Konica Minolta bizhub C250P Service Manual

Hide thumbs

Also See for bizhub C250P:

- User manual (538 pages) ,

- System administrator manual (52 pages) ,

- User manual (498 pages)

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Konica Minolta bizhub C250P

-

Page 1: Service Manual

SERVICE MANUAL FIELD SERVICE This Service Manual is designed for machine This Service Manual is designed for machine with Firmware Card Ver. 81 and onward. with Firmware Card Ver. 81 and onward. 2006.03 2006.03 Ver. 2.0 Ver. 2.0... -

Page 2: Table Of Contents

WARNING INDICATIONS ON THE MACHINE ............S-18 MEASURES TO TAKE IN CASE OF AN ACCIDENT ............S-20 Composition of the service manual ................. C-1 Notation of the service manual ..................C-2 bizhub C250P Main Unit General ........................... 1 Maintenance ......................... 11 Adjustment/Setting...................... 131 Troubleshooting...................... - Page 3 Blank Page...

-

Page 4: Safety And Important Warning Items

IMPORTANT NOTICE Because of possible hazards to an inexperienced person servicing this product as well as the risk of damage to the product, KONICA MINOLTA BUSINESS TECHNOLOGIES, INC. (hereafter called the KMBT) strongly recommends that all servicing be performed only by KMBT-trained service technicians. -

Page 5: Safety Warnings

[1] MODIFICATIONS NOT AUTHORIZED BY KONICA MINOLTA BUSINESS TECHNOLOGIES, INC. KONICA MINOLTA brand products are renowned for their high reliability. This reliability is achieved through high-quality design and a solid service network. Product design is a highly complicated and delicate process where numerous mechanical, physical, and electrical aspects have to be taken into consideration, with the aim of arriving at proper tolerances and safety factors. - Page 6 SAFETY AND IMPORTANT WARNING ITEMS [2] POWER PLUG SELECTION In some countries or areas, the power plug provided with the product may not fit wall outlet used in the area. In that case, it is obligation of customer engineer (hereafter called the CE) to attach appropriate power plug or power cord set in order to connect the product to the supply.

-

Page 7: Connection To Power Supply

SAFETY AND IMPORTANT WARNING ITEMS [3] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE KONICA MINOLTA brand products are extensively tested before shipping, to ensure that all applicable safety standards are met, in order to protect the customer and customer engi- neer (hereafter called the CE) from the risk of injury. However, in daily use, any electrical equipment may be subject to parts wear and eventual failure. - Page 8 SAFETY AND IMPORTANT WARNING ITEMS Power Plug and Cord WARNING • When using the power cord set (inlet type) that came with this product, make sure the connector is securely inserted in the inlet of the product. When securing measure is provided, secure the cord with the fixture properly.

- Page 9 SAFETY AND IMPORTANT WARNING ITEMS Wiring WARNING • Never use multi-plug adapters to plug multiple power cords in the same outlet. If used, the risk of fire exists. • When an extension cord is required, use a specified one. Current that can flow in the extension cord is limited, so using a too long extension cord may result in fire.

- Page 10 SAFETY AND IMPORTANT WARNING ITEMS Ventilation CAUTION • The product generates ozone gas during operation, but it will not be harmful to the human body. If a bad smell of ozone is present in the following cases, ventilate the room. a.

- Page 11 SAFETY AND IMPORTANT WARNING ITEMS Work Performed with the Product Powered On WARNING • Take every care when making adjustments or performing an operation check with the product powered. If you make adjustments or perform an operation check with the external cover detached, you may touch live or high-voltage parts or you may be caught in moving gears or the timing belt, leading to a risk of injury.

- Page 12 SAFETY AND IMPORTANT WARNING ITEMS Safety Checkpoints WARNING • Check electrode units such as a charging corona unit for deterioration and sign of leakage. Current can leak, leading to a risk of trouble or fire. • Before disassembling or adjusting the write unit (P/H unit) incorporating a laser, make sure that the power cord has been disconnected.

-

Page 13: Handling Of Consumables

SAFETY AND IMPORTANT WARNING ITEMS Safety Checkpoints WARNING • Make sure that all screws, components, wiring, connec- tors, etc. that were removed for safety check and mainte- nance have been reinstalled in the original location. (Pay special attention to forgotten connectors, pinched cables, forgotten screws, etc.) A risk of product trouble, electric shock, and fire exists. - Page 14 SAFETY AND IMPORTANT WARNING ITEMS Handling of Service Materials CAUTION • Use only a small amount of cleaner at a time and take care not to spill any liquid. If this happens, immediately wipe it off. A risk of fire exists. •...

- Page 15 SAFETY AND IMPORTANT WARNING ITEMS [4] Used Batteries Precautions ALL Areas CAUTION Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions. Germany VORSICHT! Explosionsgefahr bei unsachgemäßem Austausch der Batterie.

-

Page 16: Internal Laser Radiation

SAFETY AND IMPORTANT WARNING ITEMS [5] FUSE CAUTION Double pole / neutral fusing ATTENTION Double pôle / fusible sur le neutre. [6] Laser Safety • This is a digital machine certified as a Class 1 laser product. There is no possibility of danger from a laser, provided the machine is serviced according to the instruction in this manual. - Page 17 SAFETY AND IMPORTANT WARNING ITEMS U.S.A., Canada (CDRH Regulation) • This machine is certified as a Class 1 Laser product under Radiation Performance Stan- dard according to the Food, Drug and Cosmetic Act of 1990. Compliance is mandatory for Laser products marketed in the United States and is reported to the Center for Devices and Radiological Health (CDRH) of the U.S.

- Page 18 SAFETY AND IMPORTANT WARNING ITEMS Finland, Sweden LUOKAN 1 LASERLAITE KLASS 1 LASER APPARAT VAROITUS! • Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saat- taa altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle laser- säteilylle. puolijohdelaser Laserdiodin suurin teho 10 mW aallonpituus 775-800 nm VARNING!

-

Page 19: Laser Safety Label

SAFETY AND IMPORTANT WARNING ITEMS Laser Safety Label • A laser safety label is attached to the inside of the machine as shown below. * Only for the U.S.A. 4038P0C512DA Laser Caution Label • A laser caution label is attached to the outside of the machine as shown below. 4038P0C509DA S-16... -

Page 20: Precautions For Handling The Laser Equipment

SAFETY AND IMPORTANT WARNING ITEMS PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT • When laser protective goggles are to be used, select ones with a lens conforming to the above specifications. • When a disassembly job needs to be performed in the laser beam path, such as when working around the printerhead and PC Drum, be sure first to turn the printer OFF. -

Page 21: Warning Indications On The Machine

SAFETY AND IMPORTANT WARNING ITEMS WARNING INDICATIONS ON THE MACHINE Caution labels shown are attached in some areas on/in the machine. When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid burns and electric shock. High voltage •... - Page 22 SAFETY AND IMPORTANT WARNING ITEMS WARNING WARNING • Do not position the used Waste • Do not burn used Toner Cartridges. Toner Box so that it is standing Toner expelled from the fire is dan- on end or tilted, otherwise toner gerous.

-

Page 23: Measures To Take In Case Of An Accident

MEASURES TO TAKE IN CASE OF AN ACCIDENT MEASURES TO TAKE IN CASE OF AN ACCIDENT 1. If an accident has occurred, the distributor who has been notified first must immediately take emergency measures to provide relief to affected persons and to prevent further damage. -

Page 24: Composition Of The Service Manual

Composition of the service manual This service manual explains about the Field Service section of the machine. Since the Theory of Operation section is same as that of C250, refer to the Theory of Oper- ation section of C250 service manual. Field Service section gives, as information required by the CE at the site (or at the cus- tomer’s premise), a rough outline of the service schedule and its details, maintenance steps, the object and role of each adjustment, error codes and supplementary information. -

Page 25: Notation Of The Service Manual

A. Product name In this manual, each of the products is described as follows: (1) PWB-MFP: MFP Control Board PWB-M: Control Board (2) bizhub C250P: Main body (3) Microsoft Windows 95: Windows 95 Microsoft Windows 98: Windows 98 Microsoft Windows Me: Windows Me Microsoft Windows NT 4.0:... - Page 26 SERVICE MANUAL FIELD SERVICE Main Unit 2006.03 Ver. 2.0...

-

Page 27: Revision History

Revision history After publication of this service manual, the parts and mechanism may be subject to change for improvement of their performance. Therefore, the descriptions given in this service manual may not coincide with the actual machine. When any change has been made to the descriptions in the service manual, a revised version will be issued with a revision mark added as required. - Page 28 Field Service Ver. 2.0 Mar. 2006 CONTENTS bizhub C250P Main Unit General System configuration....................1 Product specifications ..................... 3 Center cross section ....................7 Paper path....................... 8 Image creation process................... 9 Maintenance Periodical check ....................11 Service schedule ....................11 Maintenance items....................

- Page 29 Field Service Ver. 2.0 Mar. 2006 Replacing the unit....................32 6.6.1 Replacing the 2nd Image Transfer Roller Unit ..........32 6.6.2 Replacing the Image Transfer Belt Unit ............32 6.6.3 Cleaning of the Image Transfer Entrance Guide......... 34 6.6.4 Cleaning of the IDC/Registration Sensor 1, 2..........35 6.6.5 Replacing the Toner Cartridge (C, M, Y, K)..........

- Page 30 Field Service Ver. 2.0 Mar. 2006 10.4.2 Service environment ................... 66 10.4.3 Preparations for Firmware rewriting ............66 10.4.4 Firmware rewriting ..................69 Other ........................70 11.1 Disassembly/Adjustment prohibited items ............70 11.2 Disassembly/Assembly/Cleaning list (Other parts)..........71 11.2.1 Disassembly/Assembly parts list..............71 11.2.2 Cleaning parts list ..................

- Page 31 Field Service Ver. 2.0 Mar. 2006 11.3.29 Color Developing Motor (M3)..............115 11.3.30 Color PC Drum Motor (M2)............... 115 11.3.31 Toner Supply Motor C/K (M7) ..............115 11.3.32 Toner Supply Motor Y/M (M6)..............116 11.3.33 Main Motor (M1) ..................116 11.3.34 Fusing Drive Motor (M4) ................

