Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Remak VCS

- Page 1 Řídicí systém pro vzduchotechnické jednotky Control units...

-

Page 3: Table Of Contents

The VCS control unit software is the intellectual property Any changes or modifications to individual components of of REMAK a.s. the VCS control unit which could affect its safe and proper functioning are forbidden. VCS control units are manufactured in accordance with... -

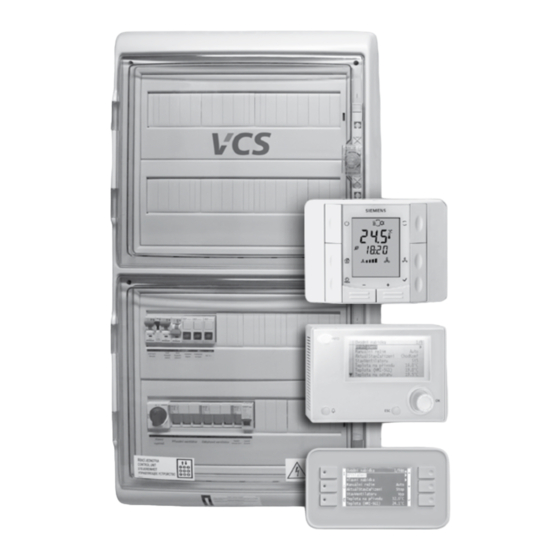

Page 4: Equipment Characteristics

In addition to local VCS controllers, so-called remote control switchboard). Both designs are equipped with transparent can be used. For this control, you need to connect VCS to LAN, doors. Th e controls are situated below these doors. Further, WAN or Internet (For production, the control unit must be the VCS control unit can be produced as a built-in assembly confi gured/ordered with the required functionality). - Page 5 "Other Controls". External control via one or two non-voltage contacts. Control from parent system When integrating HVAC with the VCS control unit into complex building management systems (BMS), it is also possible to connect to these systems. Subsequently, it is possible to control and monitor the HVAC through them.

-

Page 6: Design

Design Design Boxes Indoor VCS control units are built into plastic or sheet metal Th e control system design is based on the selection of re- cabinets with front transparent doors under which controls quired features and on its internal confi guration. Th e design are located. - Page 7 Any changes or modifi cations to individual components Th e system or device documentation also includes the oper- of the VCS control unit which could aff ect its safe and ating and inspection documentation kept during the device proper functioning are forbidden.

- Page 8 The VCS unit installed in steel switchboard boxes can also be Never use abrasive cleaners, cleaners unsuitable for plas- placed directly on the floor. The cables can be run along cable tics or acid or alkaline solutions to clean to unit.

-

Page 9: Commissioning

For a general overview of parameters available in the menu applicable local wiring standards and regulations. Before put- and access authorization of users, refer to the chapter VCS ting the unit into operation, an initial wiring inspection must – Parameter Overview and Default Factory Settings. For the be performed in accordance with the national regulations. - Page 10 Commissioning Location of Control System Sensors Figure 9 – Room sensor installation Inlet Air Temperature Sensor (NS 120) Control and anti–freeze sensors must always be situated behind the heater, respectively cooler – to measure the sup- ply air temperature. They must not be situated in the room. VO antifreeze protection sensor (NS 130R) The return water temperature sensor must be situated in the return water line from the water heater so that it will be...

-

Page 11: Control And Protection Functions

Th e fi rst device, i.e. the master controller, terminal resistor setting is performed using the soft ware (ensured by REMAK in the factory). Th e last device terminal resistor setting is performed on the last frequency inverter in the line connection. - Page 12 Main Control Features safety features are activated. The VCS control unit enables automatic control of the follow- Depending on the failure consequence, the following happens: ing basic functions for air temperature adjustment: The failure is only signalled and safety features are automati- Heating cally activated.

- Page 13 If the temperature is Electric heater control in the REMAK unit is doubled – the still falling and drops below 8°C (factory settings), the following heater thermostat failure signal is simultaneously sent to the protection actions will be immediately taken regardless of the controller and auxiliary module.

- Page 14 Control and Protection Functions Further re-lighting of the burner is possible once the protec- ence temperature (see the Data Points). The heat pump will be tion time of 150 seconds has elapsed. Modular control of started if the outdoor temperature is higher than the reference the burner is step-less based on the actual requirement (set temperature (with hysteresis of 3 °C).

