Frick QUANTUM Maintenance Manual

Hide thumbs

Also See for QUANTUM:

- Maintenance manual (116 pages) ,

- Operation manual (112 pages) ,

- Operation (84 pages)

Summary of Contents for Frick QUANTUM

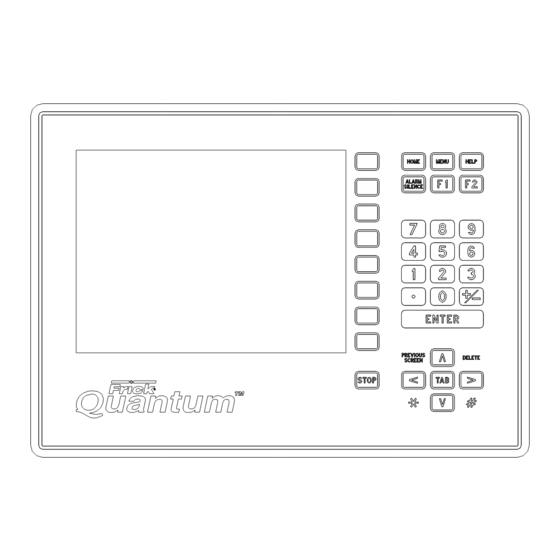

- Page 1 S90-010 M/OCT 99 File: SERVICE MANUAL - Section 90 Replaces: S90-010 OM/MAR 99 Dist: 3, 3a, 3b, 3c MAINTENANCE FRICK QUANTUM CONTROL PANEL (VERSION 3.4x)

-

Page 2: Table Of Contents

Frick Quantum Control Panel SPECIFICATIONS (& jumper and dip switch settings) S90-010 CS Frick Quantum Control Panel COMMUNICATIONS SETUP (setup and wiring for data communication using available protocols) Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. -

Page 3: Troubleshooting

Quantum. Reference the drawings at the end of this manual. lem, they usually don’t provide enough information. An ex- ample of this is the statement that the Quantum is not “boot- GENERAL INFORMATION: ing” (the main processor board is not starting). Unfortunately,... - Page 4 Did you just install new software? • If you need to clear the memory for any reason, After the Quantum has properly powered up the following clear the memory as described in the S90-010 FSI sequence of events is indicative of proper communication...

- Page 5 I/O Comm failure occurs, check the address of • Check all the items listed above for checking the dis- the board. Reference the Frick publication E90- play. If they check out OK but the display is garbled, 010 SPC. This publication contains the dipswitch...

- Page 6 #16 will also take the 0-5 Amp motor CT as an input. All PLC or Opto22 based system, the shield should of these jumper settings are listed in the Frick publication normally be tied only at the PLC or Opto22 panel.

- Page 7 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 7 If this is an older plant, has the plant wiring been brought 18. Check if one of the temperature probes has a signal up to code? wire shorted to machine ground. To do this, first pull the 10.

- Page 8 S90-010 M FRICK QUANTUM CONTROL PANEL Page 8 MAINTENANCE TROUBLESHOOTING CHART FOR FRICK QUANTUM CONTROL PANEL (REFER TO WIRING DIAGRAMS) SYMPTOM PROBABLE CAUSES and CORRECTIONS DISPLAY IS INOPERATIVE Check for power at the panel. See if any of the diagnostic lamps on the Main Board are blinking or any lights are blinking on the other boards.

- Page 9 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 9 SYMPTOM PROBABLE CAUSES and CORRECTIONS COMPRESSOR AUXILIARY SHUTDOWN Output 1 controls the Compressor Start Relay (By others). If the com- pressor does not start and the LED (D1) for Output 1 (MOD 1) is on, check for the proper panel voltage between position 4 and 1 on the P1 DIO connector on Digital I/O board #1.

- Page 10 S90-010 M FRICK QUANTUM CONTROL PANEL Page 10 MAINTENANCE SYMPTOM PROBABLE CAUSES and CORRECTIONS COMPRESSOR WILL ONLY PARTIALLY LOAD* Inspect the compressor unloading ports for worn or improperly seated (Compressor that steps on Capacity)(Continued) parts. SLIDE VALVE DOES NOT LOAD and/or UNLOAD* Verify that the Slide Valve is in the AUTO mode and that capacity control is calling for load and/or unload.

