Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Fronius Robacta Reamer X-Line J

- Page 1 / Perfect Charging / Perfect Welding / Solar Energy Operating instructions Robacta Reamer X-Line J Robacta Reamer X-Line J Alu Welding torch cleaning 42,0426,0240,EA 005-17022021 Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC).

-

Page 3: Table Of Contents

Table of contents Safety Instructions Explanation of Safety Instructions General Intended Use Environmental Conditions Obligations of the Operating Company Obligations of Personnel Particular Hazard Areas Personal Protection and Protection of Others EMC Device Classifications EMC Measures EMF measures Safety Measures at the Setup Location and during Transport Safety Measures in Normal Operation Maintenance and repair Safety Inspection... - Page 4 Technical data Technical data Robacta Reamer X-Line J, Robacta Reamer X-Line J Alu Appendix Circuit Diagram for Robacta Reamer X-Line J, Robacta Reamer X-Line J Alu Pneumatic Plan for Robacta Reamer X-Line J, Robacta Reamer X-Line J Alu Declaration of conformity...

-

Page 5: Safety Instructions

Safety Instructions Explanation of DANGER! Safety Instruc- tions Indicates an immediate danger. ▶ Death or serious injury may result if appropriate precautions are not taken. WARNING! Indicates a possibly dangerous situation. ▶ Death or serious injury may result if appropriate precautions are not taken. CAUTION! Indicates a situation where damage or injury could occur. -

Page 6: Intended Use

Intended Use The device is to be used exclusively for its intended purpose. The device is intended exclusively for the mechanical cleaning of Fronius robot welding torches in automatic mode. Utilization for any other purpose, or in any other manner, shall be deemed to be "not in accordance with the intended purpose."... -

Page 7: Personal Protection And Protection Of Others

Always integrate the device into a higher-level safety system in a secured area. If this area has to be accessed for preparatory or maintenance work, ensure that the entire system is shut down for the duration of access to this area and remains shut down to prevent unintended operation, e.g., as a result of a control error. -

Page 8: Emc Measures

EMC Measures In certain cases, even though a device complies with the standard limit values for emis- sions, it may affect the application area for which it was designed (e.g., when there is sensitive equipment at the same location, or if the site where the device is installed is close to either radio or television receivers). -

Page 9: Safety Measures In Normal Operation

Safety Measures Only operate the device when all safety devices are fully functional. If the safety devices in Normal Opera- are not fully functional, there is a risk of tion injury or death to the operator or a third party, damage to the device and other material assets belonging to the operating com- pany, inefficient operation of the device. -

Page 10: Disposal

Copyright Copyright of these Operating Instructions remains with the manufacturer. Text and illustrations were accurate at the time of printing. Fronius reserves the right to make changes. The contents of the Operating Instructions shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the Operating Instructions, we will be most grateful for your comments. -

Page 11: General

General... -

Page 13: General

General Principle The cleaning device is intended to auto- matically clean MIG/MAG welding torches. The cleaning device can be used to reli- ably clean the inside of gas nozzles and the face of the gas nozzles in a range of welding torch geometries. - Page 14 Type Art.No. www.fronius.com Chargen No. 24 V p max 6 bar (87psi.) Warning notices on the cleaning device WARNING! Danger of serious injuries due to: moving mechanical parts compressed air/parting agent mixture discharged from the parting- agent injection nozzle flying debris (chips, etc.) During maintenance and service, keep the device de-energized and depressurized.

- Page 15 Warning before the device switches on automatically...

