Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for 3D Systems BFB-3000

- Page 1 BFB-3000 Set Up and Operations Manual [Version 3.0] Document No: D100253...

-

Page 2: Introduction

BFB-3000 Set Up and Operations Manual 1 Introduction Thank you for purchasing your BFB-3000. Before first use, the BFB-3000 needs careful setting up. The list below illustrates some of the essential operations which must be carried out before operation: Remove existing prints ... -

Page 3: Table Of Contents

Introduction ........................2 Table of Contents ......................3 Manual symbols ......................5 How this manual works ....................6 Process overview – how the BFB-3000 works ..............7 BFB-3000 ........................7 Tool kit ........................8 Creating a 3D model ....................9 Initial set-up ......................... - Page 4 BFB-3000 Set Up and Operations Manual Print the first model ..................... 47 Test print ......................... 47 Essential post-print operations ................48 7.2.1 Bed flatness ....................48 7.2.2 Empty material waste bin ................49 Further printing ......................50 Further operations ....................... 51 SD card notes ......................

-

Page 5: Manual Symbols

BFB-3000 Set Up and Operations Manual 3 Manual symbols CAUTION: notes to prevent damage to the machine. DANGER: notes to prevent injury to the operator. Document No: D100253... -

Page 6: How This Manual Works

BFB-3000 Set Up and Operations Manual 4 How this manual works How the BFB-3000 3D printing process works Initial setup of the BFB-3000 machine and testing First print Links for further printing Document No: D100253... -

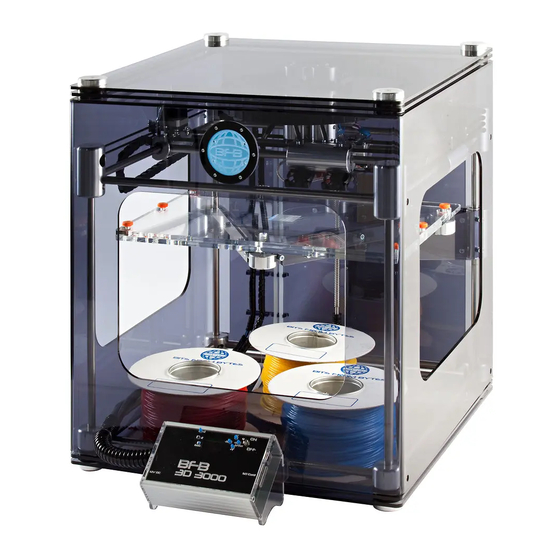

Page 7: Process Overview - How The Bfb-3000 Works

BFB-3000 Set Up and Operations Manual 5 Process overview – how the BFB-3000 works Before reading this section, please ensure that the unpacking instructions have been completed. BFB-3000 Extruders Nozzle wipe box Filament reel holders Control Document No: D100253... -

Page 8: Tool Kit

BFB-3000 Set Up and Operations Manual Tool kit Side cutters Hex drivers Model removal tool 1.5mm Allen Wrench Ø0.5mm drill bit SD card Pliers 8mm spanner Ø3mm drill bit Document No: D100253... -

Page 9: Creating A 3D Model

BFB-3000 Set Up and Operations Manual Creating a 3D model CAD software BFB “Axon” Draw your object in your 3D Load your model into Axon to modelling package automatically process the file. Save as… *.STL Save as… *.BFB Most CAD packages export to STL format. However, STL quality depends on the CAD package. Poor quality STLs may need repairing before loading into “Axon”. - Page 10 BFB-3000 Set Up and Operations Manual Extruders Delivery tubes Filament reels Document No: D100253...

- Page 11 BFB-3000 Set Up and Operations Manual Hot-end The extruders pull filament from the reel via the delivery tubes and drive through a hot-end to produce a thin molten filament of plastic. The extruder draws each layer with this filament. After each layer is produced the bed increments down so that a new layer can be drawn on top of the last, building up the 3D model.

