Frick QUANTUM Operation

Control panel

Hide thumbs

Also See for QUANTUM:

- Maintenance manual (116 pages) ,

- Operation manual (112 pages) ,

- Operation (72 pages)

Summary of Contents for Frick QUANTUM

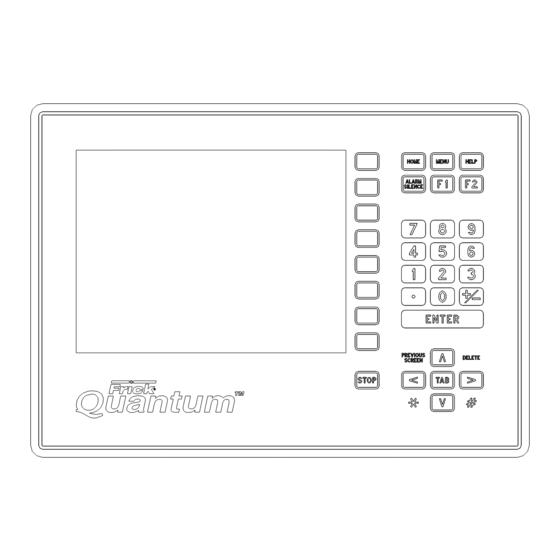

- Page 1 S90-010 O/SEP 2000 File: SERVICE MANUAL - Section 90 Replaces: S90-010 O/OCT 99 Dist: 3, 3a, 3b, 3c OPERATION FRICK QUANTUM CONTROL PANEL (VERSION 3.5x/4.0x)

-

Page 2: Table Of Contents

S90-010 O FRICK QUANTUM CONTROL PANEL Page 2 OPERATION Contents OPERATION Quick Overview of Graphic Displays ............................. 4 OVERVIEW OF OPERATOR INTERFACE ..........................5 OPERATOR ACCESS ................................5 KEYS AND KEY FUNCTIONS ............................6 KEYPAD KEYS .................................. 6 SCREEN KEYS ................................. 7 TO CHANGE SETPOINTS .............................. - Page 3 OIL PUMP STARTING LOGIC (Frick Full Lube) ........................82 QUANTUM PUBLICATIONS S90-010 O Frick Quantum Control Panel OPERATION S90-010 M Frick Quantum Control Panel MAINTENANCE S90-010 CS Frick Quantum Control Panel COMMUNICATIONS SETUP (setup and wiring for data communication using available protocols)

-

Page 4: Operation

S90-010 O FRICK QUANTUM CONTROL PANEL Page 4 OPERATION Quick Overview of Graphic Displays “OPERATING STATUS” SCREEN “Compressor Mode” SELECTION - [Remote], [Auto], [Manual Start], [Manual Stop] “Slide Valve Mode” SELECTION** - [Remote], [Auto], [Manual Load], [Manual Unload], [Remote Slide Valve]* “Capacity Mode”... -

Page 5: Overview Of Operator Interface

Quantum compressor control panel. This manual is in- recognized. Most of the displays have screen keys that de- tended to describe all presently available features for the scribe or show a function that is recognized when the coin- compressors listed in “Compressor Model Differences”. -

Page 6: Keys And Key Functions

S90-010 O FRICK QUANTUM CONTROL PANEL Page 6 OPERATION KEYS AND KEY FUNCTIONS KEYPAD KEYS DECIMAL [.] - The decimal point is used when entering a decimal value in a data field. Following is a list of the labeled keypad keys and the ac-... -

Page 7: Screen Keys

Any modification to these control settings is the sole responsibility of the user/owner and Frick disclaims any [Change Setpoints] - When at a screen that has adjustable liability for the consequences of these modifications. It... -

Page 8: Common Terminology

S90-010 O FRICK QUANTUM CONTROL PANEL Page 8 OPERATION sumed to be PSIG, an entry less than or equal to 29.7 will Alarm - An alarm setpoint has been reached or exceeded. cause a message box to appear after pressing the [EN- The compressor will continue to run if running. - Page 9 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 9 lay setpoint period, the Recycle Delay will prevent the pump. The Manual or Auto message is shown to indi- compressor from starting until the delay time expires. cate the position of the HAND-OFF-AUTO switch. If...

