Universal Robots e Series Hardware Manual

Hide thumbs

Also See for e Series:

- User manual (361 pages) ,

- Manual (108 pages) ,

- Original instructions manual (45 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Universal Robots e Series

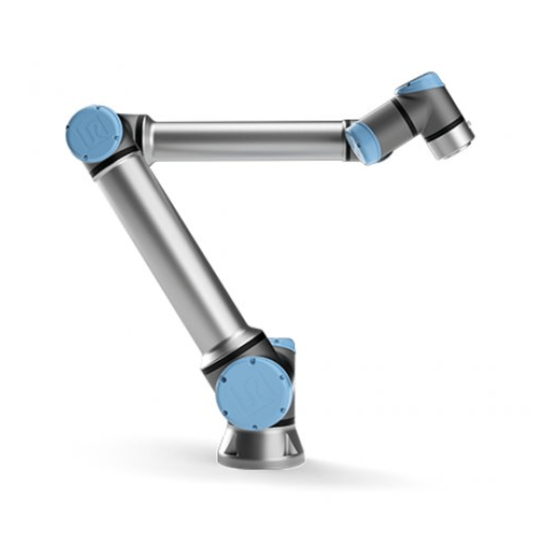

- Page 1 Universal Robots e-Series Hardware Manual UR5e Original instructions (en)

-

Page 3: Table Of Contents

Contents 1. Safety 1.1. Introduction 1.2. Warning Symbols in this Manual 1.3. General Warnings and Cautions 2. Safety-related Functions and Interfaces 2.1. Introduction 2.2. Stop Categories 2.3. Configurable Safety Functions 2.4. Safety Function 2.5. Modes 3. Mechanical Interface 3.1. Introduction 3.2. Workspace of the Robot 3.3. - Page 4 4.7. Robot Connection: Base Flange Cable 4.7.1. Base Flange Cable connector 4.8. Tool I/O 4.8.1. Tool Power Supply 4.8.2. Power Supply 4.8.3. Dual Pin Power Supply 4.8.4. Tool Digital Outputs 4.8.5. Tool Digital Inputs 4.8.6. Tool Analog Input 4.8.7. Tool Communication I/O 5. Maintenance and Repair 5.1.

-

Page 5: Safety

This chapter contains important safety information, which must be read and understood by the integrator of Universal Robots e-Series robots before the robot is powered on for the first time. In this chapter, the first subsections are general. The later subsections contain specific engineering data relevant to enable setting up and programming the robot. -

Page 6: Warning Symbols In This Manual

1. Safety • Validating that the total robot system is designed and installed correctly • Specifying instructions for use • Marking the robot installation with relevant signs and contact information of the integrator • Collecting all documentation in a technical file; including the risk assessment and this manual Limitation of Liability Any safety information provided in this manual must not be construed as a warranty, by... -

Page 7: General Warnings And Cautions

1. Safety WARNING This indicates a potentially hazardous hot surface which, if touched, could result in injury. CAUTION This indicates a situation which, if not avoided, could result in damage to the equipment. 1.3. General Warnings and Cautions This section contains some general warnings and cautions that can be repeated or explained in different parts of this manual. - Page 8 1. Safety WARNING 1. Make sure the robot arm and tool/end effector are properly and securely bolted in place. 2. Make sure the robot arm has ample space to operate freely. 3. Make sure that safety measures and/or robot safety configuration parameters have been set up to protect both programmers, operators and bystanders, as defined in the risk assessment.

- Page 9 Intended Use Universal Robots e-Series are industrial robots intended to handle tools/end effectors and fixtures, or to process or transfer components or products. As industrial robots, they are intended for use in workplaces with working adults - not patients, children or the eldery.

- Page 10 • Any use or application deviating from the intended use, specifications, and certifications is prohibited as the result could be death, personal injury and/or property damage. UNIVERSAL ROBOTS EXPRESSLY DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR ANY MISUSE. Risk Assessment One of the most important things that an integrator needs to do is to perform a risk assessment.

