Summary of Contents for Zepro ZAHD 150/200

- Page 1 Installation Instructions Tail Lift ZAHD 150/200-155/175 ZAEHD 150/200-155/175 ZEPRO Tel.: +46 (0)10-459 05 00 E-mail: zeprotech@hiab.com zepro.com 74227TL 2022-07-04...

-

Page 3: Table Of Contents

Cable routing ....................34 5.1 General .......................34 5.3 Maximum power consumption ..............35 5.2 Battery maintenance ..................35 5.4 Purging the cylinders ..................36 5.5 Platform tilt speed ..................36 5.6 Main power cable, earth cable, main fuse and main switch ......37 5.7 Control power cable ...................39 5.8 Open platform alarm ..................39 5.9 Foot controller / Warning lights ..............39 Connection ....................... 40 6.1 Connection unit ..................40 6.2 Connection ....................41 www.zepro.com... - Page 4 10.3 Work area ....................58 10.4 Warning tape .....................58 10.5 Controller sticker ..................59 10.6 Danger area ....................60 10.7 Warning flags .....................60 11 Testing and verification ..................61 11.1 Static load test ....................61 11.2 Dynamic load test ..................62 11.3 Test of safety functions ................62 12 Registration ...................... 63 13 Specifications ....................63 13.1 Weights ......................63 www.zepro.com...

-

Page 5: Important Information

NOTE refers to additional information that may help the reader understand, or perform, a given operation. Technical support If technical support is needed, please contact ZEPRO. Tel: +46 (0)10-459 05 04, E-mail: zeprotech@hiab.com. Always be ready to state the tail lift’s production number to guarantee you receive the correct information. The production number is given on the identification plate located on the tail lift frame. -

Page 6: Identifikation

Properly assembled, this product meets relevant requirements according to EN 1756-1:2001 + A1:2008. Hydraulic oil If the hydraulic oil needs to be replenished, only the oil recommended by ZEPRO is permitted to be used. Hydraulic systems with hydraulic oil tanks without labelling are only permitted to be filled with highly refined mineral oil (art. -

Page 7: Repainting

When the lift is operated repeatedly without starting or using the vehicle during lift installation or carrying out service and repairs, use the battery charger between operations to maintain battery charge. IMPORTANT The battery charger must be disconnected when operating the lift. Risk of material damage. www.zepro.com... -

Page 8: Configuration

ZAE/HD 38.2 kg 57014TL, 57013TL Volvo EDH-2/3 848-850 ZAHD 75414TL, 75413TL Volvo EDH-2/3 848-850 ZAEHD 75365TL*, 75364TL* * During installation, a shim plate in accordance with the following table is also required. Truck make Drawbar End panel Chassis Shim plate Complete weight Art. no. width EDH-3 766-770 ZAHD, ZAEHD 75383TL Volvo ZAEHD 77806TL www.zepro.com... -

Page 9: Safety Rules

Connection of third-party equipment is forbidden WARNING! Connecting third-party equipment (electric or hydraulic) to Zepro tail lifts is forbidden. Connecting third- party equipment could interfere with the lift’s system and its safety functions. Risk of injury and damage. If it is necessary to install other equipment, check the vehicle manufacturer’s body instructions and use the attachment features on the vehicle. -

Page 10: Before Installation

255x70x6 mm, corresponding to a surface moment of inertia of 1929 cm⁴ around the x-axis. See illustration. Image 7. The cross-secton of the frame beam If in doubt, contact ZEPRO for support. WARNING! The above dimensions are the minimum permit- ted for the installation of underrun protection. - Page 11 25 mm. See illustration. • Each of the individual parts of the underrun protection must have a surface area of at least 350 cm . See illustration. Min. Area: 350 cm Max 25 mm Max 25 mm Image 10. Statutory dimensions www.zepro.com...

