Summary of Contents for Zepro Z 1500

- Page 1 Installation instructions Tail Lift Z 1500/2000-135/155/175 ZEPRO Tel.: +46 (0)10-459 05 00 Email: zeprotech@hiab.com zepro.com 75976TL 2023-06-09...

-

Page 3: Table Of Contents

Sizing electrical systems ..............38 Main power cable, earth cable, main fuse and main switch ....39 Control power cable ................41 Open platform alarm ................41 Foot controller / Warning lights ............41 Connection ....................42 Cable grommet ................42 Connection ..................43 Powering up the tail lift ................51 www.zepro.com... - Page 4 Z 1500/2000 MA (TLC-B1) ..............52 Z 1500/2000 MA (ZePRO1) .............53 Z 1500/2000 MA with electric autotilt, Angle sensor IFM (TLC-B1) .54 Z 1500/2000 MA with electric autotilt, Inclinometer (ZePRO1) ..55 Z 1500/2000 MA with electric autotilt, Angle sensor IFM (ZePRO1) 56 Z 1500/2000 DA (ZePRO1) .............57...

-

Page 5: Important Information

NOTE refers to additional information that may help the reader understand, or perform, a given operation. Technical support If technical support is needed, please contact ZEPRO. Tel: +46 (0)10-459 05 04, E-mail: zeprotech@hiab.com. Always be ready to state the tail lift’s production number to guarantee you receive the correct information. The production number is given on the identification plate located on the tail lift frame. -

Page 6: Identification

Properly assembled, this product meets relevant requirements according to EN 1756-1:2001 + A1:2008. Hydraulic oil If the hydraulic oil needs to be replenished, only the oil recommended by ZEPRO is permitted to be used. Hydraulic systems with hydraulic oil tanks without labelling are only permitted to be filled with highly refined mineral oil (art. -

Page 7: Repainting

Important information Z 1500/2000-135/155/175 Repainting IMPORTANT Piston rods and cylinder covers must not be painted. Among other things, this can damage the cylinder gaskets. Boots, hydraulic hoses and cables may not be coated/painted as the solvent in the paint can damage the hoses and cables and impair durability. -

Page 8: Safety Rules

Connection of third-party equipment is forbidden WARNING! Connecting third-party equipment (electric or hydraulic) to Zepro tail lifts is forbidden. Connecting third-party equipment could interfere with the lift’s system and its safety functions. Risk of injury and damage. If it is necessary to install other equipment, check the vehicle manufacturer’s body instructions and use the attachment features on the vehicle. -

Page 9: Before Installation

Before installation Z 1500/2000-135/155/175 Before installation Vehicle chassis requirements In order to comply with the applicable underrun R6(x2) protection standards, there are requirements for the vehicle chassis on which the rear tail lift is mounted. The moment of inertia in a cross-section on the current... - Page 10 Safety rules Z 1500/2000-135/155/175 Horizontal distance from the outer edge of the member to the outside of the wheel: Max. 100 mm. See Figure 9. 0-100 mm. Figure 9. Statutory dimensions The lateral distance between the underrun protection and the moving parts of the tail lift must not exceed 25 mm.

-

Page 11: Calculating The Installed Dimensions

Safety rules Z 1500/2000-135/155/175 Calculating the installed dimensions For ease of installation it is best to calculate and specify the necessary dimensions in advance. Determine the C dimension first, then obtain the other dimensions from the relevant table. Try to place the lift as high as possible within the C dimension specified in the table. - Page 12 Safety rules Z 1500/2000-135/155/175 Figure 11. Z 1500/2000-135 715 680 680 725 630 781 580 828 530 869 480 904 430 934 Figure 12. Z 1500/2000-155 515 1023 465 1051 Figure 13. Z 1500/2000-175 www.zepro.com...

- Page 13 Safety rules Z 1500/2000-135/155/175 Figure 14. Z 1500/2000 -135 Figure 15. Z 1500/2000 -155 Figure 16. Z 1500/2000 -175 www.zepro.com...