-

Page 16: Transport

Transport Transport equip- Transport the device using the following transport equipment: ment On a pallet using a counterbalanced lift truck On a pallet using a lift truck Manually WARNING! Danger from devices and objects falling. This can result in severe personal injury and damage to property. ▶... -

Page 17: Scope Of Supply

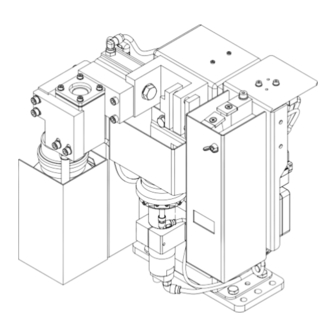

Scope of Supply Scope of Supply NOTE! The “Robacta Reamer” parting agent (item number 42,0411,8042) and the cleaning cutter are not included in the scope of supply. Work stand Cleaning device Maintenance unit Wrench for cleaning motor Compressed air relief valve Collecting container not shown: Operating Instructions... -

Page 19: Operating Controls, Connections And Mechanical Components

Operating controls, connections and mechanical components... -

Page 21: Safety

Safety Safety Please follow the safety rules below when using all the functions described in the "Oper- ating controls, connections, and mechanical components" chapter. WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in severe personal injury and damage to property. ▶... -

Page 22: Operating Controls, Connections And Mechanical Components

Operating controls, connections and mechanical components Operating Con- trols, Connec- tions, and Mech- anical Compon- ents - Front of Device Front of device Gas nozzle clamping device holds the gas nozzle in place during the cleaning process Parting agent injection device includes the parting-agent injection nozzle;... -

Page 23: Operating Controls, Connections, And Mechanical Components - Rear Of Device

Operating Con- trols, Connec- tions, and Mech- anical Compon- ents - Rear of Device Rear of device Parting agent adjusting controller to set the parting agent injection quantity Connection area for robot control Compressed air connection to supply dry compressed air at 6 bar (86.99 psi) - for more information on com- pressed air quality, see the “Specifications for the Compressed Air Supply”... -

Page 24: Operating Controls, Connections, And Mechanical Components - Side Of Device

Operating Con- trols, Connec- tions, and Mech- anical Compon- ents - Side of Device Side of device “Spray in parting agent” screw to manually check the injection device (compressed air or compressed air/parting agent mixture is sprayed out of the parting-agent injection nozzle) “Lifting device up/down”... -

Page 25: Installation And Startup

Installation and Startup... -

Page 27: Safety

Safety Safety Please follow the safety rules below when carrying out all the tasks described in the "Installation and commissioning" chapter. WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in severe personal injury and damage to property. ▶... -

Page 28: Ensuring That The Cleaning Device Is Depressurized

Ensuring that the To ensure that the cleaning device is depressurized, try to briefly activate the cleaning cleaning device device without the compressed air supply. To do this, proceed as follows: is depressurized Take protective measures: The cleaning cutter, lifting device, gas nozzle clamping device, wire cutter, and parting-agent injection nozzle could be activated. -

Page 29: Before Installation

Before installation Intended Use The cleaning device is used exclusively to mechanically clean Fronius robot welding torches in automatic mode within the limits of technical data, especially to clean the gas nozzle and gas nozzle internal space. Any other use does not constitute proper use. The manufacturer shall not be liable for any damage resulting from such improper use. -

Page 30: Measures To Ensure Safe Operation Of The Device When Operating Personnel Are Untrained

Measures to If untrained operating personnel have access to the device, the compressed air supply to ensure safe oper- the device must be disconnected for the duration of this access in accordance with "Per- ation of the formance Level d" of ISO 13849-1. device when operating person- We recommend FESTO's MS6-SV soft-start and quick exhaust valve for interrupting the... -

Page 31: Diagram Of The Programmable Logic Control (Plc)

Diagram of the programmable logic control (PLC) Diagram of the Bus module link: XXXXXXXX++ST010+IR001.ZM001-KF70 programmable Placement: XXXXXXXX++ST010+IR001.ZM001+.&EFA/1.4 logic control (PLC) Type: ProfiNet MVK-Metall DO8 /DI8 PushPull MVK-MPNIO D08 / DI8 PushPull Address: Symbolname: Function text: ++ST010+IR001.ZM001-VQ01-BG01:4 Gas nozzle free I777 ++ST010+IR001.ZM001-VQ01-BG02:4 Gas nozzle clamped I778... -

