Subscribe to Our Youtube Channel

Summary of Contents for Mecmesin MultiTest-x Series

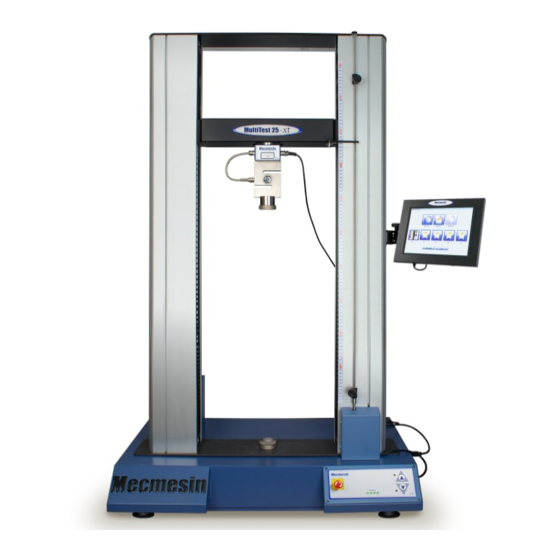

- Page 1 MultiTest- Range Motorised Test Frames Operating Instructions It is essential that you familiarise yourself with the contents of these instructions before attempting to operate the MultiTest-x range.

- Page 2 Mecmesin MultiTest-x manual...

-

Page 3: Table Of Contents

Mecmesin MultiTest-x manual Contents Introduction..................... 5 Hardware ......................5 Safe Operation of MultiTest-x Systems............... 6 System Set-up and Operation................6 Connecting up..................... 6 Loadcell ......................8 Limit Stops......................9 Control Panel ...................... 9 Software ......................10 Commands ......................10 i) Direct Command ..................10 ii) Menu Options.................... - Page 4 Mecmesin MultiTest-x manual Appendix 2 - A Guide to the Safe Use of Mains Powered Test Frames ..37 Receiving and Unpacking ................. 37 Installing the Machine ..................38 Operator Training....................39 Eye Protection and Protective Clothing ............. 39 Machine Guarding..................... 39 Continued Safe Use..................

-

Page 5: Introduction

• Appendix 1 (page 36) gives a list of items which should be included with your system. If any item is missing, please notify Mecmesin or an Authorised Agent immediately. It is strongly recommend that all the packaging and fixings be retained for any future transit requirements. -

Page 6: Safe Operation Of Multitest-X Systems

Within the European Union (EU), a copy of this Appendix will, if appropriate, be supplied in a language appropriate to your country by your local Mecmesin Agent. Note: Although movement of the test stand crosshead can be stopped via software, in... - Page 7 The required power supply voltage (110-120V or 220-240V) is indicated by the value in the red panel (3) within the fuse cartridge housing. Your local Mecmesin representative will already have checked that the fuse cartridge has been installed correctly for the supply voltage in your country. It is possible to modify your MultiTest-...

-

Page 8: Loadcell

Note that any loadcell, particularly a low capacity loadcell, is a delicate instrument. Care should always be taken to avoid excessive load, i.e. any load exceeding 120% of capacity, being applied to your loadcell. If you believe that excessive load has been applied, you should contact your local Mecmesin distributor. -

Page 9: Limit Stops

Mecmesin MultiTest-x manual Limit Stops The range of travel of the crosshead can be physically limited by using ‘limit stops’, each MultiTest-x has both an upper limit stop and a lower limit stop. Limit stop adjusters are illustrated above: MultiTest 1-x and MultiTest 2.5-x, use type (1), MultiTest 5-x uses type (2), while MultiTest 10-x and MultiTest 25-x use type (3). -

Page 10: Software

Mecmesin MultiTest-x manual operation can then be restored after the system has been re-set by twisting the [Emergency Stop] button about 60º clockwise. Software Commands There are four basic types of software instructions which can be entered via the control panel:... -

Page 11: Iii) Selecting Option Within A Menu

Mecmesin MultiTest-x manual This is an example of a screen from which one of five menu options can be chosen. Note that, as the maximum number of options which can be displayed concurrently is four, a ‘v’ in the lower right-hand corner indicates that there is at least one more menu option which can be displayed by pressing the [Jog Dn] key. -

Page 12: Booting-Up The Software

Mecmesin MultiTest-x manual be possible to key in a ‘Local Overload’ of 50.678N, but the system will only ‘remember’ 50.7N.) Note some screens can only be accessed by typing in a password. Information upon accessing, and operating within, these restricted screens appears in red. -