- Page 10 S90-010 O FRICK QUANTUM CONTROL PANEL Page 10 OPERATION • • Remote Comm. - A command was sent through Remote - The Slide Valve or capacity is being the serial com2 channel that forced Capacity Con- controlled from a remote device.

-

Page 11: Operating Status" Screen - Screen Key Set

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 11 the “High Suction Pressure Stop Load” setpoint, that determined the Suction Pressure is greater the compressor is prevented from further loading than or equal to (1.5 x oil pressure) + 10 lb., the until the Suction Pressure is less than this setpoint. -

Page 12: Operating Status - 2" Screen

Pressure. [Manual Increase] - Sends an increase signal for Power Up Time - The clock time when the Quantum the duration the key is depressed. program was started. [Manual Decrease] - Sends a decrease signal for the duration the key is depressed. -

Page 13: Main Menu" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 13 “MAIN MENU” SCREEN [Calibration] - Shows the “Analog calibration” screen. From “MAIN MENU” DISPLAY - SCREEN KEY SET this screen the following calibrations can be selected: • Change Pressure Transducer Ranges and Offsets The “Main Menu”... -

Page 14: Main Menu Selection - "Alarms/Shutdowns" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 14 OPERATION MAIN MENU SELECTION - “ALARMS/SHUTDOWNS” SCREEN This screen is accessible from the “Main Menu” screen. When Press the [ALARM SILENCE] key. (This action may an alarm or shutdown is triggered, a red descriptive mes- precede correcting the conditions causing the alarm). -

Page 15: Main Menu Selection - "Alarms/Shutdowns History" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 15 When a Shutdown occurs, the screen backlight will flash on engine room environment where audible alarms may not and off to alert an operator of the shutdown. This visual be heard. Pressing any key on the keypad will clear the alarm will help get the attention of the operator in a noisy flashing backlight. -

Page 16: Control Setup - Capacity Control Setpoints Screens

S90-010 O FRICK QUANTUM CONTROL PANEL Page 16 OPERATION The “Control Setup” screen is accessible from the Main [Motor Setpoints] Menu screen. The following are the “Control Setup” screen [Oil Setpoints] selections: [Capacity Control] - Shows a screen with selections... - Page 17 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 17 • The following is a list of all the different Capacity Control Process Temperature Mode 2 • setpoint screens: Discharge Pressure Mode 1 • Discharge Pressure Mode 2 • Suction Pressure Mode 1 •...

- Page 18 S90-010 O FRICK QUANTUM CONTROL PANEL Page 18 OPERATION Upper Cycle Time - This setpoint determines the The following setpoints are required for separate entry into amount of time in seconds that the load output is on each of the control setpoint screens listed above: and off, when in the upper proportional band.

-

Page 19: Process Temperature Control" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 19 “PROCESS TEMPERATURE CONTROL” SCREEN CONTROL SETUP - COMPRESSOR SAFETIES SETPOINTS Compressor safeties are important for the safe operation of The following safety setpoint is on this screen: the compressor. The following setpoint screens can be ac-... -

Page 20: Control Setup - Compressor Safeties - "Discharge Safeties" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 20 OPERATION CONTROL SETUP - COMPRESSOR SAFETIES - ”DISCHARGE SAFETIES” SCREEN The following Discharge Temperature setpoints are on this Starting Differential Pressure below - If the Differen- control setpoint screen: tial Pressure (the result from subtracting Suction Pres-... -

Page 21: Control Setup - Compressor Safeties - "Suction Safeties" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 21 Discharge Pressure alarm setpoint before notification “Activated” will be shown at the control setpoints that have of the alarm. been selected. The following special selection keys are on this display: Shutdown Delay - The minimum time in seconds that... -