-

Page 15: Additional Operating Modes And Functions

Control units VCS Control and Protection Functions Plate heat exchanger Inverter Unit and Single-Stage Condensing Unit Combination – air-handling unit run-out When cooling is required, the inverter will be switched on In some cases, the run-out will be performed when the first and then the output will be raised to the maximum. - Page 16 Depending on the technology used, control for the required Auxiliary After-Heating Function with EOS humidity can be performed by the VCS control unit or by an This function is applied when the main heater output is not autonomous control (e.g., integrated into the humidifier).

- Page 17 Fan Speed Compensation cooling – fan. So the change in the fan speed is applied first The VCS control unit system enables the pre-set fan speed and then active cooling is applied as the request for cooling is to be adjusted depending on the air temperature, air quality rising.

-

Page 18: Control (Hmi-Sg Controller)

/h. This value is then entered the Data Point Settings – Fans). as the maximum range of the sensor in the VCS using HMI. Single-Speed Fan Backups (ON/OFF Control) Note: In AC, the "Max. Air Flow Rate" is stated for the fan as- The backup motor is started if the main motor fails. - Page 19 It is necessary to set the following parameters of the VCS The operating mode determines which operating state will be control Unit (see List of HMI Data Points): active according to priorities (see Operating Modes).

- Page 20 Additional Operating Modes Air-Handling Unit Additional Operating Modes Figure 17 – Operating modes If no operating mode is applied and the time schedule mode is in the Stop state, the air-handling unit can be started from additional operating modes. The user can use the following additional operating modes to start the air-handling unit: Alarm A Night chilling...

- Page 21 Control units VCS Additional Operating Modes Night Chilling Termination If the following condition is fulfilled: During night chilling, cold outdoor air is used to cool internal > T rooms of the buildings, thus excess heat accumulated in buildings during the day in summer months is removed. Night...

- Page 22 Temperature modes The following parameters are set for the weekly and daily schedules: The VCS control unit system offers the possibility to maintain Start time (= end of previous interval) the controlled room or supply air temperature using two user...

- Page 23 5 °C to 40 °C Relative humidity < 85 % Controller Description Warning: To avoid unintentional unit start-up, the master switch must be Table 3 – Function Buttons description switched off and locked when repairing the VCS unit. Button Icon Name Function description...

- Page 24 Room temperature in °C digit and numerical) to be set, each for a different access level. (increment 0.1 °C) Factory set default rights to access the VCS control unit using the HMI controller: Room temperature in °F (increment 0.5 °F) Table 5 –...

- Page 25 Control units VCS Control (HMI-SG) Data Point List Access and Editing Communication Settings An overview of the structure of parameters accessible via the Once the HMI-SG controller has been connected to the control HMI-SG controller is available in the List of Data Points upon unit, the communication between both devices will be set logging in using the appropriate access right level.

- Page 26 HMI-SG controller's operating mode. System Date and Time Settings Here, the actual VCS system date and time can be set – First Control Unit Start-Up Using HMI-SG Controller these setting are required for correct functioning of the time 1) Press the Plus (T5), Minus (T4) and Mode (T8) buttons schedule programs.

- Page 27 Operating Screen (Examples) connected to the device failure detection inputs (incorrect state of the contact) occurs, the VCS control unit will au- After making the HMI-SG controller a service controller, it is tomatically put out an alarm in accordance with an internal possible to change the control unit settings.

- Page 28 Use the Program (T3) or Presence (T2) buttons to exit the Quick Menu. Only those values which are included within the given version of the VCS unit are displayed. Briefly press the OK (T6) button to display the values listed...

- Page 29 Control units VCS Control (HMI-SG) List of Data Points, Factory Settings Additional Operating Modes and Function Settings Warning: Additional operating modes and functions can be activated The device parameters are structured and made available to in the List of Data Points in the section Settings – Additional users in accordance with their user roles (access levels).

-

Page 30: List Of Data Points (Hmi-Sg Controller)

List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level Monitor Temperature °C Temperature in the inlet °C Temperature in the room 1 °C Temperature in the room 2 °C Room unit 1 °C Room unit 2 °C... - Page 31 Control units VCS List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 1 on 043 G Water cooler pump state 0 off 1 on 044 G Evaporator cooling stage 1 off...

- Page 32 List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level Humidifier state Settings Temperature modes 102 G Comfort - cooling 24.6 °C 104 G Comfort - heating 22.6 °C 106 G Economy - cooling °C 108 G...

- Page 33 Control units VCS List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level Inlet fan output St1 setting (a factor of 10) % (m /h, Pa) Inlet fan output St2 setting...

