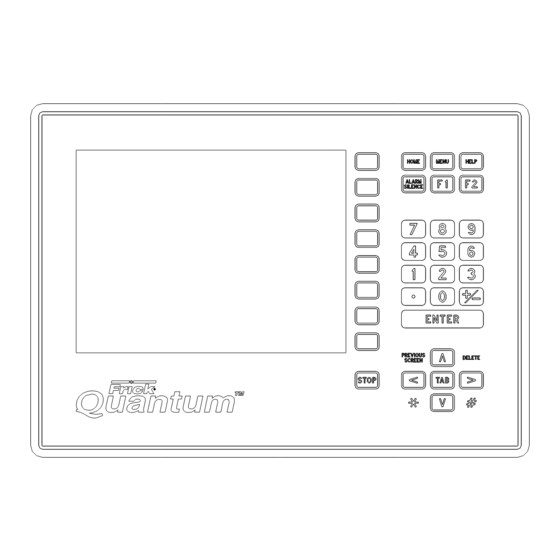

Frick QUANTUM Manuals

Manuals and User Guides for Frick QUANTUM. We have 6 Frick QUANTUM manuals available for free PDF download: Maintenance Manual, Operation Manual, Operation

Frick QUANTUM Maintenance Manual (116 pages)

HD COMPRESSOR

CONTROL PANEL

Brand: Frick

|

Category: Control Panel

|

Size: 8 MB

Table of Contents

Advertisement

Frick QUANTUM Operation Manual (112 pages)

Compressor Control Panel

Brand: Frick

|

Category: Control Panel

|

Size: 2 MB

Table of Contents

Frick QUANTUM Maintenance Manual (82 pages)

COMPRESSOR CONTROL PANEL

Brand: Frick

|

Category: Control Panel

|

Size: 4 MB

Table of Contents

Advertisement

Frick QUANTUM Operation (84 pages)

CONTROL PANEL

Brand: Frick

|

Category: Control Panel

|

Size: 5 MB

Table of Contents

Frick QUANTUM Maintenance Manual (72 pages)

Brand: Frick

|

Category: Control Panel

|

Size: 4 MB

Table of Contents

Frick QUANTUM Operation Manual (34 pages)

EVAPORATOR CONTROL PANEL

Brand: Frick

|

Category: Control Panel

|

Size: 0 MB

Table of Contents

Advertisement