- Page 11 1. Safety • Teaching the robot during set-up and development of the robot installation • Troubleshooting and maintenance • Normal operation of the robot installation A risk assessment must be conducted before the robot arm is powered on for the first time.

- Page 12 1. Safety Universal Robots identifies the potential significant hazards listed below as hazards that must be considered by the integrator. Other significant hazards can be present in a specific robot installation. 1. Penetration of skin by sharp edges and sharp points on tool/end effector or tool/end effector connector.

- Page 13 1. Safety Activate the emergency stop push-button to immediately stop all robot motion. According to IEC 60204-1 and ISO 13850, emergency devices are not safeguards. They are complimentary protective measures and are not intended to prevent injury. The risk assessment of the robot application shall conclude if additional emergency stop buttons are need.

- Page 14 1. Safety UR5e Hardware Manual...

-

Page 15: Safety-Related Functions And Interfaces

2. Safety-related Functions and Interfaces 2.1. Introduction Universal Robots e-Series robots are equipped with a range of built-in safety functions as well as safety I/O, digital and analog control signals to or from the electrical interface, to connect to other machines and additional protective devices. Each safety function and I/O is constructed according to EN ISO13849-1 (see chapter 8. Certifications on... -

Page 16: Configurable Safety Functions

IEC 61800-5-2. 2.3. Configurable Safety Functions Universal Robots robot safety functions, as listed in the table below, are in the robot but are meant to control the robot system i.e. the robot with its attached tool/end effector. The robot safety functions are used to reduce robot system risks determined by the risk assessment. - Page 17 2. Safety-related Functions and Interfaces When performing the application risk assessment, it is necessary to take into account the motion of the robot after a stop has been initiated. In order to ease this process, the safety functions Stopping Time Limit and Stopping Distance Limit can be used. These safety functions dynamically reduces the speed of the robot motion such that it can always be stopped within the limits.

- Page 18 2. Safety-related Functions and Interfaces WARNING If the robot is used in manual hand-guiding applications with linear movements, the speed limit must be set to maximum 250 mm/s for the tool/end effector and elbow unless a risk assessment shows that higher speeds are acceptable. This will prevent fast movements of the robot elbow near singularities.

-

Page 19: Safety Function

2. Safety-related Functions and Interfaces Safety Input Description Safeguard Returns from the Safeguard Stop state, when a rising edge on the Safeguard Reset Reset input occurs. Reduced Transitions the safety system to use the Reduced mode limits. Mode Three- Initiates a Stop Category 2 (IEC 60204-1) when the enabling device is fully pressed Position or fully released in manual mode only. -

Page 20: Modes

2. Safety-related Functions and Interfaces Trigger Reaction Safeguard Stop Stop Category 2. Limit Violation Stop Category 0. Fault Detection Stop Category 0. NOTE If the safety system detects any fault or violation, all safety outputs re-set to low. 2.5. Modes Normal and Reduced Mode The safety system has two configurable Modes: Normal and Reduced. - Page 21 2. Safety-related Functions and Interfaces WARNING Limits for the joint positions, the safety planes, and the tool/end effector orientation are disabled in Recovery Mode. Take caution when moving the robot arm back within the limits. Hardware Manual UR5e...

- Page 22 2. Safety-related Functions and Interfaces UR5e Hardware Manual...

-

Page 23: Mechanical Interface

3. Mechanical Interface 3. Mechanical Interface 3.1. Introduction This chapter describes the basics of mounting the parts of the robot system. Electrical installation instructions in chapter 4. Electrical Interface on page 29 must be observed. 3.2. Workspace of the Robot The workspace of the robot extends 500 mm from the base joint. It is important to consider the cylindrical volume directly above and directly below the robot base when choosing a mounting place for the robot. -

Page 24: Mounting

3. Mechanical Interface Front Tilted 3.3. Mounting Robot Arm The robot arm is mounted with four 8.8 strength, M6 bolts and four 6.6 mm mounting holes at the base. UR5e Hardware Manual... - Page 25 3. Mechanical Interface WARNING Make sure the robot arm is properly and securely bolted in place. Unstable mounting can lead to accidents. Securing the Robot Arm Figure Holes for mounting the robot. Use four M6 bolts. All measurements are in mm . below shows where to drill holes and mount the screws.

