Table of Contents

Advertisement

Quick Links

perator's

nual

I:RRF rSMAN+

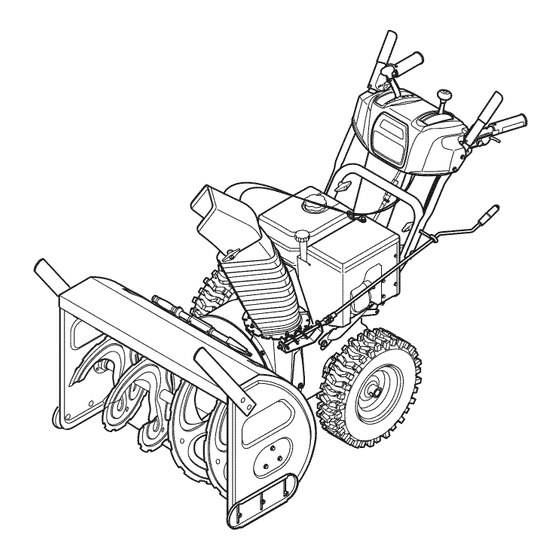

Electric Start

SNOW THROWER

Model No. 247.883971

CX

IES

CAUTION"

Before using this product,

read this manual and follow

all safety

rules and operating

instructions.

,, SAFETY

o ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

Sears Brands Management

Corporation,

Hoffman

Estates,

IL 60179, U.S.A.

Visit our website:

www.craftsman.com

Form No. 769-08168B

(June 17, 2013)

Advertisement

Table of Contents

Summary of Contents for Craftsman 247.883971

- Page 1 I:RRF rSMAN+ Electric Start SNOW THROWER Model No. 247.883971 ,, SAFETY o ASSEMBLY OPERATION MAINTENANCE PARTS LIST CAUTION" Before using this product, o ESPANOL read this manual and follow all safety rules and operating instructions. Sears Brands Management...

- Page 2 FORTWO YEARSfrom the dateof purchase,this productis warrantedagainstanydefectsin materialor workmanship. A defective productwill receivefree repairor replacementif repairis unavailable. Forwarranty coverage details to obtain free repairor replacement, v isit the web site: www.craftsman.com Thiswarranty coversONLYdefects in material and workmanship. Warranty coveragedoes NOT include: •...

- Page 3 Thissymbolpointsout importantsafety instructionswhich, if not Thismachinewasbuilt to beoperatedaccordingto the safeoperation followed, could endangerthe personalsafetyand/or property of practicesin this manual.Aswith anytype of powerequipment, yourself and others.Readandfollow all instructions in this manual carelessness o r error on the part of the operatorcanresultin seriousinjury. beforeattempting to operatethis machine.Failureto complywith these Thismachineiscapableof amputating fingers, hands,toesandfeet and instructions m ay resultin personalinjury.Whenyou seethis symbol, HEED...

-

Page 4: Operation

To r educe fire hazards, keep machine free o fgrass, leaves, or other debris Use onlyattachments andaccessories approved bythe manufacturer ( e.g. build-up. Clean up oil o r fuel spillage and r emove any f uel soaked debris. wheelweights,tire chains,cabs etc.). Never store the machine or fuel container... -

Page 5: Spark Arrestor

Check fuelline,tank,cap,andfittings frequentlyfor cracks or leaks. R eplace if necessary. Donot crankenginewith sparkplug removed. According to the Consumer Products S afetyCommission ( CPSC) andthe U.S. E nvironmental Protection Agency (EPA), thisproducthasan Average Useful Life of seven (7)years, o r 60 hoursofoperation. A tthe endof the Average Useful Life havethe machine inspected annuallybyan authorized service dealerto ensure that all mechanical andsafetysystems areworkingproperly andnotwornexcessively. -

Page 6: Safety Symbols

SAFETY SYMBOLS Thispage depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to assemble and operate. READ THE OPERATOR'S MANUAL(S) Read, understand, and follow all instructions in the manual(s) before attempting to assemble operate WARNING--... - Page 7 NOTE: R eferences to rightor left sideof the snowthroweraredetermined from the operatingpositionlookingforwardto the front of the machine. Removing From (:rate Remove s crews from the bottomofthe cratesecuring the sides, a ndendsof the shippingcrate. Liftoff the top off of the crateandsetout of thewayofthe assembly area. Remove a nddiscard plasticbagthat covers unit.