-

Page 12: Calculating The Installed Dimensions

The H dimension is the height from the ground (unloaded) to the vehicle floor level. The H dimension must not be greater that the maximum lifting height of the lift. The platform must always be able to reach ground level. www.zepro.com... - Page 13 Before installation ZAHD, ZAEHD 150/200-155/175 R58:3 Approved * without support wheel Image 11. ZAHD 150/200-155 R58:3 Approved * without support wheel 1021 1052 Image 12. ZAHD 150/200-175 www.zepro.com...

- Page 14 Before installation ZAHD, ZAEHD 150/200-155/175 R58:3 Approved * without support wheel Image 13. ZAEHD 150/200-155 R58:3 Approved 1021 * without support wheel 1052 Image 14. ZAEHD 150/200-175 www.zepro.com...

- Page 15 Before installation ZAHD, ZAEHD 150/200-155/175 Chassis width L - 16 1432 695-895 2400 Image 15. ZAHD 150/200 Chassis width L - 20 1432 695-895 2400 Image 16. ZAHD 150/200 Chassis width L - 20 1432 695-895 2400 Image 17. ZAEHD 150/200 elevated...

-

Page 16: Rear Beam Cut Outs

Image 18. Rear beam cut outs Prepare the tail lift 1. Position the support frame under the vehicle chassis. 2. Remove the connection unit cover, secured with four screws, see Image 19. Relay card/control card Image 19. Connection unit www.zepro.com... - Page 17 3. Check whether the hydraulic tank is fitted with a sealed transport plug. In this case, replace it with the regular tank cap supplied. Image 20. Where necessary, replace the transport plug with a regular tank cap MOTOR VALVE HOUSING TANK CAP OIL TANK Image 21. Hydraulic unit www.zepro.com...

-

Page 18: Temporary Connection

When installing the lift, when the lift is operated repeatedly, the battery charger must be used between opera- tions to maintain the battery charge level. IMPORTANT! The battery charger must not be connected when operating the lift. Risk of material damage. www.zepro.com... - Page 19 Blue Black White Brown Yellow Down Blue Tilt Pink Black White ( )* Tilt Brown Down Yellow Down WL1 U7 U6 U5 U5 U4 U4 U3 U2 U1 U0 Blue Tilt * applies to controllers with heating only Down Ctrl 1 Tilt Down Tilt Down www.zepro.com...

- Page 20 Di 3 Ai 2 Black (+) Lock Di 2 White (-)* Ctrl 5 Di 1 Ctrl 4 Ai 1 Spiral Ai 2 Brown Brun B Lock Gul E Yellow Blå Blue * Blå 2H Blue 2H Black (+) * applies to controllers with heating only www.zepro.com...

-

Page 21: Installation

Consult the trailer manufacturer’s body instructions and Zepro’s instruction booklet before installation. WARNING! Zepro tail lifts are only approved for installation with Zepro installation kits. Image 23. Measure and mark the mid- point of the rear beam of the trailer Support Frame 1. - Page 22 3 x M14x45 10.9 bolts at the per and lower rows of holes. front and rear edges of the bracket. Min. 200 mm. Image 28. The distance between the out- er bolts must be at least 200 mm. www.zepro.com...

-

Page 23: Platform

IMPORTANT! Make sure the cylinders are installed with the grease nipples facing up. Tighten the bolt using a torque wrench. Tightening torque: 80 Nm. Image 31. Fitting the tilt cylinder to the platform www.zepro.com... - Page 24 See illustration. NOTE! When mounting with ZEPRO's stop strip, the distance between the rear edge of the bridge and the vehicle body must be 38-40 mm. Image 32. Check the position in rela-...

- Page 25 9. Adjust the two cylinders alternately so that the platform meets the vehicle body, see Image 35 (B). 10. Tighten the lock screws of the adjusting collar using a torque wrench Tightening torque: 3-5 Nm. Image 37. Fitting the tilt cylinder to the platform www.zepro.com...

- Page 26 11. Now alternate the final adjustment between the two cylinders so that the platform meets the vehicle body, see Image 39. Image 38. Adjusting the tilt angle ~ 10 mm Lift model 1500/2000-155 300 ±5 1500/2000-175 420 ±5 Image 39. Installing boots www.zepro.com...

