Table of Contents

Advertisement

Quick Links

A l l t e s t I n s t r u me n t s , I n c .

5 0 0 C e n t r a l A v e .

F a r mi n g d a l e , N J 0 7 7 2 7

P : ( 7 3 2 ) 9 1 9 - 3 3 3 9

F : ( 7 3 2 ) 9 1 9 - 3 3 3 2

a l l t e s t . n e t

s s a l e s @ a l l t e s t . n e t

T h e t e s t & me a s u r e me n t

e q u i p me n t y o u n e e d a t

t h e p r i c e y o u w a n t .

A l l t e s t c a r r i e s t h e w o r l d ' s l a r g e s t s e l e c t i o n o f

u s e d / r e f u r b i s h e d b e n c h t o p t e s t & me a s u r e me n t

e q u i p me n t a t 5 0 % t h e p r i c e o f n e w .

O O u r e q u i p me n t i s g u a r a n t e e d w o r k i n g , w a r r a n t i e d , a n d

a v a i l a b l e w i t h c e r t i f i e d c a l i b r a t i o n f r o m o u r i n - h o u s e s t a f f

o f t e c h n i c i a n s a n d e n g i n e e r s .

• 1 0 + f u l l t i me t e c h n i c i a n s w i t h o v e r 1 5 0 y e a r s o f

s p e c i a l i z a t i o n

• 9 0 d a y w a r r a n t y & 5 d a y r i g h t o f r e t u r n o n a l l

e q u i p me n t

• • 1 - 3 y e a r w a r r a n t i e s f o r n e w a n d

p r e mi u m- r e f u r b i s h e d e q u i p me n t

• E v e r y u n i t t e s t e d t o O E M s p e c i f i c a t i o n s

• S a t i s f a c t i o n g u a r a n t e e d

Y o u h a v e p l a n s , w e w i l l h e l p y o u a c h i e v e t h e m.

A n y p r o j e c t . A n y b u d g e t .

t

G e t a q u o t e t o d a y !

C C a l l ( 7 3 2 ) 9 1 9 - 3 3 3 9 o r e ma i l s a l e s @a l l t e s t . n e t .

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Tektronix AWG5000B Series

- Page 1 T h e t e s t & me a s u r e me n t e q u i p me n t y o u n e e d a t t h e p r i c e y o u w a n t . A l l t e s t I n s t r u me n t s , I n c .

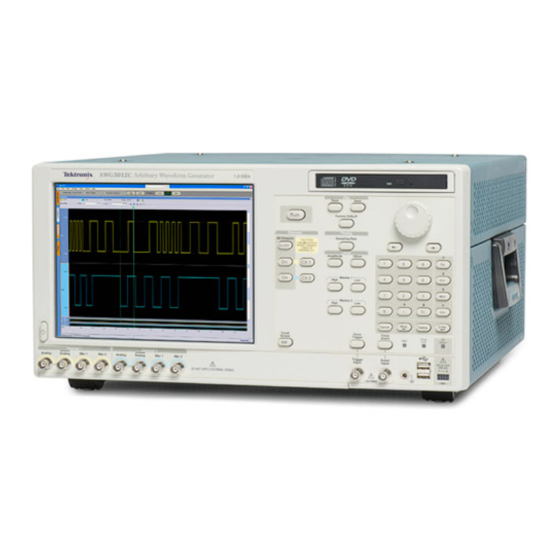

- Page 2 AWG5000B and AWG5000C Series Arbitrary Waveform Generators Service Manual *P077030401* 077-0304-01...

- Page 4 Service Manual Warning The servicing instructions are for use by qualified personnel only. To avoid personal injury, do not perform any servicing unless you are qualified to do so. Refer to all safety summaries prior to performing service www.tektronix.com 077-0304-01...

- Page 5 Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are protected by national copyright laws and international treaty provisions. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material.

- Page 6 Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

-

Page 8: Table Of Contents

Summary of Procedures..................Required Equipment..................Procedures for External Modules ................Procedures for Internal Modules (Upper) (AWG5000C Series) ........4-19 Procedures for Internal Modules (Upper) (AWG5000B Series) ........4-29 Procedures for Internal Modules (Lower)............... 4-41 AWG5000B and AWG5000C Series Service Manual... - Page 9 Table of Contents Troubleshooting....................4-52 Required Equipment..................4-52 Fault Isolation Procedure ................. 4-52 Instrument Diagnostics..................4-59 Calibration Error ................... 4-66 Hardware Error..................... 4-69 After Repair ....................4-71 Returning the Instrument for Service ..............4-72 Replaceable Parts Replaceable Parts ....................Parts Ordering Information ................. Using the Replaceable Parts List................

- Page 10 Figure 4-15: Drive module removal (AWG5000B) ............4-31 Figure 4-16: Removing the clamp cover..............4-32 Figure 4-17: Multi-Input/Output and Display Adapter board removal (AWG5000B Series)..4-33 Figure 4-18: Processor board removal (AWG5000B Series) ..........4-36 Figure 4-19: Secondary power supply, power supply, and RFI filter removal......

- Page 11 Figure 5-10: AWG5000B Series Processor module ............5-19 Figure 5-11: Power supply assembly................. 5-21 Figure 5-12: AWG5000C Series PCI/power interface module ..........5-23 Figure 5-13: AWG5000B Series PCI/power interface module ..........5-26 Figure 5-14: Fan tray assembly ................5-27 Figure 5-15: USB module ..................5-28 Figure 5-16: AWG1G/CLK1G/OUT1G modules............

- Page 12 Table of Contents List of Tables Table 3-1: Adjustments required for module replaced ............Table 3-2: Test equipment ..................Table 4-1: External inspection checklist ............... Table 4-2: Internal inspection checklist ................ Table 4-3: Required tools for module removal and reinstall..........Table 4-4: Test points voltage (J104).................

