Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Chore-Time ATF

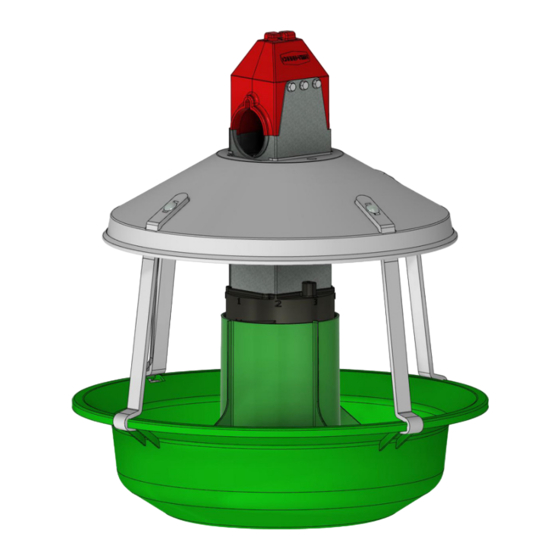

- Page 1 ™ ™ MODEL ATF and MODEL ATF PLUS Feeding System July 2022 MF2505A...

-

Page 2: Introduction

(“Extended Warranty Period”) with respect to certain Product parts (“Component Part”) as set forth in the table below. If such a defect is determined by Chore-Time to exist within the applicable period, Chore-Time will, at its option, (a) repair the Product or Component Part free of charge, F.O.B. -

Page 3: Table Of Contents

Planning ............... . 7 MODEL ATF™ and MODEL ATF™ PLUS Recommendations & Guidelines ..... 7 Manufacturer’s Recommendations: Birds per Pan . - Page 4 MODEL ATF™ End Control (Mech. Switch): 50355 & 50355G ....... .58...

-

Page 5: Safety

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Safety Caution, Warning and Danger Decals have been placed on the equipment to warn of potentially dangerous situations. Care should be taken to keep this information intact and easy to read at all times. Replace missing or damaged safety decals immediately. -

Page 6: General

The other way is for easy reference if you have questions in a particular area. The Chore-Time Adult Turkey Feeding System’s have been designed to feed poultry. Using this equipment for any other purpose or in a way not within the operating recommendations specified in this manual will void the warranty and may cause personal injury. -

Page 7: Planning

Planning MODEL ATF™ and MODEL ATF™ PLUS Recommendations & Guidelines The Chore-Time Adult Turkey Feeder is recommended for birds 5 to 6 weeks old and over. See “Manufacturer’s Recommendations: Birds per Pan” on page 8 for feeder space recommendations. Adult Tom Turkeys: 40 to 50 birds per pan. -

Page 8: Manufacturer's Recommendations: Birds Per Pan

* NOTICE: The above Manufacturer’s recommendations do not constitute a product warranty and are in no way to be considered as a guarantee of performance for poultry production. In addition, the above information in no way alters or revises the terms and conditions of any applicable Chore-Time manufacturer’s warranty. MF2505A... -

Page 9: Planning The Suspension System

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Planning the Suspension System Optional Mid Line Controls may be used for partial house brooding. (See Figure 1.) 10’[3m] Minimum 10’[3m] Minimum Item Description Item Description Brood Curtain End Control and Power Unit... -

Page 10: Suspension System

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Suspension System The feeder line suspension system is a vital part of your feeding system. Proper planning and Component Weigh in pounds (kg) installation is necessary to insure proper Tube, Auger, Feeders, & Feed 9 lbs./ft (13.4 kg./m) -

Page 11: For Systems Up To 350' (107 M)

For Systems up to 350’ (107 m) Detail "A" Detail "B" 1’ [30cm] 3’ [90 cm Maximum Maximum] Wood Framed House: Requires Support Spanning 3 Trusses Steel Framed House: Requires Support Spanning 2 Trusses Item Description Swivel Pulley Hopper Support Winch Support Roof Truss Detail "B"... -

Page 12: For Systems Over 350' (107 M)