-

Page 12: Initial Set-Up

Remove existing prints We do test prints on each BFB-3000 as part of our quality control. We leave these on the print bed to show that the printer has been checked, and to demonstrate some basic prints. Remove any previous prints with the model removal tool. Slide the edge between the bed and the first layer to remove the entire print. -

Page 13: Check The Bed Is Clear Of Any Build Material

BFB-3000 Set Up and Operations Manual Check the bed is clear of any build material Clean: no build material debris Ensure that all build material is completely removed from the bed. Use the model removal tool to remove any stuck-fast tracks. -

Page 14: Check The Bed Is Fitted Correctly

BFB-3000 Set Up and Operations Manual Check the bed is fitted correctly Ensure that bed is correctly fitted to the printer. The three bed bolt heads should sit flush in the countersinks. If not, remove the bed, then refit it - as shown in the next two sections. -

Page 15: Remove The Bed

BFB-3000 Set Up and Operations Manual 6.3.1 Remove the bed Tip: removal is easier if the bed is near the bottom of the machine. If it is too high, you can manually lower the z-axis (see “Manual move”, page 18). -

Page 16: Fit The Bed

BFB-3000 Set Up and Operations Manual 6.3.2 Fit the bed Tip: fitting is easier if the bed is near the bottom of the machine. If it is too high, you can manually lower the z-axis (see “Manual move”, page 18). -

Page 17: Power Up

BFB-3000 Set Up and Operations Manual Power up Connect the power supply from the control panel into the power socket shown in Figure 1. Turn the supply on. Turn the control box on using the power switch shown in Figure 1. -

Page 18: Manual Move

BFB-3000 Set Up and Operations Manual Manual move Get familiar with moving the axes around: Ensure that the bed is fitted properly to the machine (see “Check the bed is fitted correctly”, page 14). Using the buttons on the control panel (see “Power up”, page 17) select the ‘Manual move’... - Page 19 BFB-3000 Set Up and Operations Manual “Home” Position Figure 2: Axis designation for the BFB-3000 Document No: D100253...

-

Page 20: Check The Hot-End Nozzles Are Clean From Plastic Debris

BFB-3000 Set Up and Operations Manual Check the hot-end nozzles are clean from plastic debris Ensure that the metal nozzle tips are clean from any plastic debris. All tips should be clearly visible. Nozzle tip clearly visible, and free of any... -

Page 21: Check The Bed Is Level

BFB-3000 Set Up and Operations Manual Check the bed is level To get a good print, the bed must be level. We make every effort to level the bed before the machine leaves our factory. However, the bed may move in transit, therefore it is essential to check that the bed is still level. -

Page 22: Run File

BFB-3000 Set Up and Operations Manual The ‘Level Bed’ function moves the extruder carriage around the corners of the bed so the operator can adjust the bed bolts to achieve a level bed. Check the bed is fitted correctly (page 14). - Page 23 BFB-3000 Set Up and Operations Manual Press the X+ and X- buttons to automatically move the carriage around the corners of the print bed (view on-screen instructions for more movement options). During each movement along the side of the bed, observe from the side of the machine any change in distance between the bed and extruder’s hot-end as it moves...

- Page 24 BFB-3000 Set Up and Operations Manual Adjust the height of the bed bolts to make each side level using the 3mm hex driver from the toolkit. Underneath each of the 3 bed bolts is a locking nut which must be loosened with the 8mm spanner before the bolt can be adjusted.

- Page 25 BFB-3000 Set Up and Operations Manual Ensure that axes are checked from the appropriate side of the machine (to better judge flatness): PHOTOGRAPHS TAKEN FROM ABOVE BACK View the movements in the X axis from the front of the machine.

- Page 26 BFB-3000 Set Up and Operations Manual 2 mm Press Z+ to reduce the gap between the hot end and bed to approximately 2 mm. This will enable finer levelling. Repeat the levelling process. Caution: Observe each extruder movement. The nozzle should not touch the bed.

- Page 27 BFB-3000 Set Up and Operations Manual Remember to lock the 3 bed bolts in position by tightening the lock nut under each, using the 8mm spanner. Whilst tightening the nut, make sure that the bolt does not spin by holding it in position with the 3mm hex driver, from the top side of the bed.

