composition Please use this page freely.

-

Page 16: Chapter 2 Specifications

Specifications Specifications Dimensions and Panel Cut-out Names and Functions of Components Serial Connector (CN1) Modular Jack (MJ1) -

Page 17: General Specifications

1. Specifications Specifications General Specifications Item Specifications Rated Voltage 24 VDC 24 VDC ± 10% Permissible Range of Voltage Power Permissible Momentary Power Failure Within 1 ms Supply Power Consumption 10 W or less (Maximum Rating) Rush Current 10 A, 1 ms Ambient Temperature 0°C to +50°C −10°C to +60°C... -

Page 18: Display Specifications

1. Specifications Display Specifications Model Item UG221H-SR4 UG221-LE4, SR4 Display Device STN color LCD STN monochrome LCD Display Size 5.7-inch Colors 16 color + blink Monochrome 8-grade + blink W × H (dots) 320 × 240 Resolution W × H (mm) 0.36 ×... -

Page 19: Interface Specifications

1. Specifications Interface Specifications Item Specifications RS-232C, RS-422/485 Asynchronous type Serial Interface for PLC Connection Data length: 7, 8 bits (D-sub 25-pin, female) Parity: Even, odd, none Stop bit: 1, 2 bits Baud rate: 4800, 9600, 19200, 38400, 57600 bps Serial Interface 1 for Screen Data RS-232C, RS-422/485 (2-wire connection) Transfer/External Connection... -

Page 20: Display Function Specifications

1. Specifications Display Function Specifications Item Specifications English/Western Chinese Chinese Display Language* Japanese Korean Europe (traditional) (simplified) 1/4-size, 1-byte ANK code Latin1 ASCII code ASCII code ASCII code Chinese Chinese Hangul − Characters 2-byte 16-dot JIS #1, 2 levels (traditional) (simplified) (without Kanji) −... - Page 21 1. Specifications Function Performance Specifications Item Specifications Screens Max. 1024 Screen Memory Flash memory: Appox. 760 kbyte (varies depending on the font) Switch 192 per screen Set, reset, momentary, alternate, to light Switch Actions (Possible to press a function switch and a switch on the display at the same time) Reverse, blink, exchange of graphics Lamps 192 per screen...

-

Page 22: Dimensions And Panel Cut-Out

2. Dimensions and Panel Cut-out Dimensions and Panel Cut-out (Unit: mm) • Side View • Front View 181.6 SYSTEM POWER • Rear View • Bottom View 173.6 DIPSW 173.6 • Panel Cut-out Dimensions +0.5... -

Page 23: Names And Functions Of Components

3. Names and Functions of Components Names and Functions of Components SYSTEM DIPSW POWER 1. PLC communication connector (CN1) Used for connection between the Simple POD and a PLC or an external control unit (computer, custom controller, etc). 2. Modular jack connectors (MJ1) Used for screen data transfer and connection with temperature controller, barcode reader, UG00P-MR, etc. -

Page 24: Serial Connector (Cn1)

4. Serial Connector (CN1) Serial Connector (CN1) Serial Connector for PLC Connection To communicate with the PLC (RS-232C, RS-422/485), connect the cable to the serial connector (CN1) at the side of the Simple POD unit. Side View The serial connector pins correspond to signals as given below. CN1 (D-sub 25-pin, female) Pin No. -

Page 25: Modular Jack (Mj1)

5. Modular Jack (MJ1) Modular Jack (MJ1) This is a modular connector used for connection for screen data transfer, temperature controller, barcode reader, card recorder (UG00P-MR) or serial extension I/O (UG00P-U2). Side View Pins of modular jack 1 correspond to signals as given below. MJ1/2 Pin No. -

Page 26: Transferring Screen Data

2-10 5. Modular Jack (MJ1) Transferring Screen Data • Use modular jack 1 (MJ1) when transferring screen data. • When [Editor Port] is selected for [Modular Jack 1] on the editor, it is possible to transfer data in the RUN mode because the RUN/STOP mode (on the Main Menu screen) can be automatically selected. -

Page 27: Connection With Printer Through Serial Interface

2-11 5. Modular Jack (MJ1) Connection with Printer through Serial Interface • To connect a printer through serial interface, connect the cable to a modular jack (MJ1). • Refer to the specification sheet of the printer to be used for the connecting cable for serial interface. - Page 28 2-12 5. Modular Jack (MJ1) Please use this page freely.