- Page 11 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 11 SYMPTOM PROBABLE CAUSES and CORRECTIONS LIQUID INJECTION SOLENOID DOES NOT Output 9 controls the Liquid Injection Solenoid. If the LED (D9) for ENERGIZE* (Liquid Injection Refrigerant Cutout - Output 9 (MOD 9) is on, check for the proper panel voltage between LICO)(Continued) position 4 and 1 on the P3 DIO connector on Digital I/O board #1.

- Page 12 OCCURS AT HIGH MOTOR AMPS voltage signal for the microprocessor. If the %FLA reading from the Operating display is incorrect, contact the Frick Service Department. MOTOR LOAD CONTROL(FORCED UNLOAD) The current transformer is used to convert the AC motor amps to a DC OCCURS AT LOW MOTOR AMPS voltage signal for the microprocessor.

-

Page 13: Adding And Replacing Boards

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 13 ADDING AND REPLACING BOARDS The procedure to add an analog or a digital board is out- lined below: Replacing the Main Board involves chip replacement that 1. Remove the new board from its packing and place it on will clear the current setpoints and data stored in the non- an antistatic surface. -

Page 14: Compressor Model Differences

S90-010 M FRICK QUANTUM CONTROL PANEL Page 14 MAINTENANCE COMPRESSOR MODEL DIFFERENCES FRICK RWB, SC RXB* RDB 3-Step RDB 4-Step Other GRAM GSV, YLC GST* GSB 3-Step Slide Valve Reading 0-100% 0-100% 0-100% 0-100% Slide Valve Setpoints Slide Valve Calibration... -

Page 15: Jumper And Dipswitch Settings

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 15 JUMPER AND DIPSWITCH SETTINGS DIGITAL BOARD DIGITAL I/O BOARD COMMUNICATIONS SETTINGS 120 ohm long communications line termination. out* No termination. (standard setting) RS-422/485 transmit pull-up for long communications lines. out* No pull-up. (standard setting) RS-422 transmit pull-up for long communications lines. - Page 16 S90-010 M FRICK QUANTUM CONTROL PANEL Page 16 MAINTENANCE BOARD #1, INPUT CHANNEL #3 - OIL TEMPERATURE BOARD #1, INPUT CHANNEL #13 - REMOTE SLIDE VALVE POSITION** 0-5 volt input 4-20 ma. input 0-5 volt input 2-3* ICTD input (standard setting) 1-2* 4-20 ma.

-

Page 17: Analog Board #2

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 17 Note: IC’s must also be installed in order to enable the BOARD #2, INPUT CHANNEL #10 - TEMPERATURE \ analog output options. U15 along with at least one IC PRESSURE MONITORING AUX. #6** (U4,U5,U6 or U7) installed will enable the channel. -

Page 18: Main Board

S90-010 M FRICK QUANTUM CONTROL PANEL Page 18 MAINTENANCE BOARD #2, OUTPUT CHANNEL #2 - FUTURE BOARD #2, OUTPUT CHANNEL #4 - CONDENSER** 0-20 ma. output. 0-20 ma. output. 4-20 ma. output 2-3* 4-20 ma. output (standard setting) 4-20 ma. output 1-2* 4-20 ma. -

Page 19: Setpoint Data Sheets

SETPOINT DATA SHEETS In most cases, updating software on the Quantum panel will require clearing the current setpoints and data stored in the nonvolatile memory on the main board. It is suggested that the operator first record all control setpoints prior to performing program chip upgrades. -

Page 20: Panel Setup

S90-010 M FRICK QUANTUM CONTROL PANEL Page 20 MAINTENANCE Oil Pump (Low Oil Pressure): Running Running Alarm Alarm Alarm Shutdown Shutdown Shutdown (Differential) (Differential) delay (secs.) (Differential) (Differential) delay (secs.) NOTE: The default settings are dependent on the type of compressor pump and it’s running status as described in the “Control Setup - Oil Setpoints”... - Page 21 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 21 Communications: ID Number: _________ (range: 0 - 99) Comm. 2 Baud rate: 1200 2400 4800 9600* 19200 38400 76800 115200 *Default Communication Protocols: Frick* Allen Bradley Modbus York ISN *Default Capacity Control Selection:...