-

Page 26: Maximum Payload

3. Mechanical Interface page shows dimensions and hole pattern of the tool flange. It is recommended to use a radially slotted hole for the pin to avoid over-constraining, while keeping precise position. Do not use bolts that extend beyond 8mm to mount the tool. Very long M6 bolts can press against the bottom of the tool flange and short circuit the robot. -

Page 27: Payload Inertia

3. Mechanical Interface Payload [kg] Center of gravity offset [mm] 5.1: The relationship between the rated payload and the center of gravity offset. 3.4.1. Payload Inertia The robot can be used with high inertia payloads. The control software automatically adjusts accelerations, if you correctly enter the following in PolyScope (see: Set Payload •... - Page 28 3. Mechanical Interface UR5e Hardware Manual...

-

Page 29: Electrical Interface

4. Electrical Interface 4. Electrical Interface 4.1. Introduction This chapter describes electrical interface groups for the Robot Arm in the Control Box. Examples are given for most types of I/O. The term I/O refers to both digital and analog control signals to or from the electrical interface groups listed below. -

Page 30: Electrical Warnings And Cautions

4. Electrical Interface To connect the Ethernet cable by passing it through the hole at the base of the Control Box, and plugging it into the Ethernet port on the underside of the bracket. Replace the cap at the base of the Control Box with an appropriate cable gland to connect the cable to the Ethernet port. - Page 31 1. Make sure all equipment not rated for water exposure remain dry. If water is allowed to enter the product, lockout-tagout all power and then contact your local Universal Robots service provider for assistance. 2. Only use the original cables supplied with the robot only. Do not use the robot for applications where the cables are subject to flexing.

-

Page 32: Controller I/O

EMC problems are found to happen usually in welding processes and are normally prompted by error messages in the log. Universal Robots cannot be held responsible for any damages caused by EMC problems. 2. I/O cables going from the Control Box to other machinery and factory equipment may not be longer than 30m, unless additional tests are performed. -

Page 33: Common Specifications For All Digital I/O

4. Electrical Interface 4.4.1. Common specifications for all digital I/O This section defines electrical specifications for the following 24V digital I/O of the Control Box. • Safety I/O. • Configurable I/O. • General purpose I/O. Install the robot according to the electrical specifications which are the same for all three inputs. It is possible to power the digital I/O from an internal 24V power supply or from an external power source by configuring the terminal block called Power. -

Page 34: Safety I/O

4. Electrical Interface Terminals Parameter Unit Current* [COx / DOx] Voltage drop [COx / DOx] Leakage current [COx / DOx] Function Type [COx / DOx] IEC 61131-2 Type [COx / DOx] Digital Inputs Voltage [EIx/SIx/CIx/DIx] OFF region [EIx/SIx/CIx/DIx] ON region [EIx/SIx/CIx/DIx] Current (11-30V) [EIx/SIx/CIx/DIx] Function... - Page 35 4. Electrical Interface Emergency Stop Safeguard Stop Drive power Reset Manual Automatic or manual Frequency of use Infrequent Every cycle to infrequent Requires re-initialization Brake release only Stop Category (IEC 60204-1) Performance level of monitoring function (ISO 13849-1) Use the configurable I/O to set up additional safety I/O functionality, e.g. Emergency Stop Output. Configuring a set of configurable I/O for safety functions are done through the GUI, (see part ).

- Page 36 4. Electrical Interface Safety Connecting emergency stop buttons Most applications require one or more extra emergency stop buttons. The illustration below shows how one or more emergency stop buttons can be connected. Safety Safety Sharing the Emergency Stop with other machines You can set up a shared emergency stop function between the robot and other machines by configuring the following I/O functions via the GUI.

- Page 37 4. Electrical Interface Safeguard stop with automatic resume An example of a basic safeguard stop device is a door switch where the robot is stopped when a door is opened (see illustration below). Safety This configuration is only intended for applications where the operator cannot go through the door and close it behind him.