-

Page 14: Rear Beam Cut-Outs

1. Measure and mark the location and depth of the cut-outs on the rear beam. Centre the two rear beam cut- outs, i.e. the cut-outs must be equidistant from the beam’s centre point. 2. Cut along the markings. 3. Grind away any burrs or sharp edges. A max Figure 17. Z 1500/2000 www.zepro.com... -

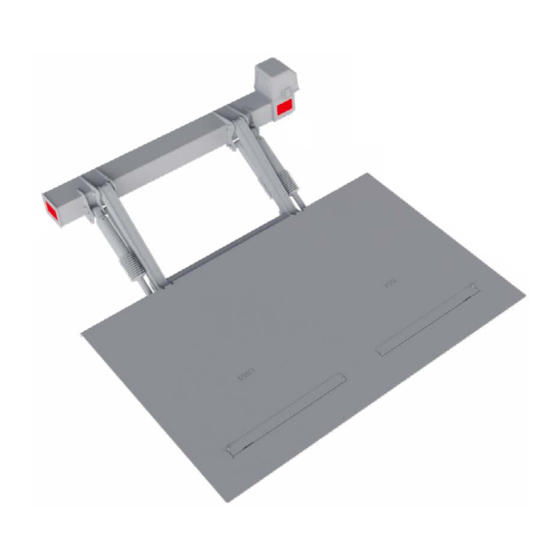

Page 15: Prepare The Tail Lift

Safety rules Z 1500/2000-135/155/175 Prepare the tail lift 1. Position the support frame under the vehicle’s chassis. 2. Remove the protective cover mounted with a rubber strap; see Figure 18. 3. Fold out the control card / relay card (B) and loosen the cabling at the connector on the hydraulic unit; see Figure 19 and Figure 20. - Page 16 Safety rules Z 1500/2000-135/155/175 54853 5. Check whether the hydraulic tank is fitted with a transport plug seal. If so, replace it with the regu- lar tank cap supplied. Figure 22. Where necessary, replace the transport plug with a regular tank cap...

-

Page 17: Temporary Connection

Safety rules Z 1500/2000-135/155/175 Temporary connection When the tail lift is installed, it is sometimes necessary to operate its functions in order to change the posi- tion of the cylinders and the lift arms. Temporarily connect the lift to enable the lift functions. - Page 18 Safety rules Z 1500/2000-135/155/175 3.6.2 Connecting the control device to the ZePRO1 control card The most commonly occurring controller (CD Control Device) models are shown below. Possible controller models vary depending on lift model, configuration and relevant market. WARNING! Make sure that the control card is disconnected from the power before connecting. Connecting more than one controller to each connection is not permitted.

- Page 19 Safety rules Z 1500/2000-135/155/175 3.6.3 Connecting the control device to the TLC-B1 relay card The connection of warning lights and the most commonly occurring controller (CD (Control Device)) models is shown below. Possible controller models vary depending on lift model, configuration and relevant market.

-

Page 20: Installation

WARNING! Figure 25. Measure and mark the mid- point of the rear beam of the vehicle Zepro tail lifts are only approved for installation with Zepro assembly kits. Frame 1. Measure and mark the midpoint of the vehicle's rear beam. - Page 21 Installation Z 1500/2000-135/155/175 When installing on chassis with pre-drilled holes, pro- ceed straight to Item 15. 9. When mounting on frame without pre-drilled holes, first install using a screw in the grooved bracket holes. Mark the centre of the vehicle frame in the grooved bracket holes, then drill Ø14 mm holes In...

- Page 22 Installation Z 1500/2000-135/155/175 When installing on chassis with pre-drilled holes 15. Bolt the mountings securely on the exterior of the vehicle frame. Install in the slot-shaped holes with at least 6 screws. Use suitable bolts (strength M14 10.9 or higher) and install the associated washer and nut on the inside of the vehicle frame.

-

Page 23: Platform

Installation Z 1500/2000-135/155/175 Platform 1. Check that all included components are clean, clean where necessary. 2. Lubricate the metal bushings on the upper bear- ing of the arms. Make sure the small holes on the inside of the bushings are filled with grease. - Page 24 Installation Z 1500/2000-135/155/175 5. Test the lift by carefully raising it to the vehicle 38 mm - 40 mm floor level and tilting it to the vertical position. Check the position in relation to the rear beam and side posts of the vehicle. See Figure 35 and Figure 36.

- Page 25 Installation Z 1500/2000-135/155/175 4. Turn the adjuster sleeve until the platform fits perfectly against the seal on the body. Figure 38. Figure 38. Adjusting the fit to the vehicle body 5. Undo the three locking screws on the other tilt cylinder.