- Page 32 Field Service Ver. 2.0 Mar. 2006 14.2 Settings in User setting..................147 14.2.1 Print Reports ..................... 147 14.2.2 System Setting..................147 14.2.3 Power Save ....................148 14.2.4 Tray Setting ....................149 14.2.5 Output Setting ................... 150 14.2.6 Printer Setting ................... 150 14.3 Settings in Admin.

- Page 33 Field Service Ver. 2.0 Mar. 2006 16.3.11 No Sleep ....................188 16.3.12 HDD Formatting..................189 16.3.13 Version Upgrade ..................189 16.3.14 Data Capture .................... 191 16.3.15 Data Backup ..................... 194 16.3.16 Software SW ..................... 194 16.4 Settings in CS Remote Care ................195 16.4.1 Outlines.....................

- Page 34 Field Service Ver. 2.0 Mar. 2006 17.7.4 Transfer Output Fine Adjustment .............. 226 17.7.5 Stabilizer ....................227 17.7.6 Thick Paper Density Adjustment ............... 228 17.7.7 TCR Toner Supply..................228 17.7.8 Monochrome Density Adjustment ............. 229 17.7.9 Dev. Bias Choice..................229 17.8 CS Remote Care ....................

- Page 35 Field Service Ver. 2.0 Mar. 2006 17.11.6 Maintenance ..................... 256 17.11.7 Service Total Counter ................256 17.11.8 Counter of Each Mode................257 17.11.9 Service Call History (Data) ............... 257 17.11.10 Paper Jam History ..................257 17.12 List Output ......................258 17.12.1 Machine Management List...............

- Page 36 Field Service Ver. 2.0 Mar. 2006 18.2 Enhanced Security Function Tree..............278 18.3 Settings in the Enhanced Security..............279 18.3.1 CE Password..................... 279 18.3.2 Administrator Password ................279 18.3.3 CE Authentication ..................279 18.3.4 IU Life Stop Setting ................... 279 Billing Setting ......................

- Page 37 Field Service Ver. 2.0 Mar. 2006 22.4.10 Misfeed at Duplex Unit pre-registration section (AD-503)......301 22.4.11 Misfeed at Fusing/Exit section ..............302 Malfunction code....................303 23.1 Alert code ......................303 23.1.1 Alert list..................... 303 23.2 Solution ......................304 23.2.1 P-5: IDC Sensor (Front) failure ..............305 23.2.2 P-28 IDC Sensor (Back) failure..............

- Page 38 Field Service Ver. 2.0 Mar. 2006 23.5.16 C2556: Abnormally high toner density detected Yellow TCR Sensor ..328 23.5.17 C2557: Abnormally low toner density detected Black TCR Sensor ..329 23.5.18 C2558: Abnormally high toner density detected Black TCR Sensor..329 23.5.19 C2559: Cyan TCR Sensor adjustment failure ...........

- Page 39 Field Service Ver. 2.0 Mar. 2006 23.5.53 C4770: JBIG0 Error .................. 334 23.5.54 C4771: JBIG1 Error .................. 334 23.5.55 C4772: JBIG2 Error .................. 334 23.5.56 C4773: JBIG3 Error .................. 334 23.5.57 C4780: Compressor 0 command buffer stop failure ......... 334 23.5.58 C4781: Compressor 1 command buffer stop failure .........

- Page 40 Field Service Ver. 2.0 Mar. 2006 23.5.90 CD011: Hard disk specifications error ............338 23.5.91 CD3##: NVRAM Data error............... 338 23.5.92 CE001: Abnormal message queue ............339 23.5.93 CE003: Task error ..................339 23.5.94 CE004: Event error ................... 339 23.5.95 CE005: Memory access error ..............339 23.5.96 CE006: Header access error ..............

- Page 41 Field Service Ver. 2.0 Mar. 2006 25.3.9 Printer Monocolor: colored spots.............. 356 25.3.10 Printer Monocolor: blurred image ............. 357 25.3.11 Printer Monocolor: blank print, black print ..........358 25.3.12 Printer Monocolor: uneven image............. 359 25.3.13 Printer 4-Color: white lines in sub scan direction, white bands in sub scan direction, colored lines in sub scan direction, and colored bands in sub scan direction....

-

Page 42: General

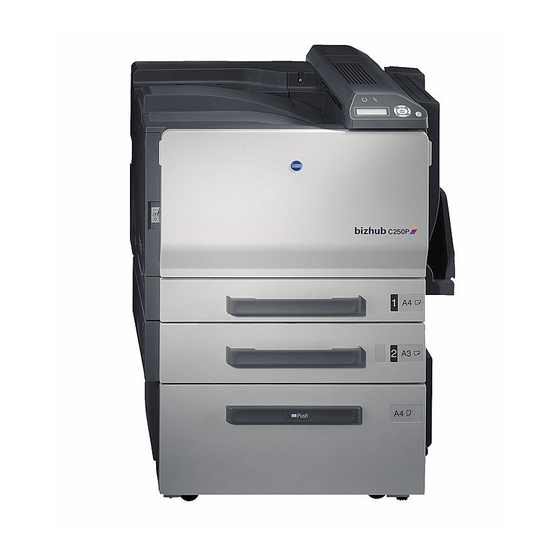

Field Service Ver. 2.0 Mar. 2006 1. System configuration General System configuration 1/2 System Front View [10] 4038F1C401AA Machine Desk DK-502 Auto Duplex Unit AD-503 Finisher FS-501 Paper Feed Cabinet PC-103 Job Separator JS-601 Paper Feed Cabinet PC-203 Finisher FS-603 Paper Feed Cabinet PC-403 [10] Punch Kit (for FS-603) PK-501 NOTE... - Page 43 1. System configuration Field Service Ver. 2.0 Mar. 2006 2/2 System Rear View PC-103 DK-502 PC-203 PC-403 4038F1E187DA Machine Security Kit SC-503 Mount Kit MK-706 Dehumidifier Heater 1C Hard Disk HD-501 Local Interface Kit EK-702...

-

Page 44: Product Specifications

Field Service Ver. 2.0 Mar. 2006 2. Product specifications Product specifications A. Type Type Desktop-type printer Printing System Electrostatic dry-powdered image transfer to plain paper Printing Process Tandem-type indirect electrostatic recording system PC Drum Type OPC (organic photo conductor) Paper Feeding System Multiple Bypass: 100 sheets (Standard) Tray1: 250 sheets... - Page 45 2. Product specifications Field Service Ver. 2.0 Mar. 2006 B. Functions 110 sec. or less Warm-up Time (at ambient temperature of 23° C/73.4° F and rated source voltage) Leading edge: 4.2 mm, Trailing edge: 4.2 mm, Image Loss Rear edge: 3 mm, Front edge: 3 mm First Print Time (Tray1, A4, full size) Monochrome print...

-

Page 46: Paper Feed Cabinet

Field Service Ver. 2.0 Mar. 2006 2. Product specifications C. Types of Paper Paper Source Type Tray1 Tray2 Multiple Bypass Plain paper ❍ ❍ ❍ (60 to 90 g/m Translucent paper – – – OHP transparencies (crosswise – feeding only) Thick paper 1 –... -

Page 47: Finisher

2. Product specifications Field Service Ver. 2.0 Mar. 2006 E. Machine Specifications Power Requirements Voltage: AC 110 V, 120 V, 127 V, 220-240 V Frequency: 50/60 Hz ± 3.0 Hz Max Power Consumption Less than 1500 W (120 V, 12 A / 220 - 240 V, 8 A) 653 (W) ×... -

Page 48: Center Cross Section

Field Service Ver. 2.0 Mar. 2006 3. Center cross section Center cross section [18] [19] [17] [16] [15] [14] [13] [12] [11] [10] 4038F1C403AA Fusing Unit [11] Waste Toner Box Transfer Belt Unit [12] Imaging Unit/Y Image Transfer Roller [13] Imaging Unit/M Bypass tray [14] Imaging Unit/C Tray1... -

Page 49: Paper Path

4. Paper path Field Service Ver. 2.0 Mar. 2006 Paper path 4038F1C404AA... -

Page 50: Image Creation Process

Field Service Ver. 2.0 Mar. 2006 5. Image creation process Image creation process [11] Transfer Belt Cleaning [1] Interface [10]Paper [8] 1st Image Transfer Separation [2] Controller Image Processing [9] 2nd Image [3] Printer Image Transfer Processing [4] PC Drum [5] PC Drum Charging [13] Main Erase... - Page 51 5. Image creation process Field Service Ver. 2.0 Mar. 2006 Transfer Belt • A charge is applied to the Transfer Belt. By potential difference, residual [11] Cleaning toner on the surface of the Transfer Belt is collected for cleaning. [12] PC Drum Cleaning • The residual toner left on the surface of the PC Drum is scraped off. •...

-

Page 52: Maintenance

Field Service Ver. 2.0 Mar. 2006 6. Periodical check Maintenance Periodical check Service schedule Guarantee period (5-year or 600,000 prints) × 10,000-print Per cycle Number × print number of times ● ● ● ● 120,000 ● ● Main Unit 200,000 ●... -

Page 53: Periodical Parts Replacement 1 (Per 120,000-Print)

6. Periodical check Field Service Ver. 2.0 Mar. 2006 6.2.2 Periodical parts replacement 1 (per 120,000-print) Number of Lubrica- Descrip- Class Parts to be replaced Check Clean Replace personnel tion tions Paper feed and image ● conditions Overall ● ● Appearance 2nd Image Transfer ●... -

Page 54: Periodical Parts Replacement 3 (Per 300,000-Print)

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6.2.4 Periodical parts replacement 3 (per 300,000-print) Number of Lubri- Class Parts to be replaced Check Clean Replace Descriptions personnel cation Paper feed and image ● conditions Overall ● ● Appearance ●... -

Page 55: Maintenance Parts

6. Periodical check Field Service Ver. 2.0 Mar. 2006 Maintenance parts • To ensure that the machine produces good prints and to extend its service life, it is rec- ommended that the maintenance jobs described in this schedule be carried out as instructed. -

Page 56: Cleaning Parts

Field Service Ver. 2.0 Mar. 2006 6. Periodical check B. Option Actual Ref.Page Descrip- No. Classification Parts name durable Parts No. in this ntity tions cycle *1 manual Pick-up Roller 300 K 4030 3005 ## Replace those Feed Roller 300 K 4030 3005 ## PC-103 three... -

Page 57: Concept Of Parts Life

6. Periodical check Field Service Ver. 2.0 Mar. 2006 Concept of parts life Life value Max. number of Description (Specification printed pages value) A waste toner full condition is detected when about Waste Toner 2,500 printed pages have been produced after a –... - Page 58 Field Service Ver. 2.0 Mar. 2006 6. Periodical check A. Conditions for Life Specifications Values • The life specification values represent the number of prints made or figures equivalent to it when given conditions (see the Table given below) are met. They can be more or less depending on the machine operating conditions of each individual user.