-

Page 13: General Safety Summary

General Safety Summary General Safety Summary Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it. To avoid potential hazards, use this product only as specified. Only qualified personnel should perform service procedures. To Avoid Fire or Personal Use proper power cord. - Page 14 General Safety Summary Terms in This Manual These terms may appear in this manual: WARNING. Warning statements identify conditions or practices that could result in injury or loss of life. CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

-

Page 15: Service Safety Summary

Service Safety Summary Service Safety Summary Only qualified personnel should perform service procedures. Read this Service Safety Summary and the General Safety Summary before performing any service procedures. Do Not Service Alone. Do not perform internal service or adjustments of this product unless another person capable of rendering first aid and resuscitation is present. -

Page 16: Environmental Considerations

See www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information. The mercury notification applies only to the AWG5000B Series instruments. Restriction of Hazardous This product has been classified as Monitoring and Control equipment, and is outside the scope of the 2002/95/EC RoHS Directive. - Page 17 Environmental Considerations AWG5000B and AWG5000C Series Service Manual...

-

Page 18: Preface

Preface This manual contains service information for your instrument. Read this preface to learn how this manual is structured, the conventions it uses, and where to find additional supplemental information related to servicing this product. You should also read the General and Service safety summaries before servicing the product. - Page 19 Preface AWG5000B and AWG5000C Series Service Manual...

-

Page 20: Operating Information

Operating Information... -

Page 22: Operating Information

For information on installing, operating, and networking the instrument, refer to the AWG5000 and AWG7000 Series Arbitrary Waveform Generators Quick Start User Manual. This manual is available on the Document CD that came with your instrument, and on the Tektronix Web site (www.tektronix.com/manuals). AWG5000B and AWG5000C Series Service Manual 1–1... - Page 23 Operating Information 1–2 AWG5000B and AWG5000C Series Service Manual...

-

Page 24: Theory Of Operation

Theory of Operation... -

Page 26: Overview

Theory of Operation This section describes the electrical operation of the AWG5000B and AWG5000C Series Arbitrary Waveform Generators. Overview The Arbitrary Waveform Generators provide various models with different frequency capabilities and numbers of channels. Each model consists of two major sections: the platform section and generator section. The platform section is common to each model. -

Page 27: Figure 2-1: Awg5000C Series Block Diagram

Theory of Operation Figure 2-1: AWG5000C Series block diagram 2–2 AWG5000B and AWG5000C Series Service Manual... -

Page 28: Figure 2-2: Awg5000B Series Block Diagram

Theory of Operation Figure 2-2: AWG5000B Series block diagram AWG5000B and AWG5000C Series Service Manual 2–3... -

Page 29: Module Overviews

Theory of Operation Module Overviews A Microsoft Windows processor system is the primary controller of the instrument. The instrument features an XGA resolution flat-panel display, a transparent touch screen, and a front panel with direct access to commonly used instrument functions. You can also make complete use of the instrument with a mouse and a keyboard. - Page 30 Theory of Operation Multi-Input/Output (MIO) The MIO board coordinates the flow of data through the Windows PCIe port (PCI port for AWG5000B series) from various devices that communicate with Board the μATX system. The devices include the display system, GPIB, TekLink, and data flow (PCIF) path to the waveform generator system.

- Page 31 1024 x 768 resolution and brightness is set to full intensity. For AWG5000C Series instruments, the display is controlled by the Processor board. For AWG5000B Series instruments, the display is controlled by the MIO board (or the display adapter board on AWG5000B Series instruments with serial numbers B020000 and above).

- Page 32 Theory of Operation Power (PWR2) Board The PWR2 board provides DC power to the fans, HDD, CD Drive, μATX board, MIO board, OUT1G board, and AWG1G board. All the power comes from the power supply and secondary power supply modules. The fan control circuit has a thermal sensor on this board.

- Page 33 Theory of Operation OUT1G Board The OUT1G board provides analog outputs to the front-panel connector. Amplitude, filter, offset, add input, and On/Off controls are added to the analog outputs. The OUT1G board consists of the following blocks: Analog differential output amplifier Selectable low-pass filter Selectable attenuator Add input from external...

-

Page 34: Adjustment Procedures

Adjustment Procedures... -

Page 36: Adjustment Interval

Adjustment Procedures This section contains information about instrument adjustment. Only qualified personnel should perform adjustment procedures. Read the Service Safety Summary and the General Safety Summary before performing any service procedures. NOTE. Before performing adjustment procedures, you must warm up the arbitrary waveform generator at least 20 minutes in an ambient temperature between 20 °C and 30 °C. -

Page 37: Required Equipment

Frequency counter Accuracy: within ± 0.01 ppm Agilent 53181A 1 ea 50 Ω BNC cable Tektronix part number 1 ea 012-0057-01 Adjustment Overview The adjustment procedure contains three adjustment items. Before performing adjustment procedures, you must warm up the arbitrary waveform generator at least 20 minutes in an ambient temperature between 20 °C and 30 °C. -

Page 38: Figure 3-1: Service Ui Menu

Adjustment Procedures Figure 3-1: Service UI menu The left half of the window with the title Calibration is the calibration part of the window. You can perform the calibrations either all in one step or individually. However, since the calibration sequence is predefined, follow the sequence from the top. -

Page 39: Calibration Procedure

Adjustment Procedures Saving the Calibration When the calibration has been performed and the results are saved to the EEPROM (regardless of the item, all results are saved to the EEPROM on the MIO board), Results to EEPROM the flag under Is Calibrated will be set to TRUE. If the calibration was successful, the Status field will display PASS. -

Page 40: Figure 3-3: 10 Mhz Reference Calibration Dialog Box

Adjustment Procedures 2. Set the frequency counter as follows: a. Input impedance: AC, 50 Ω b. Gate time: 0.1 s 3. Click the 10MHz Reference... button in the Service UI menu to display the following dialog box: Figure 3-3: 10 MHz Reference Calibration dialog box 4. - Page 41 Adjustment Procedures 3–6 AWG5000B and AWG5000C Series Service Manual...