- Page 26 Installation Z 1500/2000-135/155/175 Max. 30 mm IMPORTANT After finishing the adjustment, make sure the distance between the adjusting collar and the end of the thread is no more than 30 mm. 11. Fit the tilt cylinder boots. Figure 42. Figure 41. Adjusting the tilt angle...

- Page 27 Installation Z 1500/2000-135/155/175 4.2.2 Adjusting tilt-down angle NOTE! It is necessary to adjust the tilt angle 90º to the body before adjusting the tilt down angle (see previous page). WARNING! Figure 43. The tilt angle must be ad- To make sure the lift is safe and CE compliant, the justed to max.10°...

-

Page 28: Armstops

Installation Z 1500/2000-135/155/175 Armstops Fit end stops between the lift arms and the rear member of the vehicle floor. The left and right end stops must be reached at the same time, as high up the lift arm as possible. Installation must take place against the vehicle body. -

Page 29: Adjustable Underrun Protection

Installation Z 1500/2000-135/155/175 Adjustable underrun protection Test the position of the underrun protection without tightening the bolts to check that the statutory dimensions are obtained. Adjust if necessary then tighten the bolts with a torque wrench. 1. Fit the inner part of each bracket at one of four heights. - Page 30 Installation Z 1500/2000-135/155/175 4.6.1 Fixed underrun protection 1. Install the brackets on the tail lift frame using 3 x M12x100 bolts each, without tightening them. See Figure 51. 2. Install the centre sheet-metal profile using 4 x M12x110 bolts on the brackets. See Figure 52.

-

Page 31: Purging The Cylinders

Installation Z 1500/2000-135/155/175 Purging the cylinders Purge the lift cylinders by lowering the platform all the way to the ground a few times. It may be necessary to raise the truck to allow the platform to be lowered completely. Purge the tilt cylinders by tilting the platform all the way up to the vehicle body and then all the way down. -

Page 32: Angle Sensor / Inclinometer

Installation Z 1500/2000-135/155/175 Angle sensor / Inclinometer 4.9.1 Tail lift without autotilt 1. Install the angle sensor on the platform using the nuts, bolts and washers supplied and attach the cable using cable ties; see. Figure 55. 2. Connection is described later in section Figure 55. - Page 33 Installation Z 1500/2000-135/155/175 4.9.3 Tail lift with angle sensor IFM for autotilt 1. Install the angle sensor on the platform using the nuts, bolts and washers supplied and attach the cable using cable ties; see Figure 57 2. Route the cables and secure with cable ties.

-

Page 34: Controllers

Installation Z 1500/2000-135/155/175 4.10 Controllers 1. Install the primary controller on the side of the vehicle normally facing away from the traffic. The distance between the vehicle’s rear edge and the centre of the controller must be 300-600 mm. Connection is per- formed later in section 6 if this is not already done from the factory. - Page 35 Installation Z 1500/2000-135/155/175 4.10.1 Controllers 3+1 (CD 1) 1. Fit the controllers in the desired locations. However, 300 - 600 mm. locate them such that the operator’s working posi- tion is as safe as possible, and with an adequate overview of the load, tail lift and their working area.

- Page 36 Installation Z 1500/2000-135/155/175 Installation on the underside of the body The cable is usually connected to the controller and the controller bolted to the bracket at the factory. Bolt the bracket to the underside of the body. Use the self-adhesive drilling template supplied.

-

Page 37: Cable Routing

Cable routing Z 1500/2000-135/155/175 Cable routing General IMPORTANT In order to ensure a high degree of reliability for many years to come, it is important that components such as batteries, chargers, main current and earth cables, fuses and main switches are dimensioned correctly and assembled with great accuracy. Insufficient battery power can permanently damage the electrical components in the tail lift (solenoid, electric motor, solenoid valves, relay board/ control board and more.) -

Page 38: Sizing Electrical Systems

Cable routing Z 1500/2000-135/155/175 Sizing electrical systems Ensure that the battery and charger capacity is sufficient for the product in question and that cable with suf- ficient cross-sectional area is used. Hydraulic unit 7050 12 volt 24 Volt Pump - Motor unit... -

Page 39: Main Power Cable, Earth Cable, Main Fuse And Main Switch

Cable routing Z 1500/2000-135/155/175 Main power cable, earth cable, main fuse and main switch Main switch should always be mounted when cab switches (CS) are not used, for example when installing on trailers. Main switches can also be installed in combination with cab switches (CS) if desired. - Page 40 Cable routing Z 1500/2000-135/155/175 5.3.1 Main power switch 1. The main power switch is installed on the bracket at the factory. Bolt the bracket to the underside of the body. Use the self-adhesive drilling template supplied. 2. Connect the main power switch cable to the quick connector on the tail lift power supply cable.