Page 32: Screwing The Cleaning Device To The Solid Surface

Screwing the Cleaning Device to the Solid Surface Screwing the NOTE! cleaning device and work stand Depending on the surface (foundation), different mounting materials may be to the surface required to assemble the work stand. The mounting materials for the work stand are not part of the scope of supply for the work stand. -

Page 33: Welding Torch Cleaning Position

Welding Torch Cleaning Position Welding Torch The welding torch (gas nozzle) must be centered over the cleaning motor / cleaning cut- Cleaning Position ter, with 1-2 mm (0.039 - 0.079 inches) distance to the protective cover. -

Page 34: Adjusting The Gas Nozzle Clamping Device

Adjusting the Gas Nozzle Clamping Device Adjusting the gas CAUTION! nozzle clamping device An incorrectly set gas nozzle clamping device may damage the cleaning device and the welding torch. ▶ When using gas nozzles with an outside diameter of 25 mm (0.98 inches), the gas nozzle clamping device must not be adjusted - the gas nozzle clamping device has already been set for the use of gas nozzles with an outside diameter of 25 mm (0.98 inches) as part of the factory calibration. -

Page 35: Fitting The Cleaning Cutter

Fitting the Cleaning Cutter Fitting the clean- CAUTION! ing cutter Burning hazard due to hot cleaning cutter as a result of operation. This can result in severe burns. ▶ Before handling the cleaning cutter, allow it to cool to room temperature (+25°C, +77°F). -

Page 36: Adjusting The Position Of The Cleaning Motor

Adjusting the Position of the Cleaning Motor Adjusting the Remove protective cover (1) position of the Remove the gas nozzle from the torch cleaning motor body Loosen the screw (2) on the lifting device Make sure that the lifting device (3) is in the bottom lift position Position the welding torch in the clean- ing position (approx. -

Page 37: Setting Up The Compressed Air Supply

Setting up the Compressed Air Supply Setting up the Set up the compressed air supply: cleaning device Disconnect the compressed air supply to the cleaning device and ensure that this compressed air compressed air supply remains disconnected while the tasks described below are supply, com- being carried out on the device pressed air relief... -

Page 38: Starting Up The Parting Agent Atomizer

Starting Up the Parting Agent Atomizer Filling the parting NOTE! agent container (1 liter) and con- Only use the “Robacta Reamer” parting agent (item number 42,0411,8042) necting it to the provided by the manufacturer. cleaning device Its composition is specifically tailored for use with the cleaning device. Correct operation is not ensured when other products are used. -

Page 39: Connecting The Parting Agent Container (10 Liter) To The Cleaning Device

Connecting the NOTE! parting agent Only use the “Robacta Reamer” parting agent (item number 42,0411,8042) container (10 liter) to the clean- provided by the manufacturer. ing device Its composition is specifically tailored for use with the cleaning device. Correct operation is not ensured when other products are used. -

Page 40: Setting The Injection Quantity Of The Parting Agent Atomizer

Setting the injec- NOTE! tion quantity of To correctly set the injection quantity, the welding torch must be in the cleaning the parting agent atomizer position. Connect the cleaning device’s compressed air supply Connect the device to the robot control Activate the injection process using the robot control and check whether the injection quantity is adequate If the injection quantity is not adequate, adjust the injection quantity as required... -

Page 41: Starting Up The Fill-Level Control Sensor

Starting up the fill-level control sensor General The fill-level control sensor releases a signal as soon as the fill level in the parting agent container falls below a defined level. Operating con- ‘OUT OFF’ key trols and displays to program the sensor on the sensor ‘OUT ON’... -

Page 42: Performing A Full Adjustment

Performing a full Fill the parting agent container with adjustment parting agent Hold the ‘OUT OFF’ key for at least 6 seconds The LED on the sensor first flashes slowly and then faster after 6 seconds after releasing the ‘OUT OFF’ key, >... -