-

Page 28: Check The Bed Is Referenced To The Extruder Nozzles

BFB-3000 Set Up and Operations Manual Check the bed is referenced to the extruder nozzles After levelling the bed, the nozzles must be set to the correct height, to ensure that the first printed layer sticks properly (if the nozzle is too high the filament will not stick to the bed, if the nozzle is too low the bed may block the nozzle). - Page 29 BFB-3000 Set Up and Operations Manual Caution: If the nozzle is pushed too hard against the bed, the nozzle will be forced into the bed for the whole first layer of printing. This will damage the nozzle and the bed. Ensure that setting the nozzle against the bed does not compress the bed springs.

- Page 30 BFB-3000 Set Up and Operations Manual Pressing Enter (X+) will save the setting to the printer’s memory which is retained when the power is turned off. The Z offset value will be applied each time the printer is homed.

-

Page 31: Load The Extruders

BFB-3000 Set Up and Operations Manual Load the extruders 6.9.1 Load the filament Before loading a reel, the end of the filament must be prepared to prevent damage to the delivery tubes. This procedure is essential to prevent any damage to the delivery tubes, which may in turn block a nozzle. - Page 32 BFB-3000 Set Up and Operations Manual Reel positions for each extruder are indicated below: Delivery tubes for each extruder run from right to left, as indicated below: Tube for Tube for Tube for Extruder 3 Extruder 2 Extruder 1...

- Page 33 BFB-3000 Set Up and Operations Manual Load the type of materials into their reel positions according to the number of extruders in the BFB-3000: Number of extruders in Material for Material for Material for Extruder 3 the BFB-3000 Extruder 1...

- Page 34 BFB-3000 Set Up and Operations Manual Push filament out of the end of the delivery tube Check the filaments exit the tubes at the correct extruders: Extruder 1 Extruder 2 (Extruder 3) Document No: D100253...

- Page 35 BFB-3000 Set Up and Operations Manual Remove the pressure bearings (below) on the extruders Use the 4mm hex driver from the toolkit Pressure bearing assembly Use pliers to push the filaments into the white tube for each extruder, as far...

- Page 36 BFB-3000 Set Up and Operations Manual Re-attach the pressure bearings onto extruders. Tighten the pressure bearing springs until they are fully bound. (they will be adjusted from this position later.) Ensure filaments run on the middle (smaller) pressure bearings. If not,...

-

Page 37: Extruder Control

BFB-3000 Set Up and Operations Manual 6.9.2 Extruder control Make sure all extruders are loaded. Use ‘Manual move’ (page 18) to move the extruders to the centre of the machine, and lower the bed. This makes it easy to clean any purged material. -

Page 38: Purge The Extruder

BFB-3000 Set Up and Operations Manual Recommended maximum extrusion temperatures for materials: Material Extrusion temperature (°C) Note: Extruders share power, therefore an extruder will heat up quicker if it is the only extruder with a high target temperature. 6.9.3 Purge the extruder ... - Page 39 BFB-3000 Set Up and Operations Manual Pressure bearing bolt 4mm hex driver from toolkit Observe the end of the nozzle. A thin bead of molten plastic should come out of the nozzle. Depending on how far the filament was loaded into the extruder, this could take several minutes.

-

Page 40: Start A Print

After the machine is setup correctly you will need to run two test files, documented in the following sections. When asked to print a file you will need to follow the procedure below: Insert the SD card into the BFB-3000 control box. Turn the control box on. -

Page 41: Print A Successful Raft

BFB-3000 Set Up and Operations Manual 6.11 Print a successful raft The raft supports the model during printing: Model Raft It is essential that a good raft is printed to guarantee a good build. Therefore the height of the hot-end nozzle over the bed for the first layer is critical: ... - Page 42 BFB-3000 Set Up and Operations Manual SIDE VIEW END VIEW COMMENTS NOZZLE TOO HIGH: Not enough pressure on the filament into the bed, therefore small contact area between filament and bed. Raft may detach in mid print. Filament pushed into...

