ECR International COMBI 115 Installation, Operation And Maintenance Manual

Condensing wall mounted gas fired

Hide thumbs

Also See for COMBI 115:

- User's information manual (8 pages) ,

- User's information manual (8 pages)

Table of Contents

Advertisement

Quick Links

CONDENSING WALL MOUNTED

IN USA CONTACT:

2201 Dwyer Avenue, Utica, NY 13501

Tel. 800 325 5479

www.ecrinternational.com

GAS FIRED

COMBI Models

HEATING ONLY Models

115

150

205

75

100

125

165

IN CANDA CONTACT:

Granby Industries L.P.

Industries Granby S.E.C.

98 des Industries,

Cowansville, Qc.

J2K 0A1. Canada.

450-378-2334

supporttechnique@granbyindustries.com

www.granbyindustries.com

Advertisement

Chapters

Table of Contents

Summary of Contents for ECR International COMBI 115

- Page 1 CONDENSING WALL MOUNTED GAS FIRED COMBI Models HEATING ONLY Models IN USA CONTACT: IN CANDA CONTACT: Granby Industries L.P. Industries Granby S.E.C. 98 des Industries, Cowansville, Qc. J2K 0A1. Canada. 2201 Dwyer Avenue, Utica, NY 13501 450-378-2334 Tel. 800 325 5479 supporttechnique@granbyindustries.com www.ecrinternational.com www.granbyindustries.com...

- Page 2 COMBI MODEL - 205...

- Page 3 CONTENTS : INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ENGLISH (240013687) APPLICATION GUIDE (240013694) COMMISSIONING GUIDE (240011376) REQUIRED INSPECTION SPECIAL (240011561) BACK COVER...

- Page 4 HEAT ONLY MODEL 165...

- Page 5 CONDENSING WALL MOUNTED GAS FIRED INSTALLATION, OPERATION & MAINTENANCE MANUAL Models: COMBI Models HEATI NG ONLY Models PN 240013687 REV A [09/01/2022]...

- Page 6 V ERI FY CON TEN TS RECEI V ED M et a l W a ll Bra ck et Tem pera t ure Pressure Fully Assem bled Boiler w / 4 ea W a ll Screw s 3 0 PSI Sa fet y Relief Va lve Ga uge a nd Plugs I ncludes Essent ial...

-

Page 7: Table Of Contents

TABLE OF CON TEN TS Verify Cont ent s Received ..........2 9 - St a rt Up Procedure ..........4 9 9.1 Central Heating System Connections - Central Heat Ta ble Of Cont ent s ............3 Models Only ............. 49 Physica l Da t a.............. -

Page 8: Physica L Da T A

PH YSI CAL D ATA Dim ensions D I M EN SI ON S 7 5 / 1 0 0 / 1 2 5 1 1 5 / 1 5 0 1 6 5 / 2 0 5 Height 30" [ 763 m m ] 17 3/4 "... - Page 9 PH YSI CAL D ATA 7 5 / 1 0 0 1 2 5 H EAT 1 6 5 H EAT H EAT ON LY ON LY ON LY Bot t om View Bot t om View Bot t om View Dim ensions Dim ensions Dim ensions...

-

Page 10: I M Portan T I N Form Ati On

1 - I M PORTAN T I N FORM ATI ON 1 . Sa fet y I nform a t ion FOR YOUR SAFETY READ BEFORE OPERATING Boiler installation shall be completed by qualified agency. See glossary for addit ional inform at ion. DANGER W ARN I N G Fire, explosion, asphyxiat ion and elect rical shock... -

Page 11: I Nt Roduct Ion

2 - I N TROD U CTI ON 2 .6 The unit M UST N OT: 2 - I nt roduct ion • Direct ly heat pot able wat er. I ndirect heat ing is accept able. 2 .1 I nst allat ion shall conform t o requirem ent s of aut horit y •... -

Page 12: Com Ponent List Ing

3 - COM PON EN T LI STI N G H ea t Only - 7 5 & 1 0 0 Exhaust Port I nt ake Port I TEM H ea t Only - 7 5 & 1 0 0 Pum p wit h Air Separat or Boiler Drain Tap Gas Valve... - Page 13 3 - COM PON EN T LI STI N G H ea t Only - 1 2 5 Exhaust Port I nt ake Port I TEM H ea t Only - 1 2 5 Pum p wit h Air Separat or Boiler Drain Tap Gas Valve Low Water Pressure Cutoff...

- Page 14 3 - COM PON EN T LI STI N G H ea t Only - 1 6 5 Exhaust Port I nt ake Port I TEM H ea t Only - 1 6 5 Pum p Boiler Drain Tap Low Water Pressure Cutoff Gas Valve NTC Heating sensor ( Supply/ Return) QTY 2, ( 1 Shown for...

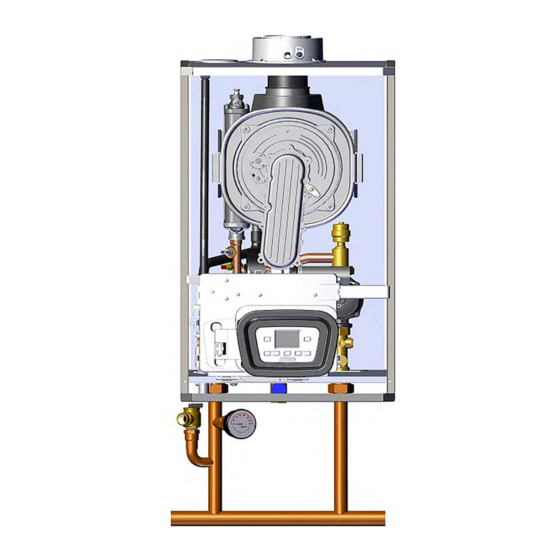

- Page 15 3 - COM PON EN T LI STI N G Com bi - 1 1 5 Exhaust Port I nt ake Port I TEM Com bi - 1 1 5 Pum p wit h Air Separat or Boiler Drain Tap Dom est ic Hot Wat er Turbine DHW Priorit y Sensor Cont rolled Fast Fill...