Page 13: Main Menu

Mecmesin MultiTest-x manual • Pressing the [2] key will set the load value to zero • Pressing the [3] key will set the position value to zero • Pressing the [4] key will run a procedure to update (if necessary) the ‘handshaking’... -

Page 14: 1>, Procedure Menu (Choosing And Running A Test Procedure)

Mecmesin MultiTest-x manual [1], <1>, Procedure Menu (Choosing and Running a Test Procedure) Choosing a Test Procedure Pressing [1] scrolls through the procedures (programs) which are available. The MultiTest-x can store up to five such procedures. Pressing [Stop/BK SP] will load the procedure selected;... - Page 15 Mecmesin MultiTest-x manual During a test the ‘status indicator’ can display: • - crosshead travelling, but ‘Threshold’ not yet reached • - crosshead travelling in response to ‘Touch’ command • - crosshead travelling in response to Segment A command •...

-

Page 16: Print Menu

Mecmesin MultiTest-x manual • A ‘local overload’ is reached (see [1], [3], [1], [4]) When a test has been completed the results will be automatically calculated and (if appropriate) displayed together with alarm status, and ‘tolerance result’, i.e. whether the specimen has passed or failed the tolerances specified for any calculation: In addition to continuing to display values from the ‘live screen’, this screen is also... -

Page 17: 1] Send Test Results

Mecmesin MultiTest-x manual [1], [2], [1] Send Test Results Test results available will be sent via RS232 port on rear panel, i.e. data can be downloaded to PC or data logger. [1], [2], [2] Send XY Data XY data available will be sent via RS232 port on rear panel. -

Page 18: 5> Baud Rate

Mecmesin MultiTest-x manual • Beneath the prompt enter the ‘Batch ID, press [Start/ENT]. This will be archived with the Procedure (see [1], [2], [3]) • Beneath the prompt enter the ‘User ID’, press [Start/ENT]. This will be archived with the Procedure (see [1], [2], [3]) and the Test... -

Page 19: 1] Acquisition Menu

Mecmesin MultiTest-x manual [1], [3], [1] Acquisition Menu [1], [3], [1], [1] Threshold The ‘threshold’ is a force value (in the units indicated) that, once exceeded, will trigger subsequent logging of data. Any value between zero and the capacity of the testing machine can be entered. If the threshold value is set to zero, data logging will start at the moment the test starts. - Page 20 Mecmesin MultiTest-x manual such as a spring test, requires that the platens touch to establish a zero position and then move to a position high enough to allow the spring to be inserted, then sample break must be disabled. [1], [3], [1], [3] Log Rate Pressing [1] will scroll through a range of data logging rates, from 0.25 to 512Hz.

-

Page 21: 2] Analysis Menu

Mecmesin MultiTest-x manual <1> to scroll through the units of force measurement available (N, kN, mN, gf, kgf, ozf, lbf) <2> to toggle between the units of time measurement available (sec, min) <3> to toggle between the units of length measurement available (mm, in) - Page 22 Mecmesin MultiTest-x manual Pressing [Start/ENT] twice (i.e. entering zero for both parameters) will create a calculation which returns the maximum load for all the test data. Entering a displacement value (in the units indicated) at the ‘Disp1’ prompt (illustrated), pressing [Start/ENT], entering another displacement value, which must occur at a later time, at the ‘Disp2’...

- Page 23 Mecmesin MultiTest-x manual • load set-point (Disp, Occurrence) • • load set-point (Disp, Occurrence) • load set-point (Disp, Occurrence) • .load at time (Time) Obviously no occurrence parameter is needed for this command, because time can only move in one direction! •...

- Page 24 Mecmesin MultiTest-x manual position’ and the position at which a ‘touch-on’ is detected (see [1], [3], [3], [7]). This calculation is either ‘on’ or ‘off’, i.e. it needs no parameters. The absolute zero position can be set from the ‘live screen’ by: •...

- Page 25 Mecmesin MultiTest-x manual However, if any calculation command has been activated (see [1], [3], [2], [1] Select Analysis, above), pressing the [2] key will display the screen which allows the limits of the first calculation to be specified. If, for example, the first analysis is a peak calculation, and the ‘Limit Type’ command (see [1], [4], <2>) has been set to ‘%TARG’, the screen displayed will be similar to,...