-

Page 59: Maintenance Procedure (Periodical Check Parts)

6. Periodical check Field Service Ver. 2.0 Mar. 2006 Maintenance procedure (Periodical check parts) NOTE • The alcohol described in the cleaning procedure of Maintenance represents the isopropyl alcohol. 6.5.1 Replacing the Tray 1 Feed Roller 1. Slide out the Tray 1. 2. -

Page 60: Replacing The Bypass Tray Feed Roller

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 3. Take off the rubber stopper [3], shaft [4], spring [5], and guide plate [6] to remove the Paper Separation Roller fixing bracket Assy [7]. 4038F2C003DB 4. Snap off the E-ring [8] and the Tray 1 Paper Separation Roller Assy [9]. - Page 61 6. Periodical check Field Service Ver. 2.0 Mar. 2006 3. Remove the Gear [3]. 4038F2C005DA 4. Snap off the E-ring [4] and remove the Bearing [5]. 4038F2C006DB 5. Snap off two C-ring [6], and remove the Bearing [7]. 4038F2C007DB...

-

Page 62: Replacing The Bypass Tray Separation Roller Assy

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6. Remove the Bypass Tray Feed Roller [8]. 7. To reinstall, reverse the order of removal. 8. Select [Service Mode] → [Counter] → [Life] of the Jig software and clear the count of [Manual Tray]. NOTE •... -

Page 63: Replacing The Tray 2 Separation Roller

6. Periodical check Field Service Ver. 2.0 Mar. 2006 4. Snap off the C-clip [5], and remove the spring [6] and the guide plate [7]. Remove the Bypass Paper Separa- tion Roller Assy [8]. 5. To reinstall, reverse the order of removal. -

Page 64: Replacing The Tray 2 Feed Roller

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 5. Remove two Screws [5] and the Tray 2 Separation Roller installation plate Assy [6]. 4038F2C013DA 6. Remove two C-rings [7] and the Shaft [8], and remove the Separation Roller fixing plate Assy [9]. NOTE •... - Page 65 6. Periodical check Field Service Ver. 2.0 Mar. 2006 4. Remove the Screws [2] and remove the Reinforcement plate [3]. 4038F2C015DA 5. Remove four Screws [4] and remove the Tray 2 Feed Roller Assy [5]. 4038F2C016DA 6. Remove two Screws [6] and the Installation flame [7] of the Tray 2 Separation Roller installation plate Assy.

- Page 66 Field Service Ver. 2.0 Mar. 2006 6. Periodical check 7. Remove two Screws [8] and Tray 2 Feed Roller cover [9]. 4037F2C006DB 8. Remove the C-ring [10] and Bushing [11]. [11] [10] 4038F2C510DA 9. Remove the C-ring [13] and Gear [14] while sliding out the Shaft Assy [12] in the direction indicated in left [12]...

-

Page 67: Replacing The Tray 2 Pick-Up Roller

6. Periodical check Field Service Ver. 2.0 Mar. 2006 10. Remove the C-ring [15] and Bushing [16], and remove the Shaft Assy [17]. [16] [15] [17] 4038F2C512DA 11. Remove two E-rings [18] and Bush- ing [19], and remove the Tray 2 Pick- [20] up Roller fixing plate Assy [20]. - Page 68 Field Service Ver. 2.0 Mar. 2006 6. Periodical check 4. Remove the Screws [2] and remove the Reinforcement plate [3]. 4038F2C015DA 5. Remove four Screws [4] and remove the Tray 2 Feed Roller Assy [5]. 4038F2C016DA 6. Remove two Screws [6], and remove the Tray 2 Separation Roller installa- tion plate Assy [7] together with Frame.

-

Page 69: Cleaning Of The Registration Roller

6. Periodical check Field Service Ver. 2.0 Mar. 2006 7. Remove two Screws [8] and Tray 2 Feed Roller cover [9]. 4037F2C006DB 8. Remove two C-rings [10] and two [10] Bushings [11], and remove the Tray [12] 2 Pick-up Roller Assy [12]. [11] [11] 4038F2C514DA... -

Page 70: Replacing The Waste Toner Box

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6.5.9 Replacing the Waste Toner Box 1. Open the Front Door. 2. Press the Waste Toner Box release lever [1]. 4038F2C541DA 3. Remove the Waste Toner Box [2]. NOTE • Raise the Waste Toner Box gently before removing it. -

Page 71: Cleaning Of The Area Around The Waste Toner Collecting Port

6. Periodical check Field Service Ver. 2.0 Mar. 2006 6.5.10 Cleaning of the Area around the Waste Toner Collecting Port 1. Remove the Waste Toner Box. See P.29 2. Wipe the areas around the Waste Toner Collecting Port [1] clean of spilled toner and dirt using a soft cloth dampened with water or alco- hol. -

Page 72: Replacing The Dust Filter/Vertical Conveyance

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6.5.13 Replacing the Dust Filter/Vertical Conveyance 1. If the optional Automatic Duplex Unit AD-503 is mounted, remove it. See AD-503 Service Manual. 2. Remove the Dust Filter/Vertical Con- veyance [1]. NOTE •... -

Page 73: Replacing The Unit

6. Periodical check Field Service Ver. 2.0 Mar. 2006 Replacing the unit 6.6.1 Replacing the 2nd Image Transfer Roller Unit A. Removal Procedure 1. Turn OFF the Main Power Switch. 2. Open the Right Door. 3. Unlock the Lock levers [1] (at two places). - Page 74 Field Service Ver. 2.0 Mar. 2006 6. Periodical check 4. Open the Right Door. 5. Remove two Screws [1] and release the Lock of the Image Transfer Belt Unit [2]. 4038F2C023DA 6. Hold the both sides and lift it to take out the Image Transfer Belt Unit [3] a little.

-

Page 75: Cleaning Of The Image Transfer Entrance Guide

6. Periodical check Field Service Ver. 2.0 Mar. 2006 B. Reinstallation Procedure 1. Insert the Transfer Belt Unit [1]. NOTE • Insert the Transfer Belt Unit with care not to allow its docking gear to be damaged by hitting it against the rail or associated part. -

Page 76: Cleaning Of The Idc/Registration Sensor 1, 2

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6.6.4 Cleaning of the IDC/Registration Sensor 1, 2 1. Remove the Image Transfer Belt. See P.32 2. Wipe the surface of the IDC/Regis- tration Sensor 1, 2 [1] clean of spilled toner and dirt using a soft cloth dampened with water or alcohol. -

Page 77: Cleaning Of The Comb Electrode

6. Periodical check Field Service Ver. 2.0 Mar. 2006 B. Reinstallation Procedure 1. Take out the new Toner Cartridge [1] from the unitary packing box and shake it well up and down 5 to 10 times. 4038F2C539DA 2. Insert the Toner Cartridge [2] by fit- ting it to the groove on the main unit. -

Page 78: Replacing The Imaging Unit (C, M, Y, K)

Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6.6.7 Replacing the Imaging Unit (C, M, Y, K) A. Removal Procedure 1. Turn OFF the Main Power Switch. 2. Unplug the power cord. 3. Open the Front Door. 4. Press the unlocking knob [1] of Imaging Unit. - Page 79 6. Periodical check Field Service Ver. 2.0 Mar. 2006 3. Tilt the Imaging Unit [3] to the left and shake it a small stroke in the tilt direction twice. Then, tilt it to the right and shake it a small stroke in the tilt direction twice.

- Page 80 Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6. Pull out the PC Drum protective sheet [6] while pressing the Imaging Unit. 7. Insert the Imaging Unit all the way. NOTE • Make sure that the Imaging Unit is inserted all the way.

-

Page 81: Replacing The Fusing Unit

6. Periodical check Field Service Ver. 2.0 Mar. 2006 6.6.8 Replacing the Fusing Unit CAUTION • Before replacing the Fusing Unit, ensure that it has had time to cool down. 1. Turn OFF the Main Power Switch and unplug the power cord from the power outlet, then wait for about 20 minutes. - Page 82 Field Service Ver. 2.0 Mar. 2006 6. Periodical check 6. Disconnect two Connectors [1]. 4038F2C206AA 7. Open the Right Cover. 8. Open the Fusing Unit Cover. 9. Remove two Screws [1], and remove the Fusing unit [2]. 4038F2C207AA...

-

Page 83: Service Tool

7. Service tool Field Service Ver. 2.0 Mar. 2006 Service tool CE Tool list Tool name Shape Personnel Parts No. Remarks PH Window Cleaning Jig 4038 2083 ## 4038F2C557DA PH Window Cleaning Jig 4038 2084 ## 4038F2C558DA Compact Flash 4038 0764 ## 4037F2C601DA... -

Page 84: Print Materials

Field Service Ver. 2.0 Mar. 2006 7. Service tool Print materials 7.2.1 Imaging Unit Single Parts (IU) Also replace the Dust filter packed in the Imaging Unit Black at the same time. Parts name Replacing period IU Black 70,000 prints IU Yellow 45,000 prints IU Magenta... -

Page 85: Service Jig

8. Service Jig Field Service Ver. 2.0 Mar. 2006 Service Jig Construction of the Service Jig 4038F2C582DA Name Description Remark Notebook PC • Starts the External Panel Controller for Commercially available adjustment. product Jig Software *1 • Allows settings, adjustments, and Supplied from KMBT (External panel Controller) checks to be made for the printer using... -

Page 86: Setting Up The Service Jig

Field Service Ver. 2.0 Mar. 2006 8. Service Jig Setting up the Service Jig 8.2.1 Prepare the unit necessary for the Service jig • This operation is necessary only when using the selector for the first time. 1. Remove the two screws from the selector, and then remove the upper cover. -

Page 87: Connecting The Service Jig

8. Service Jig Field Service Ver. 2.0 Mar. 2006 8.2.2 Connecting the Service jig 1. Using a DTP32 cross-cable, con- nect the I/O port of the X-Rite to port B of the selector. C4004U559AA 2. Using the RS232 straight cable (2), connect the COM 1 port of the com- puter to port C on the selector. -

Page 88: Connecting The Jig Software To The Printer

Field Service Ver. 2.0 Mar. 2006 8. Service Jig 8.2.3 Connecting the Jig Software to the Printer • Turn PC power ON. Turn the Printer power ON. Start the Jig Software (External panel Controller.) • When the error message is displayed during operation, follow the message for the coun- termeasure. - Page 89 8. Service Jig Field Service Ver. 2.0 Mar. 2006 5. Make sure that the Startup dialog box has appeared. 6. Check that “COM1” is selected for “Port.” Then, click the “OK” key. 4038F2C587DA 7. Check that the initial startup screen of the External Panel Controller has appeared on the PC.