For Systems over 350’ (107 m) Detail "A" Detail "C" Detail "D" Detail "B" 1’ [30cm] Maximum Maximum Maximum 3’ [90cm] Distance of Distance of Maximum Travel Travel +2" [61cm] Wood Framed House: Requires Support Spanning 3 Trusses 22" [559mm] Steel Framed House: Requires Support Spanning 2 Trusses Detail "B"... -

Page 13: Installation

Installation Installing the Suspension System Power Lift Winch Installation Power Lift Winch Support (Steel or Wood) Steel Truss Installation Wood Truss Installation Item Description Power Lift Winch Support: 2'' x 8'' [50 x 200 mm] board spanning at least 3 trusses. Power Lift Winch Truss Cable Hook: Install as shown. - Page 14 Attaching Winch Support to Trusses Item Description Feeder Line Winch & Winch Support Winch Centered on Feeder Wood Truss Installation line unless Feed Hopper is centered. Winch Centered directly over Feeder Line Hopper (End of Feed line option) Hopper (Center of Feed line option) End Control Lag Bolts...

-

Page 15: Cable Installation

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Installation Cable Installation Important! Special Support Required at Hopper Location if the Hopper is not directly under a Truss. Special Support at Hopper Locations (Wood Construction) Item Description Feeder Line Hopper Centered on Feed... - Page 16 Installation MODEL ATF™ and MODEL ATF™ PLUS Feeding System Support at Power Unit Location 3’ [91.4 cm] Maximum 3’ [91.4 cm] Wood Construction (Not directly under Truss) Maximum 3’ [91.4 cm] Maximum Steel Construction (Not directly under Truss) Item Description...

-

Page 17: Attaching The Main Winch Cable (Temporarily)

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Installation Attaching the Main Winch Cable (Temporarily) Plan for a Double-Back Pulley arrangement if over 350’ [107m] (See Figure 10.) Item Description Fasten Cable with Nails, Staples, Etc. Double Back Pulley Installations (Feed Lines over 350’ [107m]) Figure 10.Temporarily Attaching Main Winch Cable to Ceiling... -

Page 18: Screw Hook Installation

Installation MODEL ATF™ and MODEL ATF™ PLUS Feeding System Screw Hook Installation If distance raised (3) is greater than (2) then stagger Screw hooks (4) as shown. View up to Ceiling Item Description Part No. 3" [7.6 cm] Offset Distance of Cable Travel (Recommended 8’ [2.4m] on center). Do Not exceed 10’ [3m]. -

Page 19: Drop Installation

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Installation Drop Installation Item Description Part No. Pulley 3004 3/32" [2.4 mm] or 1/8" [3.18 mm] Cable Pull Direction (Toward Winch) 3/16" Cable Clamp 6" [150 mm] Cable Lock (Adjustment Leveler) See 14337 Figure 28. -

Page 20: Hopper Suspension

Installation MODEL ATF™ and MODEL ATF™ PLUS Feeding System Hopper Suspension See Chore-Time Manual MF1819 for Hopper Assembly and installation procedure. Suspension System with Offsets Figure 17. Suspension System with Offsets Screw Hook Installation Screw the hook into the truss the full length of the threads to prevent bending. The openings of the screw hooks must be pointed away from the direction of travel when the power winch raises the feeder line. -

Page 21: Drop Installation

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Installation Drop Installation 1.Attach a 3004 Pulley to each hook. 2.Thread the end of the 3/32" cable through the pulley toward the winch. Clamp this end to the 3/16” winch cable about 6" (150 mm) from the pulley, using a 3/16” cable clamp, See Figure 18 (on page 20) 3.Cut the cable long enough to allow for installation to the feeder line and to the adjustment leveler. -

Page 22: Hopper Assembly Procedure

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Hopper Assembly Procedure The 150 lb. Hopper Assembly is NOT designed for single-point suspension. The upper cross brace is designed for supporting the drop tube ONLY. This Hopper Assembly is to have Two-point suspension as stated. -

Page 23: Suspend The Hopper

MODEL ATF™ and MODEL ATF™ PLUS Feeding System 4.Assemble suspension angles and suspension braces around feeder line boot (single or twin), using 1/4-20 x 1/ 2” Hex bolts and nuts (supplied in hardware package), see figure 22. Note: The larger holes on the ends of the suspension angles need to be on the upper side of the assembly. -

