Summary of Contents for ESAB Ruffian ES 150G EDW

- Page 1 Ruffian ES 150G EDW Engine Driven Welder MMA 150A Instruction manual Valid for: Serial number: 0463 905 001 GB 20220907 HA229YY-XXXXXX...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAFETY ........................4 Meaning of symbols ..................... 4 General safety precautions for arc welding ............4 General safety precautions for engines and generators ........8 User responsibility ....................9 California Proposition 65 Warning ..............10 SÉCURITÉ ......................11 Signification des symboles ................ - Page 3 Engine troubleshooting ..................44 10 ERROR CODE ......................45 11 ORDERING SPARE PARTS ................... 46 BLOCK DIAGRAM ......................47 ORDERING NUMBERS ....................48 ACCESSORIES ......................49 Rights reserved to alter specifications without notice. © ESAB AB 2022 0463 905 001...

-

Page 4: Safety

Hot sparks or metal can lodge in rolled up sleeves, trouser cuffs, or pockets. Sleeves and collars should be kept buttoned and open pockets eliminated from the front of the clothing. 0463 905 001 - 4 - © ESAB AB 2022... - Page 5 Put on dry, hole-free gloves before turning on the power. Turn off the power, before removing your gloves. 10. Refer to ANSI/ASC Standard Z49.1 for specific grounding recommendations. Do not mistake the work lead for an earth cable. 0463 905 001 - 5 - © ESAB AB 2022...

- Page 6 When not in use, keep cylinder valves closed. Have valve protection cap in place if regulator is not connected. Secure and move cylinders by using suitable hand trucks. 0463 905 001 - 6 - © ESAB AB 2022...

- Page 7 NFPA Standard 51B, “Fire Prevention During Welding, Cutting, and Other Hot Work" CGA Standard P-1, “Precautions for Safe Handling of Compressed Gases in Cylinders” 10. ANSI Z87.1, "Occupational and Educational Personal Eye and Face Protection Devices" 0463 905 001 - 7 - © ESAB AB 2022...

-

Page 8: General Safety Precautions For Engines And Generators

Do not allow tools to cause sparks when working on a battery. Do not use welder to charge batteries or jump start vehicles. Observe correct polarity (+ and -) on batteries. 0463 905 001 - 8 - © ESAB AB 2022... -

Page 9: User Responsibility

This product is solely intended for arc welding and related process that draw less than the kVA of the system. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0463 905 001 - 9 - ©... -

Page 10: California Proposition 65 Warning

This product can expose you to chemicals including lead, which are known to the state of California to cause cancer and birth defects or other reproductive harm. Wash hands after use. For more information, go to www.P65Warnings.ca.gov. 0463 905 001 - 10 © ESAB AB 2022... -

Page 11: Sécurité

Avertir les passants de ne pas regarder l'arc et de ne pas s'exposer aux rayons de l'arc électrique ou du métal chaud. Portez des gants antidéflagrants de type gantelet, une chemise épaisse à manches 0463 905 001 - 11 © ESAB AB 2022... - Page 12 Gardez tout au sec, y compris les vêtements, la zone de travail, les câbles, le porte- torche/électrode et la source d'alimentation. Assurez-vous que toutes les parties de votre corps sont isolées de la pièce à usiner et du sol. 0463 905 001 - 12 © ESAB AB 2022...

- Page 13 Californie comme pouvant causer des malformations congénitales et, dans certains cas, le cancer (California Health & Safety Code §25249.5 et seq.) 0463 905 001 - 13 © ESAB AB 2022...

- Page 14 • Tenez les câbles et les cordons éloignés des véhicules en mouvement lorsque vous travaillez à partir d'un emplacement aérien. 0463 905 001 - 14 © ESAB AB 2022...

- Page 15 à chaud" 9. Norme CGA P-1, « Précautions pour la manipulation sécuritaire des gaz comprimés en bouteilles » 10. ANSI Z87.1, « Oeil et visage personnels professionnels et éducatifs Dispositifs de protection" 0463 905 001 - 15 © ESAB AB 2022...

-

Page 16: Consignes Générales De Sécurité Pour Les Moteurs Et Les Générateurs

Ne remplissez pas trop le réservoir - laissez de la place pour que le carburant se dilate. Ne renversez pas de carburant. Si du carburant est renversé, nettoyez-le avant de démarrer le moteur. 0463 905 001 - 16 © ESAB AB 2022... -

Page 17: Responsabilité De L'utilisateur

Respectez la polarité (+ et -) des piles. Responsabilité de l'utilisateur Les utilisateurs d'équipements ESAB ont la responsabilité ultime de s'assurer que toute personne travaillant sur ou à proximité de l'équipement respecte toutes les précautions de sécurité pertinentes. Les précautions de sécurité doivent répondre aux exigences qui s'appliquent à... -

Page 18: Avertissement De La Proposition 65 De La Californie

ESAB propose un assortiment d'accessoires de soudage et d'équipements de protection individuelle à l'achat. Pour plus d'informations sur les commandes, contactez votre revendeur ESAB local ou rendez-nous visite sur notre site Web. Avertissement de la proposition 65 de la Californie AVERTISSEMENT! L'équipement de soudage ou de coupage produit des fumées ou des gaz qui... -