- Page 16 3 - COM PON EN T LI STI N G Com bi - 1 5 0 Exhaust Port I nt ake Port I TEM Com bi - 1 5 0 Pum p wit h Air Separat or Boiler Drain Tap Dom est ic Hot Wat er Turbine DHW Priorit y Sensor Cont rolled Fast Fill...

- Page 17 3 - COM PON EN T LI STI N G Com bi - 2 0 5 Exhaust Port I nt ake Port I TEM Com bi - 2 0 5 Pum p Boiler Drain Tap Dom est ic Hot Wat er Turbine DHW Priorit y Sensor DHW Heat Exchanger Gas Valve...

-

Page 18: Loca T Ing Boiler

4 - LOCATI N G BOI LER W ARN I N G TABLE 1 : BOI LER CLEARAN CES Fire Hazard! Do not inst all on carpet ing. Failure t o M a nufa ct urer Com bu st ible follow t hese inst ruct ions could result in deat h or D im e n sion Recom m ended... -

Page 19: Clearances

4 - LOCATI N G BOI LER 4 .2 Clea ra nces Service Clea ra nces 75, 100, 115, 125 & 150 165 & 205 13 9/16 in 211/2 in [345 mm] [546 mm] Front View of Left Side View Boiler of Boiler 8 5/8 in [220 mm]... -

Page 20: Wall Mounting

4 - LOCATI N G BOI LER FI GURE 4 - 2 W a ll M ount Bra ck et ( I ncluded) CAU TI ON Boiler weight exceeds 140 pounds ( 63.5 kg) . Do not lift boiler ont o wall wit hout assist ance. Cent er bracket s. -

Page 21: Com Bust Ion Air And Vent Piping

5 - COM BU STI ON AI R AN D V EN T PI PI N G • Support piping in accordance wit h pipe m anufact urer's W ARN I N G inst ruct ion and aut horit y having j urisdict ion. I n absence Fire, explosion, and asphyxiat ion hazard. -

Page 22: Rem Oval Of Existing Boiler From Com M On Vent System

5 - COM BU STI ON AI R AN D V EN T PI PI N G 5.3 Definitions 5 .2 Rem ova l of Ex ist ing Boiler From Com m on Vent Syst em Coaxial piping – Exhaust and air int ake pipe have a When exist ing boiler is rem oved from com m on vent ing com m on axis. -

Page 23: Approved Polypropylene Manufacturers

5 - COM BU STI ON AI R AN D V EN T PI PI N G 5 .4 Approved Polypropylene M a nufa ct urers W ARN I N G Manufact urer recom m ends t his condensing boiler be * Nat alini vent ed wit h approved polypropylene vent ing m at erial. - Page 24 5 - COM BU STI ON AI R AN D V EN T PI PI N G VEN T M ATERI AL OPTI ON S ( Maxim um Equivalent Vent Lengt h Shown) 7 5 / 1 0 0 / 1 1 5 / 1 2 5 / 1 5 0 I nt ake Exhaust Com bined Vent...

-

Page 25: Coaxial Venting I Nstructions

5 - COM BU STI ON AI R AN D V EN T PI PI N G 5 .6 Coa x ia l Vent ing I nst ruct ions W ARN I N G Maximum equivalent flue lengths for Coaxial venting are: Asphyxiat ion hazard. -

Page 26: Coaxial Vent Screw Placem Ent

5 - COM BU STI ON AI R AN D V EN T PI PI N G 5 .7 Coa x ia l Vent Screw Pla cem ent - See Figure 5 - 3 Two ( 2) screws shall be fast ened t hrough t he out er int ake pipe behind t he gasket s at equal dist ances, approxim at ely 180°... -

Page 27: Twin Pipe System S

5 - COM BU STI ON AI R AN D V EN T PI PI N G W ARN I N G FI GURE 5 - 8 - 2 " / 6 0 m m & 3 " / 8 0 m m Tw in Pipe Asphyxiat ion hazard! I m proper inst allat ion could Sepa ra t ed H orizont a l Flue Term ina t ion result in deat h or serious inj ury. -

Page 28: Twin Pipe Polypropylene Adapter Kit I Nstallation

5 - COM BU STI ON AI R AN D V EN T PI PI N G Figure 5 - 1 1 - Tw in Pipe Ada pt er Kit 5 .9 Tw in Pipe Polypropylene Ada pt er Kit I nst a lla t ion 7 5 - 1 5 0 M odel Boilers for 7 5 / 1 0 0 / 1 1 5 / 1 2 5 / 1 5 0 Boilers [ See Figures 5 - 1 1 , 5 - 1 2 &... -

Page 29: Twin Pipe Cpvc Adapter Kit I Nstallation

5 - COM BU STI ON AI R AN D V EN T PI PI N G 5 .1 2 Tw in Pipe CPVC Adapt er Kit I nst allat ion 5 .1 1 Tw in Pipe Polypropylene Adapt er Kit I nst allat ion 1 6 5 / 2 0 5 Boilers 1 6 5 / 2 0 5 Boilers [ See Figures 5 - 1 1 , 5 - 1 2 , 5 - 1 7 , 5 - 1 8 &... -

Page 30: Securing Twin Pipe Polypropylene Venting

5 - COM BU STI ON AI R AN D V EN T PI PI N G Figure 5 - 2 0 - N a t a lini Cla m p W ARN I N G Asphyxiat ion hazard! I m proper inst allat ion could result in deat h or serious inj ury. - Page 31 5 - COM BU STI ON AI R AN D V EN T PI PI N G FI GURE 5 - 2 3 - ( 2 " / 6 0 m m & 3 " / 8 0 m m ) Tw in Pipe ...