-

Page 41: Control Power Cable

Open platform alarm ZEPRO recommends the installation of an alarm for open platform. This can be in the form of warning light in the cab or when mounted on a trailer, a lamp mounted on the outside of the body, visible in the rear view mir- ror from the driver's cab. -

Page 42: Connection

Connection Z 1500/2000-135/155/175 Connection Cable grommet 6.1.1 Before connection 1. Disconnect the cable grommet’s protective cover, which is secured with three screws; see Figure 74. 2. Loosen the five screws on the cable grommet, see Figure 75. Cables can now be installed/removed/ adjusted in the grommet. -

Page 43: Connection

Connection Z 1500/2000-135/155/175 Connection IMPORTANT! Make sure that the control board is disconnected from the power before connecting peripheral equipment. Risk of material damage. 1. Release and tilt out the relay board. 2. Run the cabling through the grommet. 3. Connect the relevant controller. See Section 6.2.1 - 6.2.2. - Page 44 Connection Z 1500/2000-135/155/175 6.2.1 Controller (TLC-B1) Connection of warning lights and the most commonly occurring controller (CD (Control Device)) models are shown below. Possible controller models vary depending on lift model, configuration and relevant market. WARNING! Make sure that the control board is not powered up before connecting. Connecting more than one controller to each connection is not permitted.

- Page 45 Connection Z 1500/2000-135/155/175 6.2.2 Controller (ZePRO1) The most commonly occurring controller (CD Control Device) models are shown below. Possible controller models vary depending on lift model, configuration and relevant market. WARNING! Make sure that the control board is not powered up before connecting. Connecting more than one controller to each connection is not permitted.

- Page 46 Connection Z 1500/2000-135/155/175 6.2.3 Warning light and foot controller (TLC-B1) Signal is required on relay card input S3 for the warning light to work. Depending on the model, this can be done by connecting angle sensors between S3 and S3+ or with jumper Gnd.

- Page 47 Connection Z 1500/2000-135/155/175 6.2.4 Warning lights and foot controls (ZePRO1) www.zepro.com...

- Page 48 Connection Z 1500/2000-135/155/175 6.2.5 Cab switch and open platform alarm (TLC-B1) Applies when installing without main switch www.zepro.com...

- Page 49 Connection Z 1500/2000-135/155/175 6.2.6 Cab switch and open platform alarm (ZePRO1) Applies when installing without main switch www.zepro.com...

- Page 50 Connection Z 1500/2000-135/155/175 6.2.7 Open platform alarm Applies when installing with main switch www.zepro.com...

-

Page 51: Powering Up The Tail Lift

Powering up the tail lift Z 1500/2000-135/155/175 Powering up the tail lift 1. If applicable, ensure that the main switch is in the "Off" position. 2. If applicable, ensure that the cab switch (CS) is in the "Off" position. 3. When using a fuse box, connect the cable (1) to the battery’s positive terminal and to the fuse box and place the fuse (2) above, see Figure 78. -

Page 52: Electrical And Hydraulic Diagrams

Electrical and hydraulic diagrams Z 1500/2000-135/155/175 Electrical and hydraulic diagrams Z 1500/2000 MA (TLC-B1) www.zepro.com... -

Page 53: Z 1500/2000 Ma (Zepro1)

Electrical and hydraulic diagrams Z 1500/2000-135/155/175 Z 1500/2000 MA (ZePRO1) Config 14, Firmware 9.7 or later www.zepro.com... -

Page 54: Z 1500/2000 Ma With Electric Autotilt, Angle Sensor Ifm (Tlc-B1)

Electrical and hydraulic diagrams Z 1500/2000-135/155/175 Z 1500/2000 MA with electric autotilt, Angle sensor IFM (TLC-B1) www.zepro.com... -