-

Page 29: Chapter 3 Installation

Installation Mounting Procedure Power Supply Cable Connection... -

Page 30: Mounting Procedure

1. Mounting Procedure Mounting Procedure Mounting Procedure 1. Cut out the mounting panel (max. thick: 5 mm) to match the dimensions shown below. Panel cut-out hole Mounting panel • Panel cut-out dimensions (Unit: mm) +0.5 2. Insert four fixtures attached to the Simple POD into the mounting holes, and tighten them with the locking screws. -

Page 31: Power Supply Cable Connection

2. Power Supply Cable Connection Power Supply Cable Connection Electric shock hazard DANGER Shut the power off before connecting the power supply cable. Power Supply Cable Connection • Connect the power supply cable to the terminal on the backside of the unit. DIPSW 24 VDC Power supply... -

Page 32: Chapter 4 Instructions

Instructions Coin-type Lithium Battery (UG221H-SR4 and LR4 only) DIP Switch Setting Function Switches... -

Page 33: Coin-Type Lithium Battery (Ug221H-Sr4 And Lr4 Only)

1. Coin-type Lithium Battery (UG221H-SR4 and LR4 only) Coin-type Lithium Battery (UG221H-SR4 and LR4 only) The POD is delivered without inserting the battery connector in the battery holder on the back of the unit. CAUTION Be sure to set the battery when using the calendar function or SRAM. Without battery, the contents in the SRAM or calendar will not be retained. -

Page 34: Battery Replacement

1. Coin-type Lithium Battery (UG221H-SR4 and LR4 only) 6. Turn on the power to the Simple POD unit. If the battery is not connected, the message “Data has some error. Error: 161 (24: )” is displayed on the Main Menu screen or “Format required.” is displayed on the “SRAM/Clock Adjust.” screen. “SRAM/Clock Adjust.”... - Page 35 1. Coin-type Lithium Battery (UG221H-SR4 and LR4 only) Battery Replacement Procedure Replacement batteries are available from Hakko Electronics. Name Type Contents Replacement battery for • Coin-type lithium primary cell 1 pce UG30P-BT the Simple POD • Cautions sticker 1 pce 1.

-

Page 36: Dip Switch Setting

2. DIP Switch Setting DIP Switch Setting DIP Switch (DIPSW) Setting Set the terminating resistance for RS-422/485 connection with the DIP switch. When setting the DIP switch, turn the power off. Rear View DIP switch Not used CN1 RD terminating resistance at pins 24 and 25 Not used MJ1 (modular jack 1) terminating resistance (*1) -

Page 37: Function Switches

3. Function Switches Function Switches Types • There are six function switches provided. [SYSTEM], [F1], [F2], [F3], [F4], [F5] [SYSTEM] Switch The [SYSTEM] switch works in “alternate” operations. When this switch is pressed once, the switch menu is displayed at the side of the function switches [F1] to [F5], and each function switch corresponds to the menu item displayed in the switch menu. - Page 38 3. Function Switches [F1] to [F5] Switch Functions with Switch Menu Functions Contents Selects the operation mode between STOP ↔ RUN. Mode Adjust the contrast. Holding down the switch for one second or more changes the contrast rapidly. Contrast Adjustment Dark Medium Pale...

-

Page 39: Chapter 5 Connections

Connections 1 : 1 Connection 1 : n Connection (Multi-drop) n : 1 Connection (Multi-link 2) n : 1 Connection (Multi-link) Universal Serial Communications UG-Link PLC2Way Temperature Control Network... -

Page 40: Connection

1. 1 : 1 Connection 1 : 1 Connection • One set of the Simple POD is connected to one PLC (1 : 1 connection). Simple POD SYSTEM POWER RS-232C or RS-422 (RS-485) • The host link unit of the PLC or the CPU port is used and the Simple POD (master station) establishes communications according to the protocol of the PLC. -

Page 41: Connection (Multi-Drop)

2. 1 : n Connection (Multi-drop) 1 : n Connection (Multi-drop) One Simple POD is connected to multiple PLCs. (Maximum connectable PLCs: 31) Simple POD SYSTEM POWER Maximum length (Simple POD to the terminating PLC) = 500 m RS-422/RS-485 connection (n = 1 to 31) PLC1 PLC2... -

Page 42: N : 1 Connection (Multi-Link 2)

3. n : 1 Connection (Multi-link 2) n : 1 Connection (Multi-link 2) • One PLC is connected to a maximum of four Simple POD units. • An original network is created where the Simple POD (Local Port 1) that is directly connected to the PLC is the master station, and other three Simple POD units are slave stations. -

Page 43: N : 1 Connection (Multi-Link)

4. n : 1 Connection (Multi-link) n : 1 Connection (Multi-link) • One PLC is connected to multiple Simple POD units. (Maximum connectable units: 31) Simple POD No. 1 Simple POD No. 2 Simple POD No. 3 Simple POD No. “n” (n = 1 to 31) SYSTEM SYSTEM SYSTEM... -