- Page 32 5 - COM BU STI ON AI R AN D V EN T PI PI N G FI GURE 5 - 2 6 - Tw in Pipe Side W a ll Vent ( M ult iple FI GURE 5 - 2 9 - ( 2 " / 6 0 m m ON LY) Vent Pipe w it h T Applia nces) CAN BE U SED ON ALL SI Z ES N OTE: 3"...

-

Page 33: Flexible Vent System

5 - COM BU STI ON AI R AN D V EN T PI PI N G 5 .1 4 ( 3 " / 8 0 m m Only) Flex ible Vent Syst em FI GURE 5 - 3 3 - ( 3 " / 8 0 m m Only) Flex ible Vent ing Syst em CAN BE U SED ON ALL SI Z ES Flexible vent syst em s shall only be run vert ical. - Page 34 5 - COM BU STI ON AI R AN D V EN T PI PI N G FI GURE 5 - 3 4 - Flue Term ina l Loca t ion All vent pipe and combustion air pipe and fittings shall comply with the following: Use only m anufact urer approved vent ing m at erials or vent ing m at erials prim er and glue approved t o: ULC S636 in Canada, and UL 1738 or ASTM D1784 &...

-

Page 35: Condensate Piping

5 - COM BU STI ON AI R AN D V EN T PI PI N G FI GURE 5 - 3 5 - Condensa t e Dra in W ARN I N G Asphyxiat ion hazard! Fill condensat e t rap before st art ing boiler t o avoid com bust ion product s escaping boiler. -

Page 36: Hydronic Piping

6 - H YD RON I C PI PI N G 6 .1 Genera l Boiler rat ed at 50 psig ( 3.45 bar) m axim um N o t e • Prim ary/ Secondary piping required. allowable working pressure. Boiler provided wit h •... -

Page 37: Special Conditions

6 - H YD RON I C PI PI N G FI GURE 6 - 2 Sa fet y Relief Va lve Discha rge Piping 6 .3 Sa fet y Relief Va lve a nd Air Vent • Install safety relief valve using pipe fitting provided wit h boiler. -

Page 38: Trim Piping

6 - H YD RON I C PI PI N G 6 .4 Trim Piping • Tem perat ure - Pressure Gauge. I nst all t em perat ure pressure gauge using piping provided wit h boiler. See Figure 6- 1. •... - Page 39 6 - H YD RON I C PI PI N G FI GURE 6 - 3 - Piping Dia gra m - LW CO Loca t ion Low Water Cutoff (LWCO) Arrange piping t o prevent N o t e ( See Figure 6- 5 for det ail) wat er dripping ont o boiler.

-

Page 40: External Optional Low Water Cut Off

6 - H YD RON I C PI PI N G 6.6 External Optional Low Water Cut Off FIGURE 6-5 - Low Water Cutoff - Detail These guidelines are supplied when necessary t o inst all an additional Low Water Cut Off (LWCO), for sensing a low water level condit ion in a boiler, as required by t he Aut horit y Having Jurisdict ion. -

Page 41: Manufacturer Recom M Endation - Flter On Dhw I Nlet

6 - H YD RON I C PI PI N G 6 .7 M a nufa ct urer Recom m enda t ion - Filt er on DH W I nlet Pot able wat er Pot able wat er FI LTER M a nufa ct urer Recom m enda t ion Manufacturer strongly recommends the use of a filter, filtering potable water before entering the boiler. -

Page 42: Central Heating System

6 - H YD RON I C PI PI N G 6 .8 Cent ra l H ea t ing Syst em 6 .9 Frost Prot ect ion M ode Frost prot ect ion m ode is int egrat ed int o t he appliance when Boiler is designed for use in a sealed cent ral heat ing syst em . -

Page 43: Ga S Supply Piping

7 - GAS SU PPLY PI PI N G 7 .1 Genera l D AN GER • Use piping m at erials and j oining m et hods accept able Fire Hazard. Do not use m at ches, candles, open t o aut horit y having j urisdict ion. -

Page 44: Gas Pipe Recom M Endations

7 - GAS SU PPLY PI PI N G 7 .2 Ga s Pipe Recom m enda t ions • Use of Gas Appliance Connectors (flexible connectors Configure gas pipe for proper operation and avoid issues with failure to light or maintenance of proper flame during t ypically used for gas st oves or wat er heat ers) is operation, which could cause error codes related to flame prohibit ed. - Page 45 7 - GAS SU PPLY PI PI N G This chart is sourced from NFPA- 54 2015 wit h t he BTU rat ings for t he m at erial, lengt h, and diam et er of gas pipe. I NTENDED USE: Pipe Sizing Bet ween Nat ural Gas Met er, or Propane Single - or Second- St age ( Low- Pressure) Regulat or and Appliance.