- Page 38 The illustration below shows how to connect a Three-Position Enabling Device. See section Three- Position Enabling Device for more about Three-Position Enabling Device. NOTE The Universal Robots safety system does not support multiple external Three- Position Enabling Devices. Configurable Inputs 3-Position Switch NOTE The two input channels for the Three-Position Enabling Device input have a disagreement tolerance of 1 second.

-

Page 39: General Purpose Digital I/O

4. Electrical Interface 4.4.3. General purpose digital I/O This section describes the general purpose 24V I/O (Gray terminals) and the configurable I/O (Yellow terminals with black text) when not configured as safety I/O. The common specifications section 4.4.1. Common specifications for all digital I/O on page 33 must be observed. -

Page 40: General Purpose Analog I/O

4. Electrical Interface 4.4.6. General purpose analog I/O The analog I/O interface is the green terminal. It is used to set or measure voltage (0-10V) or current (4-20mA) to and from other equipment. The following directions is recommended to achieve the highest accuracy. •... -

Page 41: Remote On/Off Control

4. Electrical Interface Analog Power Using an Analog Input This example illustrates connecting an analog sensor. Analog Power 4.4.7. Remote ON/OFF control Use remote ON/OFF control to turn the Control Box on and off without using the Teach Pendant. It is typically used: •... -

Page 42: Mains Connection

4. Electrical Interface Remote Remote OFF button This example illustrates connecting a remote OFF button. Remote CAUTION Do not press and hold the ON input or the POWER button as it switches off the Control Box without saving. You must use the OFF input for remote off control as this signal allows the Control Box to save open files and shut down correctly. - Page 43 4. Electrical Interface The mains supply is equipped with the following: • Connection to ground • Main fuse • Residual current device It is recommended to install a main switch to power off all equipment in the robot application as an easy means for lockout-tagout under service.

-

Page 44: Robot Connection: Robot Cable

4. Electrical Interface WARNING 1. Ensure the robot is grounded correctly (electrical connection to ground). Use the unused bolts associated with grounding symbols inside the Control Box to create common grounding of all equipment in the system. The grounding conductor shall have at least the current rating of the highest current in the system. - Page 45 4. Electrical Interface CAUTION Improper robot connection can result in loss of power to the robot arm. • Do not disconnect the Robot Cable when the robot arm is turned on. • Do not extend or modify the original Robot Cable. 4.7.

- Page 46 4. Electrical Interface This connector provides power and control signals for grippers and sensors used on a specific robot tool. The industrial cable listed below is suitable: • Lumberg RKMV 8-354. NOTE The Tool Connector must be manually tightened up to a maximum of 0.4Nm. The eight wires inside the cable have different colors that designate different functions.

- Page 47 4. Electrical Interface allowed. NOTE The tool flange is connected to GND (same as the red wire). 4.8.1. Tool Power Supply 4.8.2. Power Supply Access Tool I/O in the Installation Tab (see PolyScope) to set the internal power supply to 0V, 12V or 24V.

- Page 48 4. Electrical Interface Mode Active Inactive Sinking (NPN) Open Sourcing (PNP) High Open Push / Pull High Access Tool I/O in the Installation Tab (see part ) to configure the output mode of each pin. The electrical specifications are shown below: Parameter Unit Voltage when open -0.5...

- Page 49 4. Electrical Interface POWER 4.8.5. Tool Digital Inputs The Digital Inputs are implemented as PNP with weak pull-down resistors. This means that a floating input always reads as low. The electrical specifications are shown below. Parameter Type Unit Input voltage -0.5 Logical low voltage Logical high voltage Input resistance...

- Page 50 4. Electrical Interface CAUTION 1. Analog Inputs are not protected against overvoltage in current mode. Exceeding the limit in the electrical specification can cause permanent damage to the input. Using Tool Analog Inputs, Nondifferential This example shows an analog sensor connection with a nondifferential output. The sensor output can be either current or voltage, as long as the input mode of that Analog Input is set to the same on the I/O tab.

- Page 51 4. Electrical Interface Hardware Manual UR5e...

