Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK FT

- Page 1 Translation of Original Operating Manual Assembly and Operating Manual Force-torque-sensor...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 389582 Version: 03.00 | 18/05/2021 | en...

-

Page 3: Table Of Contents

Assembly and connection................... 45 Connections...................... 45 5.2.1 Mechanical connection................ 45 5.2.2 Electrical connection ................ 52 Maintenance ...................... 54 Maintenance intervals.................. 54 Checking the measured data ................ 54 EU Declaration of Conformity ................. 55 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 4: General

Dangers for persons! Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. CAUTION Material damage! Information about avoiding material damage. 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 5: Applicable Documents

• FT Nano and FT Mini • FT Gamma, FT Delta, FT Theta and FT Omega 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 6: Warranty

A wide range of accessories are available for this product For information regarding which accessory articles can be used with the corresponding product variants, see catalog data sheet. 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 7: Basic Safety Notes

• Make sure that the product is used only in the context of its defined application parameters, Technical data 11]. 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 8: Personnel Qualification

• Wear protective gloves and safety goggles when handling hazardous substances. • Wear close-fitting protective clothing and also wear long hair in a hairnet when dealing with moving components. 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 9: Notes On Safe Operation

The incorrect handling of disposal may impair the product's safety and cause serious injuries as well as considerable material and environmental harm. • Follow local regulations on dispatching product components for recycling or proper disposal. 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 10: Fundamental Dangers

Falling and violently ejected components can cause serious injuries and even death. • Take appropriate protective measures to secure the danger zone. • Never step into the danger zone during operation. 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 11: Technical Data

Fx, Fy, Fz [Hz] 3000 7200 2200 Mx, My, Mz [Hz] 3000 7200 2200 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -2.23 03.00 | FT | Assembly and Operating Manual | en | 389582... - Page 12 Fx, Fy, Fz [Hz] 3600 3400 2800 Mx, My, Mz [Hz] 3800 3500 2300 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -4.81 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 13 Fx, Fy, Fz [Hz] 3200 1400 5200 Mx, My, Mz [Hz] 4900 1300 7300 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -18.9 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 14 Fx, Fy, Fz [Hz] 5800 5600 5200 Mx, My, Mz [Hz] 4600 5400 4200 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -18.9 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 15 Fx, Fy, Fz [Hz] 3000 2400 Mx, My, Mz [Hz] 5700 3100 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -27.1 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 16 Fx, Fy, Fz [Hz] 1400 1200 1000 1250 Mx, My, Mz [Hz] 2000 1200 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -47.4 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 17 Fx, Fy, Fz [Hz] 1500 1100 Mx, My, Mz [Hz] 1700 1100 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 18 2000 Resonant frequency Fx, Fy, Fz [Hz] Mx, My, Mz [Hz] Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -191 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 19 Resonant frequency Fx, Fy, Fz [Hz] 2100 Mx, My, Mz [Hz] 3000 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 20 Fx, Fy, Fz [Hz] 1300 1100 1200 Mx, My, Mz [Hz] 1000 1000 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -191 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 21 Fx, Fy, Fz [Hz] 1200 1400 Mx, My, Mz [Hz] 1200 Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -294 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 22 360000 Resonant frequency Fx, Fy, Fz [Hz] Mx, My, Mz [Hz] Decrease in Fz due to increasing immersion depth with IP68 protection class Decrease in Fz [N/m] -506 03.00 | FT | Assembly and Operating Manual | en | 389582...

-

Page 23: Ambient Conditions And Operating Conditions

If the force-torque-sensors are used at a different ambient temperature, the accuracy of the measured values changes. Measurement error from 22°C Nano / Mini from Gamma and larger ±5°C 0.1% 0.1% ±15°C 0.5% 0.5% ±25°C 1.5% ±50°C 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 24: Maximum Permissible Load