-

Page 46: Leak Check Gas Piping

7 - GAS SU PPLY PI PI N G NOTICE FI GURE 7 - 1 Sedim ent t rap shall be locat ed upst ream of gas cont rols. 7 .3 Lea k Check Ga s Piping Pressure t est boiler and gas connect ion before placing boiler in operat ion. -

Page 47: Elect Rica L Connect Ions

8 - ELECTRI CAL CON N ECTI ON S D AN GER Model 7 5 & 1 1 5 1 2 5 1 5 0 1 6 5 2 0 5 Size 1 0 0 Elect rocut ion Hazard! HI GH VOLTAGE - Connect ions Power Supply 120V - 60Hz in t erm inal block M1 are high volt age ( 120V / 60Hz) . -

Page 48: Electrical Connections

8 - ELECTRI CAL CON N ECTI ON S FI GURE 8 - 2 Term ina l Block Loca t ions D AN GER Elect rocut ion Hazard! HI GH VOLTAGE - Connect ions in t erm inal block M1 are high volt age ( 120V / 60Hz) . Before m aking connect ions, verify appliance is disconnect ed from power supply. -

Page 49: I Nstall Room Therm Ostat

8 - ELECTRI CAL CON N ECTI ON S FI GURE 8 - 4 Room Therm ost a t Connect ions 8 .5 I nst a ll Room Therm ost a t I nst all room room t herm ost at on inside wall. Do not inst all where it will be influenced by drafts, hot or cold water pipes, lighting fixtures, television, sun rays or near a fireplace. - Page 50 8 - ELECTRI CAL CON N ECTI ON S FI GURE 8 - 6 Kt Clim a t e Curves Flow t em p Out side t em p Cent igrade ( ° C) Fahrenheit ( ° F) Boiler Boiler Point Point Tem p...

-

Page 51: Options For I Ndirect Water Heater Connections

8 - ELECTRI CAL CON N ECTI ON S FI GURE 8 - 7 Kt I ndirect St ora ge Ta nk 8 .7 Opt ions for I ndirect W a t er H ea t er Connect ions *125 Model shown - See Application Guide for size 75, 100 Heat only boiler models 75, 100 and 125 using an optional tank sensor can be electrically connected to indirect storage tank as follows:... - Page 52 8 - ELECTRI CAL CON N ECTI ON S FI GURE 8 - 8 Circula t or Pum p Connect ions For m ore inform a t ion plea se review t he a pplica t ion guide received w it h your boiler. A field supplied pump relay is necessary for system pumps.

-

Page 53: St A Rt Up Procedure

9 - START U P PROCED U RE 9 .1 Cent ra l H ea t ing Syst em Connect ions - CEN TRAL H EAT M OD ELS ON LY 7 5 , 1 0 0 & 1 2 5 H EAT ON LY 1 6 5 H EAT ON LY WITH OPTI ON AL I N DI RECT DH W CON N ECTI ON... - Page 54 9 - START U P PROCED U RE 9 .2 Cent ra l H ea t ing Syst em - H EATI N G AN D D OM ESTI C H OT W ATER 1 1 5 & 1 5 0 COM BI 2 0 5 COM BI Boiler Connect ions LEGEND...

-

Page 55: System Start Up

9 - START U P PROCED U RE 9 .3 Syst em St a rt Up FI GURE 9 - 1 Condensa t e Dra in Assem bly Follow all codes and regulations when filling the boiler. Model 205 shown ( locat ion sim ilar in all sizes) Use drain t aps t o allow syst em t o com plet ely drain. -

Page 56: Control Panel

9 - START U P PROCED U RE 9 .5 Cont rol Pa nel To ent er t he I N FO Menu press and hold for 1 second. Press and hold t he but t on for 1- 2 seconds t o increm ent t hrough t he select ions as shown in t he t able below. -

Page 57: Prior To Com M Issioning

9 - START U P PROCED U RE I f dearat ion or gas recognit ion funct ion is int errupt ed W ARN I N G by power blackout , st art funct ion again when power is Asphyxiat ion hazard! Fill condensat e t rap before rest ored. -

Page 58: Manual Calibration Function

9 - START U P PROCED U RE FI GURE 9 - 3 - Ga s I nlet Ta p - Pi 9 .9 M a nua l Ca libra t ion Funct ion: Manual Calibrat ion phase st art s at t he end of t he Aut om at ic Calibrat ion. -

Page 59: Chim Ney Sweep Function

9 - START U P PROCED U RE Gas A ( Natural Gas) Gas E ( LPG) Com bust ion 7 5 & 1 0 0 1 2 5 1 6 5 & 2 0 5 Table 1 1 5 & 1 5 0 CO2 % CO2 % O2 %... -

Page 60: Check Firing Rate

9 - START U P PROCED U RE 9 .1 5 Pa ra m et er Set t ings 9 .1 4 Check Firing Ra t e Program boiler elect ronic board param et ers as follows: Measure input , if a gas m et er is inst alled in t he syst em . •... -

Page 61: Description Of Param Eters: Factory Settings

9 - START U P PROCED U RE FACTORY SETTI N GS 9 .1 6 Descript ion Of Pa ra m et ers: Fa ct ory Set t ings 1 0 0 ,1 2 5 ,1 6 5 1 1 5 ,1 5 0 ,2 0 5 D H W Fa st M odu la t ion 0 0 = St andard Modulat ion - on DHW call for heat 10 seconds st abilizat ion t im e before P0 1... - Page 62 9 - START U P PROCED U RE The values listed below are factory defaults, there may be differences for each application Model 1 0 0 1 1 5 1 2 5 1 5 0 1 6 5 2 0 5 Natural Natural Natural...

-

Page 63: Adjusting Maxim Um Heating Power

9 - START U P PROCED U RE 9 .1 7 Adj ust ing M a x im um H ea t ing Pow er Maxim um boiler heat ing power can be reduced t o suit requirem ent s of heat ing syst em it serves. Table showing param et er P1 3 values according t o desired m axim um power m odel is shown for each single boiler. -

Page 64: 0 - Opera T Ing I Nst Ruct Ions

1 0 - OPERATI N G I N STRU CTI ON S 1 0 .2 Boiler Opera t ion FOR YOU R SAFETY READ BEFORE OPERATI N G Dom est ic hot wat er supply always t akes priorit y over cent ral W ARN I N G heat ing. -

Page 65: Dom Estic Hot Water Mode

1 0 - OPERATI N G I N STRU CTI ON S 1 0 .5 Frost Prot ect ion W ARN I N G Boiler m onit ors supply and ret urn wat er t em perat ures t o Burn, Scald Hazard! Wat er t em perat ure over 125°... -

Page 66: 1 - Genera L M A Int Ena Nce And Clea Ning

1 1 - GEN ERAL M AI N TEN AN CE AN D CLEAN I N G • Circulat or pum p and com bust ion air blower m ot or furnished D AN GER wit h boiler are perm anent ly lubricat ed from fact ory and require no further lubrication. - Page 67 1 1 - GEN ERAL M AI N TEN AN CE AN D CLEAN I N G W ARN I N G 1 1 .2 M a int ena nce And Rout ine Servicing Check and service boiler as necessary. Following service procedures m ust be perform ed by qualified service agent.