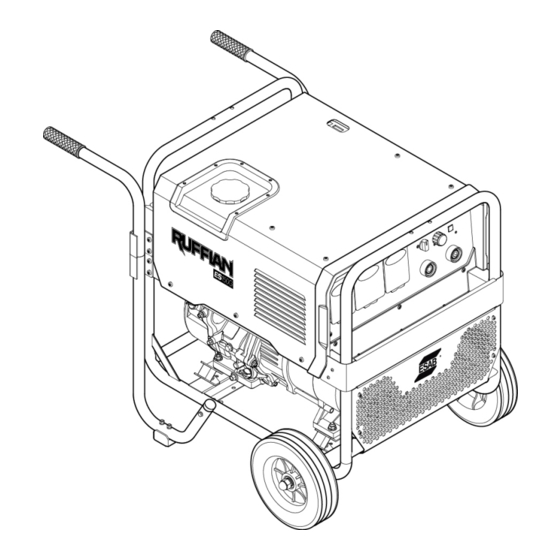

Page 19: Introduction

INTRODUCTION Overview The RUFFIAN ES 150G EDW is an autonomous DC stick welder and AC generator in one compact package. EDW stands for Engine Driven Welder. ESAB accessories for the product can be found in the "ACCESSORIES" chapter of this manual. -

Page 20: Technical Data

Enclosure class The IP code indicates the enclosure class, i.e. the degree of protection against penetration by solid objects or water. Equipment marked IP23 is intended for indoor and outdoor use. 0463 905 001 - 20 © ESAB AB 2022... -

Page 21: Fuel Consumption Curves

120 V AC and 240 V AC receptacle. WELDING & AC AUXILIARY POWER SIMULTANEOUS OUTPUT Welding Current AC auxiliary power 120V AC current 240V AC current (KW) 11.5 18.4 13.5 0463 905 001 - 21 © ESAB AB 2022... -

Page 22: Installation

Location Position the engine driven welder so that cooling air inlets and outlets are not obstructed. WARNING Secure the equipment - particularly if the ground is uneven or sloping. 0463 905 001 - 22 - © ESAB AB 2022... -

Page 23: Lifting Instructions

For mechanical lifting use the optional lifting eye included at Section 13-ACCESSORIES. The lifting eye (0707071001) includes the hardware needed to fix the device to the tubular handles of the machine. 0463 905 001 - 23 - © ESAB AB 2022... -

Page 24: Overall Tubular Frame Dimensions

Upper part left handle assembly Lower part right handle assembly Upper part right handle assembly Rear side M6x16 Hexagon Pan Head Screw assembly M6x70 Bolt 6mm Spring Washer M6 Nut 6mm Flat Washer 0463 905 001 - 24 - © ESAB AB 2022... - Page 25 8 mm Spring Washers, and four M8 Nuts. 3. Slide a Wheel onto one end of the Axle followed by a 20mm flat washer. Secure in place with a Lid Nut. Repeat for the other side. 0463 905 001 - 25 - © ESAB AB 2022...

- Page 26 7. Install the upper parts of each Handle Assembly and secure them to the frame using two M6 x 16mm Hexagon pan head screws at each side. 8. Make sure that all the hardware is tighten securely 0463 905 001 - 26 - © ESAB AB 2022...

-

Page 27: Engine Prestart Checks

To improve cold weather starting, use correct grade oil for cold weather. SAE 10W 30 oil is recommended for general use. (The SAE Viscosity Grade defines other viscosities to use in different average temperatures, see engine owner’s manual). 0463 905 001 - 27 - © ESAB AB 2022... - Page 28 Do not use gasoline that has been stored in a dirty fuel container. It can cause particles to enter the carburetor, affecting the engine performance and/or causing damage. Do not use gasoline containing more than 10% ethanol (E10). Do not use E85 ethanol. 0463 905 001 - 28 - © ESAB AB 2022...

-

Page 29: Operation

Choke Lever: It is used to alter the air-fuel ratio entering the engine Front panel connections and control devices 0463 905 001 - 29 - © ESAB AB 2022... -

Page 30: Connecting The Edw To Ground

This should be performed by a qualified electrician. Connect the grounding cable (2) between equipment ground terminal (1) to metal frame or trailer (3). Use #8 AWG or larger insulated copper wire. 0463 905 001 - 30 - © ESAB AB 2022... -

Page 31: Connecting Output Terminals

Grounding Cable (Not Supplied) Connecting output terminals The Ruffian ES 150G EDW is a DC (direct current) power source for STICK welding has Positive (+) and Negative (-) terminals for welding and return cables, in most cases the connection as follows: Connect the return cable to the negative terminal on the power source. -

Page 32: Starting And Stopping The Engine

Arc force and the Indication light is lit. 4. The ARC FORCE value is adjusted through the Amperage/ARC FORCE Control knob. The displayed value varies from -10 to 10. 0463 905 001 - 32 - © ESAB AB 2022... -

Page 33: Operating Ac Auxiliary Power (Generator)

Do not allow Generator to run out of fuel with loads connected. NOTE! Failure to connect and operate can cause damage to the Generator and/or to the appliances, tools, and equipment connected and will invalidate the Warranty of this Generator. 0463 905 001 - 33 - © ESAB AB 2022... - Page 34 NOTE! To achieve output currents above 20A at the 120VAC output, distribute the electrical loads over the 2 receptacles. This is required as each receptacle can support 20A maximum. 0463 905 001 - 34 - © ESAB AB 2022...