Page 22: Control Setup - Compressor Safeties - "Entering Process Safeties" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 22 OPERATION CONTROL SETUP - COMPRESSOR SAFETIES - ”ENTERING PROCESS SAFETIES” SCREEN This screen is shown if the “Entering Process Temperature” High Entering Process Temperature Alarm - If the option was enabled in Panel Setup. This reading is useful Entering Process Temperature is greater than or equal for monitoring the temperature of what is being processed. -

Page 23: Control Setup - "Motor Control Setpoints" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 23 CONTROL SETUP - ”MOTOR CONTROL SETPOINTS” SCREEN The following information should be recorded from the mo- High Motor Amps Stop Load - The compressor slide tor nameplate: valve will be prevented from loading until the Motor Amps is less than this setpoint. -

Page 24: Control Setup - Motor Control Setpoints - "Electric - Vfd" Screen

Rate of change - Setpoint used to adjust the speed changes sent to the VFD based on the capacity control Selectable 4 – 20 ma analog output - Signal from the Quantum to from .1-25% of the 4-20ma signal. provide the speed setpoint to the VFD controller. The VFD’s controller and hardware will need to be configured to the Cycle Time - Setpoint used in conjunction with the “Rate of... -

Page 25: Control Setup - Motor Control Setpoints - "Ram Dbs Motor Starter

Slide Valve Position to begin Speed Increase - The Slide Valve position which must be obtained before the speed 4 – 20 ma analog output - Signal from the Quantum to will begin to increase. Selectable from 0-100% of the com- provide the speed setpoint to the speed governing device. -

Page 26: Control Setup - Motor Control Setpoints - "Turbine" Screen

Rate of change - Setpoint used to adjust the speed changes sent to the VFD based on the capacity control requirements. 4 – 20 ma analog output - Signal from the Quantum to Selectable from .1-25% of the 4-20ma signal. - Page 27 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 27 High RPM Alarm Delay - The minimum time in seconds Low RPM Alarm Delay - The minimum time in seconds that that the RPM is greater than or equal to the High RPM the RPM is less than or equal to the Low RPM alarm set- alarm setpoint before notification of the alarm.

-

Page 28: Control Setup - Motor Control Setpoints - "Ram Dbs Motor Starter" Screen

This screen is available if a RAM DBS motor starter has been The following RAM DBS setpoints are modifiable from this set up for use with the Quantum. The DBS accelerates the screeen: motor in a smooth, stepless motion, therefore it reduces sup-... -

Page 29: Control Setup - "Oil Setpoints" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 29 CONTROL SETUP - ”OIL SETPOINTS” SCREEN The following oil separator setpoints are on this display: High Oil Temperature Shutdown - If the Oil Tempera- ture is greater than or equal to this setpoint, for the Low Oil Separator Temperature Alarm - If the Oil Sepa- shutdown time delay, the compressor will shut down. - Page 30 S90-010 O FRICK QUANTUM CONTROL PANEL Page 30 OPERATION The following displayed Oil Setpoints can not be modified: Additionally a safety check is made for low oil flow that will stop the compressor from loading or force the compressor Low Oil Pressure Alarm - If the Oil Pressure is less to unload.

- Page 31 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 31 “Filter Pressure Setpoints” screen. The filter value equals Liquid Injection is enabled; then, the Filter Pressure value the Filter Pressure reading minus the Oil Pressure reading, equals the Discharge Pressure reading minus the Oil Pres- with only one exception;...

-

Page 32: Control Setup - "Slide Valve Setpoints" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 32 OPERATION POINTS” SCREEN The “Slide Valve Setpoints” screen is shown if it applies to utes, the alarm message “Compressor Unable to Un- this compressor model (Reference “Compressor Model Dif- load - Alarm” is issued. -

Page 33: Control Setup - "Setback Schedule" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 33 CONTROL SETUP - ”SETBACK SCHEDULE” SCREEN Setback is another set of Capacity Control setpoints (Mode the presently active Capacity Control mode to the Mode 2 2) that is initiated and removed by time of day. Setback can (setback) setpoints at the start time. -

Page 34: Control Setup - "Options Setup" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 34 OPERATION CONTROL SETUP - ”Options Setup” SCREEN • Options that were enabled in Panel Setup, are shown. The Input Module Capacity Control Selection • following screens are possible: Auxiliary Setup • Suction Pull Down •... - Page 35 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 35 • The “Condenser Control” screen is shown if a type of “Con- Condenser Output #3 • denser Control” was selected in Panel Setup. Only the set- Condenser Output #4 - If digital control is selected points of the selected Condenser Control will show.