- Page 68 1 1 - GEN ERAL M AI N TEN AN CE AN D CLEAN I N G D AN GER Before servicing, turn off electrical power to boiler at service swit ch. Close m anual gas valve t o t urn gas supply OFF t o boiler.

-

Page 69: Draining The Boiler

1 1 - GEN ERAL M AI N TEN AN CE AN D CLEAN I N G 1 1 .6 H ydra ulic Unit ( DH W ) Com bi - 1 5 0 SH OW N For special areas, where wat er is harder t han 200 ppm or 12 grains/ gallon, inst all polyphosphat e dispenser or equivalent t reat m ent syst em , com pliant wit h current regulat ions. -

Page 70: User I Nform Ation

1 1 - GEN ERAL M AI N TEN AN CE AN D CLEAN I N G NOTICE 1 1 .1 0 User I nform a t ion Advise User of t he following im port ant inform at ion: When servicing t he appliance, check t he condit ion and position of flame sensing electrode and replace it if A. -

Page 71: 2 - Ra T Ings And Ca Pa Cit Ies

1 2 - RATI N GS AN D CAPACI TI ES 1 2 TECH N I CAL DATA 1 2 .1 Ra t ings a nd Ca pa cit y (1) ( 3) Net AHRI CH I nput, MBH (1)(2) Model CH Heat ing Rat ing Wat er,... - Page 72 1 2 - RATI N GS AN D CAPACI TI ES 1 2 .3 H igh Alt it ude Ra t ings For elevations between 2000 ft (600 m) and 10,000 ft (3048 m), use the following information: I nput, MBH (KW) Dom est ic Hot Wat er ( DHW) Circuit Heating Model...

- Page 73 1 2 - RATI N GS AN D CAPACI TI ES 1 2 .5 Ava ila ble Boiler Pum p H ea d This is a high static head pump fit for installation on any type of single or double-pipe heating systems. The automatic air valve incorporat ed in t he pum p allows quick vent ing of t he heat ing syst em .

-

Page 74: 3 - Trouble Shoot Ing

1 3 - TROU BLE SH OOTI N G 1 3 .1 Error M essa ges a nd Reset t ing t he Boiler Error Descript ion Opera t ion Gas valve connect ion fault Check cable PCB/ gas valve and gas valve plug Out door sensor fault Check sensor and cable Gas valve com m and fault... - Page 75 1 3 - TROU BLE SH OOTI N G 1 3 .1 Error M essa ges a nd Reset t ing t he Boiler - cont inued Error Descript ion Opera t ion 1 3 5 I nt ernal error Verify all cables.

- Page 76 1 3 - TROU BLE SH OOTI N G 1 3 .2 Anom a lies Ta ble for t he I nst a ller - Use t his t able t o report t he anom aly values. SYSTEM STATUS CODES 0 STANDBY 1 DHW "ON"...

- Page 77 1 4 - GLOSSARY • APPLIANCE - Device t o convert gas int o energy; t erm • DIRECT VENT BOILER - Boiler const ruct ed and inst alled so includes any com ponent , cont rol, wiring, piping or t ubing all com bust ion air is derived direct ly from out doors and all required t o be part of t he device.

- Page 78 1 4 - GLOSSARY • METRIC GAS METERS • TWO PIPE SYSTEM - Type of vent ing t hat allows for exhaust flue and intake air piping to be separated from each Natural Gas other. Fresh air may be drawn in at a different area from where flue terminal is located.

-

Page 79: Appendix A - W Iring Dia Gra M

APPEN D I X A - W I RI N G D I AGRAM S A- 2 M ODEL 7 5 & 1 0 0 - H ea t Only 240013687 REV A [ 09/ 01/ 2022]... - Page 80 APPEN D I X A - W I RI N G D I AGRAM S A- 2 M ODEL 1 2 5 - H ea t Only 240013687 REV A [ 09/ 01/ 2022]...

- Page 81 APPEN D I X A - W I RI N G D I AGRAM S A- 3 M ODEL 1 6 5 - H ea t Only 240013687 REV A [ 09/ 01/ 2022]...

- Page 82 APPEN D I X A - W I RI N G D I AGRAM S A- 1 M ODEL 1 1 5 - Com bi 240013687 REV A [ 09/ 01/ 2022]...

- Page 83 APPEN D I X A - W I RI N G D I AGRAM S A- 4 M ODEL 1 5 0 - Com bi 240013687 REV A [ 09/ 01/ 2022]...

- Page 84 APPEN D I X A - W I RI N G D I AGRAM S A- 5 M ODEL 2 0 5 - Com bi 240013687 REV A [ 09/ 01/ 2022]...

- Page 85 N OTES 240013687 REV A [ 09/ 01/ 2022]...

- Page 86 N OTES 240013687 REV A [ 09/ 01/ 2022]...

- Page 87 INSTALLATION AND CHECK-OUT CERTIFICATE Boiler Model Serial # Date Installed___________ Measured BTU/HR input____________ Installation instructions have been followed Checkout procedure and adjustments performed Maintenance and Service issues reviewed with owner/ maintenance person Installation booklet affixed on or adjacent to boiler Installer (Company) Address Phone...