- Page 90 Field Service Ver. 2.0 Mar. 2006 8. Service Jig 8. Check that the initial startup screen has changed to a panel screen. 4037F2E416AA...

-

Page 91: Electrical/Image Adjustment

9. Electrical/Image Adjustment Field Service Ver. 2.0 Mar. 2006 Electrical/Image Adjustment NOTE • Given in the following are only those adjustments that are made using the External Panel Controller. • Ensure appropriate security for Service Mode setting procedures. They should never be known to any unauthorized person not involved with service jobs. -

Page 92: X-Rite Calibration (Gradation Adjust)

Field Service Ver. 2.0 Mar. 2006 9. Electrical/Image Adjustment 9.2.1 X-Rite Calibration (Gradation Adjust) 1. Set up the Service Jig. 2. Call the Service Mode to the screen. 3. Click the X-Rite Calibration key in the Imaging Process Adjustment screen. 4. - Page 93 9. Electrical/Image Adjustment Field Service Ver. 2.0 Mar. 2006 8. Check that the dialog box appears 9. Set the selector knob to “B.” 10. Then click the OK key in the dialog box. C4004P570CA 4004D271AA 11. Check that the dialog box appears, and then click the Yes key in the dia- log box.

- Page 94 Field Service Ver. 2.0 Mar. 2006 9. Electrical/Image Adjustment 13. Insert the auto-cal strip into the X- Rite. NOTE • Insert the auto-cal strip after “INSERT CAL STRIP” appears on the X-Rite display. 4004D289AA 4004D272CA 14. If the reading was completed cor- rectly, the dialog box shown at the left appears.

- Page 95 9. Electrical/Image Adjustment Field Service Ver. 2.0 Mar. 2006 18. If the reading was completed cor- rectly, “OK” is indicated. C4004P578CA 19. Turn the test pattern around, and then feed it to read the row indicated by “B” in direction “2.” 20.

- Page 96 Field Service Ver. 2.0 Mar. 2006 9. Electrical/Image Adjustment 26. Check that “>>” appears beside “Read the Pattern of Magenta.” NOTE • From here on, read the test patterns of magenta, yellow, and black, in that order. • If “>>” appears beside “Read the Pattern of Cyan”, perform the pro- cedure for reading the cyan test C4004P582CA...

-

Page 97: Firmware Upgrade

10. Firmware upgrade Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade 10.1 Outline • There are two ways to update the Firmware: One is by directly connecting with the Printer using the Compact Flash, and the other is by downloading over a network using the Internet ISW. -

Page 98: Preparations For Firmware Rewriting By The Compact Flash

Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade 10.2 Preparations for Firmware rewriting by the Compact Flash 10.2.1 Service environment • OS: Windows 2000 • Drive which enables writing/reading of Compact flash • Compact flash (Service Tool: 4038 0764 ##) 10.2.2 Application to be used •... - Page 99 10. Firmware upgrade Field Service Ver. 2.0 Mar. 2006 4. Specify the folder for installation. Check to make sure that “Root Directory” is in default setting, [C:\cygwin]. NOTE • Make sure to check that “Root Directory” is in default setting, [C:\cygwin]. •...

- Page 100 Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade 8. Click [Next (N)]. 4037F2E549DA 9. Click [Complete] to start installing. 4037F2E550DA 10. After installing, open the Property of “My Computer”, and click the “Environmental Vari- able” of “Advanced” tab. 11. Click the “New” in System Variable Setting. 4036fs2620e0...

- Page 101 10. Firmware upgrade Field Service Ver. 2.0 Mar. 2006 12. Set the following two values as the Windows Environmental Variable. Variable name Variable value CYGWIN ntsec HOME /home/username 4036fs2621e0...

-

Page 102: Writing Into The Compact Flash

Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade 10.2.4 Writing into the Compact flash 1. Put the data of Firmware in the optional directory. (C:\C250P in the below figure) C:\C250P 4038F2E600DA NOTE • The file name of Firmware data consists of the “Release Date_Version_CHECKSUM-****.exe.”... - Page 103 10. Firmware upgrade Field Service Ver. 2.0 Mar. 2006 3. Mount the Compact flash on the PC, and check the Drive name, which was recognized in the Windows. (F-drive in the following figure) 4036fs2623e0 4. Click “Start” → “Program” → “Accessories” → “Command Prompt” to open the Com- mand Prompt.

- Page 104 Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade 7. Once the “mkcf.bat” is executed, data writing into the Compact flash is started. 8. Upon completion of writing, CHECKSUM is executed. If CHECKSUM value is precisely matched, “VERIFY OK” appears. 4038F2E402AA 9.

-

Page 105: Firmware Rewriting

10. Firmware upgrade Field Service Ver. 2.0 Mar. 2006 10.3 Firmware rewriting • The F/W is updated using the Compact flash. • Do not use the Service Jig or Jig Software for rewriting the F/W. 10.3.1 Updating method NOTE • NEVER remove or insert the Compact Flash card with the machine power turned 1. -

Page 106: Action When Data Transfer Fails

Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade 7. Turn OFF the Main Power Switch. 8. Remove the Compact Flash card from the slot. 9. Turn ON the Main Power Switch. NOTE • Do not turn OFF the Main Power Switch until “Ready to print” or serial number entry screen appears when turning ON the Main Power Switch for the first time after rewriting the firmware. -

Page 107: Updating The Firmware With The Internet Isw

10. Firmware upgrade Field Service Ver. 2.0 Mar. 2006 10.4 Updating the Firmware with the Internet ISW 10.4.1 Out line • [Internet ISW] is the system which gives the instruction for updating the Firmware with the control panel of the Printer, so the Printer will automatically receive the Firmware from the Program Server over a network for updating. - Page 108 Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade B. Protocol Setting • It performs the setting concerning the Protocol (ftp or http) for connecting to the Internet ISW. • When connecting to the Program Server using a proxy server, perform the setting for a Proxy Server.

- Page 109 10. Firmware upgrade Field Service Ver. 2.0 Mar. 2006 C. Forwarding Access Setting • To make the access setting for the Program Server which stores the Firmware data. 1. Start the Jig software and select [Service Mode] → [Internet ISW]. 2.

-

Page 110: Firmware Rewriting

Field Service Ver. 2.0 Mar. 2006 10. Firmware upgrade 10.4.4 Firmware rewriting NOTE • When performing the Internet ISW, ask the administrator for permission before- hand. A. Conducting rewriting on the control panel. 1. Perform the following setting. [Service Mode] → [Version Upgrade] → [Internet ISW] → [ISW Start] 2. -

Page 111: Other

11. Other Field Service Ver. 2.0 Mar. 2006 11. Other 11.1 Disassembly/Adjustment prohibited items A. Paint-locked Screws NOTE • Paint-locked screws show that the assembly or unit secured can only be adjusted or set at the factory and should not be adjusted, set, or removed in the field. B. -

Page 112: Disassembly/Assembly/Cleaning List (Other Parts)

Field Service Ver. 2.0 Mar. 2006 11. Other 11.2 Disassembly/Assembly/Cleaning list (Other parts) 11.2.1 Disassembly/Assembly parts list Section Part name Ref.Page Left Cover P.73 Exit Tray P.74 Lower Rear Cover P.74 Rear Left Cover P.73 Upper Rear Cover P.74 Multi Bypass Tray Left Cover P.75 Multi Bypass Tray Right Cover P.75... -

Page 113: Cleaning Parts List

11. Other Field Service Ver. 2.0 Mar. 2006 Section Part name Ref.Page PWB Box P.111 Color Developing Motor P.115 Color PC Drum Motor P.115 Toner Supply Motor C/K P.115 Toner Supply Motor Y/M P.116 Others Main Motor P.116 Fusing Drive Motor P.117 Tray 2 Lift-Up Motor P.119... -

Page 114: Disassembly/Assembly Procedure

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3 Disassembly/Assembly procedure 11.3.1 Left Cover/Rear Left Cover 4038F2C209AA 1. Open the Front Door [1]. 2. Remove three Screws [2], and remove the Left Cover [3]. 3. Remove three Screws [4], and remove the Rear Left Cover [5]. -

Page 115: Exit Tray/Upper Rear Cover/Lower Rear Cover

11. Other Field Service Ver. 2.0 Mar. 2006 11.3.2 Exit Tray/Upper Rear Cover/Lower Rear Cover 1. Remove the Left Cover and Rear Left Cover. See P.73 2. Open the Right Door and Fusing Unit Cover [1]. 3. Remove two Screws [2], and remove the Upper Rear Cover. -

Page 116: Multi Bypass Tray Left Cover/Multi Bypass Tray Right Cover/Multi Bypass Tray Upper Cover

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.3 Multi Bypass Tray Left Cover/Multi Bypass Tray Right Cover/Multi Bypass Tray Upper Cover 4038F2C212AA 1. Unhook the tab [1], and remove the Multi Bypass Tray Left Cover [2]. 2. Remove the Screws [3], and remove the Multi Bypass Tray Right Cover [4]. 3. -

Page 117: Front Door

11. Other Field Service Ver. 2.0 Mar. 2006 11.3.4 Front Door 1. Open the Front Door. 2. Remove the Screw [1] each to remove the Right and Left Stoppers [2]. 4038F2C038DB 3. Pull out the Right and Left Pins [3] to remove the Front Door [4]. -

Page 118: Control Panel

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.6 Control Panel 1. Open the Front Door. 2. Open the Right Door and the Fusing Unit Cover. 3. Remove two Screws [1]. 4. Lift it up to take out the Control Panel. -

Page 119: Tray 1

11. Other Field Service Ver. 2.0 Mar. 2006 11.3.7 Tray 1 1. Slide out the Tray 1 [1]. 4038F2C043DB 2. Slide out the Tray 1 [3] while press- ing the Slide Locks [2] at both ends. 4037F2C044DA... -

Page 120: Tray 2

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.8 Tray 2 1. Slide out the Tray 2 [1]. 4038F2C045DB 2. Remove the Screw [2], and remove the Stopper [3]. 3. Slide out the Tray 2 while pressing the Slide Locks [4]. 4038F2C046DB 11.3.9 Tray 2 Rear Right Cover/Tray 2 Rear Left Cover... -

Page 121: Tray 2 Right Rear Cover

11. Other Field Service Ver. 2.0 Mar. 2006 2. Remove four Screws [3], and remove the Tray 2 Rear Right Cover [4]. 4038F2C048DA 3. Remove three Screws [5], and remove the Tray 2 Rear Left Cover [6]. 4038F2C049DA 11.3.10 Tray 2 Right Rear Cover 1. -

Page 122: Front Cover

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.11 Front Cover 1. Remove the Front Door. See P.76 2. Remove the Left Cover, Control Panel and Exit Tray. See P.73, 77, 74 3. Remove the Toner Cartridges (C, M, Y, K). See P.35 4. - Page 123 11. Other Field Service Ver. 2.0 Mar. 2006 8. Disconnect two Connectors [4]. 4038F2C053DA 9. Remove four Screws [5]. 4038F2C054DA 10. Unhook six tabs [6], and remove the Front Cover [7]. 4038F2C055DA...