Page 24: Feeder Line Assembly And Suspension

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Feeder Line Assembly and Suspension Feeder Line Installation 1.The expanded (belled) end of each Tube (Item 1) should be toward the Feed Hopper (Item 2) end of the Line. (See Figure 24.) 2.Begin at the Hopper end of the line. -

Page 25: Feeder Line Suspension

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Feeder Line Suspension 1.Install the Hangers (Item 1) on the Tubes on 8’ (2.4 m) spacings determined by the suspension drop lines. Figure 25. See Figure 25 for proper Cable routing around the Cable Lock (Adjustment Leveler). -

Page 26: Auger Installation

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Auger Installation Note: Use extreme caution when working with the auger. The auger is under tension and may spring causing personal injury. Wear protective clothing, gloves, and safety glasses when working with the auger. - Page 27 MODEL ATF™ and MODEL ATF™ PLUS Feeding System 7.Pull the auger at the boot end until it begins 1255-9410/15 stretching then let it relax. In the relaxed position, mark the auger at the end of the boot. See Figure 27.

-

Page 28: Auger Brazing

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Auger Brazing A bronze, flux coated rod is recommended. The ends of the Auger should be flush as shown, DO NOT THREAD INSIDE EACH OTHER. See Figure 30. Be sure that there are no sharp edges or rough corners to ware against the Tube. To align the Auger for brazing, lay it in angle or channel iron and clamp it firmly in place. -

Page 29: Control Unit Installation

Control Unit Installation End Control Units The assembly instructions are very similar for the ATF™ and ATF™ PLUS controls. The primary differences between the controls are in the electrical components and protection devices. 1.Remove the four 5/16-18 x 5/8” bolts from the parts package and use them to bolt the anchor plate to the power unit. - Page 30 MODEL ATF™ and MODEL ATF™ PLUS Feeding System 6.Single Phase: Install the 90 Degree Connector, flexible conduit, electrical wire, and Conduit Connector as shown in Figure 33. Three Phase: Refer to applicable electrical standards for connecting power unit to Control Unit. Components are not supplied by Chore-Time.

-

Page 31: Mid-Line Control Units

45. Mid-Line Control Operation Chore-Time recommends having a toggle switch wired into the system to allow the feeder line to be changed from full house brooding to partial house brooding. Maintain a lower feed level in the Mid-line Control than in the rest of the Feeders. -

Page 32: Feeder Assembly And Installation

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Feeder Assembly and Installation Feed Cone Assembly Plastic Feed Level Cone 1.Assemble the Feed Level Cone (Item 1) and Adjustment Cone (Item 2) as shown in Figure 36. 2.Adjust to feed level #3 as shown. - Page 33 MODEL ATF™ and MODEL ATF™ PLUS Feeding System Cable Assembly 1.If the Feed Level Cones are to be Winch adjustable, install the Cable Assemblies at this point. Note: After the feeder operates, re-adjustment of the Feed Level Tubes may be done to achieve the desired feed level.

-

Page 34: Metal Feed Level Ring

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Metal Feed Level Ring For some applications a Shallow Pan and a short Feed Level Cone may be used. Both applications shown. Adult Turkey (Standard Pan) 1.Attach the Feed Level Tube (Item 1) to the Feed Level Ring (Item 2) as shown in Figure 39. - Page 35 MODEL ATF™ and MODEL ATF™ PLUS Feeding System Cable Assembly 1.Install Cable Assemblies (Item 1) as shown in Figure 41. Note: After the Feeder operates, re-adjustment of the Feed Level Tubes may be done to achieve the desired feed level.