Page 44: Universal Serial Communications

5. Universal Serial Communications Universal Serial Communications • A general purpose computer or an ASCII unit of the PLC (master station) controls the Simple POD (slave station) using dedicated commands. Dedicated commands General-purpose computer Read Simple POD disc Write SYSTEM RESET POWER Interrupt... -

Page 45: Ug-Link

6. UG-Link UG-Link • “UG-Link” is the network where the computer reads from and writes to the internal memory of the Simple POD, memory card, PLC memory or temperature control/PLC2 memory using a dedicated protocol. Dedicated commands Read disc Write SYSTEM RESET POWER... -

Page 46: Plc2Way

7. PLC2Way PLC2Way • The “PLC2Way” function is an original network function where one Simple POD unit can be connected to two PLCs. Even if the manufacturers of these PLCs are not the same, they can be connected to one Simple POD unit. RS-232C RS-422/RS-485 SYSTEM... -

Page 47: Temperature Control Network

8. Temperature Control Network Temperature Control Network • Using the temperature control network, the Simple POD can be connected to the temperature controller or inverter. With RS-232C, one PLC can be connected; with RS-485, a maximum of 31 temperature controllers can be connected. <PLC>... -

Page 48: Simple Pod Operations

Simple POD Operations Operational Procedures Main Menu Screen... -

Page 49: Operational Procedures

1. Operational Procedures Operational Procedures Simple POD Operation Follow the procedure below to operate the Simple POD. 1. Installation and wiring For more information, refer to “Chapter 3.” 2. Connection with devices including a PLC and a temperature controller For instructions and precautions on wiring between the Simple POD and other devices, refer to the separate PLC Connection Manual or Temperature Control Network Manual. - Page 50 1. Operational Procedures Initial Screen When the power of Simple POD is turned on for the first time, the Main Menu screen shown below on the left is displayed. Initial screen displayed when power is Main Menu screen after transferring turned on for the first time screen data SYSTEM...

-

Page 51: Main Menu Screen

2. Main Menu Screen Main Menu Screen The Main Menu screen is displayed when the Simple POD is in the STOP mode. In this state, the Simple POD is disconnected from the PLC and other external devices. Displaying the Main Menu Screen In the RUN Mode To bring up the Main Menu screen in the RUN mode, press the [SYSTEM] switch and then the [F1] switch while the vertical menu is displayed. -

Page 52: I/O Test

2. Main Menu Screen Main Menu Screen • The Main Menu screen indicates the Simple POD model, system information, and screen data information. • The Main Menu screen is the system menu screen for transferring screen data between a personal computer and the Simple POD. When transferring screen data from a personal computer to the Simple POD, this Main Menu screen must be displayed. - Page 53 2. Main Menu Screen 1-1. Serial Connection Test This is a signal test for communications through the CN1 or MJ1 connector. Perform this test if the communication is not successful when transferring screen data through MJ1, connecting the PLC using CN1, or selecting multi-link 2, temperature controller/PLC2Way or PLC for MJ1, or connecting the card recorder or serial extension I/O.

- Page 54 2. Main Menu Screen RS-485 signal test Turn the [CN1] and [RS485] switches on. Communication Port RS232C RS485 • SD/RD Test Check the signals [SD] and [RD]. 1. Install a jumper between pins 12 and 24 and between pins 13 and 25 of CN1 on the Simple POD unit.

- Page 55 2. Main Menu Screen MJ1 Test RS-232C signal test Turn the [MJ1] and [RS232C] switches on. Communication Port RS232C RS485 • RS-232C Self-loop Test Check the signals [SD] and [RD]. Connect the data transfer cable (UG00C-T) to CN1 for the test. 1.

- Page 56 2. Main Menu Screen 1-2. SYSTEM & Function Switch Test Check operations of six switches provided vertically on the right side of the Simple POD panel. Press the switch, and check that the lamp on the screen lights up while the switch is held down. 1-3.

- Page 57 2. Main Menu Screen Touch Switch Adjustment If a position different from the pressed position turns white on the touch switch test screen, follow the steps described below to adjust the touch switch position. 1. Hold down the [SYSTEM] switch and press the [F2] switch on the touch switch test screen. SYSTEM Touch Switch Adjustment SYSTEM...

-

Page 58: Memory Card Screen

6-10 2. Main Menu Screen Memory Card Screen When the [Memory Card] switch on the “Main Menu” screen is pressed, the following [Memory-Card] screen appears. This screen is used to transfer screen data between the Simple POD and a memory card. The procedure for transferring data is described below. - Page 59 6-11 2. Main Menu Screen 4. Data Selection and Transfer Selection In the “Transfer” field, select [Display <-- Card], [Display --> Card] or [Display <-> Card]. Press the desired switch to turn the switch on. Multiple switches can be pressed in the “Data Selection” field. Data selection Transfer selection 5.