- Page 8 Set-Up ShearPins Apair o freplacement auger shear pins and bow tiecotter pins have b een i ncluded with your snow thrower. They a re stored i ntheholes provided intheplastic dash p anel as seen i n Fig ure7.For i nformation regarding replacing theshear pins, see Replacing Shear Pins i nthe...

- Page 9 Drift Cutters Adding Fuel Thesnowthrowerdrift cuttersaremountedinverted a t the factoryforshipping purposes. Useextreme carewhen handling gasoline.Gasolineisextremely Remove t he fourwing knobs(twooneachside)andcarriage bolts.Place flammable andthe vaporsareexplosive. Neverfuel the machineindoorsor drift cutter inuprightpositionandre-secure. S eeFigure 9. while the engine ishotor running. E xtinguish cigarettes,cigars,pipesand othersources of ignition.

- Page 10 Whileobserving the distance betweenthe shave plateandthe ground, adjustthe skidsshoes upor down toachieve the desiredshave plateheight. SeeFigure 12. Makecertainthe entirebottomsurface ofskidshoes areagainst t he ground to avoiduneven wearonthe skidshoes; t hentighten nutsandboltssecurely. Lower Shave Shave Plate Plate Figure 11 NOTE: Onsomeengines, a threadedscrew capwill bepresent i nstead of the quarter Raise turn lockingcap.In the instance of athreadedoil cap/dipstkk,DONOT screw the Shave...

- Page 11 Confirm that the augerhascompletely stoppedrotatingandshows NOsigns of motion.Ifthe augershows ANY signs of rotating,immediately returnto the operator's positionandshutoffthe engine.WaitforALLmovingpartsto stopbeforere-adjusting the augercontrol. Testing Drive Control & SpeedSelector Lever Withthe engineturnedoff, movethespeed selectorleverinto sixth(6) position.Refer t o Figure 13. Withthe wheeldrivecontrolreleased, pushthe snowthrowerforward,then pull it back.

-

Page 12: Speedselector Lever

IMPORTANT: Donot turnthe keyinanattemptto startthe Reverse engine.Doingsomaycause it to break. There aretwo reverse (R)speeds. O ne(R1)is the slower a ndtwo (R2)isthefaster. Meets ANSi Safety Standards Craftsman Snow Throwers conform to the safety standard of the American National Standards institute (ANSI). - Page 13 ThrottleControl AugerControl ===..__ Thethrottlecontrolislocatedonthe rearofthe engine.It regulates the speed ofthe engineandwill shutoffthe enginewhen moved intothe STOP p osition. Primer carburetor t o aidinstartinga"Cold"engine,or restartinga Pressing t he primerforces fueldirectlyinto the engine's _,_P_.._.L warmengine. Oil Fill Theaugercontrolislocatedonthe left handle.Squeeze t he control g ripagainstthe handle to engage the augerandstartsnowthrowingaction.Release t o stop.

- Page 14 Chute Clean-Out Tool Two-Way Chute-Pitch Control Thetwo-waychute-pitchcontrol i s located on the [eft sideofthe handle paneland Thechuteclean-outtoolisconveniently f astened tothe rearof the augerhousing isusedto controlthe distance of snowdischarge f rom the chute. with a mountingclip.Should snowandicebecomelodgedinthe chuteassembly duringoperation, p roceed asfollowsto safely cleanthe chuteassembly a ndchute Tochange the upperchuteangleto control t he distance thatsnowisthrown, opening: pivotthe [everforwardor backward.

-

Page 15: Starting The Engine

Gasoline Theextensioncordcan beany length, but must be ratedfor 15ampsat 125 Useextreme carewhenhandling gasoline.Gasolineisextremely flammable volts,groundedand ratedfor outdoor use. and the vapors areexplosive.Neverfuel the machineindoorsor while the Ifyouhaveagrounded three-prongreceptacle, proceed asfollows.If youdonot engine ishot or running. Extinguishcigarettes, cigars,pipesand other have the properhouse wiring, DO NOT usethe electricstarterunderanyconditions. sourcesof ignition. -

Page 16: Stopping The Engine

ReplacingShearpins Theaugers aresecured to thespiralshaftwith shearpinsandbow-tiecotterpins. Toavoid unsupervisedengineoperation, never leavethe machine Ifthe augershouldstrikea foreignobjector icejam, the snowthrowerisdesigned unattendedwith the engine running.Turnthe engine off after useand sothatthe pinsmayshear.Ifthe augers will not turn, check to seeif the pinshave remove key. sheared.SeeFigure 17. Stopping The Engine NOTE: Twoextrashear p insaresupplied in the manual b ag. -