- Page 34 List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level + 1 stage + 2 stages + 3 stages + 4 stages 185 A For operating stage St2 - 4 stage - 3 stage - 2 stage - 1 stage...

- Page 35 Control units VCS List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 3 Heating + Cooling 198 S Air quality dependent fan speed compensation 0 No 1 Yes 199 S...

- Page 36 List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 216 A Control signal 0-10 V or 2-10 V, heat exchanger by-pass damper 0 0-10V 1 2-10V 217 A Control signal 0-10 V or 2-10 V, chamber by-pass damper 0 0-10V 1 2-10V Required inlet temperature extra set-point...

- Page 37 Control units VCS List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 274 U Heat pump 0 no 1 variation A 2 variation B 275 U Type of gas heating...

- Page 38 List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 340 U Cooling end point (outdoor temperature) °C 342 U Maximum cooling compensation (speed) -100 100 344 U Heating initial point (outdoor temperature) °C 346 U Heating end point (outdoor temperature)

- Page 39 Control units VCS List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 268 S The signal voltage request of START (Toshiba) Cooling 394 U Outdoor temperature to enable cooling – all versions °C...

- Page 40 List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level Mixing Minimum fresh air value setting Minimum fresh air value setting – Comfort mode (pool unit) Minimum fresh air value setting – Economy mode (pool unit) 485 U Minimum fresh air flow rate setting 487 U...

- Page 41 Control units VCS List of Data Points (HMI-SG controller) List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 1 decrease 556 U Compensation display Humidity-dependent mixing damper position compensation 560 A...

- Page 42 List of Data Points (HMI-SG controller) Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 678 A Derivative factor - AP from return water 680 A Proportional factor - AP from inlet air 682 A Integrating factor - AP from inlet air 684 A Derivative factor - AP from inlet air 686 A...

- Page 43 Control units VCS Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 770 S 771 A Derivative factor Difference between required and inlet temperature monitoring 802 G Maximum difference (±°C) °C 804 G Minimum limit (°C) °C...

- Page 44 Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 843 S Number of message repeating during error transfers 844 S Number of error transfers for communication failure evaluation 845 S Frequency inverter 1 address, inlet fan 846 S Frequency inverter 2 address, inlet fan backup or second inlet fan 847 S...

- Page 45 Control units VCS Menu HMI-SG Factory Settings Parameter Notation Reading Value Meaning code level code level 898 A Displayed time format - 12h/24h 0 24 h 1 12 h Passwords 899 S Password for Service level access 9999 901 A...

-

Page 46: List Of Failures (Hmi-Sg Controller)

List of Failures (HMI-SG controller) Failure Failure Causes Description Reduced humidifi- Reduced humidification output due to the temperature priority (swimming-pool unit) cation output – an information message. 1.) Communication error between control unit and the auxiliary fan frequency inverter (Modbus data bus) – inverter internal error; wrong settings of the frequency inverter data points –... - Page 47 Control units VCS List of Failures (HMI-SG controller) (continuation) Failure Failure Causes Description Outdoor temperature Information message – The heat pump blocked due to outdoor temperature dependent heat pump blocking Heat pump Heat pump failure – contact Humidification Humidifier failure - contact...

- Page 48 List of Failures (HMI-SG controller) (continuation) Failure Failure Causes Description Electric reheating Electric after-heater failure - thermostat Water heater Water heater pump failure - contact pump Water heating ad- ditional antifreeze Electric heating additional PMO - thermostat protection (PMO) Inlet fan Backup inlet fan error - thermo-contact 1.) Backup inlet fan error - flow sensor Inlet fan (air-...

-

Page 49: Remak Mobile App

(from v. 4.0.3) in installations / applications where you can use Wi-Fi LAN and / GSM mobile data to connect to the Internet. Mobile applications such as HMI to VCS serve as a user-friendly driver for basic HVAC control - triggering desired mode (+ switching off), setting (user-friendly parameters only) and simple operation overview (feedback). - Page 50 HMI-DM (HMI-TM) control devices ensure communication Figure 23 – HMI-DM cotroller between the VCS control unit and the user. Th ey are intended for air-handling device control, handling and service. Th e HMI control device can be connected to the POL4xx or POL6xx Info controllers.

- Page 51 Control units VCS Control (HMI-DM,HMI-TM controllers) Figure 24 – Installation on a Wall Table 2 – Function Buttons Button Activity Description (Name) - Scrolling the list upwards Press - Increases the parameter value - Hold this button longer than 1.5 s to speed up the...