-

Page 26: 3] Control Menu

Mecmesin MultiTest-x manual Once the limits of the first calculation have been specified, pressing [Start/ENT] will display the screen associated with specifying the limits of the second calculation… …and once the limits of the final calculation have been specified, pressing [Start/ENT] will display the Analysis menu (see [1], [3], [2] ). - Page 27 Mecmesin MultiTest-x manual [1], [3], [3], [1] Define T(e)st Profile Up to five test procedures can be pre-defined and stored in internal non-volatile memory for later recall and execution. Each test procedure can be named (20 alphanumeric characters maximum) individually to reflect what the test has been designed to achieve.

- Page 28 Mecmesin MultiTest-x manual run until a specific load, length or time is reached, then press [Start/ENT] key. type in the appropriate value required in (b); if this value is zero the test will run until the specimen breaks, then press [Start/ENT] to continue.

- Page 29 Mecmesin MultiTest-x manual are only required for the 1 , 11 , 21 , 31 , 41 , and 51 , cycles. Pressing [Start/ENT] displays, type in appropriate number of cycles (10 in example above), and press [Start/ENT]. An alternative way of specifying a test which only records data during particular...

- Page 30 Mecmesin MultiTest-x manual [1], [3], [3], <2> Dir(ection) - TENSION Pressing [2] will toggle between direction options available (TENSION or COMPRESSION). If, for example, a command to drive the crosshead at a particular speed (see [1], [3], [3], [1] Define Test Profile) is being executed, •...

- Page 31 Although these parameters can be adjusted – nobody apart from a Mecmesin engineer will ever need to do so. If, by any chance, an operator should encounter a screen similar to...

-

Page 32: Utilities Menu

Mecmesin MultiTest-x manual Under no circumstances should any attempt be made to make changes, this could result in serious damage of the MultiTest-x system, and will certainly invalidate any warranty associated with that system. The system should immediately be shut down by turning off the power switch located on the back panel of the test stand. -

Page 33: 3] Stiffness Fact(Or)

Note that a test of this kind can potentially cause serious damage to the Xtra loadcell. It is strongly recommended that before attempting any test of this kind all users should discuss the matter with their local Mecmesin agent who will be pleased to give further advice. -

Page 34: 5] Install Defaults

Mecmesin MultiTest-x manual Erase the current procedure name by pressing the [Stop/BK SP] key, then type in up to 20 characters to give the first procedure a new name. To enter ‘TEST-7’ press the [8] key twice, press the [3] key three times, press the [7] key five times, press the [Tare] key once, then press the [7] key once. -

Page 35: 7] Calibration

Mecmesin MultiTest-x manual The data displayed will help a Mecmesin engineer diagnose the current status of a particular system. In the unlikely event of a problem arising with a MultiTest-x, an engineer providing remote support may ask for a description of this screen to be provided by telephone or Email. -

Page 36: Support

However, in the case of a question arising which is not dealt with by this manual, your next source of information is the Mecmesin website, click on [Literature & FAQs], then select the [FAQs] option. Type your question into the ‘Search for question’ box and click on the [Search] button. -

Page 37: Appendix 2 - A Guide To The Safe Use Of Mains Powered Test Frames

Calibration certificate for Xtra loadcell(s) Appendix 2 - A Guide to the Safe Use of Mains Powered Test Frames Mecmesin test frames have been designed and manufactured in a controlled system to ensure compliance with all relevant European Union Directives. Receiving and Unpacking Upon receiving the Mecmesin test frame ensure adequate equipment is available to safely lift the test frame from the packaging. -

Page 38: Installing The Machine

- either 110V or 230V AC. The label on the fuse holder immediately adjacent to the mains inlet connector indicates which voltage the system is set for. If the machine does not correspond to your supply, inform Mecmesin or an Authorised Representative, who will rectify the situation. Connecting a mains powered test frame to the wrong mains-supply will almost certainly cause extensive damage to the equipment. -

Page 39: Operator Training

Machine Guarding If, after the assessment, it is considered that machine guarding is needed, then contact your local supplier who, through Mecmesin, can arrange the supply of a suitable guard offering the required level of protection. -

Page 40: Continued Safe Use

LIFTING INSTRUCTIONS: DECLARATION OF CONFORMITY: Please refer to the literature section of the Mecmesin website for a copy of the EC Declaration of Conformity relevant to your machine. IF IN DOUBT CONSULT YOUR LOCAL SUPPLIER TO ENSURE CONTINUED... -