Page 17: Maintenance

MAINTENANCE SCHEDULE Followthe maintenance s chedule givenbelow.This chartdescribes s ervice Beforeperforming anytypeof maintenance/service, d isengageall controls guidelines only.Use the Service Logcolumn to keeptrackofcompleted andstop the engine.Wait until all moving partshavecometo acomplete maintenance t asks.Tolocatethe nearest S ears Service C enter o r to schedule service, stop.Remove the keyto preventunintended starting. - Page 18 Ifthe engine hasbeenrunning, the muffler will be veryhot. Becareful not to touchthe muffler. NOTE: C heck t he sparkplugonceaseason or every25hoursof operation. C hange the sparkplugonceaseason or every100hours. Toensureproper e ngineoperation, t he sparkplug mustbeproperlygapped and freeof deposits. Remove t he sparkplug bootanduseasparkplug wrenchto remove the plug.SeeFigure 20.

-

Page 19: Carburetor Adjustment

Wheels Check thatthe sparkplug washer isingoodconditionandthreadthe spark plugin byhandto preventcross-threading. At leastonceaseason, r emove bothwheels.Clean andcoatthe axles with a Afterthe sparkplug isseated, t ightenwith asparkplugwrenchto compress multipurpose automotive grease beforereinstalling wheels. the washer. Chute Directional Control NOTE: Wheninstallinganewsparkplug,tighten 1/2-turnafter thespark Once aseason, l ubricatethe eyebolt bushingandthe spiral w ith 3-in-1oil. -

Page 20: Shaveplateand Skidshoes

ShavePlateand SkidShoes Theshave plateandskidshoes on the bottomofthe snowthroweraresubjectto wear. T heyshouldbechecked periodically andreplaced whennecessary. Skid Shoes NOTE: The skidshoes on thismachine havetwo wearedges. W henoneside wearsout,theycanberotated180 °to usethe otheredge. Remove t he sixcarriage boltsandhexnutsthatsecure the two skidshoes to the sides ofthe augerhousing. R eferto Figure 24. Position the newskidshoes andsecure with the carriage boltsandhexnuts. -

Page 21: Belt Replacement

Wheeldrivecontrol Auger Control Refer totheAdjustment section o ftheAssembly instructions toadjust thewheel Refer totheAssembly section f orinstructions onadjusting t heauger control cable. drive control. Tofurther c heck t headjustment, proceed asfollows: Skid Shoes Withthe snowthrowertippedforward(be certainto runthe Refer totheAssembly section f orinstructions onadjusting t heskid shoes. - Page 22 4. Loosen the bolt s hown inFigure 31securing the belt k eeper bracket and remove the other bolt. Push t he belt k eeper and bracket upoffthe engine pulley. Loosen z-fitting Figure33 Placea blockof woodunderneath theaugerhousingas shownin Figure31 Figure34 and separate augerhousingfromtheframebytiltingthe Auger Belt Replacement housingforwardand pullingup the handles.

-

Page 23: Changing Friction Wheel

pter Post Brake PulleySlot Figure 35 Figure36 NOTE: If the pulleyadapterwas removedwith thepulley,align the Rollthe drivebeltoff the lowerdrivepulley. splinesof the pulleyadapterand augerinput shaft, and pushthe pulley Removethe belt fromthe engine pulley. and adapterontothe inputshaft. Referto Figure36. Installthe newbelton the pulleysin the reverseorder and re-tensionwith the idler pulley. - Page 24 Usinga 3/4" wrench,hold the hex shaftand removethe hex screwand bellevillewasherand bearingfrom left sideof the frame.Referto Figure38. RemoveHex Screw Friction WheelAss'y. BellevilleWasher Slide Hex ShaftOut RightSide © Figure40 10. Slidethe hexshaft throughthe rightside of the frametowardthe Idt sideand throughthe frictionwheelassembly. 11. After makingcertainthat the chainis on boththe large and the smallsprocket,alignthe hex shaftwith the hexhub of the small Figure38 sprocket,and slidethe shaftthroughthe sprocket.

- Page 25 If the snowthrowerwill not beusedfor 30daysor longer, o r if it is theendof thesnowseason whenthe lastpossibility of snowisgone,the equipmentneeds to bestored properly.Follow storageinstructions belowto ensuretop performance f rom thesnowthrowerformanymoreyears. PreparingSnowThrower PreparingEngine Whenstoringthe snowthrowerin anunventilated or metalstorage shed, Engines s toredover30daysneedto bedrained of fuel to prevent d eterioration and careshouldbetakento rustproof t he equipment.