- Page 52 Control (HMI-DM,HMI-TM controllers) Value Settings Display Layout If the description and value of the parameter is highlighted on Figure 26 – LCD isplay the line, the highlighted value can be changed. Turn the knob (or use the Up and Down buttons) to select the line.

- Page 53 80 m. Switch the HMI@Web main switch on. If a greater distance between the PC and the VCS control unit controlled by the HMI@Web controller is desired, it will be necessary to use a structured network (Ethernet) including active network elements – see * This cable is not part of delivery.

- Page 54 Control (HMI@Web – Connection to PC and LAN/WAN) Connection of the VCS control unit After setting the HMI@Web unit (following the below de- with the HMI@Web controller to the LAN scribed procedure), and when the HMI@Web default address complies with network addressing, it is only necessary to en- Warning able new hardware in the infrastructure administration –...

- Page 55 Control units VCS Control (HMI@Web – Connection to PC and LAN/WAN) 3rd Step Setting the Web@HMI for Connection Figure 35 – Log-in screen The Web@HMI controller can be configured from the web interface (the same one which serves for normal operation of the system).

- Page 56 Control (HMI@Web – Connection to PC and LAN/WAN) 4th Step: How to Change the HMI@Web Controller IP Then it is necessary to send (plan) the change entry – after Address that, the settings must be finished using the option "Apply + +Reset".

- Page 57 IP address via port 80 (http). Other communication ports must be DISABLED to keep the operation secure! REMAK does not bear any responsibility for any misuse of the HMI@Web software (Windows CE) or unauthor- ized penetration of the inner LAN network due to insuf- ficient inner network security.

- Page 58 Control (HMI@Web – Connection to PC and LAN/WAN) Internet Settings (Explorer Cookies): Figure 43 – Temporary Files' Settings (IE) Go to the Internet Explorer menu "Tools" / "Internet Options" >> "Privacy" >> "Advanced" >> "Accept Cookies" (see fig. # 16) Figure 41 –...

- Page 59 Control units VCS Control (HMI@Web – Connection to PC and LAN/WAN) Basic HMI@Web Operation HMI@Web Environment Description Settings – Recapitulation Th e Web controller HMI@Web is controlled using the fol- The basic HMI@Web system commissioning settings to lowing buttons: prepare it for operating staff :...

-

Page 60: Scada (Supervisory Control And Data Acquisition)

The VCS is equipped with a web server running SCADA VCS. time is assigned with a desired program state (fan speed Just connect the VCS to the LAN / WAN and then use the stages and temperature mode). The program state can be... - Page 61 Control units VCS List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Menu HMI-DM,HMI-TM a HMI@WEB Factory settings Menu Meaning Value Units Monitor Monitor Current modes Current modes ActStateEquipment Current device state FanStageExtCnt Fan output stage (external control) FanStatus Fan state...

-

Page 62: List Of Data Points (Hmi-Dm, Hmi-Tm And Hmi@Web Controller)

List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Menu HMI-DM,HMI-TM a HMI@WEB Factory settings Menu Meaning Value Units StateHumidifier Humidifier state Settings Settings Date Date and Time time TimeValidity System time validity Temp modes Temperature modes Comfort - Heating Comfortable heating 22.6 0 °C... - Page 63 Control units VCS List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Menu HMI-DM,HMI-TM a HMI@WEB Factory settings Menu Meaning Value Units RundownTmTrans Time transition to 1St speed - two-speed fans BlckHighSpeedFan Outdoor temperature-dependent fan speed interlocking °C ForceStrtTimOn1St Forced fan start-up to 1St speed (TRN – damper output absent) °C...

- Page 64 List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Menu HMI-DM,HMI-TM a HMI@WEB Factory settings Menu Meaning Value Units MinRunTm Minimum operating time for heat pump heating 9999 BlckTmAgainStrt Re-heating blocking ActiveHeatPump Heat pump switching on HysOffHeatPump Digital output opening hysteresis AlarmFromOutTmp Information - outdoor temperature dependent heat pump heating blocking StartAnalogVal...

- Page 65 Control units VCS List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Menu HMI-DM,HMI-TM a HMI@WEB Factory settings Menu Meaning Value Units CompHEnd Heating end point (outdoor temperature) °C MaxValCompStgHtg Maximum heating compensation (speed) -100 100 ActValComStgFanHtg Current heating speed compensation...

- Page 66 List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Menu HMI-DM,HMI-TM a HMI@WEB Factory settings Menu Meaning Value Units GasHeatingMaximalTempFlueGas Maximum temperature of flue gas PropFactor Proportional factor IntegFactor Integrating factor DifferFactor Derivative factor GasHeatingMinimumTempFlueGas Minium temperature of flue gas PropFactor Proportional factor IntegFactor...