-

Page 124: Mechanical Control Board (Pwb-M)

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.12 Mechanical Control Board (PWB-M) NOTE • If a Finishing Option is installed, remove if from the main unit before trying to remove the Mechanical Control Board. • When removing the Finishing Option, support the Horizontal Transport Unit with your hand to prevent if from dropping. - Page 125 11. Other Field Service Ver. 2.0 Mar. 2006 6. Remove six Screws [5], and remove the Mechanical Control Board [6]. 4038F2C059DA NOTE • When Mechanical Control Board (PWB-M) is replaced, relocate the Parameter Chip (IC6). Mount the Parameter Chip (IC6) of old Mechanical Control Board onto the new Mechanical Control Board.

-

Page 126: Dc Power Supply (Pu1)

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.13 DC Power Supply (PU1) NOTE • If a Finishing Option is installed, remove if from the main unit before trying to remove the DC Power Supply. • When removing the Finishing Option, support the Horizontal Transport Unit with your hand to prevent if from dropping. - Page 127 11. Other Field Service Ver. 2.0 Mar. 2006 6. Disconnect the Connector [7], and remove the Harness [9] from the Wire saddles [8]. 4038F2C064DA 7. Remove two Screws [10], and remove the Power Supply Cooling Fan Motor/1 [11]. [11] [10] 4038F2C065DA 8.

-

Page 128: Slide Interface Board (Pwb-Sif)

Field Service Ver. 2.0 Mar. 2006 11. Other 9. Remove four Screws [12], and [12] [13] remove the DC Power Supply [13]. [12] 4038F2C067DB 11.3.14 Slide Interface Board (PWB-SIF) 1. Remove the Lower Rear Cover. See P.74 2. Remove all the Connectors and the Flat Cable on the Slide Interface Board. -

Page 129: Mfp Control Board (Pwb-Mfp)

11. Other Field Service Ver. 2.0 Mar. 2006 4. Disconnect the Connector [2] con- necting to the MFP Control Board and remove the Slide Interface Board [3]. 4038F2C076DA 11.3.15 MFP Control Board (PWB-MFP) 1. Remove the Upper Rear Cover, Lower Rear Cover and Rear Right Cover. - Page 130 Field Service Ver. 2.0 Mar. 2006 11. Other 5. Remove the DIMM0 and DIMM1 [3] on the MFP Control Board. 4038F2C078DC 6. Disconnect the Connector [4] and Flat Cable [5]. 4038F2C079DA 7. Remove four Bolts [6] and six Screws [7], and remove the Interface cover [8].

-

Page 131: Dimm0 (Work0), Dimm1 (Work1)

11. Other Field Service Ver. 2.0 Mar. 2006 8. Remove thirteen Screws [9], and remove the MFP Control Board [10]. NOTE • When the MFP Control Board is replaced, mount the removed NVRAM to the new MFP Control Board. • When the MFP Control Board is replaced, make sure to update the firmware. -

Page 132: Hard Disk Drive (Hdd)

Field Service Ver. 2.0 Mar. 2006 11. Other 3. Remove the DIMM0 [2] and DIMM1 [2]. 4038F2C082DB 11.3.17 Hard Disk Drive (HDD) 1. Remove the Upper Rear Cover, Lower Rear Cover and Rear Right Cover. See P.74, 76 2. Remove thirteen Screws, and remove the Shield cover [1]. -

Page 133: High Voltage Unit (Hv1)

11. Other Field Service Ver. 2.0 Mar. 2006 4. Remove the four Screws [3], and remove the Hard Disk Drive Assy [4]. 4038F2C084DA 5. Remove four screws [5] and the Flat cable [6], and remove the Hard Disk Drive [7]. NOTE •... -

Page 134: Tray 1 Paper Size Board (Pwb-I)

Field Service Ver. 2.0 Mar. 2006 11. Other 3. Remove five Screws [2] and the tab [3], and remove the High Voltage Unit [4]. NOTE • When installing the High Voltage Unit, make sure that the terminal end surely contacts. 4038F2C086DA NOTE •... -

Page 135: Tray 2 Control Board (Pwb-Z-Pc)

11. Other Field Service Ver. 2.0 Mar. 2006 4. Remove the Lever [4]. 5. Remove the Tray 1 Paper Size Board [5]. 4038F2C516DA 11.3.20 Tray 2 Control Board (PWB-Z-PC) 1. Remove the Tray 2 Rear Right Cover and Tray 2 Rear Left Cover. See P.79 2. - Page 136 Field Service Ver. 2.0 Mar. 2006 11. Other 4. Remove the Harness [5] from the Wire saddle [4]. 4038F2C091DA 5. Remove all the Connectors on the Tray 2 Control Board. 4038F2C092DA 6. Remove four Screws [6], and remove the Tray 2 Control Board [7]. 4038F2C093DA...

-

Page 137: Tray 2 Paper Size Board (Pwb-I-Pc)

11. Other Field Service Ver. 2.0 Mar. 2006 11.3.21 Tray 2 Paper Size Board (PWB-I-PC) 1. Slide out the Tray 2. 2. Remove the Tray 2 Rear Right Cover and Tray 2 Rear Left Cover. See P.79 3. If the optional paper feed cabinet is mounted, disconnect the Connector [1]. - Page 138 Field Service Ver. 2.0 Mar. 2006 11. Other 6. Remove three Screws [6], and remove the Tray 2 Control Board Assy [7]. 4038F2C095DA 7. Remove two Claws [8] and the Con- nector [9], and remove the Tray 2 Paper Size Board Assy [10]. [10] 4038F2C096DA 8.

-

Page 139: Ph Interface Board (Pwb-D)

11. Other Field Service Ver. 2.0 Mar. 2006 11.3.22 PH Interface Board (PWB-D) 1. Remove the Front Cover. See P.81 2. Remove the Image Transfer Belt Unit. See P.32 3. Remove two Screws [1], and remove the Front Right Cover [2]. 4038F2C097DA 4. - Page 140 Field Service Ver. 2.0 Mar. 2006 11. Other 6. Remove two Screws [7] each, and remove the Imaging Unit Roll Assy [8] of each color. 4038F2C100DA 7. Remove all the Connectors and the Flat Cables on the PH Interface Board. 4038F2C101DA 8.

-

Page 141: Multi Bypass Unit

11. Other Field Service Ver. 2.0 Mar. 2006 11.3.23 Multi Bypass Unit 1. Remove the Multi Bypass Tray Right Cover and the Multi Bypass Tray Left Cover. See P.75 2. Disconnect five Connectors [1]. 4038F2C103DA 3. Remove four Screws [2], and remove the Multi Bypass Unit [3]. -

Page 142: Ph Unit

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.24 PH Unit A. Removal Procedure 1. Remove the Front Cover. See P.81 2. Remove the Image Transfer Belt Unit. See P.32 3. Remove the Screw [1] and discon- nect the Connector [2] respectively, and remove three Imaging Unit Guide rails [3]. - Page 143 11. Other Field Service Ver. 2.0 Mar. 2006 6. Remove the Stopper [8] of the PH Unit (Black). NOTE • When removing the Stopper, use care so that both ends of the Stop- per will not open but stay parallel as shown on the left.

- Page 144 Field Service Ver. 2.0 Mar. 2006 11. Other Remove the PH Unit [14]. [14] 8. Follow the same procedures to remove all PH Units. 4037F2C112DB B. Reinstall Procedure 1. Fit the back of the PH Unit [1] into the plate spring [2] of installation plate.

- Page 145 11. Other Field Service Ver. 2.0 Mar. 2006 4. Reinstall the Stopper [7]. NOTE • When reinstalling the Stopper, use care so that both ends of the Stop- per will not open but stay parallel as shown on the left. Keep using the Stopper after once stretched out may cause uneven pitch or other image troubles.

-

Page 146: Transport Drive Assy

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.25 Transport Drive Assy 1. Remove the PWB Box. See P.111 2. Remove the High Voltage Unit. See P.92 3. Remove the Color Developing Motor. See P.115 4. Remove the Color PC Drum Motor. See P.115 5. - Page 147 11. Other Field Service Ver. 2.0 Mar. 2006 9. Remove five Screws [7] and the Connector [8], and remove the Rear Handle Assy [9]. 4038F2C121DA 10. Disconnect the Connector [10]. [12] 11. Remove the Harnesses [12] from [11] five Wire Saddles [11]. [12] [10] [11]...