-

Page 36: Control Setup - Options Setup - "Compressor Sequence Control" (Mode 1) Screen

Slide Valve and will work with ex- If the system Discharge Pressure is above the Condenser isting Frick RWB, RXB, and RXF panels. Serial communica- Control setpoint: tion using the Com-1 port is used for this sequencing. See... - Page 37 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 37 ”Compressor Sequence Control” (MODE 1) SCREEN Lower Proportional Band - A band, measured in the Proportional units of the Capacity Control setpoint, below the lower Distance dead band, where proportional unload control is used.

- Page 38 S90-010 O FRICK QUANTUM CONTROL PANEL Page 38 OPERATION The load limiting setpoints are used if no compressors are the minimum Slide Valve position, “B” is still contribut- running and the equalized system is to be slowly pulled ing somewhat to the capacity. To take “B” off line would down to normal.

-

Page 39: Compressor Sequence Overview

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 39 Lowering the “Unload Minimum Slide Valve Position” set- Compressor Sequence Status point, or lengthening the “Stop Time Delay”, or lengthening The active Capacity Control setpoints and Capacity Con- the “Minimum Run Time” can be used to prevent a com- trol reading are only shown here for referencing. -

Page 40: Control Setup - Options Setup - "Compressor Sequence Control" (Mode 2) Screen

2 option was selected in Panel Setup. This option is not The active capacity control setpoints and Capacity Control applicable for standard Frick products. It is only available reading are shown here for referencing. for Gram compressors. Compressor Sequencing setpoints... - Page 41 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 41 • Control Type: controller attempts to maintain the Capacity Control set- Leader - The panel is selected as the Leader for • point by loading and unloading in response to the following compressor sequencing control.

- Page 42 S90-010 O FRICK QUANTUM CONTROL PANEL Page 42 OPERATION Leader's current reading falls below its “Capacity Con- The Cycle Time setpoint determines the amount of time the output is on and off, when in the proportional band. At the trol” setpoint plus the “Upper Dead Band” setpoint, the...

-

Page 43: Compressor Sequence Overview

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 43 COMPRESSOR SEQUENCE OVERVIEW On an initial start-up of a compressor, the compressor started will load to the “Minimum Capacity when Run- ning” setpoint and remain at or above this setpoint until The above settings are used to sequence the compressors stopping. - Page 44 S90-010 O FRICK QUANTUM CONTROL PANEL Page 44 OPERATION COMPRESSOR SEQUENCE CONTROL (MODE 2) WIRING Grammatic 2502 or Quantum Grammatic 1502 Digital Board 2 P1-1 Start / DI-4 Follower Start Output 1 Input 4 P1-2 Capacity Up / DI-5 Follower Capacity Up...

-

Page 45: Control Setup - Options Setup "Compressor Interlock" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 45 CONTROL SETUP - OPTIONS SETUP “Compressor Interlock” SCREEN This screen is shown if the “Compressor Interlock” option of When Compressor Interlock is activated, the program checks “Compressor Sequencing” was selected in Panel Setup. -

Page 46: Control Setup - Options Setup - "Input Module Selection" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 46 OPERATION CONTROL SETUP - OPTIONS SETUP - ”Input Module Selection” SCREEN This screen is shown if the ”Input Module Capacity Control display will be the capacity control that will be made Selection” was enabled in Panel Setup. These modes will... -