- Page 52 4. Electrical Interface UR5e Hardware Manual...

- Page 53 Service Manual. See the Service Manual: Chapter 5 for full inspection plan for trained individuals All parts returned to Universal Robots shall be returned according to terms in the Service Manual. 5.1. Safety Instructions After maintenance and repair work, checks must be done to ensure the required safety level.

- Page 54 5.3. Inspection 5.3.1. Robot Arm Inspection Plan The table below is a checklist of the type of inspections recommended by Universal Robots. Perform inspections regularly, as advised in the list. Any listed parts found to be in an unacceptable state must be repaired or replaced.

- Page 55 5. Maintenance and Repair You can access the Service Manual (http://www.universal-robots.com/support) for more on how to perform inspections. Inspection action type Timeframe Monthly Biannually Annually Check blue lids* ✘ Check flat rings ✘ Check robot cable ✘ Check robot cable ✘ connection V = Visual inspection * = Must also be checked after heavy collision...

- Page 56 5.3.3. Control Box Inspection Plan The table below is a checklist of the type of inspections recommended by Universal Robots. Perform inspections regularly, as advised in the list. Any listed parts found to be in an unacceptable state must be repaired or replaced.

- Page 57 5. Maintenance and Repair 5.3.4. Control Box Visual Inspection 1. Disconnect the power cable from Control Box. 2. Check for any dirt/dust outside the Control Box. • Clean with ESD vacuum cleaner if needed. NOTICE Using compressed air to clean inside the Control Box can damage components. •...

- Page 58 5. Maintenance and Repair 3. Pull/Push the robot arm to a horizontally elongated position and release. 4. Verify the robot can maintain its position when not being held with the Freedrive button still pressed. UR5e Hardware Manual...

- Page 59 1. Make sure not to overload your back or other bodyparts when lifting the equipment. Use proper lifting equipment. All regional and national lifting guidelines shall be followed. Universal Robots cannot be held responsible for any damage caused by transportation of the equipment.

- Page 60 6. Transportation • Fold the robot as much as possible – do not transport the robot in the singularity position • Move the center of gravity in the robot as close to the base as possible • Secure each tube to a solid surface on two different points on the tube •...

- Page 61 VI, polybrominated biphenyls and polybrominated diphenyl ethers. Fee for disposal and handling of electronic waste of Universal Robots e-Series robots sold on the Danish market is prepaid to DPA-system by Universal Robots A/S. Importers in countries covered by the European WEEE Directive 2012/19/EU must make their own registration to the national WEEE register of their country.

- Page 62 7. Disposal and Environment UR5e Hardware Manual...

- Page 63 8. Certifications Third party certification is voluntary. However, to provide the best service to robot integrators, Universal Robots chooses to certify its robots at the recognized test institutes listed below. You can find copies of all certificates in the chapter 12. Certificates on page 73 TÜV NORD...

- Page 64 EU declarations. European directives are available on the official homepage: http://eur- lex.europa.eu. According to the Machinery Directive, Universal Robots’ robots are partly completed machines, as such a CE mark is not to be affixed. You can find the Declaration of Incorporation (DOI) according to the Machinery Directive in the chapter Declarations and Certificates.

- Page 65 9. Stopping Time and Stopping Distance 9. Stopping Time and Stopping Distance You can set user-defined safety rated maximum stopping time and distance. See 2.1. Introduction on page 15 Safety Menu Settings. If user-defined settings are used, the program speed is dynamically adjusted to always comply with the selected limits.

- Page 66 9. Stopping Time and Stopping Distance Stopping time for joint 0 (BASE) Stopping time in seconds for 33% of 5kg Stopping time in seconds fo 66% of 5kg Stopping time in seconds for maximum payload of 5kg Stopping distance for joint 1 (SHOULDER) Stopping distance in meters for 33% of 5kg Stopping distance in meters for 66% of 5kg Stopping distance in meters for maximum payload of 5kg...