-

Page 148: Hopper Drive Assy

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.26 Hopper Drive Assy 1. Remove the Transfer Drive Assy. See P.105 2. Disconnect seven Connectors [1]. 4038F2C124DB 3. Remove the Harness from four Wire Saddles [2]. 4038F2C125DA 4. Remove two Screws [3], and remove the Duct [4]. -

Page 149: Right Door Assy

11. Other Field Service Ver. 2.0 Mar. 2006 5. Remove four Screws [5] and two Claws [6], and remove the Hopper Drive Assy [7]. 4038F2C127DA 11.3.27 Right Door Assy 1. Remove the PWB Box. See P.111 2. Remove the High Voltage Unit. See P.92 3. - Page 150 Field Service Ver. 2.0 Mar. 2006 11. Other 6. Remove six Screws [4], and remove the Motor cover [5]. 4038F2C156DA 7. Open the Right Door. 8. Remove three Screws [6], and remove the Reinforcement plate [7] of the right door and spring [8]. 4038F2C159DA 9.

- Page 151 11. Other Field Service Ver. 2.0 Mar. 2006 10. Remove two Screws [10], and remove the Metal blanking plate [11]. [10] [11] 4038F2C577DA 11. Remove five Screws [12] and the [12] [13] [12] Connector [13], and remove the Rear Handle Assy [14]. [14] [12] 4038F2C578DA...

-

Page 152: Pwb Box

Field Service Ver. 2.0 Mar. 2006 11. Other 13. Remove the Front Door. [17] [16] See P.76 14. Slide out the Tray 1. 15. Remove two Screws [16], and remove the Front Right Cover [17]. [16] 4038F2C580DA 16. Remove the Screw [18], and remove [20] [18] the Shaft [19]. - Page 153 11. Other Field Service Ver. 2.0 Mar. 2006 3. Disconnect the Flat Cable [2] on the MFP Control Board, and remove two Presser Bars [3] of Flat Cable. 4038F2C140DA 4. Disconnect the Flat Cable [4] on the Slide Interface Board, and remove the Presser Bar [5] of Flat Cable.

- Page 154 Field Service Ver. 2.0 Mar. 2006 11. Other 6. Disconnect the Connector [7], and remove the Harness from the Wire Saddle [8]. 7. Remove two tabs [9], and remove [10] the Cooling Fan Motor/2 [10]. 4038F2C143DA 8. Remove the Harness [12] from two [12] Wire Saddles [11].

- Page 155 11. Other Field Service Ver. 2.0 Mar. 2006 10. Disconnect the Connector [15], and remove the Harness from the Wire Saddle [16]. [16] [15] 4038F2C146DA 11. Remove the Screw [17] of the [17] Ground terminal. 4038F2C147DA 12. Remove eight Screws [18], and remove the PWB Box [19].

-

Page 156: Color Developing Motor (M3)

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.29 Color Developing Motor (M3) 1. Remove the PWB Box. See P.111 2. Remove the Connector [1] and four Screws [2], and remove the Color Developing Motor [3]. 4038F2C149DA 11.3.30 Color PC Drum Motor (M2) 1. -

Page 157: Toner Supply Motor Y/M (M6)

11. Other Field Service Ver. 2.0 Mar. 2006 11.3.32 Toner Supply Motor Y/M (M6) 1. Remove the PWB Box. See P.111 2. Remove the Connector [1] and two Screws [2], and remove the Toner Supply Motor Y/M [3]. 4038F2C152DA 11.3.33 Main Motor (M1) 1. -

Page 158: Fusing Drive Motor (M4)

Field Service Ver. 2.0 Mar. 2006 11. Other 5. Remove six Screws [4], and remove the Motor cover [5]. 4038F2C156DA 6. Remove the Connector [6] and four Screws [7], and remove the Main Motor [8]. 4038F2C157DA 11.3.34 Fusing Drive Motor (M4) 1. - Page 159 11. Other Field Service Ver. 2.0 Mar. 2006 4. Remove the Harness from the Wire Saddle [2]. 4038F2C154DA 5. Remove six Screws [4], and remove the Motor cover [5]. 4038F2C156DA 6. Remove the Connector [6] and two Screws [7], and remove the Fusing Drive Motor [8].

-

Page 160: Tray 2 Lift-Up Motor (M3-Pc)

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.35 Tray 2 Lift-Up Motor (M3-PC) 1. Pull out the Tray 2. 2. Remove the Tray 2 Rear Right Cover. See P.79 3. If the optional paper feed cabinet is mounted, remove it. 4. - Page 161 11. Other Field Service Ver. 2.0 Mar. 2006 4. Remove the Harness of the Motor Assy [4] from five Wire Saddles [3]. 5. Disconnect two Connectors [5]. 4038F2C167DA 6. Remove two Screws [6], and remove the Motor Assy [7]. 4038F2C168DA 7.

-

Page 162: Tray 2 Vertical Transport Motor (M2-Pc)

Field Service Ver. 2.0 Mar. 2006 11. Other 11.3.37 Tray 2 Vertical Transport Motor (M2-PC) 1. Pull out the Tray 2. 2. Remove the Tray 2 Rear Right Cover and the Tray 2 Rear Left Cover. See P.79 3. Remove two Screws [1], and remove the Reinforcement plate [2]. -

Page 163: Idc/Registration Sensor/1, Idc/Registration Sensor/2 (Se1/Se2)

11. Other Field Service Ver. 2.0 Mar. 2006 7. Remove two Screws [8], and remove the Tray 2 Vertical Transport Motor [9]. 4038F2C520DA 11.3.38 IDC/Registration Sensor/1, IDC/Registration Sensor/2 (SE1/SE2) 1. Remove the Image Transfer Belt Unit. See P.32 2. Remove the Multi Bypass Unit. See P.100 3. - Page 164 Field Service Ver. 2.0 Mar. 2006 11. Other 6. Remove the Claws [6] of both sides, and remove the Sensor cover [7]. NOTE • Use care not to miss the spring [8]. 4038F2C171DA 7. Remove two Screws [9] and Connec- tor [10], and remove the IDC/Regis- tration Sensor/1 [11].

-

Page 165: Cleaning Procedure

11. Other Field Service Ver. 2.0 Mar. 2006 11.4 Cleaning procedure NOTE • The alcohol described in the cleaning procedure represents the isopropyl alcohol. 11.4.1 PH Window 1. Open the Front Door. 2. Remove the PH Window Cleaning Jig [1]. 4038F2C547DA 3. -

Page 166: Image Transfer Belt Unit

Field Service Ver. 2.0 Mar. 2006 11. Other 11.4.2 Image Transfer Belt Unit 1. Remove the Image Transfer Belt Unit. See P.32 2. Using a dried soft cloth, wipe the Image Transfer Belt [1]. NOTE • If it is difficult to clean with dried soft cloth, dampen a soft cloth with a solvent. -

Page 167: Bypass Tray Feed Roller

11. Other Field Service Ver. 2.0 Mar. 2006 3. Using a soft cloth dampened with alcohol, wipe the Tray 1 Separation Roller [3] clean of dirt. 4038F2C176DA 11.4.5 Bypass Tray Feed Roller 1. Remove the Multi Bypass Unit. See P.100 2. -

Page 168: Tray 2 Feed Roller/Tray 2 Pick-Up Roller

Field Service Ver. 2.0 Mar. 2006 11. Other 3. Remove the Screw [3], and remove the Bypass Tray Separation Roller Assy [4]. 4038F2C010DA 4. Using the soft cloth dampened with alcohol, wipe the Bypass Paper Sep- aration Roller [5]. 4038F2C178DA 11.4.7 Tray 2 Feed Roller/Tray 2 Pick-up Roller 1. - Page 169 11. Other Field Service Ver. 2.0 Mar. 2006 4. Remove two Screws [3], and remove the Jam processing cover [4]. NOTE • Make sure the position of the Mylar when installing the Jam processing cover. 4038F2C012DB 5. Remove two Screws [5] and the Tray 2 Separation Roller installation plate Assy [6].

-

Page 170: Tray 2 Separation Roller

Field Service Ver. 2.0 Mar. 2006 11. Other 11.4.8 Tray 2 Separation Roller 1. Slide out the Tray 2. 2. Open the Vertical transport door. 3. Remove two Claws [1], and remove the Vertical transport door [2]. 4038F2C011DA 4. Remove two Screws [3], and remove the Jam processing cover [4]. -

Page 171: Tray 2 Transport Roller

11. Other Field Service Ver. 2.0 Mar. 2006 6. Using a soft cloth dampened with alcohol, wipe the Tray 2 Separation Roller [7]. 4038F2C523DA 11.4.9 Tray 2 Transport Roller 1. Open the Vertical Transport Door. 2. Using a soft cloth dampened with alcohol, wipe the Tray 2 Transport Roller [1]. -

Page 172: Adjustment/Setting

Field Service Ver. 2.0 Mar. 2006 12. How to use the adjustment section Adjustment/Setting 12. How to use the adjustment section • “Adjustment/Setting” contains detailed information on the adjustment items and proce- dures for this machine. • Throughout this “Adjustment/Setting,” the default settings are indicated by “ ”. Advance Checks •... -

Page 173: Control Panel

13. Control Panel Field Service Ver. 2.0 Mar. 2006 13. Control Panel 13.1 Identification and Functions of Keys on Control Panel 4038F3E188DA Name Description [1] Left Arrow keys • Pressing this key while entering the letters will delete the letters left side of the cursor. -

Page 174: Utility Mode Function Tree

Field Service Ver. 2.0 Mar. 2006 13. Control Panel 13.2 Utility Mode function tree • The function tree is shown to comply with the format displayed on the screen. • To display each item for the Admin. Setting, enter the Password and log in. NOTE •... - Page 175 13. Control Panel Field Service Ver. 2.0 Mar. 2006 System Language User Setting Setting Setting Daylight Savings Auto Reset Date/Time Date Time Time Zone Set Date Daylight (Adjusting) Savings Power Save Low Power Sleep Mode Auto Tray Tray Setting Select Tray Priority Auto Tray Select...

- Page 176 Field Service Ver. 2.0 Mar. 2006 13. Control Panel Printer User Setting Basic Setting Paper Size Setting Org. Direction Spool Setting Size Change Banner Setting Banner Tray PCL Setting Font Number Symbol Set Line/Page Font Size CR/LF Mapping PS Error PS Setting Print *1:The subfunction of a lower...

- Page 177 13. Control Panel Field Service Ver. 2.0 Mar. 2006 Admin. Network DNS Auto TCP/IP DNS Server Setting Setting Obtain Priority DNS Substitute DNS1 Substitute DNS2 Permit Setting IP Filtering Access Range 1 Setting Range 2 Setting Range 3 Setting Range 4 Setting Range 5 Setting...