-

Page 42: Maintenance

Maintenance... -

Page 44: Preparation

Maintenance This section contains information needed to do periodic and corrective maintenance on the instrument. The following subsections are included: Preparation – Tells you how to prepare for arbitrary waveform generator maintenance. Preparation Preventing ESD – Provides general information on preventing damage to internal modules when doing maintenance. -

Page 45: Inspection And Cleaning

Maintenance Do not allow anything capable of generating or holding a static charge on the work station surface. Handle circuit boards by the edges when possible. Do not slide the modules over any surface. Avoid handling modules in areas that have a floor or work-surface covering capable of generating a static charge. -

Page 46: Table 4-1: External Inspection Checklist

Maintenance Inspection and Cleaning The collection of dirt on internal components can cause them to overheat and fail. Dirt also provides an electrical conduction path that could cause an instrument procedures failure, especially under high-humidity conditions. Inspect the instrument as often as operating conditions require. - Page 47 Maintenance Cleaning Procedure – Exterior. Do the following steps to clean the instrument exterior: 1. Remove loose dust on the outside of the instrument with a lint-free cloth. Use care to avoid scratching the clear glass display shield. 2. Remove remaining dirt with a lint-free cloth dampened in a general purpose detergent-and-water solution.

-

Page 48: Table 4-2: Internal Inspection Checklist

NOTE. If steps 1 and 2 do not remove all the dust or dirt, please contact Tektronix. (See Contacting Tektronix at the front of this manual.) Lubrication. There is no periodic lubrication required for the instrument. -

Page 49: Removal And Installation Procedures

Removal and Installation Procedures Removal and Installation Procedures This section contains procedures for removal and installation of all mechanical and electrical modules. Preparation WARNING. Before performing this or any other procedure in this manual, read the General Safety Summary and Service Safety Summary found at the beginning of this manual. -

Page 50: Summary Of Procedures

Removal and Installation Procedures Summary of Procedures Disassembly for replacement is best achieved by removing and replacing the modules in a specific order. Complete disassembly is best achieved by the following procedures in the order given in the following figures. Figure 4-1: Disassembly procedures for external modules and internal modules (top) AWG5000B and AWG5000C Series Service Manual 4–7... -

Page 51: Required Equipment

Removal and Installation Procedures Figure 4-2: Disassembly procedures for internal modules (bottom) Required Equipment Most modules in the instrument can be removed with a screwdriver handle mounted with a size T-15, Torx screwdriver tip. All equipment required to remove and reinstall the modules is listed in the following table. Table 4-3: Required tools for module removal and reinstall General Item #... -

Page 52: Procedures For External Modules

Removal and Installation Procedures Procedures for External Modules Handle Unit You need a screwdriver with a T-20 Torx tip (items 1 and 4). Removal. To remove the handle unit, follow these steps: (See Figure 4-3 on page 4-10.) 1. Remove the two screws securing the handle base bracket to the cosmetic cover. -

Page 53: Figure 4-3: Handle, Snaps, Cosmetic Covers, And Front-Trim Unit Removal

Removal and Installation Procedures 3. Remove the two screws (side) and three screws (bottom) securing the cosmetic cover to the chassis. 4. Loosen the cover with a detaching tool, such as a flat-blade screwdriver. 5. Tilt the rear side of the cover up, and then pull it off the chassis. Installation. - Page 54 Removal and Installation Procedures Front-Trim Unit You need a screwdriver with a T-15 Torx tip and angle-tip tweezers (items 1, 2, and 8). Removal. To remove the front-trim unit, follow these steps: (See Figure 4-3 on page 4-10.) 1. Remove the handle unit, snaps, and cosmetic covers. 2.

-

Page 55: Figure 4-4: Emi Cover Removal

Removal and Installation Procedures Figure 4-4: EMI cover removal 4–12 AWG5000B and AWG5000C Series Service Manual... - Page 56 Removal and Installation Procedures Hard Disk Assembly Removal. To remove the removable hard disk assembly, follow these steps: 1. Orient the instrument so that its bottom is down on the work surface and its rear is facing you. 2. Loosen the two thumb screws securing the hard disk assembly to the instrument.

-

Page 57: Figure 4-5: Fan Tray Unit Removal

Removal and Installation Procedures Figure 4-5: Fan tray unit removal Front-Panel Unit You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the front-panel unit, follow these steps: (See Figure 4-6 on page 4-16.) 1. - Page 58 Removal and Installation Procedures Front-Panel Assembly You need a screwdriver with a T-15 Torx tip (items 1 and 2). (AWG5000C Series) Removal. To remove the front-panel assembly, follow these steps: (See Figure 4-6 on page 4-16.) 1. Remove the handle unit, snaps, cosmetic covers, front-trim unit, and EMI covers.

-

Page 59: Figure 4-6: Disassembly Of Front-Panel Assembly (Awg5000C Series)

Figure 4-6: Disassembly of front-panel assembly (AWG5000C Series) Front-Panel Assembly You need a screwdriver with a T-15 Torx tip (items 1 and 2). (AWG5000B Series) Removal. To remove the front-panel assembly, follow these steps: (See Figure 4-7 on page 4-18.) 1. - Page 60 Removal and Installation Procedures 3. Remove the touch screen module: a. Remove the two screws securing the touch screen module to the front-panel bracket. b. Disconnect the cable from J200 on the LCDA board. c. Lift the touch screen module away from the front-panel bracket. 4.

-

Page 61: Figure 4-7: Disassembly Of Front-Panel Assembly (Awg5000B Series)

Removal and Installation Procedures Figure 4-7: Disassembly of front-panel assembly (AWG5000B Series) 4–18 AWG5000B and AWG5000C Series Service Manual... -

Page 62: Procedures For Internal Modules (Upper) (Awg5000C Series)

Removal and Installation Procedures Procedures for Internal Modules (Upper) (AWG5000C Series) Drive-Bay Module You need a screwdriver with a T-15 Torx tip and a wire cutter (items 1, 2, and 9). Removal. To remove the drive-bay module, follow these steps: (See Figure 4-9 on page 4-21.) 1. - Page 63 Removal and Installation Procedures DVD-ROM Drive You need a screwdriver with a T-15 Torx tip and a #1 Phillips screwdriver (items 1, 2, and 5). Removal. To remove the DVD-ROM drive, follow these steps: (See Figure 4-9 on page 4-21.) 1.

