Summary of Contents for ESAB ES 150i PRO

- Page 1 ES 150i PRO, ES 200i PRO Instruction manual Valid for: HA017-, HA020-xxxx-xxxx 0463 715 001 GB 20210113...

-

Page 3: Table Of Contents

Routine maintenance ................Cleaning instruction ................TROUBLESHOOTING ................ORDERING SPARE PARTS ................ KEY SPARE PARTS .................... 22 DIAGRAM ......................ORDERING NUMBERS ..................24 ACCESSORIES ....................25 Rights reserved to alter specifications without notice. 0463 715 001 © ESAB AB 2021... -

Page 4: Safety

Safety Data Sheets (SDSs). Safety precautions Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 5 If equipped with ESAB cooler Use ESAB approved coolant only. Non-approved coolant might damage the equipment and jeopardize product safety. In case of such damage, all warranty undertakings from ESAB cease to apply. Recommended ESAB coolant ordering number: 0465 720 002.

- Page 6 There may be potential difficulties in ensuring electromagnetic compatibility of class A equipment in those locations, due to conducted as well as radiated disturbances. 0463 715 001 - 6 - © ESAB AB 2021...

- Page 7 For further information contact the nearest ESAB dealer. ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0463 715 001 - 7 - ©...

-

Page 8: Introduction

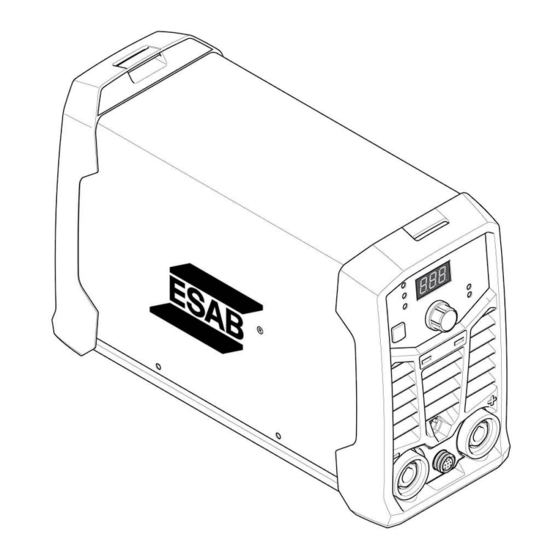

2 INTRODUCTION INTRODUCTION Overview ES 150i PRO, ES 200i PRO is an inverter-based power source intended for MMA (Manual Metal Arc) and TIG (Tungsten Inert Gas) welding. ESAB accessories for the product can be found in the "ACCESSORIES" chapter of this manual. -

Page 9: Technical Data

3 TECHNICAL DATA TECHNICAL DATA Technical data ES 150i PRO ES 200i PRO Outlet voltage 240 V±15% 115 V±15% 240 V±15% 115 V±15% 1~ 50/60 Hz 1~ 50/60 Hz 1~ 50/60 Hz 1~ 50/60 Hz Primary current 20 A 29 A 29 A 29 A Lift TIG 12.5 A 24 A 19 A 24 A No-load power demand when in energy saving 50 W... - Page 10 3 TECHNICAL DATA ES 150i PRO ES 200i PRO Continual sound <70 dB <70 dB <70 dB <70 dB pressure at no-load Dimensions l × w × h 403×153×264 mm 403×153×264 mm (15.8×6×10.4 in.) (15.8×6×10.4 in.) Weight 8.4 kg 9.85 kg Insulation class transformer Enclosure class IP23S IP23S Application class Duty cycle The duty cycle refers to the time as a percentage of a ten-minute period that you can weld or cut at a certain load without overloading.