Page 43: Manually Checking The Cleaning Device Functions

Manually Checking the Cleaning Device Functions Safety WARNING! For the following tasks, the cleaning device must be supplied with compressed air. This results in danger from the rotating cleaning cutter, cleaning motor moving up/ down, gas nozzle clamping device moving out/in, flying parts (chips, etc.), com- pressed air/parting agent mixture escaping from the parting-agent injection nozzle. - Page 44 Clamp gas nozzle/cleaning motor on Check the following while the function is executed: The function of the gas nozzle clamping device The function of the cleaning motor Clamp gas nozzle/cleaning motor on Clamp gas nozzle/cleaning motor on Cleaning motor up/down function Check the following while the function is executed: The insertion depth of the cleaning cutter into the gas nozzle Cleaning motor up/down...

-

Page 45: Start Up The Cleaning Device

Start up the Cleaning Device Requirements for The following requirements must be met in order to start up the cleaning device: Start-up Opera- Cleaning device work stand screwed tightly to the surface tion Cleaning device screwed tightly to the work stand Gas nozzle clamping device set - not when using a gas nozzle with an outside dia- meter of 25 mm (0.98 inches). -

Page 46: Cleaning Program Sequence

Cleaning Program Sequence Safety CAUTION! Danger due to improper installation and commissioning. This can result in damage to property. ▶ The cleaning device's functions must be manually checked before starting automatic operation. ▶ Only start automatic mode once the cleaning device has been installed and commis- sioned properly. -

Page 47: Cleaning Program Sequence

Cleaning Pro- Inicio gram Sequence Mover a la posición C - aprox. 25 mm (0.98 in) A unlado del cortador de hilo - Velocidad: Modo velocidad rápida Mover a la posición D - Moviéndose hacia el cortador de hilo - Velocidad: 10 cm/s (236.22 ipm) Establecer - señal externa “Cortar el electrodo de... - Page 48 Mover a la posición A - aprox. 50 mm (1.97 in) posicionada centralmente sobre el dispositivo de limpieza - Velocidad: Modo velocidad rápida Demanda de salida (señal de salida Sin tobera de gas) Demanda = baja - Baja o alta (Tobera de gas con tensor) Demanda = alta Detener...

- Page 49 Establecer - Purga de gas de aire a presión con antorcha de soldadura Restablecer - Entrada “motor de limpieza abierto” (tan pronto como la señal “motor de limpieza abierto” esté alta) Restablecer - Entrada “Tobera de gas de la brida, motor de limpieza encendido, purga de gas de aire a presión con antorcha de soldadura”...

- Page 50 Mover a la posición F (posición de inyección) - aprox. 10–35 mm (0.39–1.38 in) de profundidad dentro del dispositivo de inyección - Velocidad: 10 cm/s (236.22 ipm) Establecer - Entrada “Rociar con líquido antiproyecciones” Esperar 0.7 segundos Restablecer - Entrada “Rociar con líquido antiproyecciones”...

-

Page 51: Cleaning Device Signal Sequences

Cleaning Device Signal Sequences Cleaning device 24 VDC signal sequences 0 VDC Clamp gas nozzle, cleaning motor on Cleaning motor up/down Spray in parting agent Gas nozzle free Gas nozzle clamped Cleaning motor rotated (pulse signal) Parting agent container full Cleaning motor bottom Cleaning motor top... -

Page 52: Wire Cutter Signal Sequence

Wire Cutter Signal Sequence Wire cutter signal 24 VDC sequence 0 VDC Cut the wire electrode Wire cutter open Wire cutter closed... -

Page 53: Service, Maintenance And Disposal

Service, maintenance and disposal... -

Page 55: Safety

Safety Safety Follow the safety rules below when carrying out all the tasks described in the "Service, maintenance, and disposal" chapter. WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in severe personal injury and damage to property. ▶... -