- Page 67 9. Stopping Time and Stopping Distance Stopping time for joint 1 (SHOULDER) Stopping time in seconds for 33% of 5kg Stopping time in seconds for 66% of 5kg Stopping time in seconds for maximum payload of 5kg Stopping distance and time for joint 2 (ELBOW) Stopping distance in meters for all payloads Stopping time in seconds for all payloads Hardware Manual...

- Page 68 9. Stopping Time and Stopping Distance UR5e Hardware Manual...

- Page 69 • Effective May 2021: UR10e specification improvement to 12.5kg maximum payload. Serial Number Starting 20205000000 and higher Universal Robots e-Series (UR3e, UR5e, UR10e and UR16e) shall only be put into service upon being integrated into a final Incorporation: complete machine (robot system, cell or application), which conforms with the provisions of the Machinery Directive and other applicable Directives.

- Page 70 10. Declarations and Certificates It is declared that the above products fulfil, for what is supplied, the following Directives as detailed below: (When this incomplete machine is integrated and becomes a complete machine, the integrator is responsible for determining that completed machine fulfils all applicable Directives and update the harmonized and other standards.) (I) EN ISO 10218-1:2011 TÜV Nord Certificate # 44 708 14097607, (I) EN ISO 13849-1:2015 TÜV Nord Certificate # 44 207 14097610,...

- Page 71 11. Warranty Information 11. Warranty Information 11.1. Product Warranty Direct your warranty inquiries to either of the following Universal Robots A/S entities: • Global Support • Service Support You can also access product related information on myUR 11.2. User Manual Disclaimer Universal Robots A/S continues to improve the reliability and performance of its products, and as such reserves the right to upgrade products, and product documentation, without prior warning.

- Page 72 11. Warranty Information UR5e Hardware Manual...

- Page 73 12. Certificates 12. Certificates TÜV NORD Hardware Manual UR5e...

- Page 74 12. Certificates UR5e Hardware Manual...

- Page 75 12. Certificates China RoHS Hardware Manual UR5e...

- Page 76 12. Certificates KCC Safety UR5e Hardware Manual...

- Page 77 12. Certificates KC Registration Hardware Manual UR5e...

- Page 78 12. Certificates Environmental Test Certificate Climatic and mechanical assessment Client Force Technology project no. Universal Robots A/S 117-32120 Energivej 25 5260 Odense S Denmark Product identification UR 3 robot arms UR 3 control boxes with attached Teach Pendants. UR 5 robot arms UR5 control boxes with attached Teach Pendants.

- Page 79 13. Applied Standards 13. Applied Standards This section describes relevant standards applied to the development of the development and manufacturing of the UR robot, including the robot arm, Control Box and Teach Pendant . A standard is not a law, but a document developed by stakeholders within a given industry. Standards contain requirements and guidance for a product or product group.

- Page 80 This Canadian national standard is a national adoption of both ISO 10218-1 and ISO 10218-2 combined into one document. CSA added User to clauses within Part 2. Part 2 of this standard is intended for the integrator of the robot system/ robot application, and not Universal Robots. IEC 61000-6-2...

- Page 81 13. Applied Standards Part 3-1: Immunity requirements for safety-related systems and for equipment intended to perform safety-related functions (functional safety) - General industrial applications This standard defines extended EMC immunity requirements for safety-related functions. Conforming to this standard ensures the safety functions perform even if other equipment exceeds the EMC emission limits defined in the IEC 61000 standards.

- Page 82 13. Applied Standards ISO 9409-1 Manipulating industrial robots – Mechanical interfaces Part 1: Plates The tool flange on UR robots conforms to a type according to this standard. Robot tools (end- effectors) should also be constructed according to the same type to ensure proper fitting to the mechanical interface of the specific UR robot.

- Page 83 13. Applied Standards IEC 60664-1 IEC 60664-5 Insulation coordination for equipment within low-voltage systems Part 1: Principles, requirements and tests Part 5: Comprehensive method for determining clearances and creepage distances equal to or less than 2 mm EUROMAP 67:2015, V1.11 Electrical Interface between Injection Molding Machine and Handling Device / Robot The E67 accessory module to interface, that interfaces with injection molding machines, complies with this standard.