In this range, the force-torque-sensor still functions perfectly, but the measured values may deviate. In this range, the strain gages are in saturation, and the force-torque-sensor may get damaged. 03.00 | FT | Assembly and Operating Manual | en | 389582... - Page 25 [Nmm] [Nmm] SI-8-0.05 14.1 1/682 1/682 3/364 5/728 SI-16-0.1 28.2 1/341 1/341 3/182 5/364 SI-32-0.2 56.4 1/171 1/171 3/92 5/184 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 26 Calibration [Nmm] [Nmm] [Nmm] [Nmm] SI-12-0.12 1/320 1/320 1/64 1/64 SI-25-0.25 1/160 1/160 1/32 1/32 SI-50-0.5 1/80 1/80 1/16 1/16 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 27 Nano25 (including IP 65 and IP 68) Calibration [Nm] [Nm] [Nm] [Nm] SI-125-3 1/48 1/16 1/1320 1/2640 SI-250-6 1000 1/24 1/660 1/1320 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 28 Calibration [Nmm] [Nmm] [Nmm] [Nmm] SI-9-0.125 1/512 1/512 1/40 1/40 SI-18-0.25 1/256 1/256 1/20 1/20 SI-36-0.5 1/128 1/128 1/10 1/10 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 29 Technical data Mini27-Titan Calibration [Nm] [Nm] [Nm] [Nm] SI-40-2 3/200 3/100 3/8000 1/4000 SI-80-4 3/100 3/50 3/4000 1/2000 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 30 Calibration [Nm] [Nm] [Nm] [Nm] SI-20-1 1/200 1/100 1/8000 1/8000 SI-40-2 1/100 1/50 1/4000 1/4000 SI-80-4 1/50 1/25 1/2000 1/2000 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 31 [Nm] [Nm] [Nm] SI-62-0.75 0.75 1.25 0.0313 0.0313 0.00037 0.0006 SI-125-1.5 0.0625 0.0625 0.00074 0.0012 SI-250-3 0.125 0.125 0.00147 0.0024 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 32 Calibration [Nm] [Nm] [Nm] [Nm] SI-60-3 1/60 7/240 3/8000 1/3200 SI-120-6 1/30 7/120 3/4000 1/1600 SI-240-12 1/15 7/60 3/2000 1/800 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 33 Mini45 (including IP 65 and IP 68) Calibration [Nm] [Nm] [Nm] [Nm] SI-145-5 1/16 1/16 1/752 1/1504 SI-290-10 1/376 1/752 SI-580-20 1160 1/188 1/376 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 34 [Nm] [Nm] SI-700-30 1700 7/24 9/1600 1/320 SI-1400-60 1400 3400 7/12 9/800 1/160 SI-2800-120 2800 6800 1 1/4 9/400 1/80 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 35 [Nm] [Nm] [Nm] SI-475-20 9/112 3/28 5/1496 7/2992 SI-950-40 1900 9/56 3/14 5/748 7/1496 SI-1900-80 1900 3800 9/28 5/374 7/748 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 36 Calibration [Nm] [Nm] [Nm] [Nm] SI-32-2.5 1/160 1/80 1/2000 1/2000 SI-65-5 1/80 1/40 10/1333 10/1333 SI-130-10 1/40 1/20 1/800 1/800 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 37 Delta (including IP 60, IP 65 and IP 68) Calibration [Nm] [Nm] [Nm] [Nm] SI-165-15 1/32 1/16 1/528 1/528 SI-330-30 1/16 5/1333 5/1333 SI-660-60 1980 10/1333 10/1333 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 38 Calibration [Nm] [Nm] [Nm] [Nm] SI-1000-120 1000 2500 1/40 1/80 SI-1500-240 1500 3750 1/20 1/40 SI-2500-400 2500 6250 1/20 1/20 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 39 Calibration [Nm] [Nm] [Nm] [Nm] SI-475-20 1/14 3/28 5/1496 7/2992 SI-950-40 1900 3/14 5/748 7/1496 SI-1900-80 1900 3800 5/374 7/748 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 40 Calibration [Nm] [Nm] [Nm] [Nm] SI-1000-120 1000 2500 1/40 1/80 SI-1500-240 1500 3750 1/20 1/40 SI-2500-400 2500 6250 1/20 1/20 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 41 1800 4500 5/96 5/144 SI-3600-700 3600 9000 1 1/2 5/48 5/72 SI-7200-1400 7200 18000 1400 1400 1 1/2 5/24 5/36 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 42 Technical data Omega250 Calibration [Nm] [Nm] [Nm] [Nm] SI-4000-500 4000 8000 SI-8000-1000 8000 16000 1000 1000 SI-16000-2000 16000 32000 2000 2000 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 43 [kNm] [kN] [kN] [kNm] [kNm] SI-10000-1500 1/640 1/240 3/8000 3/16000 SI-20000-3000 1/320 1/120 3/4000 3/8000 SI-40000-6000 1/160 1/60 3/2000 3/4000 Ranges of measurement FTD, FTN, FTW, FTE resolution 03.00 | FT | Assembly and Operating Manual | en | 389582...