-

Page 22: Calibration

S90-010 M FRICK QUANTUM CONTROL PANEL Page 22 MAINTENANCE Pumpdown DX Circuit: Enable Disable Kilowatt Monitor Calibration and Setup: Enable Disable Auxiliary Analog Temperatures and Pressures: Enable Disable Entering Process Temperature: Enable Disable Slide Valve Position Control: Remote Control Setpoint:... - Page 23 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 23 Sensor Sensor Sensor Type High End Low End ICTD Temperature (default is (default is 1 - 5 Vdc, 0 - 5 Vdc Sensor 463.1 -459.4 (default = ICTD) Suction Discharge Separator...

-

Page 24: Capacity Control Setpoints

S90-010 M FRICK QUANTUM CONTROL PANEL Page 24 MAINTENANCE CAPACITY CONTROL SETPOINTS SUCTION PRESSURE CONTROL MODE #1 setting default range Capacity control setpoint _____ 20 psig 30" - 135 psig Upper proportional band _____ 4 psig 0 - 20 psig... -

Page 25: Process Temp Control Mode #1

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 25 PROCESS TEMP CONTROL MODE #1 setting default range Capacity control setpoint _____ 40°F -238 - 302°F Upper proportional band _____ 4°F 0 - 20 °F Upper dead band _____ 1°F 0 - 10°F... -

Page 26: Discharge Pressure Control Mode #1

S90-010 M FRICK QUANTUM CONTROL PANEL Page 26 MAINTENANCE DISCHARGE PRESSURE CONTROL MODE #1 setting default range Capacity control setpoint _____ 150 psig 0 - 350** psig Upper proportional band _____ 5 psig 0 - 20 psig Upper dead band... -

Page 27: Discharge Temp Control Mode #1

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 27 DISCHARGE TEMP CONTROL MODE #1 setting default range Capacity control setpoint _____ 150°F 32 - 482°F Upper proportional band _____ 4°F 0 - 20°F Upper dead band _____ 1°F 0 - 10°F... -

Page 28: Compressor Safeties

S90-010 M FRICK QUANTUM CONTROL PANEL Page 28 MAINTENANCE COMPRESSOR SAFETIES DISCHARGE SAFETIES setting default range High discharge temp stop load _____ 180°F 0 - 249.8°F High discharge temp force unload _____ 190°F 0 - 249.8°F High discharge temp alarm _____ 200°F... -

Page 29: Motor Control

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 29 MOTOR CONTROL setting default range Motor amps _____ 0 - 3000 Volts _____ 0 - 5000 Service factor _____ 1.15* 0.0 - 2.0 Horse power _____ 0 - 3000 CT factor... -

Page 30: Main Oil Injection

S90-010 M FRICK QUANTUM CONTROL PANEL Page 30 MAINTENANCE MAIN OIL INJECTION On at Discharge Temp. (32 – 212 deg.F) default 150 delay (0-300 sec) default 5 LIQUID INJECTION On at Oil Temp. (100 – 150 deg.F) default 122 delay (0-300 sec) default 5... -

Page 31: Compressor Sequence Setpoints

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 31 Analog Control Analog Control upper dead band _____ (range: 0 - 20 psig) (default: 0.0 psig) Analog Control lower dead band _____ (range: 0 - 20 psig) (default: 0.0 psig) Analog Control response time... -

Page 32: Auxiliary Analogs

S90-010 M FRICK QUANTUM CONTROL PANEL Page 32 MAINTENANCE AUXILIARY ANALOGS Auxiliary Disabled Check Always Check Running Analog 1 Analog 2 Analog 3 Analog 4 Analog 5 Analog 6 Analog 7 Analog 8 Analog 9 Analog 10* High High High... -

Page 33: Flow Diagram D.c. Voltage Harness

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 33 FLOW DIAGRAM D.C. VOLTAGE HARNESS I/O BOARD POWER SUPPLY FLOPPY DRIVE I/O BOARD +5V, +12V, GND +5V, +12V, -12V, GND HARD DRIVE +5V, +12V, -12V, GND A/D BOARD A/D BOARD MAIN BOARD... -

Page 34: Power Supply Diagram (Condor)

S90-010 M FRICK QUANTUM CONTROL PANEL Page 34 MAINTENANCE QUANTUM PANEL D.C. POWER SUPPLY DIAGRAM (CONDOR) Replacement Part # 640C0022G01 INPUT: J1 INPUT: J2 AMP P/N: 640445-5 AMP P/N: 1-640445-3 .312 CTR CONNECTOR, 3 CIRCUITS .156 CTR CONNECTOR, 13 CIRCUITS... -