-

Page 64: Figure 4-9: Drive Module Removal (Awg5000C Series)

Removal and Installation Procedures Figure 4-9: Drive module removal (AWG5000C Series) AWG5000B and AWG5000C Series Service Manual 4–21... -

Page 65: Figure 4-10: Multi-Input/Output Removal (Awg5000C Series)

Removal and Installation Procedures Multi-Input/Output Board You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the Multi-Input/Output (MIO) board, follow these steps: (See Figure 4-10.) 1. Remove the handle unit, snaps, cosmetic covers, front-trim unit, EMI covers, hard disk assembly, and drive-bay module. - Page 66 Removal and Installation Procedures Processor Module You need a screwdriver with a T-15 Torx tip and a 3/16 inch open-end wrench (items 1, 2, and 7). NOTE. Before you remove the processor module, you need to disconnect the ribbon cable at J1000 from the AWG1G board. (See page 4-44, AWG1G 2 CH Board.) (See page 4-46, AWG1G 4 CH Board.) Removal.

-

Page 67: Figure 4-11: Processor Board Removal (Awg5000C Series)

Removal and Installation Procedures Figure 4-11: Processor board removal (AWG5000C Series) 4–24 AWG5000B and AWG5000C Series Service Manual... - Page 68 Removal and Installation Procedures Secondary Power Supply You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the secondary power supply, follow these steps: (See Figure 4-19 on page 4-39.) 1. Remove the handle unit, snaps, cosmetic covers, front-trim unit, EMI covers, hard disk assembly, drive-bay module, and Multi-Input/Output board.

- Page 69 Removal and Installation Procedures RFI Filter You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the power supply, follow these steps: (See Figure 4-12 on page 4-27.) 1. Remove the handle unit, snaps, cosmetic covers, and EMI covers. 2.

-

Page 70: Figure 4-12: Secondary Power Supply, Power Supply, And Rfi Filter Removal

Removal and Installation Procedures Figure 4-12: Secondary power supply, power supply, and RFI filter removal AWG5000B and AWG5000C Series Service Manual 4–27... -

Page 71: Figure 4-13: Power Board Removal

Removal and Installation Procedures Power Board You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the Power board, follow these steps: (See Figure 4-13.) 1. Remove the handle unit, snaps, cosmetic covers, front-trim unit, EMI covers, hard disk assembly, drive-bay module, power supply, Multi-Input/Output board, and Processor board. -

Page 72: Procedures For Internal Modules (Upper) (Awg5000B Series)

Removal and Installation Procedures Procedures for Internal Modules (Upper) (AWG5000B Series) Drive-Bay Module You need a screwdriver with a T-15 Torx tip and a wire cutter (items 1, 2, and 9). Removal. To remove the drive-bay module, follow these steps: (See Figure 4-15 on page 4-31.) - Page 73 Removal and Installation Procedures DVD-ROM Drive You need a screwdriver with a T-15 Torx tip and a #1 Phillips screwdriver (items 1, 2, and 5). Removal. To remove the DVD-ROM drive, follow these steps: (See Figure 4-15 on page 4-31.) 1.

-

Page 74: Figure 4-15: Drive Module Removal (Awg5000B)

Removal and Installation Procedures Figure 4-15: Drive module removal (AWG5000B) AWG5000B and AWG5000C Series Service Manual 4–31... -

Page 75: Figure 4-16: Removing The Clamp Cover

Removal and Installation Procedures Multi-Input/Output Board You need a screwdriver with a T-15 Torx tip (items 1 and 2). (AWG5000B Series Serial Removal. To remove the Multi-Input/Output (MIO) board, follow these steps: Numbered B010000 to (See Figure 4-17 on page 4-33.) B019999) 1. -

Page 76: Figure 4-17: Multi-Input/Output And Display Adapter Board Removal (Awg5000B Series)

Figure 4-17: Multi-Input/Output and Display Adapter board removal (AWG5000B Series) Multi-Input/Output Board You need a screwdriver with a T-15 Torx tip (items 1 and 2). (AWG5000B Series Serial Removal. To remove the Multi-Input/Output (MIO) board, follow these steps: Numbered B020000 and (See Figure 4-17.) Above) 1. - Page 77 Installation. To install, reverse this procedure. Display Adapter You need a screwdriver with a T-15 Torx tip (items 1 and 2). (AWG5000B Series Serial Removal. To remove the Display Adapter board (ADD2 board), follow these Numbered B020000 and steps: (See Figure 4-17 on page 4-33.) Above) 1.

- Page 78 Removal and Installation Procedures Processor Module You need a screwdriver with a T-15 Torx tip and a 3/16 inch open-end wrench (items 1, 2, and 7). NOTE. Before you remove the processor module, you need to disconnect the ribbon cable at J1000 from the AWG1G board. (See page 4-44, AWG1G 2 CH Board.) (See page 4-46, AWG1G 4 CH Board.) Removal.

-

Page 79: Figure 4-18: Processor Board Removal (Awg5000B Series)

Removal and Installation Procedures Figure 4-18: Processor board removal (AWG5000B Series) 4–36 AWG5000B and AWG5000C Series Service Manual... - Page 80 Removal and Installation Procedures Secondary Power Supply You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the secondary power supply, follow these steps: (See Figure 4-19 on page 4-39.) 1. Remove the handle unit, snaps, cosmetic covers, front-trim unit, EMI covers, MIO board enforcement bracket, hard disk assembly, drive-bay module, and Multi-Input/Output board.

- Page 81 Removal and Installation Procedures RFI Filter You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the power supply, follow these steps: (See Figure 4-19 on page 4-39.) 1. Remove the handle unit, snaps, cosmetic covers, and EMI covers. 2.