- Page 26 Enginefails to start Chokecontrolnot in CHOKEposition. Movechokecontrolto CHOKEposition. Sparkplugwire disconnected. Connectwireto sparkplug. Faultysparkplug. Clean,adjustgap,or replace. Fueltank emptyor stalefuel. Filltank with clean,freshgasoline. Enginenot primed. Primeengineas instructedin the OperationSection. Keynot inserted. Insertkeyfully intothe switch. Connectone end of the extensioncordto the electric Extensioncordnot connected(when usingelectricstartbutton,on modelsso starteroutletand the otherend to a three-prong equipped).

- Page 27 Craftsman Snow Thrower Model 247.883971 66 60 43 41...

- Page 28 Craftsman Snow Thrower Model 247.883971 918-0281A Bracket Assy, Auger Brake 684-04151-4028 Spiral Assy, LH 684-0090B-0637 Impellar, 16" 684-04152-4028 Spiral Assy, RH 931-2643 Tool, Cleanout 684-04214-0691 Housing, Auger - 33" 710-0376 Scr,Hex Cap, 5/16-18 x 1.00 731-05162 Spacer, 1.0 x 1.5 x 2 710-04484 Screw, 5/16-18 x .750...

- Page 29 Craftsman Snow Thrower Model 247.883971 7 58...

- Page 30 731-0903E LowerChute 684-04308A Chute CrankAssembly 731-1313C ChuteTilt CableGuide 684-04350 Joint Block Assembly 710-0276 936-0231 Fiat Washer Screw,Carriage,5/16-18x 1.0 710-04682 784-5594-0637 CableBracket Screw,Hex,3/8-16x 2.00 Lock,Gr5 710-0572 631-04133A HandleClutchLock- LH Screw,Carriage,5/16-18x 2.5 710-3118 631-04134B HandleClutchLock- RH Screw,Hex,3/8-16x 1.0Lock,Gr5 712-04063 931-04187A HandlePanel FlangeLock Nut,5/16-18 912-3010 HexNut,5/16-18 646-0012...

- Page 31 Craftsman Snow Thrower Model 247.883971 "93 78 _3 56...

- Page 32 Craftsman Snow Thrower Model 247.883971 05244B Housing,Bearing 732-04385 TorsionSpring,.750I.D.x .968 Lg. 618-0279P 936-0158 Washer,Lock,5/8 Dogg,SteeringDrive,LH 618-0280P Dogg,SteeringDrive,RH 736-0242 Wsh,Bell., .34x .872x .06 918-0282E ShaftAssembly,Steering 936-0864 Wash,.375x .812x .060 918-04178 Assembly,FrictionWheel 936-0329 Washer,Lock,1/4 718-04034 Wheel,Friction,Bonded 936-3015 FiatWasher,.469x .875x .105 710-0896 Screw,Hex Wash...

- Page 33 Craftsman Snow Thrower IViodel 247.883971 Continuedfrom previouspage 710-0627 Screw,Hex Cap,5/16-24 710-0191 Hex Hd. Screw,3/8-24x 1.25GR8 710-0607 Screw,Hx Wash HdTapp 710-0624 Screw,Hex Cap,5/16-24x 1.50 710-0654A Screw,3/8-16x 1.00 710-0809 Screw,1/4-20x 1.25 738-04439 Hex HeadScrew,5/16-24x .875 710-0347 Hex HeadScrew,3/8-16x 1.75 914-0105 SquareKey,3/16 x 1.00...

- Page 34 Craftsman Snow Thrower Model 247.883971 777122341 777S32636 1. KEEP AWAYFROMROTATING IMPELLER ANDAUGER. CONTACT WITHIMPELLER O RAUGER CANAMPUTATE HANDS ANDFEET. 2. USECLEAN-OUT TOOLTO UNCLOG DISCHARGE CHUTE, 3. DISENGAGE CLUTCH LEVERS, STOP ENGINE, ANDREMAIN BEHIND HANDLES UNTILALLMOVINGPARTS HAVESTOPPED BEFORE UNCLOGGING OR SERVICINGMACHINE, 4.