- Page 27 The tightening torque for lock screws is between 3-5 Nm. Test all functions. WARNING! The tilt angle of both cylinders must be adjusted to be the same, otherwise they may be damaged. Adjusting collar Lock screw Bolt End stop Washer Image 42. Tilt cylinder www.zepro.com...

-

Page 28: Armstops

2. Fit the rubber strip to the track. 3. Secure the rubber strips by swaging the tracks together at the bottom. Image 43. Installing a sealing strip NOTE! To fit an upper edge seal, create a 45° mitre against the vertical strips. www.zepro.com... -

Page 29: Underrun Protection

Image 46. The outer part of the brack- If necessary, tap carefully with a rubber hammer. ets can be fitted in one of five positions Image 47. Fit the member end caps www.zepro.com... -

Page 30: Angle Sensor / Inclinometer

Tail lift with inclinometer for autotilt 1. Install the inclinometer on the platform using the nuts, bolts and washers supplied and attach the cable using cable time; see Image 49. 2. Connection is described later in section Image 49. Installing inclinometers www.zepro.com... - Page 31 (autotilt angle) can be adjusted. 1. Loosen the two screws without removing them, see Image 51. 2. Adjust the position of the angle sensor to the desired angle, Image 3. Retighten the screws. Image 51. Adjusting the autotilt angle www.zepro.com...

-

Page 32: Controllers

Take care not to bend cables with too tight a radius as this can cause damage. 300-600 mm. Image 52. Installing controllers WARNING! The primary controller must always be fitted on the side that is facing away from moving traffic. Fitting in any other way involves increased risk of injury. Image 53. Installing controllers www.zepro.com... - Page 33 3. Any additional controllers can be installed in an optional location. 4. Run the controller cabling to the tail lift cable grom- met. Connection is described later in section 6. Image 54. Installing control- ler CD 1 with two-handed grip. www.zepro.com...

-

Page 34: Cable Routing

Take care not to bend cables to too tight a radius as this can cause damage. Image 55. Protect the cable against sharp edges and use cable grommets Image 56. Always use shrink hose over the cable connection when fitting cable terminals www.zepro.com... -

Page 35: Maximum Power Consumption

When installing the lift and when carrying out service and repair work, when the lift is operated repeatedly without the vehicle being started and used, the battery charger must be used between operations to main- tain the battery’s charge level. NOTE! The battery charger must not be connected when operating the lift. Risk of damage. www.zepro.com... -

Page 36: Purging The Cylinders

45°). As long as these buttons are held in, the platform will be tilted downwards at the highest possible speed to -10º. In this way, the time for opening the platform from vertical to horizontal position can be minimised without sacrificing safety. www.zepro.com... -

Page 37: Main Power Cable, Earth Cable, Main Fuse And Main Switch

6. Route the main power cable from the tail lift to the fuse box/battery plus terminal. Prepare the cable with a cable terminal and shrink hose without connecting. Connection is described later in section Image 59. Connection to the bat- Image 60. Connection to the fuse box tery's positive terminal www.zepro.com... - Page 38 The positive cable to the battery and main fuse is connected later in Section , after the cable has been routed/installed. Image 62. Installation of main Image 61. Installation of main switch on universal bracket switch to CD 19 controller Drainage Image 63. Main power switch www.zepro.com...

-

Page 39: Control Power Cable

Open platform alarm ZEPRO recommends the installation of an alarm for open platform. This can be in the form of warning light in the cab or when mounted on a trailer, a lamp mounted on the outside of the body, visible in the rear view mirror from the driver's cab. -

Page 40: Connection

2. Loosen the unused cable grommets. Cables can now be installed/removed/adjusted in the grommets. 6.1.2 After connection 1. Tighten the cable grommets when all the cables are in a suitable position. 2. Replace the connection unit cover, see Image Relay card/control card Image 67. Connection unit www.zepro.com... -

Page 41: Connection

3. Where applicable, connect the warning lights. See Section 6.2.3 - 6.2.4. 4. Where appropriate, plug in cab switch (CS) and open platform alarm. See section 6.2.5 -6.2.7. 5. Replace the cable grommets and connection unit, see section 6.1.2. ZePRO1 TLC-B1 www.zepro.com... - Page 42 Blue Tilt CD10 Black White ( )* Down WL1 U7 U6 U5 U5 U4 U4 U3 U2 U1 U0 Brown Yellow Down CD14 Down Down Ctrl 1 Tilt Down Ctrl 2 For connection of foot controller and warning Tilt 6.2.3 lights, see electrical diagram in Section Ctrl 3 Down * applies to controllers with heating only www.zepro.com...