-

Page 82: Figure 4-19: Secondary Power Supply, Power Supply, And Rfi Filter Removal

Removal and Installation Procedures Figure 4-19: Secondary power supply, power supply, and RFI filter removal AWG5000B and AWG5000C Series Service Manual 4–39... -

Page 83: Figure 4-20: Power Board Removal

Removal and Installation Procedures Power Board You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the Power board, follow these steps: (See Figure 4-20.) 1. Remove the handle unit, snaps, cosmetic covers, front-trim unit, EMI covers, MIO board enforcement bracket, hard disk assembly, drive-bay module, power supply, Multi-Input/Output board, and Processor board. -

Page 84: Procedures For Internal Modules (Lower)

Removal and Installation Procedures Procedures for Internal Modules (Lower) Front Connector Board You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the Front Connector board, follow these steps: (See Figure 4-21 on page 4-42.) 1. -

Page 85: Figure 4-21: Front Connector Board, Clk1G Module, Awg1G Board, And Out1G Boards Removal

Removal and Installation Procedures Figure 4-21: Front Connector board, CLK1G module, AWG1G board, and OUT1G boards removal (4-channel model) 4–42 AWG5000B and AWG5000C Series Service Manual... - Page 86 Removal and Installation Procedures CLK1G Module You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the CLK1G module, follow these steps: (See Figure 4-22 on page 4-44.) 1. Remove the handle unit, snaps, cosmetic covers, front-trim unit, and EMI covers.

-

Page 87: Figure 4-22: Disassembly Of The Clk1G Module

Removal and Installation Procedures Figure 4-22: Disassembly of the CLK1G module AWG1G 2 CH Board You need a screwdriver with a T-15 Torx tip (items 1 and 2). Removal. To remove the AWG1G 2 channel board, follow these steps: (See Figure 4-21 on page 4-42.) 1. -

Page 88: Figure 4-23: Cable Post On The Awg1G Board (2 Ch)

Removal and Installation Procedures Figure 4-23: Cable post on the AWG1G board (2 CH) 5. Disconnect the cables at J1050, J2000, and J5000 from the AWG1G board. 6. Disconnect these Peltola cables: The cable at J6020A from the AWG1G board to the CH1 & CH2 OUT1G board (J1000). -

Page 89: Figure 4-24: Cable Post On The Awg1G Board (4 Ch)

Removal and Installation Procedures The cable at J1440 from the AWG1G board to the Event Input connector. The cable at J3011 from the AWG1G board to the External Clock Input connector. The cable at J3020 from the AWG1G board to the Oscillator Output connector. - Page 90 Removal and Installation Procedures 4. Disconnect the cables at J1050, J1060, J2000, and J5000 from the AWG1G board. 5. Disconnect these Peltola cables: The cable at J6020A from the AWG1G board to the CH1 & CH2 OUT1G board (J1000). The cable at J6030A from the AWG1G board to the CH1 & CH2 OUT1G board (J2000).

-

Page 91: Figure 4-25: Location Of The Cable Ties

Removal and Installation Procedures The cable at J3011 from the AWG1G board to External Clock Input connector. The cable at J3020 from the AWG1G board to Oscillator Output connector. The cable at J3010 from the AWG1G board to the CLK1G board. 6. - Page 92 Removal and Installation Procedures 5. Disconnect these Peltola cables: The cable at J1000 from the CH1 & CH2 OUT1G board to the AWG1G board (J6020A). The cable at J2000 from the CH1 & CH2 OUT1G board to the AWG1G board (J6030A). The cable at J3000 from the CH1 &...

-

Page 93: Figure 4-26: Location Of The Cable Ties

Removal and Installation Procedures Figure 4-26: Location of the cable ties 4. Disconnect these cables: The cable at J5000 from the CH3 & CH4 OUT1G board to the AWG1G board (J1060). The cable at J7000 from the CH3 & CH4 OUT1G board to the CH1 & CH2 OUT1G board (J7000). - Page 94 Removal and Installation Procedures 6. Remove the nine screws securing the CH3 & CH4 OUT1G board to the chassis. 7. Lift the board away from the chassis. Installation. To install, reverse this procedure. AWG5000B and AWG5000C Series Service Manual 4–51...

-

Page 95: Troubleshooting

PC troubleshooting and Microsoft Windows operating system skills. Details of PC and Windows operation and service are not in this manual. For assistance, contact your local Tektronix Service Center. Required Equipment You will need a digital multimeter to check voltages of the power supply, secondary power supply, and PWR board. -

Page 96: Figure 4-27: Primary Troubleshooting Tree (1)

Troubleshooting Figure 4-27: Primary troubleshooting tree (1) AWG5000B and AWG5000C Series Service Manual 4–53... -

Page 97: Figure 4-28: Primary Troubleshooting Tree (2)

Troubleshooting Figure 4-28: Primary troubleshooting tree (2) 4–54 AWG5000B and AWG5000C Series Service Manual... -

Page 98: Figure 4-29: Pwr Board Test Points (J104)

Troubleshooting Checking the Power To check the power supply voltages, power on the instrument and connect the (–) lead of a multimeter to chassis ground. Supply Voltages To measure the output voltages of the power supply, check the voltages at J104 on the PWR board with the digital multimeter and compare each reading to the values listed in the following table. -

Page 99: Figure 4-30: Secondary Power Supply Test Points (Cn51 And Cn61)

Troubleshooting Checking the Secondary To measure the output voltages of the secondary power supply, check the voltages at CN51 and CN61 on the power supply with the digital multimeter and compare Power Supply Voltages each reading to the values listed in the following table. If the voltages are within the allowance, your power supply is functional. -

Page 100: Figure 4-31: Awg1G Board Test Points (J2000)

Troubleshooting Checking the Voltages on To measure the output voltages of the PWR board, check the voltages at J2000 on the AWG1G board with the digital multimeter and compare each reading to the AWG1G Board the values listed in the following table. If the voltages are within the allowance, your PWR board is functional. -

Page 101: Figure 4-32: Out1G Board Test Points (J7000)

Troubleshooting Checking the Voltages on To measure the output voltages of the PWR board, check the voltages at J7000 (or J6000) on the OUT1G board with the digital multimeter and compare each the OUT1G Board reading to the values listed in the following table. If the voltages are within the allowance, your PWR board is functional. -