- Page 178 Field Service Ver. 2.0 Mar. 2006 13. Control Panel Admin. Network TCP/IP Host Name Host Name Setting Setting DNS Domain DNS Auto Obtain Default Name Search Name 1 Search Name 2 Search Name 3 Dynam- icDNS Set NetWare IPX Setting IPX Setting Ethernet Frame...

- Page 179 13. Control Panel Field Service Ver. 2.0 Mar. 2006 Admin. Network AppleTalk Printer Name Setting Setting Zone Name Bonjour Bonjour Setting Bonjour Name WINS WINS Setting DNS Auto Obtain WINS Server IP 1 WINS Server IP 2 Printer Printer Setting NetBIOS Name Print Service...

- Page 180 Field Service Ver. 2.0 Mar. 2006 13. Control Panel Admin. Network Discovery Discovery SNMP v3 Setting Setting Setting User User Name Read User Name Setting Security Level Auth- Password Priv- Password Write Setting User Name Security Level Auth- Password Priv- Password TCP Socket TCP Socket...

- Page 181 13. Control Panel Field Service Ver. 2.0 Mar. 2006 Admin. Network Auth. http Server IPP Auth. Setting Setting System realm Accept IPP Support Info. Print Job Cancel Job Acquire Job Valid Job Attributes Printer Attrib. Printer Printer Info. Name Printer Location Printer Info.

- Page 182 Field Service Ver. 2.0 Mar. 2006 13. Control Panel Admin. Time NTP Server IP Address Setting Adjustment Add. DNS Host Name Port No. User Box Delete User Oper. Del. Secure Secure Print Doc. Auto Delete List Output Mode List Call Center Security Admin.

- Page 183 13. Control Panel Field Service Ver. 2.0 Mar. 2006 Admin. Authentica- OpenAPI Login Name Setting tion Password Data Capture Tech. Rep. Mode Banner Printing...

-

Page 184: Settings In Control Panel

Field Service Ver. 2.0 Mar. 2006 13. Control Panel 13.3 Settings in Control panel 13.3.1 Procedure Cancel key 4038F3E188DA Message window Menu/Select Key A. Job Operation 1. Make sure that the Default screen (Ready to print) is being displayed, and press the Menu/Select key on the control panel. -

Page 185: Settings In Job Operation (Account Track)

13. Control Panel Field Service Ver. 2.0 Mar. 2006 13.4 Settings in Job Operation (Account Track) • Setting items for Job operation can be used only when the optional Hard Disk is mounted. • When Account Track is being performed, the Account name and the Password need to be entered. -

Page 186: Settings In Paper Tray

Field Service Ver. 2.0 Mar. 2006 13. Control Panel 13.5 Settings in Paper Tray • It sets the paper type for each Tray. A. Tray 1 Size Purpose/Use To set the paper size for the 1st Drawer. Setting/ The default setting is “A4” paper. Procedure B. -

Page 187: User Setting

14. User Setting Field Service Ver. 2.0 Mar. 2006 14. User Setting 14.1 User Setting Function Setting Procedure 14.1.1 Procedure Cancel key 4038F3E188DA Message window Menu/Select Key 1. Make sure that the Default setting (Ready to print) is displayed, and press the Menu/ Select key on the control panel. -

Page 188: Settings In User Setting

Field Service Ver. 2.0 Mar. 2006 14. User Setting 14.2 Settings in User setting 14.2.1 Print Reports Functions • To output the report or Demo Page concerning the print setting. • To check the setting concerning the printer. • The types of report available for output are as follows. Meter Count : Prints the total checklist. -

Page 189: Power Save

14. User Setting Field Service Ver. 2.0 Mar. 2006 C. Auto Reset Functions • To set the period of time until Auto Reset starts. • To change the period of time until Auto Reset starts functioning. Setting/ • The default setting is 1 min. Procedure “1 min.”... -

Page 190: Tray Setting

Field Service Ver. 2.0 Mar. 2006 14. User Setting 14.2.4 Tray Setting A. Auto Tray Select Functions • To set the Tray for the Auto select when the Auto Paper function is set. • To select the Tray for Auto Paper function. Setting/ •... -

Page 191: Output Setting

14. User Setting Field Service Ver. 2.0 Mar. 2006 14.2.5 Output Setting A. Print Output Functions • To set the timing for printing for the PC print job or Fax received. Batch Print : Starts printing when all data are received Page Print : Starts printing every time data for each page are received Setting/ •... - Page 192 Field Service Ver. 2.0 Mar. 2006 14. User Setting (4) Bind Direction Functions • To set the binding direction during duplex printing when not specified by the printer driver during PC printing. • To use when binding direction cannot be specified by the printer driver during printing by Windows DOS, etc.

- Page 193 14. User Setting Field Service Ver. 2.0 Mar. 2006 (9) Org. Direction Functions • To set the default setting for the direction of the original during PC printing. Setting/ • The default setting is Portrait. Procedure “Portrait” Landscape (10) Spool Setting Functions •...

- Page 194 Field Service Ver. 2.0 Mar. 2006 14. User Setting (13) Banner Tray Functions • To set the paper source to be used for banner printing. • When changing the paper source for banner printing. Setting/ • The default setting is Auto. Procedure Tray 1 Tray2...

- Page 195 14. User Setting Field Service Ver. 2.0 Mar. 2006 Font List 000 Courier 027 Albertus Medium 054 ITC Bookman Demi 001 CG Times 028 Albertus Extra Bold 055 ITC Bookman Light Italic 002 CG Times Bold 029 Arial 056 ITC Bookman Demi Italic New Century Schoolbook 003 CG Times Italic 030 Arial Bold...

- Page 196 Field Service Ver. 2.0 Mar. 2006 14. User Setting (2) Symbol Set Functions • To set the Font Symbol Set when not specified by the printer driver during PC print- ing. • To use when the Font Symbol Set cannot be specified by the printer driver during printing from Windows DOS, etc.

-

Page 197: Settings In Admin. Setting

14. User Setting Field Service Ver. 2.0 Mar. 2006 14.3 Settings in Admin. Setting 14.3.1 Procedure Cancel key 4038F3E188DA Message window Menu/Select Key 1. Make sure that the Default setting (Ready to print) is displayed, and press the Menu/ Select key on the control panel. 2. -

Page 198: Network

Field Service Ver. 2.0 Mar. 2006 14. User Setting 14.3.4 Network A. TCP/IP (1) TCP/IP Setting Functions • To set whether to enable or disable TCP/IP setting. • To disable TCP/IP setting. Setting/ • The default setting is ON. Procedure “ON”... - Page 199 14. User Setting Field Service Ver. 2.0 Mar. 2006 (3) DNS Server Functions • To set the DNS Server. • When changing the DNS server setting method. DNS Auto Obtain : To disable the Auto Obtaining of the DNS Server Address. Priority DNS : To enter Priority DNS Server.

- Page 200 Field Service Ver. 2.0 Mar. 2006 14. User Setting (5) RAW Port No. Functions • To set the RAW port No. • To set the RAW port number for the printer. Setting/ 1. Select the necessary port number 1 to 6. Procedure 2.

- Page 201 14. User Setting Field Service Ver. 2.0 Mar. 2006 B. NetWare (1) IPX Setting Functions • To set the NetWare (IXP). • To change the NetWare (IPX) setting. IPX Setting: To use NetWare (IPX) setting. Ethernet Frame: To specify the Frame type for transmission. Setting/ <IPX Setting>...

- Page 202 Field Service Ver. 2.0 Mar. 2006 14. User Setting 2. PServer Functions • To set the Print server. • When changing the print server setting PServer Name: To enter the PServer name. PServer Password: To enter the PServer password. Polling Interval: To set the interval to search the print queue.

- Page 203 14. User Setting Field Service Ver. 2.0 Mar. 2006 C. AppleTalk (1) AppleTalk Set Functions • To set whether to enable or disable the AppleTalk setting. • To use AppleTalk setting. Setting/ • The default setting is OFF. Procedure “OFF” (2) Printer Name Functions •...

- Page 204 Field Service Ver. 2.0 Mar. 2006 14. User Setting E. SMB (Server Message Block) (1) WINS (Windows Internet Name Service) 1. WINS Setting Functions • To set whether or not to enable the WINS setting. • To use the WINS (Windows Internet Name Service) setting is necessary. •...

- Page 205 14. User Setting Field Service Ver. 2.0 Mar. 2006 3. Print Service Functions • To set the Print service name. • To set the Print service name. Setting/ • Enter the Print Service name. (up to 13 characters) Procedure 4. Workgroup Functions •...

- Page 206 Field Service Ver. 2.0 Mar. 2006 14. User Setting (4) v3 Setting 1. Context Name Functions/ • To set the Context Name which is used for SNMP v3. Setting/ • Enter the Context Name. (up to 63 characters) Procedure 2. Discovery Set Functions •...

- Page 207 14. User Setting Field Service Ver. 2.0 Mar. 2006 4. Write Setting Functions • To set the name of the Reading/Writing Authority User which is used for SNMP v3. User Name: To set the user name Security Level: To set the security level of the user Auth.

- Page 208 Field Service Ver. 2.0 Mar. 2006 14. User Setting G. TCP Socket (1) TCP Socket (Binary Mode) 1. TCP Socket Set Functions • To set whether or not to use the TCP Socket setting of Binary Mode. • To use when using the application, etc. for TCP Socket transmission by Binary Mode. Setting/ •...

- Page 209 14. User Setting Field Service Ver. 2.0 Mar. 2006 H. http Server (1) http Server Set Functions • To set whether or not to use the http Server setting. • Not to use the http Server setting. Setting/ • The default setting is ON. Procedure “ON”...

- Page 210 Field Service Ver. 2.0 Mar. 2006 14. User Setting 2. IPP Auth. Functions • To set the IPP Authentication. IPP Auth. Set: To set whether or not to use the IPP Authentication setting. Auth. System: To change the Authentication system for IPP Authentication. User Name: To set the user name when basic or digest is selected for the authentication system...