Page 56: Ensuring That The Cleaning Device Is Depressurized

CAUTION! Danger due to hot cleaning cutter as a result of operation. Serious burns may result. ▶ Before handling the cleaning cutter, allow it to cool to room temperature (+25 °C, +77 °F). Ensuring that the To ensure that the cleaning device is depressurized, try to briefly activate the cleaning cleaning device device without the compressed air supply. -

Page 57: Service, Maintenance And Disposal

Service, maintenance and disposal General The cleaning device does not usually require maintenance. To ensure the cleaning device remains operational over time, there are a number of care and maintenance tasks that need to be carried out, however: Before every Check the fill level in the parting agent container and top up the parting agent con- start-up tainer if necessary... -

Page 58: Disposal

Disposal Materials should be disposed of according to valid national and regional rules. -

Page 59: Troubleshooting

Troubleshooting... -

Page 61: Safety

Safety Safety Follow the safety rules below when carrying out all the tasks described in the "Troubleshooting" chapter. WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in severe personal injury and damage to property. ▶... -

Page 62: Ensuring That The Cleaning Device Is Depressurized

CAUTION! Danger due to hot cleaning cutter as a result of operation. Serious burns may result. ▶ Before handling the cleaning cutter, allow it to cool to room temperature (+25 °C, +77 °F). Ensuring that the To ensure that the cleaning device is depressurized, try to briefly activate the cleaning cleaning device device without the compressed air supply. -

Page 63: Troubleshooting

Troubleshooting Errors in the Pro- Parting agent is not injected gram Sequence Parting agent container is full Cause: Injection quantity too low Remedy: Extend injection time Cause: Intake filter of the parting agent hose in the parting agent container is con- taminated Remedy: Clean the suction filter of the parting agent hose with compressed air (for... - Page 64 Lifting device does not move up or down Cause: Compressed air supply missing Remedy: Set up the compressed air supply Cause: No signal from robot Remedy: Check robot program Cause: Solenoid valve has mechanical fault Remedy: Contact service team (solenoid valve needs replacing) Cause: Throttle valve cannot be adjusted or is faulty Remedy:...

-

Page 65: Technical Data

Technical data... -

Page 67: Technical Data

Technical data Robacta Reamer Supply voltage + 24 V DC X-Line J, Robacta Nominal output 10.8 W Reamer X-Line J Nominal pressure 6 bar 86.99 psi Air consumption 420 l/min 443.81 qt./min Standard I/O (X1) Input: + 24 V DC / max. 100 mA Output: + 24 V DC / max. -

Page 69: Appendix

Appendix... -

Page 70: Circuit Diagram For Robacta Reamer X-Line J, Robacta Reamer X-Line J Alu

Circuit diagram: Circuit Diagram for Robacta Reamer X-Line J, Robacta Reamer X-Line J Alu -XS0 WHITE Q778 BLUE BLACK Q777 -XS1 Q780 BLUE BLACK Q779 -XS2 Q782 BLUE BLACK Q781 -XS4 BROWN +24V US WHITE I778 BLUE BLACK I777 +A1-X1... -

Page 71: Pneumatic Plan For Robacta Reamer X-Line J, Robacta Reamer X-Line J Alu

Pneumatic Plan for Robacta Reamer X-Line J, Robacta Reamer X-Line J Alu... -

Page 72: Declaration Of Conformity

Verantwortung, Hereby certifies on its sole se déclare seule responsable du fait dass folgendes Produkt: responsibility that the following que le produit suivant: product: Robacta Reamer X-Line J Robacta Reamer X-Line J Robacta Reamer X-Line J (Alu) (Alu) (Alu) Gasdüsenreinigungsgerät... - Page 76 FRONIUS INTERNATIONAL GMBH Froniusstraße 1 A-4643 Pettenbach AUSTRIA contact@fronius.com www.fronius.com Under www.fronius.com/contact you will find the addresses of all Fronius Sales & Service Partners and locations...

Need help?

Do you have a question about the Robacta Reamer X-Line J and is the answer not in the manual?

Questions and answers