- Page 88 I M PO RTA N T I n accordance with Section 325 (f) (3) of the Energy Policy and Conservation Act, this boiler is equipped with a feature that saves energy by reducing the boiler water tem perature as the heating load decreases. This feature is equipped with an override which is provided prim arily to perm it the use of an external energy m anagem ent system that serves the sam e function.

- Page 89 APPLI CATI ON GUI DE FOR USE WI TH H EATI N G ON LY - 7 5 , 1 0 0 , 1 2 5 , 1 6 5 & COM BI - 1 1 5 , 1 5 0 , 2 0 5 This m anual has been prepared for use wit h t he appropriat e I nst allat ion, Operat ion and Maint enance Manual.

- Page 90 T ABLE O F CO N T EN T S I m port a nt Sa fet y I nform a t ion ..................3 La bor Sa ving Piping M a nifolds / N ea r Boiler Piping Connect ions ........4 Genera l I nform a t ion - H ydronic Piping ................

-

Page 91: I M Port A Nt Sa Fet Y I Nform A T Ion

I M P O RT AN T SAFET Y I N FO RM AT I O N 1 . 1 . Becom e fa m ilia r w it h sym bols ident ifying Becom e fa m ilia r w it h sym bols ident ifying 3 . -

Page 92: La Bor Sa Ving Piping M A Nifolds / N Ea R Boiler Piping Connect Ions

LABO R SAV I N G P I P I N G M AN I FO LD S / N EAR BO I LER P I P I N G CO N N ECT I O N S 7 5 , 1 0 0 & 1 2 5 H EATI N G ON LY 1 6 5 H EATI N G ON LY W I TH OPTI ON AL I N D I RECT D H W CON N ECTI ON 7 5 , 1 0 0 &... - Page 93 LABO R SAV I N G P I P I N G M AN I FO LD S / N EAR BO I LER P I P I N G CO N N ECT I O N S 1 1 5 & 1 5 0 COM BI 2 0 5 COM BI LEGEN D 1 1 5 &...

-

Page 94: Genera L I Nform A T Ion - H Ydronic Piping

GEN ERAL I N FO RM AT I O N - H Y D RO N I C P I P I N G FOR YOUR SAFETY READ BEFORE OPERATING W ARN I N G Burn and scald hazard! Manufacturer requires inst allat ion of field supplied ant i- scald valve. - Page 95 GEN ERAL I N FO RM AT I O N - H Y D RO N I C P I P I N G Use of I ndirect W a t er H ea t er ( DH W ) H ea t ing 1st Degree Burn 2nd and 3rd Degree Burn Water...

-

Page 96: Genera L I Nform A T Ion - W Iring

GEN ERAL I N FO RM AT I O N - W I RI N G Elect rical W iring I nform at ion: D O N O T use 120 V t herm ost at N o t e All field wiring shall conform t o t he aut hority having t erm inals ( M1- # 1 and # 2) . -

Page 97: Piping Legend

P I P I N G LEGEN D PI PI N G LEGEN D ZONE VALVE BALL VALVE DHW INDIRECT TANK AI R SEPARATOR INDIRECT TANK AQUASTAT CI RCULATOR 1 0 K Ω INDIRECT DHW TANK SENSOR DRAI N TEMPERATURE & PRESSURE GAUGE COMBINATION FILL EXPANSION TANK FLOW CHECK VALVE... -

Page 98: W/ Zone Circulat Ors & Dhw Tank- Piping Diagram

7 5 , 1 0 0 , 1 2 5 W / Z O N E CI RCU LAT O RS & D H W T AN K- P I P I N G D I AGRAM PN 240013694 REV. A [09/01/2022]... -

Page 99: W/ I Ndirect Zone Circulat Ors, Dhw T Ank W/ Sensor - Wiring Dia

7 5 , 1 0 0 , 1 2 5 W / I N D I RECT Z ON E CI RCU LATORS, D H W TAN K W / SEN SOR - W I RI N G D I A. PN 240013694 REV. -

Page 100: W/ I Ndirect Zone Circulat Ors & Dhw Tank W/ T - St At - Wi Ri Ng Dia

7 5 , 1 0 0 , 1 2 5 W / I N D I RECT Z ON E CI RCU LATORS & D H W TAN K W / T- STAT - W I RI N G D I A. NEC Cla ss 2 Lo w Vo lta g e PN 240013694 REV. -

Page 101: Wit H Zone Valves & Dhw Tank - Pi Pi Ng Diagram

7 5 , 1 0 0 , 1 2 5 W I T H Z O N E V ALV ES & D H W T AN K - P I P I N G D I AGRAM PN 240013694 REV. A [09/01/2022]... -

Page 102: Wit H Zone Valves, Dhw Tank W/ Sensor - Wiring Diagram

7 5 , 1 0 0 , 1 2 5 W I T H Z O N E V ALV ES, D H W T AN K W / SEN SO R - W I RI N G D I AGRAM PN 240013694 REV. -

Page 103: Zone Valves, Dhw T Ank W/ T - St At - Wiring Diagram

7 5 , 1 0 0 , 1 2 5 Z O N E V ALV ES, D H W T AN K W / T- ST AT - W I RI N G D I AGRAM NEC C la ss 2 Lo w Vo lta g e PN 240013694 REV. -

Page 104: Wit H Zone Circulat Ors - Pi Pi Ng Diagram

1 6 5 W I T H Z O N E CI RCU LAT O RS - P I P I N G D I AGRAM PN 240013694 REV. A [09/01/2022]... -

Page 105: Indirect Zone Circulat Ors, Dhw Tank W/ T- St At - Wiring Dia

1 6 5 I N D I RECT Z O N E CI RCU LAT O RS, D H W T AN K W / T- ST AT - W I RI N G D I A. NEC C la ss 2 Lo w Vo lta g e PN 240013694 REV. -