- Page 67 Control units VCS List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Menu HMI-DM,HMI-TM a HMI@WEB Factory settings Menu Meaning Value Units PropFactor Proportional factor IntegFactor Integrating factor DifferFactor Derivative factor HrecDampCompHumidity Humidity-dependent mixing damper position compensation factors PropFactor Proportional factor...

- Page 68 List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) Function activation - Max. limit of fresh air ac- ActiveMaxFrshAirDHrec cording to T outdoor (vent. unit) Apply + Reset Reset after configuration of additional modes/functions HMI-SG HMI-SG DisplayedRoomTemp Room temperature display, combined or inlet temperature SetpoitRangeCorr Required value compensation setting +/- °C...

- Page 69 Control units VCS List of Data Points (HMI-DM, HMI-TM and HMI@WEB controllers) ActGatewayAdr Current gate address GivenIPAdr IP address input GivenMaskAdr Mask address input GivenGateAdr Gate address input HostName Host name MACAdrress MAC address Web user name HMI@WEB user name:...

- Page 70 List of failures (HMI-DM, HMI-TM and HMI@WEB controllers) Failure name Failure Description SupplyTmpSnsr Inlet air temperature sensor RoomTmpSnsr Room air temperature sensor HMI-SG1 Local HMI-SG1 controller HMI-SG2 Local HMI-SG2 controller ReturnAirTmpSnsr Outlet air temperature sensor OutTmpSnsr Outdoor temperature sensor HtgFrstTmpSnsr Return water temperature sensor FrostTmpSnsrHeatEx Antifreeze protection temperature sensor...

-

Page 71: List Of Failures (Hmi-Dm, Hmi-Tm And Hmi@Web Controller)

(outlet) air temperature monitoring. Remote Signalling HeatPumpDefrost Heat pump defrosting function The VCS Control unit can optionally be equipped with one or two outputs for remote signalling. Inlet Pressure Unconnected or damaged Depending on the configuration, the following: pressure sensor - inlet fan Only failure (non-potential contact, max. -

Page 72: Connection To The Master System (Lonworks Standard)

Controller Menu. Thus it can Network Variable: nviPress_Flow03 be determined if the outdoor temperature sensor is connected directly Description: Not used to the VCS control unit or its temperature reading is sent through the Object: SNVT_count communication (LonWorks). Network Variable: nviPress_Flow04... - Page 73 Control units VCS Connection to the Master System (LonWorks Standard) Active Req. cooling temperature (Comfort) Default: Value: Not used State: Req. heating temperature Remark: The State must be set to "1" to be used (cascade, inlet) for the Value Req. cooling temperature...

- Page 74 Connection to the Master System (LonWorks Standard) Network Variable: nvoPress02 Network Variable: nvoPerc09 Description: Not used Description: Air humidity in the inlet Object: SNVT_press_p Object: SNVT_lev_count Network Variable: nvoPress_Flow00 Network Variable: nvoPerc10 Description: Current request for the inlet fan Description: Air humidity in the room Object: SNVT_flow...

- Page 75 Control units VCS Connection to the Master System (LonWorks Standard) Cooling DX, 2st >5 Not defined Heat recovery State: Inactive Active Water heating - pump Network Variable: nvoState Electric heating, Stop Description: Alarm classes, Control mode Electric heating, 1st Object:...

- Page 76 Connection to the Master System (LonWorks Standard) Pressure differences (air-flow), outlet Remark: *The bit name order can be reversed in some LON software tools Outdoor air humidity Air humidity difference, inlet Network Variable: nvoDO Air humidity difference, room 53 Description: Alarms Dew point Object:...

-

Page 77: Connection To The Master System (Modbus Standard)

The Modbus communication protocol works using the Master/ 16-bit for real values (Unsigned Word) Slave principle. The Slave function is used for the VCS control 16-bit for status values (Signed Word) unit communication with the master system. Thus, the VCS... - Page 78 VCS control system variants at the discretion of REMAK a.s. For example, if the VCS control system (air-handling device) has not been equipped with gas heating, it will not be possible to use these variables.

- Page 79 Control units VCS Connection to the Master System (ModBus Standard) Input states (Read) (continuation) Adress Description Values/Units Remarks 1x0027 Supply fan alarm OK*Alarm 1x0028 Supply fan fdbk OK*Alarm 1x0029 Sply fan deviation Passive*Active 1x0030 Exhaust fan alarm OK*Alarm 1x0031 Exhaust fan fdbk...