Page 55: Z 1500/2000 Ma With Electric Autotilt, Inclinometer (Zepro1)

Electrical and hydraulic diagrams Z 1500/2000-135/155/175 Z 1500/2000 MA with electric autotilt, Inclinometer (ZePRO1) Config 14, Firmware 9.8 or later www.zepro.com... -

Page 56: Z 1500/2000 Ma With Electric Autotilt, Angle Sensor Ifm (Zepro1)

Electrical and hydraulic diagrams Z 1500/2000-135/155/175 Z 1500/2000 MA with electric autotilt, Angle sensor IFM (ZePRO1) www.zepro.com... -

Page 57: Z 1500/2000 Da (Zepro1)

Electrical and hydraulic diagrams Z 1500/2000-135/155/175 Z 1500/2000 DA (ZePRO1) Config 16, Firmware 9.7 or later www.zepro.com... -

Page 58: Lubrication And Oil Level Check

Lubrication and oil level check Z 1500/2000-135/155/175 Lubrication and oil level check The following lubrication points must be greased on installation. They must then be lubricated at least 4 times a year. Lubrication NOTE! Use LE lubricant 4622 or the equivalent. -

Page 59: Marking

Marking Z 1500/2000-135/155/175 Marking Below, an overview of the location of the different markings is shown. Images of markings and additional information can be found under the relevant subchapter for subsequent pages. 10.1 10.4 10.3 10.5 10.5 10.6 10.7 Figure 84. Overview of labelling... -

Page 60: Loading Diagram

Marking Z 1500/2000-135/155/175 10.1 Loading diagram Affix the load diagram in a suitable, conspicuous place on the platform and in the vicinity of the primary con- troller or in the designated location on the controller (CD19). Figure 85. Load diagram for load capacity 1500 kg, load centre distance 1000 mm. -

Page 61: Identification Plate

Marking Z 1500/2000-135/155/175 10.2 Identification plate The identification plate is fixed on to the tail lift’s frame. Affix the corresponding sticker version of the identification plate, preferably by the cab door post to facilitate identification. The identification plate contains the following infor- mation: •... -

Page 62: Controller Sticker

Marking Z 1500/2000-135/155/175 10.5 Controller sticker Affix the controller sticker next to the relevant controller. The stickers are available in standard versions and in reversed version for affixing on the opposite side of the vehicle. Make sure the stickers are affixed so the image of the vehicle/tail lift on the sticker is in the same direction as the vehicle on which it is affixed. - Page 63 Marking Z 1500/2000-135/155/175 10.5.1 Autotilt additional sticker There is an additional sticker affixed next to the control device sticker on tail lifts fitted with autotilt. The stickers are available in standard versions and in a latterally reversed version for affixing on the opposite side of the vehicle.

-

Page 64: Danger Area

Marking Z 1500/2000-135/155/175 10.6 Danger area If one is fitted, affix the sticker on the inside of the vehicle body next to the hand control unit. www.hiab.com 65977TL 2020-05-14 Figure 95. Danger area 10.7 Warning flags Install warning flags as close to the top and as close... -

Page 65: Testing And Verification

Testing and verification Z 1500/2000-135/155/175 Testing and verification Testing and verification of the tail lift takes place in accordance with the installation/delivery inspection. Verify that the tail lift is suitable for the vehicle in question and for the intended use. 11.1 Static load test 11.1.1 Deformation... -

Page 66: Dynamic Load Test

Testing and verification Z 1500/2000-135/155/175 11.2 Dynamic load test. 11.2.1 Test with max. load • Place a test load on the platform, as shown in table (for each lift model/lift capacity). • Check that the lift operates correctly in the normal range of movement, i.e. up, down, tilting at ground level and tilting at vehicle floor level. -

Page 67: Registration

Complete Lift chassis (except platform) Lift components (included in complete lift chassis) 69 kg Z 1500-135 315 kg Support frame Z 1500 92 kg Z 1500-155 328 kg Support frame Z 2000 51 kg... - Page 68 BUILT TO PERFORM Zepro, Del and Waltco are Hiab trade marks for tail lifts. Hiab is a world-leading supplier of equipment, intelligent services and digital solutions for on-road load handling. As an industry pioneer, our company commitment is to increase the efficiency...

Need help?

Do you have a question about the Z 1500 and is the answer not in the manual?

Questions and answers