Page 102: Instrument Diagnostics

Troubleshooting Instrument Diagnostics The primary diagnostics for the instrument are accessible through the AWG application software. The instrument diagnostics check the basic functionality of analog outputs at every power on. The instrument diagnostics run after Windows has booted up and run its own set of system checks. If any failures occur at power on, a pop-up message indicates that a failure has occurred and provides an error code: Diagnostics error codes (See Table 4-8 on page 4-60.) -

Page 103: Table 4-8: Diagnostics Error

Troubleshooting Table 4-8: Diagnostics error Possible defect Error code Error log message on board Note AWG register readback 120000000 HwDiagAwgRegister AwgController AWG1G AWG1G: U1000 address_0x21 register diag. Fail expected data=xxxx actual data=xxxx 120000001 HwDiagAwgRegister AwgController AWG1G AWG1G: U1000 address_0x23 register diag. Fail expected data=xxxx actual data=xxxx 120000002 HwDiagAwgRegister AwgController... - Page 104 Troubleshooting Table 4-8: Diagnostics error (cont.) Possible defect Error code Error log message on board Note 120000014 HwDiagAwgRegister Ch2 TEK0015-TNO AWG1G AWG1G: U1000, U4310D, U4420D address_REG register diag. Fail expected data=xxxx actual data=xxxx TNO: TEK0015 number REG: Register number 120000023 HwDiagAwgRegister AD9736 failed channel=1 AWG1G AWG1G: U1000, U6000A...

- Page 105 Troubleshooting Table 4-8: Diagnostics error (cont.) Possible defect Error code Error log message on board Note CH 2 waveform memory 122000000 HwDiagWaveformMemory channel2, testNo AWG1G AWG1G: U4000B, U4500B, U4510B, Data bus [IC-Pin] Error expected data=xxxxxxxx U4520B, U4530B, U4600B, U4610B, actual data=xxxxxxxx testNo: 1’st 2’nd IC: IC U4620B, U4630B.

- Page 106 Troubleshooting Table 4-8: Diagnostics error (cont.) Possible defect Error code Error log message on board Note 125000003 HwDiagDataTiming channel=4, Value is out of a AWG1G, CLK1G AWG1G: U1000 CLK1G: U3200 range max=xx min=xx Clock register read back 130000000 HwDiagClockRegister PLL_MUX_HIGH=0 AWG1G, CLK1G AWG1G: U1000 CLK1G: U3200 130000001...

- Page 107 Troubleshooting Table 4-8: Diagnostics error (cont.) Possible defect Error code Error log message on board Note Output 1 analog level 141XP0031 Analog Level Diag CHX positive (negative) 6db OUT1G OUT1G: K1100, K2100, K3100, K4100 attenuator failed. expected 0.5005, actual xxxxx 141XP0032 Analog Level Diag CHX positive (negative) 12db OUT1G...

- Page 108 Troubleshooting Table 4-8: Diagnostics error (cont.) Possible defect Error code Error log message on board Note 141XP0055 Analog Level Diag CHX 20mhz filter gain OUT1G OUT1G: K1120, K1125, K2120, K2125, balance failed. K3120, K3125, K4120, K4125 141XP0056 Analog Level Diag CHX 100mhz filter gain OUT1G OUT1G: K1120, K1125, K2120, K2125, balance failed.

-

Page 109: Calibration Error

Troubleshooting Table 4-8: Diagnostics error (cont.) Possible defect Error code Error log message on board Note 151XP0043 Analog Level Diag CHX positive (negative) read AWG1G AWG1G: U6000, U6015 [C-D] D/A gain21 failed. Expected 0.150V, actual xxxxxV 151XP0052 Analog Level Diag CHX 6db att gain balance OUT1G OUT1G: K1100, K2100, K3100, K4100 failed. -

Page 110: Table 4-9: Calibration Error

Troubleshooting Table 4-9: Calibration error Possible defect Error code Error log message on board Note 200XP0031 Analog Level Calibration CHX positive (negative) OUT1G OUT1G: K1100, K2100, K3100, K4100 6db attenuator failed. Expected:0.5005, actual:xxxx 200XP0032 Analog Level Calibration CHX positive (negative) OUT1G OUT1G: K1105, K2105, K3105, K4105 12db attenuator failed. - Page 111 Troubleshooting Table 4-9: Calibration error (cont.) Possible defect Error code Error log message on board Note 200X00045 Analog Level Calibration CHX D/A gain balance2 AWG1G AWG1G: U6000 failed. 200X00046 Analog Level Calibration CHX D/A gain balance3 AWG1G AWG1G: U6000 failed. 200X00047 Analog Level Calibration CHX D/A gain balance4 AWG1G...

-

Page 112: Hardware Error

Troubleshooting Hardware Error The following table lists the instrument hardware related errors. Table 4-10: Hardware error Possible defect Error code Error log message on board Note 300000000 The system cannot find the device specified. MIO: U100, U200, U220, Y230 300000001 The device is not ready. - Page 113 Troubleshooting Table 4-10: Hardware error (cont.) Possible defect Error code Error log message on board Note 300000057 The AD9736 FIFO adjustment failed in AWG1G AWG1G: U1000, U6000D channel 4. 300000058 The phase adjustment of two TEK0015 failed AWG1G AWG1G: U1000, U4310A, U4420A in channel 1.