Page 106: Wit H Zone Valves - Pi Pi Ng Diagram

1 6 5 W I T H Z O N E V ALV ES - P I P I N G D I AGRAM PN 240013694 REV. A [09/01/2022]... -

Page 107: Wit H I Ndirect Zone Valves, Dhw Tank, Tank T- St At - Wiring Diagram

1 6 5 W I TH I N D I RECT Z ON E V ALV ES, D H W TAN K, TAN K T- STAT - W I RI N G D I AGRAM NEC C la ss 2 Lo w Vo lta g e PN 240013694 REV. -

Page 108: 205 Wit H Zone Circulat Ors - Pi Pi Ng Diagram

1 1 5 , 1 5 0 & 2 0 5 W I T H Z O N E CI RCU LAT O RS - P I P I N G D I AGRAM PN 240013694 REV. A [09/01/2022]... -

Page 109: 205 Wit H Zone Circulat Ors - Wiring Diagram

1 1 5 , 1 5 0 & 2 0 5 W I T H Z O N E CI RCU LAT O RS - W I RI N G D I AGRAM NEC C la ss 2 Lo w Vo lta g e PN 240013694 REV. -

Page 110: 205 Wit H Zone Valves - Pi Pi Ng Diagram

1 1 5 , 1 5 0 & 2 0 5 W I T H Z O N E V ALV ES - P I P I N G D I AGRAM PN 240013694 REV. A [09/01/2022]... -

Page 111: 205 Wit H Zone Valves - Wiring Diagram

1 1 5 , 1 5 0 & 2 0 5 W I T H Z O N E V ALV ES - W I RI N G D I AGRAM NEC C la ss 2 Lo w Vo lta g e PN 240013694 REV. -

Page 112: External Buffer Tank - Piping Diagram

EX T ERN AL BU FFER T AN K - P I P I N G D I AGRAM Buffer Ta nk Piping When inst alling low m ass syst em s, addit ional wat er m ass may be required to avoid short cycling by the boiler. In t hese applicat ions it is recom m ended t hat a buffer t ank be inst alled. - Page 113 EX T ERN AL BU FFER T AN K - P I P I N G D I AGRAM Buffe r Ta nk On Ce nt r a l H e a t Cir cuit W it h Pr im a r y Pum p a nd Supplie d M a nifold N OTE : Accept able prim ary pum p locat ions: Eit her 1 or 2.

-

Page 114: External Buffer Tank - Wiring Diagram

EX T ERN AL BU FFER T AN K - W I RI N G D I AGRAM Buffer Ta nk Pum p W iring Cont rolling A Prim a ry Pum p On A Com bi Boiler W it h Zone Va lves, N o I ndirect Ta nk PN 240013694 REV. - Page 115 EX T ERN AL BU FFER T AN K - W I RI N G D I AGRAM Bu ffe r Ta n k Pu m p W ir in g Con t r ollin g A Pr im a r y Pu m p On A Com bi Boile r W it h Zon e Pu m ps, Ar go ARM 4 P Zon e Con t r ol a n d A8 2 2 - I I PN 240013694 REV.

- Page 116 EX T ERN AL BU FFER T AN K - W I RI N G D I AGRAM Bu ffe r Ta n k Pu m p W ir in g Con t r ollin g A Pr im a r y Pu m p On A Com bi Boile r W it h Zon e Va lve s a n d I n dir e ct Ta n k W it h Pr ior it y, Ar go UZ3 a n d AR8 2 2 - I I Zon e Con t r ols ZO NE VA L VES...

-

Page 117: Opt Iona L Equipm Ent

O P T I O N AL EQ U I P M EN T Opt iona l Equipm ent I M PORTAN T: Sensors supplied wit h t his boiler are propriet ary t o t he m anufact urer. Use of alt ernat e m arket sensors WI LL dim inish boiler perform anc 1k Ω... -

Page 118: Accessories

ACCESSO RI ES 1. 1K Ohm (1k Ω) Outdoor Temperature 1k Ω Sensor Kit - BD7 1 0 4 8 7 3 0 2 V • Use the Outdoor Sensor (OAS) Kit with Heating Only or Combi Boilers. • Wire Cont rol t o boiler M2 t erm inal st rip, t erm inals 4 and 5 as shown. -

Page 119: Indirect Storage Tank Sensor Kit

ACCESSO RI ES 2. 10k Ω Indirect Storage Tank Sensor Kit Param et er PO3 for H ea t ing Only boiler, wit h no N o t e indirect t ank rem ains Fact ory Set at 08. No change Heat ing Only boiler can be elect rically connect ed t o is required. -

Page 120: Single Zone Circulat Or Wiring Using Argo Ar822- I I

CI RCU LAT O R CO N N ECT I O N S - W I RI N G D I AGRAM SI N GLE Z O N E CI RCU LAT O R W I RI N G U SI N G ARGO AR8 2 2 - I I PN 240013694 REV. -

Page 121: 100 - Heat Only Wiring Diagram

7 5 & 1 0 0 - H EAT O N LY W I RI N G D I AGRAM M O D EL 7 5 & 1 0 0 - H EAT O N LY PN 240013694 REV. A [09/01/2022]... -

Page 122: Heat Only Wiring Diagram

1 2 5 - H EAT O N LY W I RI N G D I AGRAM M O D EL 1 2 5 - H EAT O N LY PN 240013694 REV. A [09/01/2022]... - Page 123 1 6 5 - H EAT O N LY W I RI N G D I AGRAM M O D EL 1 6 5 - H EAT O N LY PN 240013694 REV. A [09/01/2022]...