- Page 80 Input states (Read) (continuation) Adress Description Values/Units Remarks 1x0064 1x0065 1x0066 1x0067 1x0070 Filter alarm OK*Alarm 1x0071 Supply filter alarm OK*Alarm 1x0072 Exh filter alarm OK*Alarm 1x0073 Fire alarm OK*Alarm 1x0074 Supply tmp fire alm OK*Alarm 1x0075 Exh tmp fire alarm OK*Alarm 1x0076 Inlet temperature (antifreeze protection)

- Page 81 Control units VCS Connection to the Master System (ModBus Standard) Input states (Read) (continuation) Adress Description Values/Units Remarks 1x0101 1x0102 RmUTmp1 °C OK*Alarm 1x0103 RmUTmp2 °C OK*Alarm 1x0104 BrnrFlueTmp °C OK*Alarm 1x0105 PreElHtgTmp °C OK*Alarm Input register (Read) Adress Description...

- Page 82 Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks Bit6 Bit7 Bit8 Bit9 Bit10 Bit11 Bit12 Bit13 Bit14 Bit15 3x0006 Digital inputs (Word 2) 0-65535 0-1 for each bit or counted binary to a decimal number Bit0 Bit1 Bit2...

- Page 83 Control units VCS Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks Bit6 Bit7 Bit8 Bit9 Exhaust fan, running Bit10 Exhaust fan, off Bit11 Bit12 Bit13 Bit14 Bit15 3x0010 Digital outputs (Word 2) 0-65535...

- Page 84 Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks Bit6 Heat pump DO 1 Bit7 Bit8 Extra el heating, off Bit9 Extra el heating, stage 1 Bit10 Bit11 Bit12 Bit13 Request for humidification Bit14 Bit15 3x0012 Digital outputs (Word 4)

- Page 85 Control units VCS Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks Bit7 Exhaust back up Bit8 Cooling Bit9 OverHeat Burner heating Bit10 Heating recovery Bit11 Bit12 Heating recovery frost Bit13 Bit14 Heating recovery damper...

- Page 86 Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks Bit8 Bit9 Bit10 Bit11 Bit12 Bit13 Room unit 1,2 - temperature Bit14 Supply temperature deviation Bit15 Room/Exh temp deviation Alarms (Word 4) 3x0016 0-65535 0-1 for each bit or counted binary to a decimal number Bit0 Supply press/flow deviation...

- Page 87 Control units VCS Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks 10=Stop 11=OverRun 12=StartUp 12=Start 3x0018 Act fan step Off*Stage1*Stage2*St age3*Stage4*Stage5 3x0019 3x0020 Op mode man st/tmp 0-11 Auto*Off*Eco St1*Comf St1*Eco St2*Comf St2*Eco St3*Comf...

- Page 88 Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks 3x0041 Htg pump cmd Off*On 3x0042 El htg outp signal 0 - 100% 3x0043 El heating cmd Off*On 3x0044 Heat pump Cooling 0 - 100% 3x0045 Heat pump 0 - 100%...

- Page 89 Control units VCS Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks 3x0078 3x0079 3x0080 3x0081 3x0082 3x0083 3x0084 Outdoor air humidity - relative %r.H. 3x0085 Outdoor air humidity - absolute `-x.y - +x.y g/kg...

- Page 90 Connection to the Master System (ModBus Standard) Input register (Read) (continuation) Adress Description Values/Units Remarks 3x0113 Act exh fan stpt 0-100% (0 - x l/s) 3x0114 3x0115 3x0116 3x0117 3x0120 Hour 3x0121 Minute 3x0122 Second 3x0123 Year 3x0124 Month 3x0125 3x0130 Burner flue temp °C...

- Page 91 Control units VCS Connection to the Master System (ModBus Standard) Holding register (Read/Write) [03:H] (continuation) Adress Description Values/Units Remarks Bit13 Bit14 Bit15 Unsigned Word Present value 4x0005 Control state required by BMS Auto*Off*St1*St2*St3* (variant without air temperature St4*St5 conditioning) 4x0006 Device state –...

- Page 92 Connection to the Master System (ModBus Standard) Holding register (Read/Write) [03:H] (continuation) Adress Description Values/Units Remarks 4x0033 4x0034 4x0035 4x0036 Sply max limit `-x.y - +x.y °C (factor 10) Higt limit 4x0037 Sply min limit `-x.y - +x.y °C (factor 10) Low limit 4x0039 Set-point of relative humidity - Comfort 0 - x %r.H.