Page 35: Main Processor Board

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 35 QUANTUM MAIN PROCESSOR BOARD MAIN BOARD Part #: 640D0061H01 Replacement Part # 640C0025G01 COMMUNICATIONS JUMPERS (SEE CHART) P7 IDE HARD DRIVE CONNECTOR P8 FLOPPY DRIVE CONNECTOR I/O COMMUNICATION ACTIVITY LAMPS 1 2 3... -

Page 36: Digital I/O Board #1

S90-010 M FRICK QUANTUM CONTROL PANEL Page 36 MAINTENANCE DIGITAL I/O BOARD #1 INPUT MODULE OUTPUT MODULE OUTPUT MODULE COMPR. START/RUN COMPR. AUX INPUT MODULE NEUTRAL OIL PUMP #1 OUTPUT MODULE START/RUN OIL PUMP #1 AUX INPUT MODULE SLIDE VALVE LOAD... -

Page 37: Digital I/O Board #2

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 37 DIGITAL I/O BOARD #2 INPUT MODULE OUTPUT MODULE OUTPUT MODULE READY TO RUN OPTIONAL REMOTE ENABLE OUTPUT MODULE OPTIONAL NEUTRAL INPUT MODULE REMOTE START/RUN/STOP OPTIONAL REMOTE LOAD INPUT MODULE OPTIONAL REMOTE UNLOAD... -

Page 38: Analog Board #1

S90-010 M FRICK QUANTUM CONTROL PANEL Page 38 MAINTENANCE ANALOG BOARD #1 SUCTION TEMP DISCH TEMP TEMP TEMP LEAVING PROCESS TEMPERATURE PRESS PIN 8 = ANALOG OUTPUT #4 PIN 7 = GND PIN 6 = ANALOG OUTPUT #3 FILTER PIN 5 = GND... -

Page 39: Analog Board #2

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 39 ANALOG BOARD #2 FUTURE PID #1 FUTURE PID #2 FUTURE PID #3 ENTERING PROCESS TEMPERATURE TEMP/ PRESS MONITORING AUXILIARY ANALOG #1 TEMP/ PRESS MONITORING AUXILIARY ANALOG #2 PIN 8 = ANALOG OUTPUT #4... -

Page 40: Control Center Assembly

S90-010 M FRICK QUANTUM CONTROL PANEL Page 40 MAINTENANCE QUANTUM CONTROL CENTER ASSEMBLY (Sheet 1 of 2) - Page 41 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 41 QUANTUM CONTROL CENTER ASSEMBLY (Sheet 2 of 2)

-

Page 42: Control Center Assembly Rxf 12 - 50 Only

S90-010 M FRICK QUANTUM CONTROL PANEL Page 42 MAINTENANCE QUANTUM CONTROL CENTER ASSEMBLY (Sheet 1 of 2) RXF 12 - 50 ONLY... - Page 43 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 43 QUANTUM CONTROL CENTER ASSEMBLY (Sheet 2 of 2) RXF 12 - 50 ONLY...

- Page 44 S90-010 M FRICK QUANTUM CONTROL PANEL Page 44 MAINTENANCE WIRING DIAGRAM - RWF (Sheet 1 of 4)

- Page 45 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 45 WIRING DIAGRAM - RWF (Sheet 2 of 4)

- Page 46 S90-010 M FRICK QUANTUM CONTROL PANEL Page 46 MAINTENANCE WIRING DIAGRAM - RWF (Sheet 3 of 4)

- Page 47 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 47 WIRING DIAGRAM - RWF (Sheet 4 of 4)

-

Page 48: Wiring Diagrams Rwb Ii

POWER SOURCE ALL POWER SOURCES SHALL BE GROUNDED ON ONE SIDE -ISOLATED AND SEPARATED FROM OTHER INDUCTIVE LOADS SUCH AS LIGHTING CIRCUITS -OR FROM FRICK SUPPLIED OR SPECIFIED STARTER, USE MINIMUM #12 AWG FOR FEED ALL NEUTRALS ENTERING NEUTRAL IF SEPARATE FEED OR VOLTAGE FOR HEATER CIRCUIT IS DESIRED, THIS ENCLOSURE SHALL REMOVE JUMPERS 1 TO 1A &... - Page 49 OR BE RUN IN SAME CONDUIT AS ANY QUANTUM CONTROL WIRING ENTERING OR LEAVING QUANTUM PANEL NO SINGLE PHASE OVER 300 VOLTS SHALL ENTER OR LEAVE QUANTUM PANEL ALL QUANTUM WIRING TO BE #16 AWG STRANDED WIRE UNLESS SPECIFIED OTHERWISE.