Page 41: Appendix 4 - Technical Details

Mecmesin MultiTest-x manual Appendix 4 – Technical Details The state-of-art electronics built into MultiTest-x testing machines utilises a 32 bit microprocessor delivering fast, accurate data acquisition together with automatic control of product testing procedures. Historically motorised tension/compression testers for quality control evaluation of manufactured products have been based upon force gauges and test stands with potentiometer controls (‘open loop’... -

Page 42: Tutorial 1 (Creating And Running A Simple Test)

Mecmesin MultiTest-x manual test programs will be developed, then refined into more sophisticated procedures for testing and analysis. Three programs will be developed: 1) A very simple dual segment tensile testing program. No test specimen will be required, but a loadcell with a capacity of at least 50N is recommended. -

Page 43: Setting Initial Conditions

Mecmesin MultiTest-x manual • The MultiTest-x system is fitted with a loadcell with a capacity of 50 newtons or greater • The lowest part of the fixture is at least 500mm above the ‘anvil plate’ (the flat black plate on the base of the MultiTest); press and hold the [Jog Up] key if it is not. -

Page 44: Choosing A Name

Mecmesin MultiTest-x manual Note: If a new test procedure regularly behaves in an unexpected manner, the most probable reason is that one of the initial setting is influencing the test in a way that had not been anticipated when the program was being developed. If, for example, step (iii) above is omitted, when the Tutorial-1 procedure is run, it could fail almost immediately if a sensitive sample break setting remains from a previous test. -

Page 45: Setting The Pass/Fail Limits

Mecmesin MultiTest-x manual ii) Activate the Minimum calculation, <1>, scroll to the next calculation, [Jog Dn] iii) Activate the Average calculation, <1>, scroll to the next calculation, [Jog Dn], iv) press [Stop/BK SP] to return to the Analysis Menu (Note that continuing to scroll down would allow other calculations to be activated, if required.) -

Page 46: Running The Program

Mecmesin MultiTest-x manual Press the [Stop/BK SP] key twice to return to the Main Menu. 6) Running the Program At the Main Menu screen, press [1] until ‘TUTORIAL-1’ is displayed ii) Press [Stop/BK SP], to load ‘TUTORIAL-1’ and display the ‘live screen’... -

Page 47: Tutorial 2

‘collapses’. The test conditions would satisfy, in part, the requirements of standards used by the packaging industry, e.g. ASTM D2659-95 or BS4839 Part 2 (including subsequent revisions). Mecmesin can also supply a suitable ‘vented compression plate’ (part number 406-196) Typically the pass/fail assessment carried out after this type of test would check the following: •... -

Page 48: Setting Initial Conditions

Mecmesin MultiTest-x manual • No limits need to be specified for original container height Before starting to set up the test procedure, check that: • The MultiTest-x system is fitted with a loadcell with a capacity of 500 newtons or greater •... -

Page 49: Choosing A Name

Mecmesin MultiTest-x manual ix) Set the crosshead to ‘park’ a few millimetres above the next undistorted sample at the end of the test. If, the crosshead is set manually just above the top of the first specimen, and if specimens vary in height by no more than one or two millimeters, setting ‘-2mm’... -

Page 50: Setting The Pass/Fail Limits

Mecmesin MultiTest-x manual The first calculation and second calculations have now been set up with default parameters. No parameters need to be set for the third calculation. The parameters of the second calculation will need to be changed. Set displacement to 4mm and occurrence to ‘1’. -

Page 51: Archiving The Data

Mecmesin MultiTest-x manual ix) Before running Segment A the MultiTest-x will detect that the ‘touch-on’ facility is active, then a touch-on routine will be executed. 7) Archiving the Data The data associated with this test: v) The Test Results vi) The ‘Raw’ XY Data... -

Page 52: Appendix 6 - Flow Charts

Mecmesin MultiTest-x manual Appendix 6 – Flow Charts Software Menu Options The following flow charts constitute, in effect, a series of ‘maps’ showing all the facilities of the MultiTest-x software and how they link to one another. Using this, or the Adobe Acrobat version of this manual, will make it much easier to find your way around the software quickly and efficiently. - Page 53 Appendix 6: MultiTest-x Menu Options Page 1 On the following pages are flowcharts to help you to navigate the menus on the MultiTest-x. [1] Displaying the Main Menu 1) Procedure 1 2) Print Menu Press 3) Setup Menu [1/Menu] 4) Utilities Menu [1], <1>, Choosing and Running a Test Procedure Press [Stop/BK SP] 1) Procedure 1...