- Page 35 Craftsman Engine Model 483-$UBForSnow Model 247.883971 710-04915 Bolt M6x12 951-11339 Muffler Shield 710-04915 Bolt M6x12 951-10757 Throttle Control Knob 951-11595 Control Panel 731-05632 951-10637 Key Switch Assembly 951-11302 Choke Knob i 10 710-04914 Bolt M6xlO 951-11181 i 11 Exhaust Pipe Shield...

- Page 36 Craftsman Engine Model 483-SLIB ForSnow Model 247.883971 --134 135--_ 137138 __0/138 147-Carburetor RebuildKit 139_ _139 ID - Throttle Shaft Cover 710-05392 Stud M6-8x100 Idle Jet Rivet 710-05056 Stud M6-8x118 951-11315 Carburetor Intake Gasket Idle Jet Assembly 951-11316 Carburetor Insulator Idle Speed Adjusting...

- Page 37 Craftsman Engine Model 483-$UBForSnow Model 247.883971 144- GasketKit- Complete 145- GasketKit- External 146- CompleteEngine...

- Page 38 Craftsman Engine Model 483-$UBForSnow Model 247.883971 951-11951 710-06062 Bolt M8x45 Connecting Rod Assembly 951-11952 Piston 710-06063 Bolt M8x35 951-11953 710-04968 Bolt M6x16 Piston Pin Snap Ring 951-11954 Piston Pin 951-11320 Oil Tube Support Bracket 951-12579 710-05349 Bolt M6x8 Piston Ring Set...

- Page 39 Craftsman Engine Model 483-$UBForSnow Model 247.883971 11o_ 116"--_) _11311s 120 119 144-Gasket K it-Co replete 145- Gasket Kit- I:xternal 146- Complete Engine...

- Page 40 Craftsman Engine Model 483-$UBForSnow Model 247.883971 951-12081 951-11337 Valve Kit Exhaust Lash Cap 951-11337 Valve Kit 951-11965 Push Rod Guide 951-11962 951-11981 Tappet Rocker Arm Assembly 951-11335 Push Rod Kit 710-04962 Bolt, Pivot 951-11966 Rocker Arm 951-12555 Cylinder Head Kit (Inc.106,110-112,125)

- Page 41 Craftsman Engine Model 483-$UBForSnow Model 247.883971 710-04965 Screw M4 X 55 951-11313 Cooling 951-11196 Electric Starter 951-11314 Starter Cup 712-04220 710-04967 Bolt M8x55 Flywheel Nut, M14x1.5 710-04968 Bolt M6x16 951-11305 Ignition Coil Assembly 710-05350 710-04915 Bolt M6x12 Ignition Coil Bolt...

- Page 42 Craftsman Engine Model 483-$UBForSnow Model 247.883971 26 / 34 32 951-12533 951-11336 Fuel Line Kit Fuel Cap Assembly 951-I 1933 Fuel Level Indicator 951-11700 Fuel Hose Clamp 710-04921 Bolt M8x14 710-04970 Bolt M8x20 951-11182 750-05312 Fuel Tank Mounting Bracket Bushing,...

-

Page 43: Owner's Warranty Responsibilities

FEDERAL and/or CALIFORNIA EMISSION CONTROL W ARRANTY STATEMENT YOUR WARRANTY RIGHTS ANDOBLIGATIONS MTD Consumer Group Inc, the United States Environmental Protection Agency (EPA), and for those products certified for sale in the state of California, the California Air Resources Board (CARB) are pleased to explain the emission (evaporative and/or exhaust) control... -

Page 44: Warranted Parts

10. Add-on o rmodified parts t hatare not e xempted bythe AirResources Board m ay not b eused. The use ofany non-exempted add-on o r modified parts b ytheultimate purchaser willbegrounds fordisallowing awarranty claims. MTD Consumer Group I nc willnotbeliable t o warrant failures ofwarranted parts c aused bytheuse ofanon-exempted add-on o rmodified part. - Page 45 Look For Relevant Emissions Durability Period and Air index information On Your Engine Emissions Label Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must display information regarding the Emissions Durability Period and the Air Index. Sears Brands Management Corporation makes this information available to the consumer on our emission...

- Page 46 Congratulations on making a smart purchase. Your new Craftsman® product is designed manufactured for years of dependable operation. But like all products, it may require repair from time to time. That's when having a Repair Protection Agreement can save you money and aggravation.

- Page 47 Your Home For troubleshooting, product manuals and expert advice: managernylife www.managemylife.com For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself.

Need help?

Do you have a question about the 247.883971 and is the answer not in the manual?

Questions and answers