- Page 50 S90-010 M FRICK QUANTUM CONTROL PANEL Page 50 MAINTENANCE WIRING DIAGRAM - RWB II (Sheet 3 of 4) ANALOG BOARD #1 SEE NOTE 4A WHITE WHITE TE-1 CHANNEL 1 BLACK BLACK ICTD SUCT TEMP CABLE #1 WHITE WHITE TE-2 CHANNEL 2...

- Page 51 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 51 WIRING DIAGRAM - RWB II (Sheet 4 of 4)

-

Page 52: Rxf (12-50)

S90-010 M FRICK QUANTUM CONTROL PANEL Page 52 MAINTENANCE WIRING DIAGRAM - RXF (12-50) - (Sheet 1 of 4) - Page 53 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 53 WIRING DIAGRAM - RXF (12-50) - (Sheet 2 of 4)

- Page 54 S90-010 M FRICK QUANTUM CONTROL PANEL Page 54 MAINTENANCE WIRING DIAGRAM - RXF (12-50) - (Sheet 3 of 4)

- Page 55 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 55 WIRING DIAGRAM - RXF (12-50) - (Sheet 4 of 4)

-

Page 56: Rxf (58-101) - Rxb

POWER SOURCE ALL POWER SOURCES SHALL BE GROUNDED ON ONE SIDE -ISOLATED AND SEPARATED FROM OTHER INDUCTIVE LOADS SUCH AS LIGHTING CIRCUITS -OR FROM FRICK SUPPLIED OR SPECIFIED STARTER, USE MINIMUM #12 AWG FOR FEED ALL NEUTRALS ENTERING NEUTRAL IF SEPARATE FEED OR VOLTAGE FOR HEATER CIRCUIT IS DESIRED, THIS ENCLOSURE SHALL REMOVE JUMPERS 1 TO 1A &... - Page 57 NO SINGLE PHASE OVER 300 VOLTS SHALL ENTER OR LEAVE MICRO PANEL ALL CONTROL CENTER WIRING TO BE #16 AWG STRANDED WIRE UNLESS SPECIFIED OTHERWISE. FOR INSTALLATION OF RXB-RXF QUANTUM PACKAGE TEST PROCEDURE, SEE MMIB NO. 4.11.10.12 FOR INSTALLATION OF COMPUTER BOARDS AND EPROMS, SEE MMIB NO.

- Page 58 S90-010 M FRICK QUANTUM CONTROL PANEL Page 58 MAINTENANCE WIRING DIAGRAM - RXF (58-101) - RXB (Sheet 3 of 4) ANALOG BOARD #1 SEE NOTE 4A WHITE WHITE TE-1 CHANNEL 1 BLACK BLACK ICTD SUCT TEMP CABLE #1 WHITE WHITE...

- Page 59 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 59 WIRING DIAGRAM - RXF (58-101) - RXB (Sheet 4 of 4)

-

Page 60: Rdb

POWER SOURCE ALL POWER SOURCES SHALL BE GROUNDED ON ONE SIDE -ISOLATED AND SEPARATED FROM OTHER INDUCTIVE LOADS SUCH AS LIGHTING CIRCUITS -OR FROM FRICK SUPPLIED OR SPECIFIED STARTER, USE MINIMUM #12 AWG FOR FEED ALL NEUTRALS ENTERING NEUTRAL IF SEPARATE FEED OR VOLTAGE FOR HEATER CIRCUIT IS DESIRED, THIS ENCLOSURE SHALL REMOVE JUMPERS 1 TO 1A &... - Page 61 OR BE RUN IN SAME CONDUIT AS ANY QUANTUM CONTROL WIRING ENTERING OR LEAVING QUANTUM PANEL NO SINGLE PHASE OVER 300 VOLTS SHALL ENTER OR LEAVE QUANTUM PANEL ALL CONTROL CENTER WIRING TO BE #16 AWG STRANDED WIRE UNLESS SPECIFIED OTHERWISE.