- Page 54 Appendix 6: MultiTest-x Menu Options Page 2 [1], [2] Using the Print Menu to Download Data Send Test Results to RS232 port. Data can be downloaded to PC or Press [1] 1) Send Test Results datalogger 1) Procedure 1 Press [2] 2) Send XY Data Send XY Data to RS232 port.

- Page 55 Appendix 6: MultiTest-x Menu Options Page 3 [1], [3], [1], [2] Sample Break 1) Threshold Sample Break (%): 1) Procedure 1 1) Acquisition Menu 2) Sample Break Type in 50.0 2) Print Menu Press Press Press Press Appropriate 2) Analysis Menu 3) Log Rate Percent Drop from PK 3) Setup Menu...

- Page 56 Appendix 6: MultiTest-x Menu Options Page 4 [1], [3], [1], [4] Local Overload 1) Threshold 1) Procedure 1 1) Acquisition Menu 2) Sample Break Press [Stop/BK SP] 2) Print Menu Local Overload (N): Press Press Press 2) Analysis Menu 3) Log Rate Press to clear the value 3) Setup Menu...

- Page 57 Appendix 6: MultiTest-x Menu Options Page 5 [1], [3], [2], [1] Select Analysis Press <1> Press 1) Procedure 1 1) Select Analysis 1)PK Ld <>Disp-ON If ‘O N’ is displayed 1) Acquisition Menu to toggle 2) Print Menu 2) Set Limits press [Start/ENT] to Press Press...

- Page 58 Appendix 6: MultiTest-x Menu Options Page 6 Screens displayed will depend on what Limit Type has been [1], [3], [2], [2] Set Limits set (See [1],[4],<2>) 1) Procedure 1 1) Select Analysis 1) Acquisition Menu Pk Ld <>Disp Press 2) Print Menu 2) Set Limits Press Press...

- Page 59 Appendix 6: MultiTest-x Menu Options Page 7 [1], [3], [3] Using the Control Menu [1], [3], [3], [1] Define T(e)st Profile Press 1) Define Tst Profile SegA (speed units) 2) Dir-TENSION Type in speed and press [Start/ENT] 3) Post Test-STOP END CH SegA: 1) Procedure 1 1) Acquisition Menu...

- Page 60 Appendix 6: MultiTest-x Menu Options Page 8 [1], [3], [3], <2> Dir(ection) - TENSION Press 1) Define Tst Profile 1) Define Tst Profile <2> to toggle 2) Dir-TENSION 2) Dir-COMPRESSION between 3) Post Test-STOP TENSION 3) Post Test-STOP 1) Procedure 1 1) Acquisition Menu 4) Jog Rate 4) Jog Rate...

- Page 61 Appendix 6: MultiTest-x Menu Options Page 9 [1], [3], [3], [5] Home Location 1) Define Tst Profile 2) Dir-TENSION 3) Post Test-STOP 1) Procedure 1 1) Acquisition Menu 4) Jog Rate Home Location(mm) 2) Print Menu Press Press Press Press [Jog Dn] Type in 2) Analysis Menu 5) Home Location...

- Page 62 Appendix 6: MultiTest-x Menu Options Page 10 [1], [3], [3], [7] Touch Load 1) Define Tst Profile 2) Dir-TENSION 3) Post Test-STOP 1) Procedure 1 1) Acquisition Menu 4) Jog Rate 2) Print Menu Press Press Press 2) Analysis Menu 5) Home Location 3) Setup Menu [1/Menu]...

- Page 63 Appendix 6: MultiTest-x Menu Options Page 11 [1], [4] Utilities Menu [1], [4], [1] Set Date/Time Month(MM): Press Press 1)Set Date/Time 1)Set Date 1) Procedure 1 2)Limit Type-ABS 2)Set Time 2) Print Menu Hour(HH): Press 3)Stiffness Fact Press 3) Setup Menu [1/Menu] 4)Procedure Name BKSP)Exit...

- Page 64 Appendix 6: MultiTest-x Menu Options Page 12 [1], [4], <2> Limit Type-ABS Press 1)Set Date/Time 1)Set Date/Time 1) Procedure 1 <2> to toggle 2)Limit Type-ABS 2)Limit Type-%TARG 2) Print Menu between Press Press 3)Stiffness Fact 3)Stiffness Fact 3) Setup Menu ABS and %TARG [1/Menu] 4)Procedure Name...