-

Page 36: Pan Supports

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Pan Supports Standard ATF 1.Attach three Standard Pan Supports (Item 1) and one Swing Down Pan Support (Item 2) to the Pan Shield using Rivets (Item 3) supplied. Pay special attention to where you locate the Swing Down Support so that the Pans will swing the direction for easiest access for cleaning. -

Page 37: Assembling Feeder

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Assembling Feeder 1.Insert the Feeder Tube Assembly into the Pan Shield making sure it is oriented such that the Swing Down Pan Support (Item 1) is in the desired location. 2.Hook the Swing Down Pan Support on the Hole that is formed in the Feeder Pan. -

Page 38: Feeder Installation

Bent down tab formed into the Auger Tube. These Spacer Clips keep the Feeder from moving side to side on the Auger Tube. 2.Fasten the Feeders to the Feed Tube using the ATF Drop Tops (Item 2) and #10-3/8" Screws (Item 3) as shown. -

Page 39: Winch Adjustable Feed Level Cones

Winch Adjustable Feed Level Cones Chore-Time’s Adult Turkey Feeder can be equipped to provide Winch adjustable Feed Level Cones. Existing systems can be (easily) upgraded to include Feed Level Cone winching components. The Feed Level Cones are adjusted using a Winch and cable. The maximum line length for each Winch is 200’(61 m). The Winch should be located in the middle of the line of Feeders See Figure 47. - Page 40 MODEL ATF™ and MODEL ATF™ PLUS Feeding System 3.Feed the Cable through the Feeder Support Cones to the Winch. Winch Cable Routing shown in Figure 48. 4.Route the Cable through the Center Hub of the Winch as shown below in Figure 48.

-

Page 41: Attaching Feeder Cable Assemblies

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Attaching Feeder Cable Assemblies 1.With both end of the Cable securely anchored and Spring stretch set, run the Actuator up and down 2 to 3 times. Return the Actuator to A position. -

Page 42: Anti-Roost Installation

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Anti-Roost Installation 1.Unroll the bulk anti-roost cable. Note: If the cable is unrolled as shown in Figure 51, taking 5 loops of the coil with one hand and then changing hands to remove 5 loops as it is unrolled the cable will lie flat during installation. -

Page 43: Anti-Roost Jumper

MODEL ATF™ and MODEL ATF™ PLUS Feeding System 9.At the control unit, after clamping the cable to the spring, cut the cable about 8" to 10" [200 to 250 mm] longer than necessary. Feed the end of the cable through the center of the spring, around the first insulator on the control unit, and clamp the cable using the cable clamp supplied with the control unit. - Page 44 MODEL ATF™ and MODEL ATF™ PLUS Feeding System 2.Install the poultry trainer or line charger, as shown in Figure 56 or Figure 57. 3.Route the charger wire from the poultry trainer or line charger to the anti-roost system. Secure the charger wire to the anti-roost cable, using a cable clamp.

-

Page 45: Wiring Diagrams

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Wiring Diagrams End & Mid-Line Control Wiring Diagrams: Single Phase(Ø) Single Phase(Ø) Wiring Diagram Single Phase(Ø) Wiring Diagram w/Motor Starter MF2505A... -

Page 46: End & Mid-Line Control Wiring Diagrams: Three Phase(Ø)

MODEL ATF™ and MODEL ATF™ PLUS Feeding System End & Mid-Line Control Wiring Diagrams: Three Phase(Ø) Three Phase(Ø) Wiring Diagram: 220/230 V. MF2505A... -

Page 47: Sensor Control Wiring Diagram

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Three Phase(Ø) Wiring Diagram: 380/415 V. Sensor Control Wiring Diagram MF2505A... -

Page 48: Operation

Operation Maintaining the Feeding System Floor Feeding System Maintenance The MODEL ATF™ and MODEL ATF™ PLUS require minimum maintenance. However, a routine periodic inspection of the equipment will prevent unnecessary problems. Maintenance should be done by a qualified technician. ALWAYS DISCONNECT POWER TO THE SYSTEM WHEN SERVICING OR MAINTAINING THE EQUIPMENT. -

Page 49: Mechanical Switch Adjustment Procedure For Control Units

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Operation Mechanical Switch Adjustment procedure for Control Units A. Turn the adjustment Screw clockwise until it clicks. Adjustment Screw B. Turn the adjustment Screw counter-clockwise 2 to 2-1/4 turns. Proximity Sensor Adjustment procedure for... -