- Page 43 Ai 2 Brown Lock Yellow Blue Blue 2H Black (+) CD12 CD11 Brown Yellow Blue Grey Lock Black (+) White (-) CD14 Brown Brown CD10 Yellow Yellow Blue For connection of foot controller and warning 6.2.4 lights, see electrical diagram in Section Black (+) Black (+) White (-)* White (-)* * applies to controllers with heating only www.zepro.com...

- Page 44 Warning light and foot controller (TLC-B1) Signal is required on relay card input S3 for the warning light to work. Depending on the model, this can be done by connecting angle sensors between S3 and S3+ or with jumper Gnd. Sig.(+) Down www.zepro.com...

- Page 45 Connection ZAHD, ZAEHD 150/200-155/175 6.2.4 Warning lights and foot controls (ZePRO1) www.zepro.com...

- Page 46 Connection ZAHD, ZAEHD 150/200-155/175 6.2.5 Cab switch and open platform alarm (TLC-B1) Applies when installing without main switch www.zepro.com...

- Page 47 Connection ZAHD, ZAEHD 150/200-155/175 6.2.6 Cab switch and open platform alarm (ZePRO1) Applies when installing without main switch www.zepro.com...

- Page 48 Connection ZAHD, ZAEHD 150/200-155/175 6.2.7 Open platform alarm Applies when installing with main switch www.zepro.com...

-

Page 49: Powering Up The Tail Lift

9. Where fitted, set the cab switch to the ON position. Image 69. Connection to the bat- Image 68. Connection to the fuse box tery's positive terminal Image 70. Correct installation Image 71. Incorrect installation Image 72. Cover, fuse box www.zepro.com... -

Page 50: Electrical And Hydraulic Diagrams

Electrical and hydraulic diagrams ZAHD, ZAEHD 150/200-155/175 Electrical and hydraulic diagrams ZAHD / ZAEHD 150/200 MA (TLC B1) www.zepro.com... -

Page 51: Zahd / Zaehd 150/200 Ma (Zepro1)

Electrical and hydraulic diagrams ZAHD, ZAEHD 150/200-155/175 ZAHD / ZAEHD 150/200 MA (ZePRO1) www.zepro.com... -

Page 52: Zahd / Zaehd 150/200 Ma Autotilt (Tlc-B1)

Electrical and hydraulic diagrams ZAHD, ZAEHD 150/200-155/175 ZAHD / ZAEHD 150/200 MA Autotilt (TLC-B1) www.zepro.com... -

Page 53: Zahd / Zaehd 150/200 Ma, Autotilt (Inclinometer) (Zepro1)

Electrical and hydraulic diagrams ZAHD, ZAEHD 150/200-155/175 ZAHD / ZAEHD 150/200 MA, Autotilt (Inclinometer) (ZePRO1) www.zepro.com... -

Page 54: Zahd / Zaehd 150/200 Ma, Autotilt (Ifm) (Zepro1)

Electrical and hydraulic diagrams ZAHD, ZAEHD 150/200-155/175 ZAHD / ZAEHD 150/200 MA, Autotilt (IFM) (ZePRO1) www.zepro.com... -

Page 55: Lubrication And Fluid Level Check

Check the fluid level in the tank during service, top up if necessary. The marking on the hydraulic tank indi- cates the type of hydraulic fluid used. Mineral hydraulic fluid, product no. 21963 (1 litre), or biodegradable synthetic fluid, product no. 22235 (1 litre). Image 73. Lubrication points www.zepro.com... -