-

Page 114: After Repair

Troubleshooting Table 4-10: Hardware error (cont.) Possible defect Error code Error log message on board Note 300000209 The download (AwgController) timeout period MIO, AWG1G MIO: U300, AWG1G: U1000, has expired. MIO-AWG1G cable 300000210 The system cannot find the file specified. Software/disk drive (PLD121B.Bit) 300000211... -

Page 115: Returning The Instrument For Service

Returning the Instrument for Service When repacking the instrument for shipment, use the original packaging material. If it is unavailable or unfit for use, contact your local Tektronix representative to obtain new packaging. Seal the shipping carton with an industrial stapler or strapping tape. -

Page 116: Replaceable Parts

Replaceable Parts... -

Page 118: Parts Ordering Information

Tektronix field office or representative will contact you concerning any change in part number. Part Number Revision Tektronix part numbers contain two digits that show the revision level of the part. For most parts in this manual, you will find the letters XX in place of the Level revision level number. -

Page 119: Using The Replaceable Parts List

For more information about the module exchange program, call 1-800-833-9200. Outside North America, contact a Tektronix sales office or distributor; see the Tektronix Web site (www.tektronix.com) for a list of offices. Module Repair and Return. You may ship your module to us for repair, after which we will return it to you. - Page 120 Replaceable Parts Replaceable parts list – Cosmetics Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 5-1- COSMETICS 335-2286-00 MARKER, LABEL, IDENTIFICATION; AWG5014C 335-2287-00 MARKER, LABEL, IDENTIFICATION; AWG5012C 335-2288-00 MARKER, LABEL, IDENTIFICATION; AWG5002C 335-1966-00 MARKER;...

- Page 121 Replaceable Parts Figure 5-1: Cosmetics 5–4 AWG5000B and AWG5000C Series Service Manual...

- Page 122 Replaceable Parts Replaceable parts list – EMI covers Fig. & index Tektronix Serial no. Serial no. number part number effective dis-cont’d Name & description 5-2- EMI COVERS 200-4992-01 COVER, EMI, TOP (AWG5000B) 200-5156-00 COVER, EMI, TOP (AWG5000C) 200-5034-01 COVER, EMI, BOTTOM 211-1050-00 SCREW,MACHINE;...

- Page 123 Replaceable Parts Replaceable parts list – AWG5000C Series Chassis assembly Fig. & index Tektronix Serial no. Serial no. number part number effective dis-cont’d Name & description 5-3- CHASSIS ASSEMBLY 131-6417-00 CONTACT,ELEC; GROUNDING,0.600 L X 0.250 W X 0.220 D, ELECTROLESS NICKEL PLATE 348-0966-00 GROMMET,PLASTIC;BLACK,ROUND,0.625 ID...

- Page 124 Replaceable Parts Replaceable parts list – AWG5000B Series Chassis assembly Fig. & index Tektronix Serial no. Serial no. number part number effective dis-cont’d Name & description 5-4- CHASSIS ASSEMBLY 131-6417-00 CONTACT,ELEC; GROUNDING,0.600 L X 0.250 W X 0.220 D, ELECTROLESS NICKEL PLATE 348-0966-00 GROMMET,PLASTIC;BLACK,ROUND,0.625 ID...

- Page 125 Replaceable Parts Replaceable parts list – AWG5000C Series front-panel assembly Fig. & index Tektronix Serial no. Serial no. number part number effective dis-cont’d Name & description 5-5- FRONT-PANEL ASSEMBLY 259-0193-00 FLEX CIRCUIT; ON/STAND BY SWITCH 407-5537-00 BRACKET; TOUCH SCREEN 211-1236-00 SCREW, MACHINE;...

- Page 126 Replaceable Parts Figure 5-5: AWG5000C Series front-panel assembly AWG5000B and AWG5000C Series Service Manual 5–9...

- Page 127 Replaceable Parts Replaceable parts list – AWG5000B Series front-panel assembly Fig. & index Tektronix part Serial no. Serial no. number number effective dis-cont’d Name & description 5-6- FRONT-PANEL ASSEMBLY 065-0762-01 TOUCH SCREEN ASSEMBLY 211-1050-00 SCREW,MACHINE; 6-32 X 0.312 L,PNH,STL CAD PLT,T15 119-6813-00 DISPLAY 10.4 INCH NL10276BC24-13...

- Page 128 Replaceable Parts Figure 5-6: AWG5000B Series front-panel assembly AWG5000B and AWG5000C Series Service Manual 5–11...

- Page 129 Replaceable Parts Replaceable parts list – AWG5000C Series drive modules Fig. & index Tektronix Serial no. Serial no. number part number effective dis-cont’d Name & description 5-7- DRIVE MODULE 407-5156-00 BRACKET,DVD-CD/RW;ADAPTER FOR DVD-CD/RW SLIMLINE 211-1050-00 SCREW,MACHINE; 6-32 X 0.312 L,PNH,STL CAD PLT,T15 211-0950-00 SCREW,MACHINE;...

- Page 130 Replaceable Parts Figure 5-7: AWG5000C Series drive modules AWG5000B and AWG5000C Series Service Manual 5–13...

- Page 131 Replaceable Parts Replaceable parts list – AWG5000B Series drive modules Fig. & index Tektronix Serial no. Serial no. number part number effective dis-cont’d Name & description 5-8- DRIVE MODULE 407-5365-00 BRACKET, REINFORCEMENT; MIO BOARD HOLDER WHEN INSTALLED 211-1050-00 SCREW,MACHINE; 6-32 X 0.312 L,PNH,STL CAD PLT,T15 407-5156-00 BRACKET,DVD-CD/RW;ADAPTER FOR DVD-CD/RW SLIMLINE...

- Page 132 Replaceable Parts Figure 5-8: AWG5000B Series drive modules AWG5000B and AWG5000C Series Service Manual 5–15...

- Page 133 Replaceable Parts Replaceable parts list – AWG5000C Series Processor module Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 5-9- PROCESSOR MODULE 407-5195-01 BRACKET;DRIVE BAY UNIT 211-1050-00 SCREW,MACHINE; 6-32 X 0.312 L,PNH,STL CAD PLT,T15 343-1627-00 CABLE,CLAMP;...

- Page 134 Replaceable Parts Figure 5-9: AWG5000C Series Processor module AWG5000B and AWG5000C Series Service Manual 5–17...

- Page 135 Replaceable Parts Replaceable parts list – AWG5000B Series Processor module Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 5-10- PROCESSOR MODULE 407-5195-01 BRACKET;DRIVE BAY UNIT 211-1050-00 SCREW,MACHINE; 6-32 X 0.312 L,PNH,STL CAD PLT,T15 343-1627-00 CABLE,CLAMP;...

- Page 136 Replaceable Parts Figure 5-10: AWG5000B Series Processor module AWG5000B and AWG5000C Series Service Manual 5–19...