Page 50: Feeder Line

Operation MODEL ATF™ and MODEL ATF™ PLUS Feeding System Feeder Line Keep anti-roost cables tightly stretched. This increases the effectiveness of the electro-guard anti-roost system and keep the pans from being tilted when birds push against them. Remove all feed from the feeder when there are no birds in the house and when the building is washed and disinfected. -

Page 51: Power Lift Winch Maintenance

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Operation Power Lift Winch Maintenance Refer to Figure 62. Grease the Winch every 6 months with 1 to 2 shots of common industrial or automotive grease. DO NOT OVER GREASE THE WINCH. -

Page 52: Trouble Shooting The Feeding System

Operation MODEL ATF™ and MODEL ATF™ PLUS Feeding System Trouble Shooting the Feeding System ALWAYS DISCONNECT POWER TO THE SYSTEM WHEN SERVICING OR MAINTAINING THE EQUIPMENT. FAILURE TO DISCONNECT POWER MAY CAUSE INJURY OR DEATH. Service and maintenance work should be done by a qualified technician only. -

Page 53: Parts Listing

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing Parts Listing 150# Hopper Components Without Cover With Cover 48926 49267 Description Part Number Hopper Half 49028 49028 Switch brace 50966 50966 Cover 48675 Cable Assembly 2809-3 2809-3 Clevis Pin... - Page 54 Parts Listing MODEL ATF™ and MODEL ATF™ PLUS Feeding System Part No. 49358 Hopper Suspension Kit Item Description Part No. Part No. Single Boot Twin Boot Clevis Pin, 5/16'' x 1'' 2797-1 2797-1 Adjustment Bracket 2706 2706 Hair Pin 2664...

-

Page 55: Single Boot Components Part No. 6821

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing Single Boot Components Part No. 6821 Item Description Part No. Item Description Part No. Boot Weldment 4224 5/16-18 x 7/8 Low head cap screw 47867 Tube Clamp 24062 Anchor and Bearing Ass’y... -

Page 56: Feeder Line Components

Parts Listing MODEL ATF™ and MODEL ATF™ PLUS Feeding System Feeder Line Components Item Description Part No. Auger 6820-0 ATF 10 ft. 2 hole tube 53628-1 * ATF 10ft. 3 hole tube 53628-4 * ATF 20ft. 3 hole tube 53628-2 * ATF 20ft. -

Page 57: This Page Left Blank Intentionally

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing This page left blank intentionally..MF2505A... -

Page 58: Model Atf™ End Control (Mech. Switch): 50355 & 50355G

MODEL ATF™ End Control (Mech. Switch): 50355 & 50355G MODEL ATF™ PLUS End Control (Mech. Switch): 50358 & 50358G 60 65... - Page 59 **These components may be ordered as an assembly Part No. 49085 Drive Tube Weldment 47584 47584 47584 47584 These components included in Pan Support Package 25813 (ATF) or 49154 (ATF Plus) Items included in Cone Kit 50359 Items included in 49086 Hardware Package...

-

Page 60: Model Atf™ Plus End Control (With Proximity Sensor): 56960 & 56960G

MODEL ATF™ PLUS End Control (With Proximity Sensor): 56960 & 56960G 46 47... - Page 61 .25 x 10 Vinyl Tubing 14454-10 14454-10 ** These included in 49154 Pan Support Package Flex Conduit 26982-1 26982-1 Included in ATF Control Hardware Package 49086 ATF Adjustment Cone 49801 49801 Included in 57014 Proximity Control Kit ATF Adjustment Cone 49802...

-

Page 62: Model Atf™ Plus End Control (Mech. Switch): 49146/49146G

Parts Listing MODEL ATF™ and MODEL ATF™ PLUS Feeding System MODEL ATF™ PLUS End Control (Mech. Switch): 49146/49146G MF2505A... - Page 63 MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing 49146 49146G ™ ™ PLUS PLUS Mech. Switch Mech. Switch Control Control w/Red Pan w/Green Pan Item Description Part No. Cover, Insulator Assembly 49043 49043 Danger Decal 2527-9 2527-9 Tube Support...