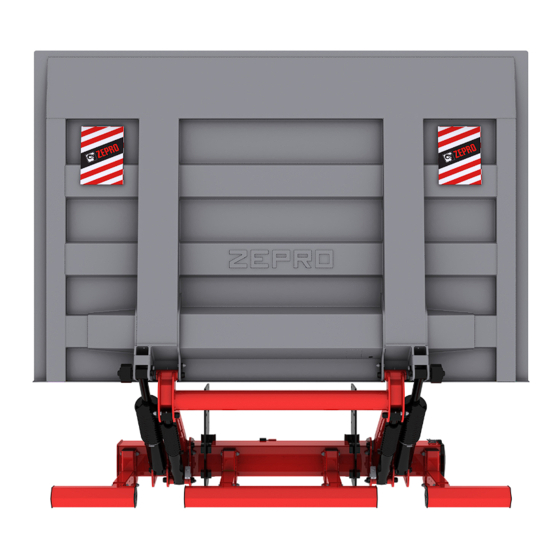

Page 56: Marking

Below, an overview of the location of the different markings is shown. Image of marking and further information can be found under the each subchapter for subsequent pages. 10.4 10.1 10.3 10.5 10.6 10.5 10.6 10.7 Image 74. Overview of labelling www.zepro.com... -

Page 57: Loading Diagram

Affix the load diagrams for the appropriate lift model close to the primary controller and in a suitable clearly visible position on the vehicle body. Image 75. Load diagram for load capacity 1500 kg, centre of gravity distance 750 mm. Image 76. Load diagram for load capacity 2000 kg, centre of gravity distance 750 mm. www.zepro.com... -

Page 58: Identification Plate

Affixed along the platform edge strips to mark the plat- form edges in its lowered position. The location of the warning tape often coincides with the contour marking, in which case the warning tape can be omitted. Image 79. Warning tape www.zepro.com... -

Page 59: Controller Sticker

For applications without 2-hand operation, this www.hiab.com part of the sticker is discarded. 55053TL 2020-03-04 Image 80. Controller sticker for CD 1, 2, 9 www.hiab.com www.hiab.com 77661TL 2020-03-04 55055TL 2020-03-04 Image 81. Controller sticker for CD 10 Image 84. Controller sticker for CD 4 www.zepro.com... -

Page 60: Danger Area

Attach warning flags as close as possible to the top and edge of the platform, where there is no risk of them coming loose when the platform is lowered to the ground. Swage the tracks together to secure the warning flags. Image 86. Warning flags www.zepro.com... -

Page 61: Testing And Verification

Static load (Test load 1.25 x tail lift loading capacity). For tail lifts with load centre of 750 mm Capacity Load 1500 kg Load 2000 kg Distance out in platform (L) 1500 kg 940 mm 2000 kg 1250 mm 940 mm Deformation Max. 15 mm Drift Max 2º Image 87. Testing and verification www.zepro.com... -

Page 62: Dynamic Load Test

That all safety and operating decals are installed in their respective position. • That the platform’s mechanical lock is functioning correctly (where applicable). • That the instructions for using the tail lift have been left in the driver’s cabin. • That the CE declaration of conformity has been completed. www.zepro.com... -

Page 63: Registration

Alu. platform 2205x2540 mm 194 kg Steel platforms Steel platform 2000x2540 mm 335 kg Lift components (part of cpl. lift chassis). Frame half ZAHD 150/200 28,7 kg Frame half ZAEHD 150/200 31,3 kg Liftarm ZAHD/ZAEHD 150/200-155 55,8 kg Liftarm ZAHD/ZAEHD 150/200-175 60,5 kg 3-part underrunbar cpl. - Page 64 BUILT TO PERFORM Zepro, Del and Waltco are Hiab brands for tail lifts. Hiab is a world-leading supplier of equipment, intelligent services and digital solutions for on-road load handling. As an industry pioneer our company commitment is to increase the efficiency of...

Need help?

Do you have a question about the ZAHD 150/200 and is the answer not in the manual?

Questions and answers