-

Page 11: Installation

WARNING! Falling equipment can cause serious personal injury and equipment damage. Lift the unit with handle on top of case. 0463 715 001 - 11 - © ESAB AB 2021... -

Page 12: Mains Supply

A protective ground connection must be made, in accordance with regulations. Rating plate with supply connection data. Recommended fuse sizes and minimum cable area for the ES 150i PRO, ES 200i PRO ES 150i PRO ES 200i PRO Supply voltage 240 VAC... - Page 13 4 INSTALLATION Recommended fuse sizes and minimum cable area for the ES 150i PRO, ES 200i PRO Supply voltage 240 VAC 115 VAC Maximum recommended extension cord length 100 m (328 ft) 100 m (328 ft) Minimum recommended extension cord size 2.5 mm 2.5 mm WARNING! If used under 115 VAC input supply, the supply plug rating must be greater than 20 A.

-

Page 14: Operation

Connect the return cable to the other output on the power source. Secure the return cable’s contact clamp to the workpiece, and make sure that there is a good contact between the workpiece and the output for the return cable on the power source. 0463 715 001 - 14 - © ESAB AB 2021... -

Page 15: Turning The Power On/Off

Do not turn off the power source during welding (with load). Fan control The ES 150i PRO, ES 200i PRO is fitted with a fan as needed feature. Fan as needed automatically switches the cooling fan off when it is not required. This has two main advantages;... - Page 16 This is indicated by a lit VRD indicator on the panel. Cel 6010 (ES 200i PRO only) Optimised arc characteristics for cellulosic electrodes such as 6010 and similar. 0463 715 001 - 16 - © ESAB AB 2021...

-

Page 17: Setting Panel

The maximum setting of the power source will be determined by the respective front panel control, irrespective of the remote control device setting. 0463 715 001 - 17 - © ESAB AB 2021... -

Page 18: Maintenance

Cleaning instruction To maintain the performance and increase the lifetime of the power source it is mandatory to clean it regularly. How often depends on: 0463 715 001 - 18 - © ESAB AB 2021... - Page 19 Open the enclosure and use a vacuum cleaner to remove any accumulated dirt, metal filings, slag and loose material. Keep the shunt and lead screw surfaces clean as accumulated foreign material may reduce the welders output welding current. 0463 715 001 - 19 - © ESAB AB 2021...

-

Page 20: Troubleshooting

Refer to power source “Duty cycle” section in "TECHNICAL DATA", page 9. Make sure that the air inlets or outlets are not clogged. Clean the inside of the machine using routine maintenance methods. 0463 715 001 - 20 - © ESAB AB 2021... -

Page 21: Ordering Spare Parts

Repair and electrical work should be performed by an authorised ESAB service technician. Use only ESAB original spare and wear parts. The ES 150i PRO, ES 200i PRO is designed and tested in accordance with the international and European standards EN60974-1, EN60974-10 and AS60974.1. On completion of service or repair work, it is the responsibility of the person(s) performing the work to ensure that the product still complies with the requirements of the above standards. -

Page 22: Key Spare Parts

Sleeve socket 8 pin with harness set 0464 672 887 Digital display board set - ES 200i PRO 0464 672 891 Digital display board set - ES 150i PRO 0464 673 007 EMC filter board 0463 715 001 - 22 -... -

Page 23: Diagram

DIAGRAM DIAGRAM For serial number HA017-XXXX-XXXX and HA020-XXXX-XXXX. 0463 715 001 - 23 - © ESAB AB 2021... -

Page 24: Ordering Numbers

ORDERING NUMBERS ORDERING NUMBERS Ordering number Denomination Type Notes 0700 500 088 Power source ES 150i PRO Australia 0700 500 090 Power source ES 200i PRO Australia 0463 715 * Instruction manual Technical documentation is available on the Internet at: www.esab.com... -

Page 25: Accessories

0700 500 084 Remote control, Handheld remote, MMA 4 W4014450 Remote control, Foot pedal, with 4,5 m (15 ft) cable, 8 PIN 0700 500 085 Plastic case (Toolbox) 0700 500 086 Shoulder strap 0463 715 001 - 25 - © ESAB AB 2021... - Page 26 For contact information visit esab.com ESAB AB, Lindholmsallén 9, Box 8004, 402 77 Gothenburg, Sweden, Phone +46 (0) 31 50 90 00 http://manuals.esab.com...

Need help?

Do you have a question about the ES 150i PRO and is the answer not in the manual?

Questions and answers