-

Page 43: Print The Raft Check File

BFB-3000 Set Up and Operations Manual 6.11.1 Print the raft check file To make sure your printer is correctly setup, you will need to print the raft check file. This file is already included on the SD card supplied in your toolkit. -

Page 44: Examine The Raft Check File

BFB-3000 Set Up and Operations Manual 6.11.2 Examine the raft check file RAFT MAGNIFICATION NOTES NOZZLE TOO HIGH: Wavey tracks, or tracks narrower than 1.2 mm (use vernier calipers to check). See “Perfect the raft” (page 46). NOZZLE TOO LOW:... -

Page 45: Potential Problems

BFB-3000 Set Up and Operations Manual 6.11.3 Potential problems If the raft pad appears damaged, match the imperfection to the two scenarios below, and follow the corrective action suggested. Note that there may be some imperfections in the raft, but that the process is very forgiving and even the images shown below will generally not spoil a full print. -

Page 46: Perfect The Raft

BFB-3000 Set Up and Operations Manual 6.11.4 Perfect the raft If analysis of the raft check file yields any problems, you will need to re-examine some of the setup stages: ERROR CORRECTIVE ACTION See “Check the bed is referenced to the Nozzle too high extruder nozzles”... -

Page 47: Print The First Model

7 Print the first model Test print To get your BFB-3000 printer up and running as quickly as possible, we have already loaded a .BFB file of a duck for you to immediately make. Make sure materials are loaded as per “Load the filament” (page 31). -

Page 48: Essential Post-Print Operations

BFB-3000 Set Up and Operations Manual Essential post-print operations 7.2.1 Bed flatness New beds will distort slightly due to heating from the extruder. Check bed flatness with a straight edge (e.g. ruler) after each print: Slight ‘bowing’ can be detected using the edge of a ruler. -

Page 49: Empty Material Waste Bin

BFB-3000 Set Up and Operations Manual 7.2.2 Empty material waste bin After each print you will need to empty the nozzle wipe box Lower the bed (see “Manual move”, page 18) to access the nozzle wipe box. Remove the waste box from the machine and dispose of the plastic deposits. -

Page 50: Further Printing

BFB-3000 Set Up and Operations Manual 8 Further printing Now your printer is set up, you will need to visit our website at www.bitsfrombytes.com Download and install Axon software (illustrated in page 9). Check for free updates - we issue updates regularly to continually improve printing performance. -

Page 51: Further Operations

All .BFB files (exported from Axon) must be saved to the root of the SD card. Any files in folders on SD card will not be displayed on the BFB-3000. The SD card must be no larger than 2 Gb. -

Page 52: Notes On Materials

BFB-3000 Set Up and Operations Manual Notes on materials 9.3.1 Properties Material Properties High toughness. Non-degradable. Do not print area larger than 100 mm square – ABS has relatively high shrinkage on cooling, and some geometries for larger prints are prone to warping. -

Page 53: Control Panel Functions

BFB-3000 Set Up and Operations Manual Control panel functions After turning the BFB-3000 on, the control panel presents the main menu (below). > RUN FILE EXTRUDER MAPPING MANUAL MOVE EXTRUDER CONTROL HOME TOOL HEAD SETTINGS Use the Z buttons to scroll up and down the menu. - Page 54 BFB-3000 Set Up and Operations Manual Use the Y buttons to change the mapping. Press X+ to save, or Escape to quit without saving. Axon builds the BFB file using Gcodes. The file is readable with any text viewing program.

-

Page 55: Manual Move

BFB-3000 Set Up and Operations Manual 9.4.3 Manual move See “Manual move”, page 18. 9.4.4 Extruder control See “Extruder control”, page 37. 9.4.5 Home tool head Push ‘Enter’ to move all axes to their home position. Make sure the bed is in position before homing the tool head. The bed contains a sensor necessary for homing. -

Page 56: Set Z Height

9.4.6.1 Extruder offsets Extruder offsets defines the position of extruders 2 and 3 in the BFB-3000, relative to extruder 1. Settings here should only be changed after performing a nozzle calibration print. Visit our website to download the calibration procedure and determine the offsets values. - Page 57 BFB-3000 Set Up and Operations Manual 9.4.7.1 Set bed type The bed design in the machine dictates how the machine operates. > V2 Black composite V1 Clear perspex Use the Z buttons to select the bed type. Press X+ to save, or Escape to quit without saving.

- Page 58 Use the Z buttons to select the option. Press X+ to save, or Escape to quit without saving. Incorrect general settings will severely affect the BFB-3000 print quality. Do not change any general settings without fully understanding each setting first.