- Page 60 6-12 2. Main Menu Screen Messages during Data Transfer If an error occurs during data transfer, the message window shown on the right is displayed. The kinds and the contents of the messages are shown below. The same messages are used for the memory card and CF card.

-

Page 61: Communication Parameter Screen

6-13 2. Main Menu Screen Communication Parameter Screen When the [Comm. Para.] switch on the Main Menu screen is pressed, the “Comm. Param.” screen, shown below, is displayed. This screen is used to check the Simple POD communication parameter settings. The Main Menu screen is displayed again. -

Page 62: Sram/Clock

6-14 2. Main Menu Screen SRAM/Clock • The SRAM/Clock setting is effective with UG221H-SR4 and LR4 only. • To use the built-in clock of the Simple POD or to use the SRAM memory or cassette, it is necessary to select [SRAM/Clock Setting] from the [System Setting] menu and make the SRAM/clock setting. -

Page 63: Extension Program Information

6-15 2. Main Menu Screen Date and Time Setting 1. Move the cursor using the [←] / [→] switch, and change the value by pressing the [+] / [−] switch. 2. When the desired date and time are set, press the [Set] switch to determine the setting. 3. -

Page 64: Extended Function Setting

6-16 2. Main Menu Screen Extended Function Setting When the [Editor: MJ1] switch on the Main Menu screen is pressed, the following “Extended Function Setting” screen appears. Set the baud rate to be used when transferring screen data between the Simple POD and a modem. 1. -

Page 65: Error Correction

Error Correction Error Messages Troubleshooting... -

Page 66: Error Message

1. Error Message Error Message There are five kinds of error messages displayed on the POD: 1. Communication error 2. Check 3. Warning 4. SYSTEM ERROR 5. Touch switch is active Communication Error * When you go to [Comm. Parameter], bring up the [Detail] tab window and set [Continue] for [Comm. - Page 67 1. Error Message Error Message Contents Solution Examine the CPU error code and solve the Error code received The PLC sent an error code (NAK). problem. The PLC’s SD (TXD) remains at the low Examine the connection between the PLC’s Break level.

-

Page 68: Check

1. Error Message Check Error Message Contents Solution At the start of communications, the Simple POD regards the There is no setting for the value in the read area “n + 2” as the screen number. Screen No. Error received screen. Check that the value in the read area “n + 2”... -

Page 69: System Error

1. Error Message SYSTEM ERROR When a system error is detected, the following error screen is displayed on the POD. SYSTEM ERROR : 32 SYSTEM TEA : XXXXXXXX EXPEVT : XXXXXXXX SSR : XXXXXXXX SPC : XXXXXXXX R0 : XXXXXXXX R1 : XXXXXXXX R2 : XXXXXXXX R3 : XXXXXXXX... -

Page 70: Troubleshooting

2. Troubleshooting Troubleshooting In the Event of an Error Perform the steps below: 1. If the current error matches a symptom in the following table, correct it by following the instructions provided. 2. If the error does not match the symptoms in the table, contact your local distributor. Please provide the distributor with the information on the POD model, serial number, symptom of the error, error message (if shown), etc. - Page 71 2. Troubleshooting Symptom Cause Solution “SYSTEM ERROR: xx” The following causes are probable, depending occurs. on the symptoms. 1) Turning the power off and back on corrects 1) If communication is stable after turning the the error. power on again, continue and observe SYSTEM ERROR : 32 SYSTEM ↓...

-

Page 72: Chapter 8 Inspection And Maintenance

Inspection and Maintenance Inspection and Maintenance Warranty Policy... -

Page 73: Inspection And Maintenance

1. Inspection and Maintenance Inspection and Maintenance Be sure to turn off the power before conducting inspection or maintenance. Failure to DANGER do so could cause an electric shock or damage to the unit. Daily Inspection • Check that the screws on the POD are tightened firmly. •... -

Page 74: Warranty Policy

2. Warranty Policy Warranty Policy Inquiries about Failure Please direct inquiries about failure or repair to your local distributor. Your information on the POD model, serial number, symptom of the failure, error message (if shown), etc. will be appreciated. Warranty Period The product is under warranty for one year after the date of purchase or delivery to the specified place. - Page 75 Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome, Shinagawa-ku, Tokyo 141-0032, Japan E-mail: micrex-sx@fujielectric.co.jp URL: http://www.fujielectric.com/ Issued as FE consolidated edition, June 2011 Materials covered in this document are subject to revision due to the modification of the product.

Need help?

Do you have a question about the POD UG221H-LE4 and is the answer not in the manual?

Questions and answers