Page 47: Control Setup - Options Setup - "Auxiliary Setup" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 47 CONTROL SETUP - OPTIONS SETUP - ”Auxiliary Setup” SCREEN This screen is shown if a type of “Auxiliary 1 and 2” control [Auxiliary 1 Type Shutdown] - If the Auxiliary 1 is pres- was selected in Panel Setup. -

Page 48: Control Setup - "Suction Pressure Pull Down" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 48 OPERATION CONTROL SETUP - “SUCTION PRESSURE PULL DOWN” SCREEN This screen is shown if the “Suction Pull Down” option was This screen has the following setpoints: selected in Panel Setup. This option is only valid when in Suction Pressure Reduction Step Pressure Band - Suction Pressure Capacity Control. -

Page 49: Control Setup - "Auxiliaries 3 - 8 Setup" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 49 CONTROL SETUP - “AUXILIARIES 3 - 8 SETUP” SCREEN The Auxiliaries #3 - #8 are programmable digital inputs on refer to the auxiliary (3-8) that has been selected for Digital I/O Board #2. These additional auxiliaries have the setup. -

Page 50: Control Setup - "Auxiliary Analog Temperatures & Pressures" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 50 OPERATION CONTROL SETUP - “AUXILIARY ANALOG TEMPERATURES & PRESSURES” SCREEN The Temperature/Pressure Monitoring Auxiliary Analogs #1- High Shutdown Delay - The minimum time in seconds #9 and the Side Load/Economizer analog inputs of Analog that the analog reading is greater than or equal to the Board #2 are set up here. -

Page 51: Control Setup - "Pumpdown/Dx Circuit Setup" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 51 Low Alarm - If the analog reading is less than or equal to [Change Setpoints] - Changes the alarm settings and this setpoint, for the alarm time delay, an alarm occurs. -

Page 52: Main Menu Selection - "Security Setup" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 52 OPERATION On when above - If the compressor is running and [Slide Valve Position] - The Slide Valve setpoints will control was selected as “and at proper Slide Valve po- be used to turn on and off this digital output, when the sition”, then the DX Circuit output is on if the Slide Valve... -

Page 53: Main Menu Selection - "Analog Calibration" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 53 [No Access] - Select this key to change the current access to the system. A password must be reentered access privilege to no access. This cancels security to gain security access after pressing this key. -

Page 54: Analog Calibration - "Pressure Calibration" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 54 OPERATION • The following analog calibration selections are shown: Calibrate Remote Control Setpoint (If applicable, see Panel Setup) • Change Pressure Transducer Ranges and Offsets • Calibrate Slide Valve Position (If applicable, see Panel •... -

Page 55: Analog Calibration - "Temperature Calibration" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 55 ANALOG CALIBRATION - ”Temperature Calibration” SCREEN This display shows a thermometer and the current tem- The Setting for the “Current Value” is blank until a tempera- perature readings for: ture for calibration is selected from the screen keys. A screen key exists for each of the displayed temperature readings. -

Page 56: Analog Calibration - "Calibrate Motor Current" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 56 OPERATION ANALOG CALIBRATION - ”Calibrate Motor Current” SCREEN This screen shows the current reading of the motor amps. Note: The motor current must be calibrated while the Select the [Calibration Setpoints] screen key to modify compressor is running and preferably with the compres- what should be shown as the current reading. -

Page 57: Analog Calibration - "Calibrate Slide Valve" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 57 The “Calibrate Slide Stop” screen is shown if it applies to at the current position. The slide valve position should the compressor model (Reference “Compressor Model Dif- be unloaded until it does not interfere with decreasing ferences”). -

Page 58: Analog Calibration - "Calibrate Remote Control Setpoint" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 58 OPERATION table, both depict what is presently selected to be calibrated. The minimum Slide Valve value represents the furthermost [Set Minimum Point] - This key should be selected position the Slide Valve can be unloaded to and is always when the Slide Valve is at the furthermost unload posi- set at 0%. -