-

Page 211: I/F Setting

14. User Setting Field Service Ver. 2.0 Mar. 2006 5. Printer Info. Functions • To set the Printer information. Printer Name: To set the Printer Name. Printer Location: To set the Printer Location. Printer Info.: To set the Printer Info. Setting/ <Printer Name>... -

Page 212: Time Adjustment

Field Service Ver. 2.0 Mar. 2006 14. User Setting C. USB Timeout Functions • To set the timeout period for USB transmission. • To make the timeout period longer according to the network condition. Setting/ • The default settings are 60 sec. Procedure “60 sec”... -

Page 213: User Box Oper

14. User Setting Field Service Ver. 2.0 Mar. 2006 14.3.7 User Box Oper. A. Delete User Box Function/Use • To delete the unnecessary box without data. Setting/ 1. Enter the Box number (up to nine numerical characters) to be deleted. Procedure 2. - Page 214 Field Service Ver. 2.0 Mar. 2006 14. User Setting B. HDD Setting (1) HDD Password Functions • To set the Lock Password for the hard disk. • To enter the Lock Password for the hard disk. Setting/ • Enter the password (up to 8 on-byte characters) Procedure •...

- Page 215 14. User Setting Field Service Ver. 2.0 Mar. 2006 (3) Overwrite All • Overwrite All overwrites meaningless data to all areas, in which image data is stored, thereby destroying the structure of the image data. • Destroying the data structure prevents any data left in the areas from being leaked out even when the HDD is stolen.

- Page 216 Field Service Ver. 2.0 Mar. 2006 14. User Setting (4) Overwrite Temp. • The image data sent from the PC is temporarily written to the HDD and memory areas. • Overwrite Temp overwrites meaningless data to the HDD and memory areas, to which image data has been temporarily written, thereby destroying the image data after the completion of the print cycle.

-

Page 217: Openapi

14. User Setting Field Service Ver. 2.0 Mar. 2006 (6) Encryption Key • It can be set only when the optional Security Kit (SC-503) is mounted. Functions • To set Encryption key necessary to mount the optional Security Kit SC-503. •... -

Page 218: Data Capture

Field Service Ver. 2.0 Mar. 2006 14. User Setting C. Port No. (SSL) Functions • To set the access port (SSL) for other systems with OpenAPI when using Page Scope Data Administrator. • To change the access port number (SSL) for other systems with OpenAPI. Setting/ •... -

Page 219: Adjustment Item List

15. Adjustment item list Field Service Ver. 2.0 Mar. 2006 15. Adjustment item list Replacement Part/Service Job Adjustment/Setting Items ❍ Print Positioning: Leading Edge Machine Printer Area ❍ Print Positioning: Side Edge HDD R/W Check Memory/ State HDD Adjust HDD Format Confirmation Table Number Firmware Version... - Page 220 Field Service Ver. 2.0 Mar. 2006 15. Adjustment item list ✽ This table shows the adjustment items that are required when a part of the machine has been replaced. Priority order, if applicable, during the adjustment procedures is indicated by the corresponding number in the parentheses. ❍...

-

Page 221: Tech. Rep. Mode

16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 16.1 Calling the Tech. Rep. Mode to Screen NOTE • Ensure appropriate security for Tech. Rep. mode function setting procedures. 16.1.1 Procedure Cancel key 4038F3E188DA Message window Menu/Select Key 1. -

Page 222: Tech. Rep. Mode Function Tree

Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 16.2 Tech. Rep. Mode function tree Ready to Print Operation Paper Tray User Setting Admin. Setting *1 Tech.Rep. Counter Mode *1 Reset *1: Password Running needs to be Mode entered. Option Board List Output Serial... - Page 223 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 Tech. Rep. Data *2: Unavailable when Data Capture is prohibited Mode Capture *2 on the utility mode Data Backup Software SW Switch No. Assignment Assignment CS Remote System Care Selection Mainte.

- Page 224 Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE Tech. Rep. CS Remote Detail Set: Center Tel Mode Care Modem Device Tel Data/Time Initial Trans. RAM Clear Log Print Software SW Switch No. Assignment Assignment Reset Command Server Server for POP3 Server Setting POP3 Login...

- Page 225 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 Tech. Rep. CS Remote Server Connect Send Setting Mode Care Setting Timeout Auth. Setting TX/RX Test Data Initialize...

-

Page 226: Settings In Tech. Rep. Mode

Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 16.3 Settings in Tech. Rep. Mode 16.3.1 Counter Reset Functions • To check the number of hours or times each of the different maintenance parts has been used. • To clear the count of each counter. •... -

Page 227: List Output

16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 16.3.4 List Output Machine Management List Functions • To produce an output of a list of setting values, adjustment values, Total Counter val- ues, and others. • At the end of setup or when a malfunction occurs. Setting/ <Selecting Report>... -

Page 228: Image Controller

Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 16.3.6 Image Controller Functions • To set the type of the controller. • “Peripheral Mode” appears when “Others” is selected. • When setting up the controller. Setting/ Image Controller Procedure •... -

Page 229: Initialization

16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 16.3.9 Initialization A. Data Clear Functions • To initialize the setting data. • To clears the setting data. NOTE • When removing or installing the hard disk after registering the data below, be sure to clear the data. -

Page 230: Hdd Formatting

Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 16.3.12 HDD Formatting Functions • To format the hard disk • The function proceeds in the order of Physical Format to Logical Format. • If the hard disk is yet to be formatted, the trouble code “C-D010” will appear. Ignore this code and continue with the formatting procedure. - Page 231 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 B. Internet ISW • By using this setting, the Firmware stored in the Server can be downloaded over internet for upgrading. • For details for upgrading the Firmware, refer to “Firmware upgrade” in the Maintenance section.

-

Page 232: Data Capture

Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 16.3.14 Data Capture Functions • When an error occurs, it acquires the print job data in order to analyze the cause of the error. • When an error occurs, this will be used to analyze the cause of the error according to the print job data. - Page 233 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 6. Using the “ls” command, display the list of the file available for capture. 4037F3E540DA 7. Using the “binary” command, set the File transfer mode to the binary transfer. 4037F3E541DA...

- Page 234 Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 8. Using the “get” command, transfer the data for capture to PC. 4037F3E542DA 9. Finish the command prompt. NOTE • After receiving capture data, select [Admin. Setting] → [Data Capture], and select “Prohibit”...

-

Page 235: Data Backup

16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 16.3.15 Data Backup Functions • To backup nonvolatile data (data stored in NVRAM) in the Printer to the Flash mem- ory. • To backup current data in order to prevent data in NVRAM from being erased unex- pectedly. -

Page 236: Settings In Cs Remote Care

• For resetting up the machine which CS Remote Care has already been set up, clear the RAM for CS Remote Care before resetting. See P.205 • When using the telephone line for connection, use the recommended modem. (For recommended modem, contact responsible person of KONICA MINOLTA.) Procedure Step Using the telephone line modem Using E-mail Register the device ID to the application at CS Remote Care Center. - Page 237 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 Procedure Step Using the telephone line modem Using E-mail Setting the date and time for CS Remote Care 1. Select the Detail Set: *** → Date/Time. (***: modem or e-mail) 2.

- Page 238 Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE Procedure Step Using the telephone line modem Using E-mail Executing the initial transmission Receiving the initial connection E-mail mes- 1. Select the CS Remote Care → Detail Set: sage Modem → Initial Trans. Sending the initial connection E-mail message 2.

-

Page 239: Software Sw Setting For Cs Remote Care

16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 16.4.3 Software SW setting for CS Remote Care NOTE • SW bits data are written into the NVRAM every time a change is made. In case you changed bit data by accident, be sure to restore the previous state. A. - Page 240 Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE SW No. Functions Default SW 05 Modem redial interval 4 to 7 Reservation — — SW 06 Modem redial times Reservation — — SW 07 Redial for response time out Do not redial Redial 1 to 7 Reserved...

- Page 241 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 SW No. Functions Default SW 12 Timer 2 Dial request completed → CONNECT reception SW 13 0 to 7 Reservation — — SW 14 Timer 4 Line connection → Start request telegram delivery SW 15 Timer 5...

- Page 242 Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE *1: Baud rate Mode 01-7 01-6 01-5 01-4 9600 bps 19200 bps “38400 bps” *2: Modem redial interval Mode 05-3 05-2 05-1 05-0 1 minute 2 minutes “3 minutes” 4 minutes 5 minutes 6 minutes 7 minutes...

- Page 243 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 *5: Retransmission times on E-Mail delivery error Mode 09-6 09-5 09-4 09-3 09-2 09-1 09-0 0 to 9 times 000 0000 to 000 1001 “10 times” 11 to 99 times 000 1011 to 110 0011 *6: Timer 1 (RING reception →...

-

Page 244: Setup Confirmation

Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE 16.4.4 Setup confirmation • Follow the steps below to make sure that CS Remote Care has been properly set 1. Call the Service Mode to the screen. 2. Select the CS Remote Care. 3. -

Page 245: Detail On Settings

16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 16.4.8 Detail on settings A. System Selection Functions • To select the system type for remote diagnosis. • Use to newly build or change the system. Setting/ • The default setting is E-Mail. Procedure “E-Mail”... - Page 246 Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE (3) RAM Clear Functions • To clear the following data at the Center ID Code, Primary Setting, Date/Time Input, and Common DT. • To be used for setting CS Remote Care. •...

- Page 247 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 D. Server Setting • Server Setting can be set only when [E-Mail] is selected by System Setting. (1) Server for RX <POP3 server> Functions • To set the POP3 server address used for the CS Remote Care. •...

- Page 248 Field Service Ver. 2.0 Mar. 2006 16. TECH. REP. MODE (2) Receive <E-mail Address> Functions • To set the e-mail address used for the CS Remote Care. • To set the e-mail address. Setting/ • The default setting is No. Procedure •...

- Page 249 16. TECH. REP. MODE Field Service Ver. 2.0 Mar. 2006 (3) Send Setting <SMTP server> Functions • To set the SMTP sever address for transmission used for the CS Remote Care. • To set the SMTP server address Setting/ <Input IP Address> Procedure •...

-

Page 250: List Of The Cs Remote Care Error Code

0004 Timeout of Incoming request response • Contact responsible person of (No response to incoming (starting) request KONICA MINOLTA. MSG) 0005 Timeout of CONNECT at receiving • Check if the power of the (No response to ATA) modem is ON. - Page 251 Solution 000F Transmitting RING Buffer Full • Contact responsible person of (When the Transmitting RING Buffer is full.) KONICA MINOLTA. 0010 RX FIF0 ERROR • Contact responsible person of (when Read / Write error occurs at RX FIF0) KONICA MINOLTA.

-

Page 252: Troubleshooting For Cs Remote Care