-

Page 124: Com Bi Wiring Diagram

1 1 5 - CO M BI W I RI N G D I AGRAM M O D EL 1 1 5 - CO M BI PN 240013694 REV. A [09/01/2022]... - Page 125 1 5 0 - CO M BI W I RI N G D I AGRAM M O D EL 1 5 0 - CO M BI PN 240013694 REV. A [09/01/2022]...

- Page 126 2 0 5 - CO M BI W I RI N G D I AGRAM M O D EL 2 0 5 - CO M BI PN 240013694 REV. A [09/01/2022]...

-

Page 127: Altitude Effects On Boiler Performance

ALT I T U D E EFFECT S O N BO I LER P ERFO RM AN CE MODEL 75 CALCULATED EFFECTS OF HI-ALTITUDE ON BOILER PERFORMANCE 80,000 75,000 70,000 65,000 60,000 HEAT MODE 55,000 Net Rating Heat Mode 50,000 45,000 40,000 1,000... - Page 128 ALT I T U D E EFFECT S O N BO I LER P ERFO RM AN CE MODELS 125/150 CALCULATED EFFECTS OF HI-ALTITUDE ON BOILER PERFORMANCE 160,000 140,000 120,000 DHW MODE 100,000 HEAT MODE 80,000 60,000 NET RATNG HEAT MODE 40,000 2,000 4,000...

-

Page 129: Applica T Ion Ta Ble - Indirect Hot W A T Er T A Nk Perform A Nce Cha

AP P LI CAT I O N T ABLE - I N D I RECT H O T W AT ER T AN K P ERFO RM AN CE CH ART H EATI N G ON LY BOI LERS 7 5 , 1 0 0 , 1 2 5 , 1 6 5 Boile r Ou t pu t Boile r Pr e ssu r e... -

Page 130: Lw Co W Iring Dia Gra

LO W W AT ER CU T O FF • Locat e LWCO sensing device in t he supply Low W at er Cut Off - Heat ing Only and Com bi Boilers piping, above t he m inim um height of boiler. See Figure page 42, Piping Diagram . -

Page 131: Piping Dia Gra M - Lw Co Loca T Ion

LO W W AT ER CU T O FF P I P I N G D I AGRAM - LW CO LO CAT I O N Arrange piping t o prevent wat er N o t e dripping ont o boiler. I llust rat ions are m eant t o show syst em piping concept only. -

Page 132: Low Water Cutoff - Detail

LO W W AT ER CU T O FF LO W W AT ER CU T O FF - D ET AI L PN 240013694 REV. A [09/01/2022]... -

Page 133: Error Code Ta Ble

ERRO R CO D E T ABLE N ot e: When inst ruct ed press and hold “ RESET” for I nit ia l Fa ult Finding Check s bet ween 1- 3 seconds t o reset t he boiler. Check gas, wat er and elect rical supplies are available at t he boiler Ta ble of Error Codes... -

Page 134: Troubleshoot Ing Cha

T RO U BLESH O O T I N G CH ART PN 240013694 REV. A [09/01/2022]... - Page 135 T RO U BLESH O O T I N G CH ART PN 240013694 REV. A [09/01/2022]...

-

Page 136: Fa Ult Solut Ion Sect Ions

FAU LT SO LU T I O N SECT I O N S Fault Finding Solutions Sections Power supply 120V Main terminals L and N Check electrical supply Connection OK at connector x1 0 Integrity of the fuse Replace fuse Main or Display Display PCB fault... - Page 137 FAU LT SO LU T I O N SECT I O N S PN 240013694 REV. A [09/01/2022]...

- Page 138 FAU LT SO LU T I O N SECT I O N S Overheat thermostat operated or Check for and correct any system faulty. faults (water circulation). Allow to cool. Continuity �I across thermostat terminals � Replace safety thermostat more than 1.5 ohm '---------------' Is E11 O is still flashing Check Flow, Return,...

- Page 139 FAU LT SO LU T I O N SECT I O N S PCB connector x22 Hall With water running effect sensor terminals. Is main water filter and through DHW circuit, Check the voltage is Check DHW NTC assembly clean and measure red and white Replace PCB approximately 5 VDC...

-

Page 140: Param Eter Ch An Ge H I Story

P ARAM ET ER CH AN GE H I ST O RY Pa ra m et er Cha nged Cha nged Da t e Rea son From IN USA CONTACT: IN CANDA CONTACT: Gra nby I ndust ries L.P. I ndust ries Gra nby S.E.C. 98 des Industries, Cowansville, Qc. - Page 141 IMPORTANT INFORMATION READ THIS LEAFLET BEFORE COMMISSIONING THE BOILER IMPORTANT: Upon startup of this new boiler please call ECR International, Inc. Technical Support for installation assistance and registration. Technical Support and Product Registration Monday - Friday 8AM to 6PM Eastern time.

- Page 142 INFORMATIONS IMPORTANTES LIRE CET IMPRIMÉ AVANT DE METTRE LA CHAUDIÈRE EN MARCHE IMPORTANT : Lors du démarrage de cette nouvelle chaudière veuillez appeler recueil International, Inc. de support technique pour l'assistance à l'installation et l'enregistrement. Support technique et enregistrement du produit lundi - vendredi 8h00 à...

- Page 143 Required Inspection Schedule To Be Completed By Qualified Service Technician Date Completed Inspection Items Year Year Year Year Check boiler and system piping for any sign of Near boiler piping leakage, verify pipes are properly supported. Check condition of all vent pipes and joints. Verify Vent vent piping terminations are free of obstructions Piping...

Need help?

Do you have a question about the COMBI 115 and is the answer not in the manual?

Questions and answers