Page 59: Analog Calibration - "Calibrate Slide Valve Position" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 59 ANALOG CALIBRATION - ”Calibrate Slide Valve Position” SCREEN This shows if “Slide Valve Position Control” was enabled in [Remote Slide Valve] from the Slide Valve mode screen Panel Setup. This screen is used to calibrate the analog command keys on the “Operating Status”... -

Page 60: Analog Calibration - "Calibrate Auxiliary Analog" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 60 OPERATION ANALOG CALIBRATION - ”Calibrate Auxiliary Analog” SCREEN This shows if YORK S-7 was enabled as the compressor analog signal of the level input. Channel 13 on analog board type in Panel Setup. This screen is used to calibrate the 1 is used to monitor the liquid level. -

Page 61: Control Setup - "Analog Output Setup" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 61 CONTROL SETUP - ”Analog Output Setup” SCREEN CONTROL SETUP - ”Analog Output Setup” SCREEN... -

Page 62: Analog Calibration - "Kilowatt Monitor Calibration" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 62 OPERATION ANALOG CALIBRATION - ”Kilowatt Monitor Calibration” SCREEN This shows if “Kilowatt Monitor Calibration and Setup” was the Kilowatt input. The current value of the kW Monitoring enabled in Panel Setup. This screen is shown for calibrating analog input is displayed on the “Operating Status”... -

Page 63: Panel Setup - "Change Current Time And Date" Screen

This PANEL SETUP - key changes between enabling A-B(Allen-Bradley), ”Temperature Units — ModBus, York ISN, or Frick communication protocol. For SCREEN degrees Fahrenheit or Celsius” further setup reference publication S90-010 CS. [Detect I/O Boards] - Select this key to detect all con- The following screen keys are provided: nected Analog and Digital boards. -

Page 64: Panel Setup - "Selectable Options" Display

S90-010 O FRICK QUANTUM CONTROL PANEL Page 64 OPERATION • The Capacity Control options that were enabled in Panel Discharge Pressure Control Modes • Setup are shown. Only two control modes can be enabled. Discharge Temperature Control Modes A control mode that is currently the active Capacity Control... - Page 65 Reference the Quantum drawings [Sequence Mode 1] - This key is provided to se- for proper setup of options. Screen setup features are also lect a method of sequencing compressors using selected from this screen.

- Page 66 S90-010 O FRICK QUANTUM CONTROL PANEL Page 66 OPERATION Suction Pressure Pull Down - This option provides for ings. For further setup see the “Auxiliary Analog Tem- a slow lowering of the Suction Pressure when in Suc- peratures & Pressures” screen and the “Calibrate Aux- tion Pressure Capacity Control.

-

Page 67: Panel Setup - Selectable Options - "Screen Settings" Screen

[Disable] - Disables the screen saver. [Standard Screen] - Frick “Blue” screen color is used. [Enable] - Enables the screen saver. When there is no keypad activity at the panel this screen saver will turn off [Mono Screen] - A gray screen color is used. -

Page 68: Main Menu" Selection - "Real Time Trending" Screen

S90-010 O FRICK QUANTUM CONTROL PANEL Page 68 OPERATION “MAIN MENU” SELECTION - “REAL TIME TRENDING” SCREEN Real time trending saves 250 recordings of the data items time period to view. The “Data Log View” screen shows (hg) from the “Operating Status” screen. The data is stored in values in parenthesis. -

Page 69: Real Time Trending" Screen - Data Log View

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 69 “REAL TIME TRENDING” SCREEN - DATA LOG VIEW “REAL TIME TRENDING” SCREEN - TRENDING VIEW Because real time trending saves 250 recordings of the 250 “Real Time Trending - Operating Status View” screens data items from the “Operating Status”... -

Page 70: Real Time Trending - Operating Status View

S90-010 O FRICK QUANTUM CONTROL PANEL Page 70 OPERATION REAL TIME TRENDING - OPERATING STATUS VIEW MAIN MENU SELECTION - “HISTORY TRENDING” SCREEN History trending saves 75 recordings of the data items from are recorded. The time interval ranges from 15 min- the “Operating Status”... -