- Page 137 Replaceable Parts Replaceable parts list – Power supply assembly Fig. & index Tektronix Serial no. Serial no. number part number effective dis-cont’d Name & description 5-11- POWER SUPPLY ASSEMBLY 342-1152-00 INSULATOR,FOR 119B12800 ZWQ130-5224 POWER SUPPLY, POLYCARBONATE, SAFETY CONTROLLED 335-1724-00 MARKER,IDENT; LABEL,WARNING,2.0 X 1.0,0.0035 SILVER POLY, W/ACRYLIC ADHESIVE;TMSSK1,SAFETY CONTROLLED...

- Page 138 Replaceable Parts Figure 5-11: Power supply assembly AWG5000B and AWG5000C Series Service Manual 5–21...

- Page 139 Replaceable Parts Replaceable parts list – AWG5000C Series PCI/power interface module Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 5-12- PCI/POWER INTERFACE MODULE 174-5246-00 CABLE ASSY ELEC: 2 X 12P,31IN L,AWG16 X 24,39-01-2245,...

- Page 140 Replaceable Parts Figure 5-12: AWG5000C Series PCI/power interface module AWG5000B and AWG5000C Series Service Manual 5–23...

- Page 141 Replaceable Parts Replaceable parts list – AWG5000B series PCI/power interface module Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 5-13- PCI/POWER INTERFACE MODULE 174-5246-00 CABLE ASSY ELEC: 2 X 12P,31IN L,AWG16 X 24,39-01-2245,...

- Page 142 Replaceable Parts Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 335-1665-00 MARKER,IDENT; LABEL,REAR IO,SAFETY CONTROLLED, LEXAN, 335-1723-00 MARKER,IDENT; LABEL,REAR IO,SAFETY CONTROLLED, LEXAN, 335-1978-00 MARKER,IDENT; LABEL,REAR I/O,MAIN,LEXAN, SAFETY CONTROLLED 348-1952-00 GROMMET, PLASTIC; U SHAPE, 2.210 L, NATURAL,...

- Page 143 Replaceable Parts Figure 5-13: AWG5000B Series PCI/power interface module 5–26 AWG5000B and AWG5000C Series Service Manual...

- Page 144 Replaceable Parts Replaceable parts list – Fan tray assembly Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 5-14- FAN TRAY ASSEMBLY 211-1050-00 SCREW,MACHINE; 6-32 X 0.312 L,PNH,STL CAD PLT,T15 211-1213-01 SCREW, METRIC 5 X 10MM, FLATHEAD, STL, ZINC, POSI...

- Page 145 Replaceable Parts Replaceable parts list – USB module Fig. & index Tektronix Serial no. Serial no number part number effective discont’d Name & description 5-15- USB MODULE 348-1898-00 GASKET,ELEC;CONDUCTIVE URETHANE FORM 0.196X0.196X0.850, W/ADHESIVE, CHOMERICS #77-12-3611-00085, SOFT-SHIELD 3500 342-1169-00 INSULATOR,PLATE,USB-DC BOARD 671-6350-01 CIRCUIT BOARD ASSY;...

- Page 146 Replaceable Parts Replaceable parts list – AWG1G/CLK1G/OUT1G modules Fig. & Tektronix index part Serial no. Serial no. number number Model effective discont’d Name & description 5-16- AWG1G/CLK1G/OUT1G MODULES 337-4400-00 AWG50x2C BRACKET, BNC CABLES AWG50x2B 337-4400-00 AWG50x4C BRACKET, BNC CABLES AWG50x4B...

- Page 147 Replaceable Parts Figure 5-16: AWG1G/CLK1G/OUT1G modules 5–30 AWG5000B and AWG5000C Series Service Manual...

- Page 148 Replaceable Parts Replaceable parts list – CLK1G module Fig. & index Tektronix Serial no. Serial no. number part number effective discont’d Name & description 5-17- CLK1G MODULE 174-5315-00 CABLE ASSY ELEC: RF,COAX,7.1IN L,50 OHM, PELTOLA, PELTOLA,FLEX COAX CABLE 211-0691-00 SCR, ASSEM WSHR; 6-32 X 0.625, PNH, 410 SS PASSIVATED, T-15...

- Page 149 Replaceable Parts Replaceable parts list – AWG1G module Fig. & Tektronix index part Serial no. Serial no. number number Model effective discont’d Name & description 5-18- AWG1G MODULE 174-5292-00 AWG50x2C CABLE ASSY ELEC: RF,COAX,4IN L,50 OHM, PELTOLA, AWG50x2B PELTOLA,FLEX COAX CABLE...

- Page 150 Replaceable Parts Figure 5-18: AWG1G module AWG5000B and AWG5000C Series Service Manual 5–33...

- Page 151 Replaceable Parts Replaceable parts list – BNC bracket Fig. & Tektronix index part Serial no. Serial no. number number Model effective discont’d Name & description 5-19- BNC BRACKET 211-0734-00 SCREW,MACHINE; 6-32 X 0.250,FLH100,STL,CDPL,T-10 TORX DR 386-7485-01 PLATE,BOTTOM:BRACKET FRONT BNC,14.975 X 1.160 X 0.060,AL...

- Page 152 Replaceable Parts Figure 5-19: BNC bracket AWG5000B and AWG5000C Series Service Manual 5–35...

- Page 153 Replaceable Parts Replaceable parts list – Rear connectors Fig. & Tektronix index part Serial no. Serial no. number number Model effective discont’d Name & description 5-20- REAR CONNECTORS 174-5312-00 CABLE ASSY ELEC: RF,COAX,14.2IN L,50 OHM, PELTOLA,FLEX COAX CABLE 174-5314-00 AWG50x2C CABLE ASSY ELEC: RF,COAX,12.8IN L,50 OHM,...

- Page 154 Replaceable Parts Figure 5-20: Rear connectors AWG5000B and AWG5000C Series Service Manual 5–37...

Need help?

Do you have a question about the AWG5000B Series and is the answer not in the manual?

Questions and answers