- Page 93 Control units VCS Connection to the Master System (ModBus Standard) Holding register (Read/Write) [03:H] (continuation) Adress Description Values/Units Remarks Advanced mode Signed Word PresentValue 4x0070 4x0071 4x0072 4x0073 4x0074 4x0075 4x0076 4x0077 4x0078 4x0079 4x0080 4x0081 4x0082 CaseFlowLimtMinDev °C (factor 10)

- Page 94 Connection to the Master System (ModBus Standard) Holding register (Read/Write) [03:H] (continuation) Adress Description Values/Units Remarks 4x0104 4x0105 4x0106 4x0107 4x0108 4x0109 4x0110 4x0111 4x0112 4x0113 4x0114 4x0115 4x0116 Control constants 4x0201 Cooling (factor 100) Gain - Signed Word 4x0202 Cooling 0 - x sec Integral - Unsigned Word...

- Page 95 Control units VCS Connection to the Master System (ModBus Standard) Holding register (Read/Write) [03:H] (continuation) Adress Description Values/Units Remarks 4x0223 Electrical heating 0 - x sec Integral - Unsigned Word 4x0224 Electrical heating 0 - x sec Differential - Unsigned Word...

- Page 96 Connection to the Master System (ModBus Standard) Holding register (Read/Write) [03:H] (pokračování) Adress Description Values/Units Remarks 4x0260 Exhaust fan 0 - x sec Differential - Unsigned Word 4x0261 Humidification (divider 100) Gain - Signed Word 4x0262 Humidification 0 - x sec Integral - Unsigned Word 4x0263 Humidification...

-

Page 97: Connection To The Master System (Bacnet Standard)

BACnet/IP (BMS) restart and other settings of the BACnet server can be carried out through the web page (calling the address set in the VCS The VCS control unit enables integration of the centralized control unit). For detailed information on the BACnet/IP Stand-... - Page 98 Connection to the Master System (BacNet Standard) List and Description of Basic Data Points ((continuation)) OpModeBmsTimeSt.Swtch BMS control mode (control, master system) OpModeBmsTimeStTmp.Swtch BMS control mode (control, master system) TmpSpv.CoSpvHtg Required value for heating - Comfort TmpSpv.CoSpvClg Required value for cooling - Comfort TmpSpv.EcSpvHtg Required value for heating - Economy TmpSpv.EcSpvClg...

-

Page 99: Pool Units - Descriptioon Of Control

Control units VCS POOL UNITS – description of control The VCS also allows the control of air-conditioning units Pro-Vapor Pool Unit (Units without Integrated Heat Pump) designed to ventilate swimming pools (swimming pools, water - The required humidity is achieved by mixing. By supplying parks, rehabilitation complexes with water procedures, etc.). - Page 100 POOL UNITS – description of control Circulating damper intervention is the same, except for the inlet and outlet dampers, which are controlled according to the humidity Enabled in economy mode heating or dehumidification stage requirement (Economy mode, dehumidification of the 1st 1.

-

Page 101: Plc Controller For Compressor Output Control

Control units VCS PLC Controller for Compressor Output Control The selection is made by the relay – KA11 (closed = heating). Then the unit output is controlled by the 0-10V analogue signal. Operation of the unit is indicated by a dry contact, the same way as an error. - Page 102 PLC Controller for Compressor Output Control Viewing Temperatures and Alarms 2. Using the buttons, select "PASS" and press the SET button to confirm. 3. Using the buttons, enter the numerical code Viewing Temperatures required for the parameter group in question (Level 1 or 1.

- Page 103 Control units VCS PLC Controller for Compressor Output Control P-17 Coolant: Used coolant type. Application Version Settings (0= R404A, 1=R22,2=R744, 3 = R290, 4 = R134A, 5 = R407C, 6 = R410A, 7 = R427A, 8 = R507A). One compressor with output P-32 PID HP Udz: PID control upper insensitive zone.

- Page 104 PLC Controller for Compressor Output Control Additional Display Views (P-79 parameter) Code Description Outr The sensor is out of the measuring range. An06 Digital compressor discharge temperature. An10 Evaporation temperature An11 Condensation temperature An12 Evaporation pressure An13 Condensation pressure An14 Inlet temperature 1 An15 Inlet temperature 2...