Page 71: Main Menu" Screen - "Service Screen" Screen

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 71 [Operating Status View] – Accesses the “History Trend- The History Trending data is viewed the same as the Real ing” Display for viewing the data as it was on the “Oper- Time Trending data except that only 75 records are saved ating Status”... -

Page 72: Operation Overview

S90-010 O FRICK QUANTUM CONTROL PANEL Page 72 OPERATION OPERATION OVERVIEW seconds after the compressor status switches to “Run- ning”, the low oil pressure alarm and shutdown safe- Initial Setup Procedure: ties are ignored. Factory Setup should be performed by a Factory Rep-... - Page 73 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 73 The Remote Slide Valve Position option can be used. This • Remote C.C step 1 for step units - If the Capacity option, which is enabled in Panel Setup, is not available for Mode is in Remote, this input is used to step on all compressor models (Reference “Compressor Model Dif-...

-

Page 74: Alarms/Shutdowns Messages

S90-010 O FRICK QUANTUM CONTROL PANEL Page 74 OPERATION ALARMS/SHUTDOWNS MESSAGES Auxiliary #6 Shutdown - The Auxiliary #6 input module has been setup to indicate a shutdown when it is deenergized and it became deenergized. When a Shutdown occurs, the display backlight will flash on and off to alert an operator of the shutdown. - Page 75 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 75 after 12 seconds from the compressor stop command the High Auxiliary Analog #3 Alarm - The Auxiliary Analog #3 Motor Current reading is above the “Low Motor Amps Shut- value was greater than or equal to the high Auxiliary Ana- down”...

- Page 76 S90-010 O FRICK QUANTUM CONTROL PANEL Page 76 OPERATION High Economizer Alarm - The Auxiliary Analog #10 value Low Auxiliary Analog #2 Shutdown - The Auxiliary Analog was greater than or equal to the high Auxiliary Analog #10 #2 value was less than or equal to the low Auxiliary Analog alarm setpoint for its time delay.

- Page 77 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 77 Low Entering Process Temperature Shutdown - The En- Missing Oil Pressure Shutdown - The Oil Pressure (PSIA) tering Process Temperature was less than or equal to the is less than the Suction Pressure (PSIA) added to 15.0, “Low Entering Process Temperature Shutdown”...

-

Page 78: Quantum Automatic Capacity Control (Electric, Vfd, Engine, Turbine) Version 3.5X

S90-010 O FRICK QUANTUM CONTROL PANEL Page 78 OPERATION QUANTUM AUTOMATIC CAPACITY CONTROL (Electric, VFD, Engine, Turbine) Version 3.5x... - Page 79 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 79 QUANTUM AUTOMATIC CAPACITY CONTROL (Electric, VFD, Engine, Turbine) Version 3.5x...

-

Page 80: Oil Pump Starting Logic (Frick Prelube, Cycling, Demand)

S90-010 O FRICK QUANTUM CONTROL PANEL Page 80 OPERATION OIL PUMP STARTING LOGIC (Frick PreLube, Cycling, Demand) -

Page 81: Oil Pump Starting Logic (Frick No Pump )

FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 81 OIL PUMP STARTING LOGIC (Frick No Pump ) -

Page 82: Oil Pump Starting Logic (Frick Full Lube)

S90-010 O FRICK QUANTUM CONTROL PANEL Page 82 OPERATION OIL PUMP STARTING LOGIC (Frick Full Lube) - Page 83 FRICK QUANTUM CONTROL PANEL S90-010 O OPERATION Page 83...

- Page 84 S90-010 O FRICK QUANTUM CONTROL PANEL Page 84 OPERATION York Refrigeration 100 CV Avenue, P.O. Box 997 Waynesboro, Pennsylvania USA 17268-0997 Phone: 717-762-2121 • Fax: 717-762-8624 Printed in U.S.A. Subject To Change Without Notice...

Need help?

Do you have a question about the QUANTUM and is the answer not in the manual?

Questions and answers