-

Page 35: Ac Auxiliary Power Guide

1400 1400 Table Saw 9" 4500 1500 Air Compressor 1/2 HP 3000 1000 6" 1720 Bench Grinder 8" 3900 1400 1/2 HP 3150 High Pressure Washer 3/4 HP 4500 1400 0463 905 001 - 35 - © ESAB AB 2022... - Page 36 Starting Watts Running Watts Froster 3100 Radio 50-200 50-200 1/8 HP 1/6 HP 1250 Furnance Blower 1/4 HP 1600 1/3 HP 2100 1/2 HP 3225 Lights bulbs as indicated on the bulb 0463 905 001 - 36 - © ESAB AB 2022...

-

Page 37: Maintenance

Replace air filter element Check fuel filter, clean or replace if needed Check and adjust valve clearance when engine is cold Replace spark plug and set gap 0463 905 001 - 37 - © ESAB AB 2022... -

Page 38: Engine Oil Change

4. Remove the drain plug and the oil dipstick and drain the oil completely. 5. Reinstall the drain plug. 6. Fill crankcase with new oil to the specified level on the dipstick. 7. Reinstall the oil dipstick and tighten it secure 0463 905 001 - 38 - © ESAB AB 2022... -

Page 39: Air Filter Element Maintenance

Operating engine with loose or damaged air cleaner components could cause premature wear and failure. Replace all bent or damaged components. NOTE! Running engine with cover positioned for cold weather operation in normal conditions can damage engine. 0463 905 001 - 39 - © ESAB AB 2022... -

Page 40: Spark Plug Maintenance

5. Install the adjusted spark plug into cylinder head if it is in a good condition or replace it by a new one. Torque the spark plug to 27 N·m (20 ft. lb.). 0463 905 001 - 40 - © ESAB AB 2022... -

Page 41: Welder Routine Maintenance

During cleaning, always wear recommended personal safety equipment, such as ear plugs, safety glasses, masks, gloves and safety shoes. Turn off the engine. WARNING! Wait at least 30 seconds for the capacitors to discharge before continuing. 0463 905 001 - 41 - © ESAB AB 2022... - Page 42 After having finished cleaning the welder module, reattach the top cover with the ten screws. Tighten the screws on the top cover with 3 Nm ± 0.3 Nm (26.6 in lb. ± 2.6). 0463 905 001 - 42 - © ESAB AB 2022...

-

Page 43: Troubleshooting

Check fuel level and fuel system. Maintain air cleaner and spark plug according to engine manual. Contact your authorized service center to check and adjust engine speed or the governor linkage for smooth, non-binding operation. 0463 905 001 - 43 - © ESAB AB 2022... -

Page 44: Engine Troubleshooting

Check fuel level and quality. Fill fuel tank with fresh 87+ octane stabilizer-treated unleaded gasoline. Do not use gasoline with more than 10% ethanol (E15, E20, E85, etc.). 0463 905 001 - 44 - © ESAB AB 2022... -

Page 45: Error Code

Action: The error code will automatically disappear and the Fault indicator light will be turned off when the power source has cooled down and is ready for use again. If the error persists, contact a service technician. 0463 905 001 - 45 - © ESAB AB 2022... -

Page 46: Ordering Spare Parts

Repair and electrical work should be performed by an authorized ESAB service technician. Use only ESAB original spare and wear parts. The Ruffian ES 150G EDW is designed and tested in accordance with the international and European standards IEC 60974-1. On completion of service or repair work, it is the responsibility of the person(s) performing the work to ensure that the product still complies with the requirements of the above standards. -

Page 47: Block Diagram

APPENDIX BLOCK DIAGRAM 0463 905 001 - 47 - © ESAB AB 2022... -

Page 48: Ordering Numbers

ORDERING NUMBERS Ordering number Denomination Type Notes 0707 070 150 Engine Driven Welder RUFFIAN ES 150G EDW 0463 905 001 Instruction manual RUFFIAN ES 150G EDW 0463 906 001 Spare parts list manual RUFFIAN ES 150G EDW 0463 907 001... -

Page 49: Accessories

Protective Cover, ES 150G EDW 0707071002 WS200E13 Electrode Holder 200 A and Lead Assembly, 4m (13 ft), 50 mm WS200G10 Ground Clamp 200 A and Lead Assembly, 3 m (10 ft), 50 mm 0463 905 001 - 49 - © ESAB AB 2022... - Page 50 For contact information visit esab.com ESAB, 2800 Airport Rd., Denton, TX 76207, Phone 1 (800) 426 - 1888 http://manuals.esab.com...

Need help?

Do you have a question about the Ruffian ES 150G EDW and is the answer not in the manual?

Questions and answers