- Page 65 Appendix 6: MultiTest-x Menu Options Page 13 [1], [4], [4] Procedure Name 1)Set Date/Time 1) Procedure 4* 2)Limit Type-ABS 2) Print Menu Procedure4 Name: Press 3)Stiffness Fact Press 3) Setup Menu Press [1/Menu] 4)Procedure Name 4) Utilities Menu Procedure4 5)Install Defaults 6)Diagnostics Press [Stop/Bk SP] to erase the procedure name and type the new name and 7)Calibration...

- Page 66 Appendix 6: MultiTest-x Menu Options Page 14 [1], [4], [6] Diagnostics 1)Set Date/Time 1) Procedure 1 2)Limit Type-ABS 2) Print Menu Press Press 3)Stiffness Fact 3) Setup Menu [1/Menu] 4)Procedure Name 4) Utilities Menu 5)Install Defaults 17359 Press Press [Jog Dn] 6)Diagnostics ENC: [Stop/BK SP] and hold for...

-

Page 67: Developing A Procedure

Mecmesin MultiTest-x manual Developing a Procedure The following flow chart highlights each stage that should be considered and worked through when a new procedure needs to be developed. Although the flow chart does refer to the development of Tutorial 1 (see above), these stages would be typical of... - Page 68 Appendix 6: MultiTest-x Program Development Page 1 Creating and Running a Simple Test START Set the Initial Conditions i) Set force units to ‘N’ and distance units to ‘mm’ [1], [3], [1], [5] Engineering Units ii) Set the local overload to 50N [1], [3], [1], [4] Local Overload iii) Make sure sample break is disabled [1], [3], [1], [2] Sample Break iv) Specify a tension test [1], [3], [3], <2>...

- Page 69 Appendix 6: MultiTest-x Program Development Page 2 Set the Pass/Fail Limits Set the required tolerance limits using Set Limits [1], [3], [2], [2] Enter the lower limit for the Peak result as 20N. Press [Start/ENT] Enter the upper limit for the Peak result as 25N. Press [Start/ENT] iii) Enter the lower limit for the Minimum result as 15N.

-

Page 70: Appendix 7 - Drawings & Dimensions

Mecmesin MultiTest-x manual Appendix 7 – Drawings & Dimensions... -

Page 71: Multitest 1-X

Mecmesin MultiTest-x manual MultiTest 1-x To be added... -

Page 72: Multitest 2.5-X

Mecmesin MultiTest-x manual MultiTest 2.5-x To be added... -

Page 73: Multitest 5-X

Mecmesin MultiTest-x manual MultiTest 5-x To be added... -

Page 74: Multitest 10-X

Mecmesin MultiTest-x manual MultiTest 10-x To be added... -

Page 75: Multitest 25-X

Mecmesin MultiTest-x manual MultiTest 25-x To be added... -

Page 76: Index

Mecmesin MultiTest-x manual Index absolute zero position, 24 date setting, 32 alarm status, 16 downloading data. See Menu, Print archiving data. See Menu, Print dual segment test. See Procedure, dual automatically downloading data, 26 segment baud rate, setting, 18 emergency stop. See stopping test Calculations FAQs. - Page 77 Mecmesin MultiTest-x manual load peaks. See Calculations, peak load pass/fail criteria. See tolerance limits, load troughs. See Calculations, minimum setting load Password-protected facilities loadcell deflection compensation. See calibration screen, 35 stiffness, system gain control, 31 loadholding, 27, 29, 51 re-installing defaults, 34...

- Page 78 Mecmesin MultiTest-x manual taring. See zeroing, load units of measurement. See measurement Technical details units measurement accuracy, 41 measurement resolution, 41 tension test, setting, 30 voltage, mains supply, 7 test speed, setting, 27 threshold, 19 time setting, 32 tolerance limits, setting, 24...

- Page 79 Mecmesin MultiTest-x manual...

- Page 80 256 South Rd. Hilton RH13 0SZ South Australia 5033 England Ph (08) 8352 5511 General Enquiries: +44 (0) 1403 799979 info@si-instruments.com +44 (0) 1403 799975 www.si-instruments.com Service & Calibration +44 (0) 1403 799920 +44 (0) 1403 799925 www.mecmesin.com info@mecmesin.com DEALER STAMP...

Need help?

Do you have a question about the MultiTest-x Series and is the answer not in the manual?

Questions and answers