- Page 105 Control units VCS PLC Controller for Compressor Output Control Standard Setting Values Code Description Range: Def. P-51 PID Cond Ti 100.0 S-00 Set Te -10.0…10.0°C P-52 PID Cond Td S-01 Set Tc 30.0…90.0°C 63.0 P-53 PID Cond _Utz S-02 Set Cond 20.0…S-01°C...

-

Page 106: Electronic Expansion Valve Overheating Controller Ec3-X33

Electronic Expansion Valve Overheating Controller EC3-X33 If the output relay is not used, the user must ensure proper safety regarding power supply breakdown-related failures. Output for EX4 at 24 V DC, max. 0.8 A to 8 valves 0...60 °C 1...25 °C (the longest Teplota okolí... - Page 107 Control units VCS Electronic Expansion Valve Overheating Controller EC3-X33 Conductor Marking and Purpose Digital input I operation according to com- EX valve connection using terminated cable mands for the compressor/thermostat (A white, B black, C brown, D blue) Operating EX8 (respectively EX7)

- Page 108 Electronic Expansion Valve Overheating Controller EC3-X33 ECD-002 Display with Buttons (LED Indicators and Settings) Flashes: The valve opens. On: The valve is open Flashes: The valve closes. Settings: Parameter On: The valve opens. Increases Scrolls On: Command to run Off: N/A Flashes: Exhaust On: Alarm Decreases...

- Page 109 Control units VCS Electronic Expansion Valve Overheating Controller EC3-X33 Main Parameters – change if other settings are desired Factory Actual Code Parameter description and options Min. Max. settings settings Password Coolant: 0 = R22 1 = R134a 2 = R507 3 = R404A 4 = R407C 5 = R410A 6 = R124...

- Page 110 Electronic Expansion Valve Overheating Controller EC3-X33 ECD-002 Display Installation The ECD-002 display can be connected at any time during operation. The EC2-371 is integrated into a 71 x 29mm panel – see dimensional drawing. Insert the device into the panel (1). The swivel lugs must be inserted into the device edges.

- Page 111 Control units VCS Electronic Expansion Valve Overheating Controller EC3-X33 Illustrative Procedure of EC3-X33 and ECD-002 Settings Data display Dimensions EX3-X33 EX3-X33 EX3-X33 ECD-002...

-

Page 112: Khd-S1

KHD-S1_ _.R Backup System Wiring Diagram Capacity control 0...10 V Faults Fresh air Unit Alarm Comp Mode: Header Heat/Cool ON/OFF Main switch Failure Filter Filtr (21/28bar) 4...20 mA Relief air Valve in position without power (Cu8 -50) (1.7/2.7bar) 4...20 mA Building wall Legend: Note: The 4-way valve is displayed in the "cooling"... -

Page 113: Unit Activation

Control units VCS Unit Activation Unit Activation Unicon Air Flow Sensor Settings Sensor operation (Mode) – set to 5.00 Check the correct interconnection of the control unit and air- Adjust measuring range in Pa (in accordance with max. pres- handling unit. Check the motors (frequency inverters) - power sure of the fan). - Page 114 Unit Activation Coolant Handling To ensure stepless air-flow control using the Unicon sensor and to prevent the fan output cycling, we recommend setting The used HFC type coolants (e.g. R404A, R407C, R410A,…) the frequency inverter start-up and run-down ramps to 180 fall into the category of monitored greenhouse substances s (Danfoss frequency inverter –parameters 3-41 and 3-42).

- Page 115 If a failure (incorrect state of the contact) Electric Heater Specialities occurs, the VCS control unit will automatically put out an alarm in accordance with an internal algorithm – indicating The EOS series electric heater design provides safe, reliable the faulty object and in case of severe failures stopping the and long service life.

-

Page 116: Troubleshooting

Verify the water cooler circulation pump activation and operation (at active cooling signal above 20% = 2V) Spare parts are not included in the VCS unit delivery. Antifreeze Protection Sensor Failure If any spare parts are needed, they can be ordered from the manufacturer or regional distributor. -

Page 117: Disposal And Recycling

Printing and language mistakes are reserved. These Installation and Operating Instructions (as a whole or a part) must not be printed or copied without prior written permission from REMAK a. s., Zuberská 2601, Rožnov pod Radhoštěm, Czech Republic These Installation and Operating Instructions are the sole property of REMAK a. - Page 118 REMAK a.s. Zuberská 2601, 756 61 Rožnov pod Radhoštěm, tel.: +420 571 877 778, fax: +420 571 877 777, email: remak@remak.eu, internet: www.remak.eu...

Need help?

Do you have a question about the VCS and is the answer not in the manual?

Questions and answers