-

Page 64: Model Atf™ Mid-Line Control (Mech. Switch): 57359

Parts Listing MODEL ATF™ and MODEL ATF™ PLUS Feeding System MODEL ATF™ Mid-Line Control (Mech. Switch): 57359 MODEL ATF™ PLUS Mid-Line Control (Mech. Switch): 57358 MF2505A... - Page 65 MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing 57359 57358 ATF™ ATF™ PLUS Mech. Switch Mech. Switch Mid-Line Mid-Line Control Control Item Description Part No. ATF Plus Control Drop Tube Wldmt. 57220 ATF Control Drop Tube Weldment 57360...

-

Page 66: Drop Tube Assembly: Part No. 49147

Drop Tube Assembly: Part No. 49147 Item Description Part No. Item Description Part No. Diaphragm Assembly 4889 4-40 x 3/4 Pn Hd Screw 4143-2 Paddle 4890 4-40 Nut 3511 Snap Action Switch 46324 10-32 Blind Rivet Nut 51515 Barrier 6936 Conduit Assembly (Not Shown) 27866 Switch Bracket... -

Page 67: Model Atf™ Control Unit Components Part No. 49040/49040G

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing MODEL ATF™ Control Unit Components Part No. 49040/49040G 49040 49040G 49040 49040G Control w/ Control w/ Control w/ Control w/ Red Pan Green Pan Red Pan Green Pan Item Description Part No. -

Page 68: Drop Tube Assembly Part No. 28072

Drop Tube Assembly Part No. 28072 Item Description Part No. Item Description Part No. Diaphragm Assembly 4889 Paddle 4890 4-40 x 3/4 Pn Hd Screw 4143-2 Snap Action Switch 46324 4-40 Nut 3511 Barrier 6936 10-32 Blind Rivet Nut 51515 Switch Bracket 51516 Conduit Assembly... -

Page 69: Winch Kit Part No. 53197

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing Winch Kit Part No. 53197 10 11 2381-052 10/15 Item Description Part No. Item Description Part No. Winch Base Assembly 48933 Spring .62 x 11" 24302 Insulator Assembly 53202 2" Tube Clamp... -

Page 70: Miscellaneous Suspension Components

Parts Listing MODEL ATF™ and MODEL ATF™ PLUS Feeding System Miscellaneous Suspension Components 2381-058 10/15 Item Description Part No. 3/16" Cable 1213 Cable Lock 14337 Pulley with Swivel 3004 Heavy Duty Pulley Assembly 2014 Pulley 2500 3/16" Cable Clamp Screw Hook... -

Page 71: Model Atf™ Feeder Pan Assemblies

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing MODEL ATF™ Feeder Pan Assemblies One Swing Down Strut on appropriate models 2 x3 57162 57163 57162 57162G 57163 57163G ATF Feeder ATF Feeder w/ ATF Feeder w/ ATF Feeder w/ w/Metal Cone &... -

Page 72: Model Atf™ Plus Feeder Pan Assemblies

Parts Listing MODEL ATF™ and MODEL ATF™ PLUS Feeding System MODEL ATF™ Plus Feeder Pan Assemblies 2 x3 57100 57099 57099 57099G 57100 57100G ATF Plus Feeder w/ ATF Plus Feeder w/ ATF Plus Feeder ATF Plus Feeder Metal Cone &... -

Page 73: H2 Plus Pan Adapter Kit

MODEL ATF™ and MODEL ATF™ PLUS Feeding System Parts Listing H2 Plus Pan Adapter Kit This Product will be used where the day old Turkeys will be started on the Adult Turkey Feeder for the first 5 weeks. After 5 weeks, the Pan Assembly will be removed and the Adult Pan installed. - Page 74 Page No. Description of Change Various Various Changes to Consolidate some Manuals 35840 Contact your nearby Chore-Time distributor or representative for additional parts and information. CTB, Inc. PO Box 2000 Milford, Indiana 46542-2000 USA Phone (574) 658-4101 Fax (877) 730-8825 Email: choretime@choretime.com...

Need help?

Do you have a question about the ATF and is the answer not in the manual?

Questions and answers