-

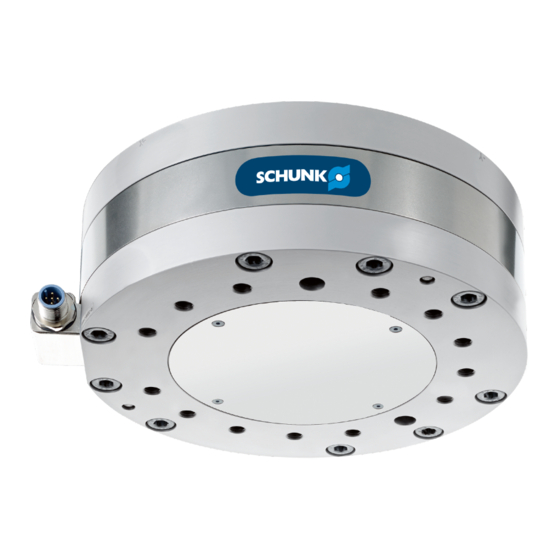

Page 44: Design And Description

Exemplary design shown on FT Gamma Removable interface plate, robot side Sensor cable connection Tool side 4.2 Description Rigid 6-axis force-torque-sensor for precise measuring in all six degrees of freedom 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 45: Assembly

The values apply to the whole mounting surface to which the mounting surface product is mounted. Requirements for evenness of the mounting surface (Dimensions in mm) Edge length Permissible unevenness < 100 < 0.02 > 100 < 0.05 03.00 | FT | Assembly and Operating Manual | en | 389582... - Page 46 Adapter plate for robot flange and adapter plate for tool side Robot Adapter plate for robot flange Mounting screws Force-torque-sensor Adapter plate for tool side End effector Alignment pin Centering collar 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 47 Only mount the sensor if the corresponding interface has • been put into operation to check the saturation. If an error occurs during assembly, wait until the error • disappears. 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 48 1. Loosen the mounting screws (1) and remove the interface plate (2). 2. Incorporate the screw connection diagram (3) of the robot into the interface plate. Observe requirements for adapter plate, ✓ Mechanical connection 47]. 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 49 4. Apply Loctite 222 threadlocker to the mounting screws (6) and (8). 5. Fasten the adapter plate (7) to the end effector (9) with mounting screws (6). 6. Fasten the end effector (9) to the force-torque-sensor (5) with mounting screws (8). 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 50 5. Apply Loctite 222 threadlocker to the mounting screws (6) and (8). 6. Fasten the adapter plate (7) to the end effector (9) with mounting screws (6). 7. Fasten the end effector (9) to the force-torque-sensor (5) with mounting screws (8). 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 51 4. Apply Loctite 222 threadlocker to the mounting screws (6) and (8). 5. Mount the adapter plate (7) on the force-torque-sensor (5) with mounting screws (8). 6. Mount the end effector (9) on the adapter plate (7) with mounting screws (6). 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 52 Leave enough clearance to allow the robot to move. • Designation Diameter [mm] Bending radius [mm] static dynamic FT-TW FT-C3 FT-CM FT-CW FT-CT 30.5 FT-C 30.5 10.0 FT-C-MTR FT-C-MTS FT-CF-MTR 42.5 FT-CF-MTS 03.00 | FT | Assembly and Operating Manual | en | 389582...

- Page 53 2. Observe the static bending radius (3) and fasten the sensor cable close to the connector (4). 3. Observe the dynamic bending radius (5) so that the robot (1) can move. 03.00 | FT | Assembly and Operating Manual | en | 389582...

-

Page 54: Maintenance

3. Position the robot arm so that an additional load is applied. 4. Record the measured output value again. 5. Determine the differences between the two measured output values and use them as the accuracy deviation. 03.00 | FT | Assembly and Operating Manual | en | 389582... -

Page 55: Eu Declaration Of Conformity

Signed for and on behalf of: SCHUNK GmbH & Co. KG Dr.-Ing. Manuel Baumeister, Technology & Innovation, Mechatronics & Sensors Lauffen/Neckar, May 2021 03.00 | FT | Assembly and Operating Manual | en | 389582... - Page 56 Translation of Original Operating Manual SCHUNK GmbH & Co. KG Clamping and gripping technology Bahnhofstr. 106 - 134 D-74348 Lauffen/Neckar Tel. +49-7133-103-0 Fax +49-7133-103-2399 info@de.schunk.com schunk.com Folgen Sie uns I Follow us...

Need help?

Do you have a question about the FT and is the answer not in the manual?

Questions and answers