- Page 59 BFB-3000 Set Up and Operations Manual 9.4.7.2.1 Ignore G92 The “ignore G92” setting is required because of the previous method of managing extruder offsets which involves using the Gcode G92 command. The user was required to determine the extruder 2 offset value through printing the calibration print. The calculated offset value was then entered into Axon.

-

Page 60: Maintenance Operations

BFB-3000 Set Up and Operations Manual Maintenance operations 9.5.1 Updating your printer Visit our website at www.bitsfrombytes.com to check for free upgrades. This may include: Firmware (the software inside the control box) Hardware (mechanical improvements) 9.5.2 Adjusting the nozzle wipe The nozzle wipe should sit slightly higher than the height of the nozzle tip, so that when the nozzle is moved over the wipe, the wipe brushes over the nozzle tip. - Page 61 BFB-3000 Set Up and Operations Manual To adjust the height of the nozzle wipe, remove the nozzle wipe box and loosen the M3 nuts and bolts on the back of the wipe using the 2.5mm hex driver supplied in the toolkit.

-

Page 62: Fine Adjustment To Level The Nozzles

BFB-3000 Set Up and Operations Manual 9.5.3 Fine adjustment to level the nozzles Nozzles must be level for a reliable print. If one nozzle is lower than the other, it may damage the print. To evaluate if the nozzles are level: ... - Page 63 BFB-3000 Set Up and Operations Manual The ø 0.5 mm nozzle orifice only has 1.0 mm thickness. Remove as little material as possible to achieve level nozzles. Do not remove more than 1.0 mm, otherwise the orifice will begin to widen, and the nozzle will be permanently damaged.

-

Page 64: Handling A Ground-Out Filament

BFB-3000 Set Up and Operations Manual 9.5.4 Handling a ground-out filament If a pressure bearing is poorly assembled, or the nozzle suffers from a blockage (e.g. printing too close to the bed), the back of the filament may be ground out by the extruder drive shaft. - Page 65 BFB-3000 Set Up and Operations Manual Cut filament using side cutters Heat extruder to melt plastic using “Extruder control”, page 37. Remove loaded section using pliers Examine the removed filament to confirm the cause: Normal drive shaft teeth...

-

Page 66: Handling Snapped Filament In The Delivery Tube

BFB-3000 Set Up and Operations Manual 9.5.5 Handling snapped filament in the delivery tube If filament snaps in more than one place in the delivery tube, the tube needs to be flushed of any trapped broken sections before the filament can be reloaded. - Page 67 BFB-3000 Set Up and Operations Manual Unclip delivery tube from back panel at all points Pull out delivery tube full out of bottom bracket Bring delivery tube up to top of the machine Document No: D100253...

- Page 68 BFB-3000 Set Up and Operations Manual Pull delivery tube out of the energy chain from extruder end completely removing it from the machine Energy chain Prepare an end of filament from the reel – rounding the edges as per standard...

- Page 69 BFB-3000 Set Up and Operations Manual Push reel filament down delivery tube, from the nut end Hold tube in a coil to match the natural bend of the filament, making it easier to push out the trapped segments of filament.

- Page 70 BFB-3000 Set Up and Operations Manual Tape up on non-nut end of the tube so that the filament cannot move in the tube. Insert the taped end back down inside the energy chain from the extruder end Push the tube all the way back down the energy chain.

- Page 71 BFB-3000 Set Up and Operations Manual On exiting the energy chain, remove the tape Re-clip the delivery tube against the back panel Run the delivery tube under the second steel bar at the back of the machine. Document No: D100253...

- Page 72 BFB-3000 Set Up and Operations Manual Remove the support filament from the delivery tube Position the nut-end of the tube so that the nut sits comfortably on the extruder body Finally, reload filament, as “Load the filament”, page 31 Document No: D100253...

-

Page 73: Troubleshooting

BFB-3000 Set Up and Operations Manual Troubleshooting Please visit our website at www.bitsfrombytes.com to use our troubleshooting guides. Troubleshooting Please visit our website at www.bitsfrombytes.com to raise a support ticket. Specifications Please visit our website at www.bitsfrombytes.com to view specification sheets on the BFB-3000.

Need help?

Do you have a question about the BFB-3000 and is the answer not in the manual?

Questions and answers