- Page 62 S90-010 M FRICK QUANTUM CONTROL PANEL Page 62 MAINTENANCE WIRING DIAGRAM - RDB (Sheet 3 of 4) ANALOG BOARD #1 SEE NOTE 4A WHITE WHITE TE-1 CHANNEL 1 BLACK BLACK ICTD SUCT TEMP CABLE #1 WHITE WHITE TE-2 CHANNEL 2...

- Page 63 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 63 WIRING DIAGRAM - RDB (Sheet 4 of 4)

-

Page 64: Digital I/O Board 2

S90-010 M FRICK QUANTUM CONTROL PANEL Page 64 MAINTENANCE WIRING DIAGRAM QUANTUM DIGITAL I/O BOARD 2 (Sheet 1 of 2) POWER FROM SHT 1 WIRING TO CONNECTORS P1-P6 ON BOARD #2 TO BE #18 AWG MOD 1 READY TO RUN... - Page 65 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 65 WIRING DIAGRAM QUANTUM DIGITAL I/O BOARD 2 (Sheet 2 of 2) NOTE A: A SURGE SUPPRESSOR OR MOV TO BE INSTALLED ACROSS ALL INDUCTIVE LOADS IN CONTROL CENTER. SURGE SUPPRESSOR SUPPRESSOR SPECIFICATIONS: RC NETWORK CONSISTING OF A .1 MFD CAPACITOR, 600...

-

Page 66: Digital I/O Board - Rxf 12 - 50 Only

S90-010 M FRICK QUANTUM CONTROL PANEL Page 66 MAINTENANCE WIRING DIAGRAM QUANTUM DIGITAL I/O BOARD (Sheet 1 of 2) - RXF 12 - 50 ONLY... - Page 67 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 67 WIRING DIAGRAM QUANTUM DIGITAL I/O BOARD (Sheet 2 of 2) - RXF 12 - 50 ONLY...

-

Page 68: Analog I/O Board 2

S90-010 M FRICK QUANTUM CONTROL PANEL Page 68 MAINTENANCE WIRING DIAGRAM QUANTUM ANALOG I/O BOARD 2 (Sheet 1 of 2) ANALOG BOARD #2 FUTURE CHANNEL 1 PID #1 ISOLATED 4-20 MA DEVICE CABLE #21 FUTURE CHANNEL 2 PID #2 ISOLATED 4-20... - Page 69 FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 69 WIRING DIAGRAM QUANTUM ANALOG I/O BOARD 2 (Sheet 2 of 2) CHANNEL 11 TEMPERATURE PRESSURE MONITORING ANALOG AUXILIARY #7 NOTE 1A: ALL ANALOG LOW VOLTAGE WIRING TO BE RUN IN SEPARATE CONDUIT FROM ALL OTHER WIRING...

-

Page 70: Quantum Multicompressor Sequencing Rs-485 Communications

S90-010 M FRICK QUANTUM CONTROL PANEL Page 70 MAINTENANCE WIRING DIAGRAM QUANTUM MULTICOMPRESSOR SEQUENCING RS-485 COMMUNICATIONS COM-1 COM-2 COM-2 Belden # 8761 Belden # 8761 Belden # 8761 #22 AWG or equal #22 AWG or equal #22 AWG or equal... -

Page 71: Pressure Transducer Conversion Data

FRICK QUANTUM CONTROL PANEL S90-010 M MAINTENANCE Page 71 PRESSURE TRANSDUCER CONVERSION DATA (Data Instruments Model SA) 100 psi 200 psi 300 psi 500 psi Sensor Range - psig* Range - psig* Range - psig* Range - psig* Voltage High... -

Page 72: Recommended Spare Parts

S90-010 M FRICK QUANTUM CONTROL PANEL Page 72 MAINTENANCE RECOMMENDED SPARE PARTS - CURRENT DESIGN Part Number Description Spare-1 Spare-2 Spare-3 640D0061H01 Main 486 processor circuit board 640D0062H01 Input/output circuit board #1 640C0024G02 Input/output circuit board #2 640D0063H01 Analog circuit board #1...

Need help?

Do you have a question about the QUANTUM and is the answer not in the manual?

Questions and answers