- Page 84 13. Applied Standards UR5e Hardware Manual...

- Page 85 Hardware Manual UR5e...

- Page 86 14. Technical Specifications 14. Technical Specifications Robot type Weight Maximum payload Reach Joint ranges ± 360 ° for all joints All wrist joints: Max 360 °/s. Speed Other joints: Max 180 °/s . Tool: Approx. 1 m/s / Approx. 39.4 in/s. System Update Frequency 500 Hz Force Torque Sensor Accuracy Pose Repeatability...

- Page 87 14. Technical Specifications TP Cable: Teach Pendant to Control Box 4.5 m / 177 in Standard (PVC) 6 m/236 in x 13.4 mm Robot Cable: Robot Arm to Control Box Standard (PVC) 12 m/472.4 in x 13.4 mm (options) HiFlex (PUR) 6 m/236 in x 12.1 mm HiFllex (PUR) 12 m/472.4 in x 12.1 mm Hardware Manual UR5e...

- Page 88 Universal Robots e-Series Safety Functions and Safety I/O are PLd, Category 3 (ISO 13849-1), with certification by TŰV NORD (certificate # 44 207 14097610). For Safety Function (SF) Descriptions see: Safety-related Functions and Interfaces.

- Page 89 15. Safety Functions Tables SF# and Tole- Safety Description What happens? PFHd Affects rance Function Pressing the Estop PB on Category 1 stop 1.30E- Robot 1,2,3,4 the pendant or the External (IEC 60204-1) including Emergency Estop (if using the Estop robot tool Stop Safety Input) results in a (according to...

- Page 90 15. Safety Functions Tables SF# and Tole- Safety Description What happens? PFHd Affects rance Function Sets upper and lower limits Will not allow 5° 1.20E- Joint Joint for the allowed joint motion to exceed (each) Position positions. Stopping time any limit settings. Limit (soft and distance is not a Speed could be...

- Page 91 15. Safety Functions Tables SF# and Tole- Safety Description What happens? PFHd Affects rance Function Joint Torque Exceeding the internal joint Limit torque limit (each joint) results in a Cat 0 stop3. This is shown as SF #5 in the Generation 3 (CB3) UR robots.

- Page 92 15. Safety Functions Tables SF# and Tole- Safety Description What happens? PFHd Affects rance Function The Force Limit is the force Will not allow 1.50E- Force Limit exerted by the robot at the motion to exceed (TCP) TCP (tool center point) and any limit settings.

- Page 93 15. Safety Functions Tables SF# and Safety Description PFHd Affects Function SF10 When configured for Estop output and there is an Estop 4.70E-08 External UR Robot condition (see SF1), the dual outputs are LOW. If there is connection Estop no Estop condition, dual outputs are high. Pulses are not to logic Output used but are tolerated.

- Page 94 15. Safety Functions Tables SF# and Tole- Safety Description What happens? PFHd Affects rance Function SF15 Real time monitoring of Will not allow 50 ms 1.20E- Robot Stopping conditions such that the the actual Time Limit stopping time limit will not be stopping time to exceeded.

- Page 95 15. Safety Functions Tables SF# and Tole- Safety Description What happens? PFHd Affects rance Function SF17 Safety function which The “safe home 1.7 ° 1.20E- External Safe monitors a safety rated output” can only connection Home output, such that it ensures be activated to logic Position...

- Page 96 15. Safety Functions Tables Safety Description PFHd Affects Function Mode When the external connections are Low, Operation Mode Input to SF2 Robot switch (running/ automatic operation in automatic mode) is in (See SF2 INPUT effect. When High, mode is programming/ teach. safeguard Recommendation: Use with a 3-position enabling device.

- Page 97 16. Table 2 16. Table 2 UR e-Series robots comply with ISO 10218-1:2011 and the applicable portions of ISO/TS 15066. It is important to note that most of ISO/TS 15066 is directed towards the integrator and not the robot manufacturer. ISO 10218-1:2011, clause 5.10 collaborative operation details 4 collaborative operation techniques as explained below.

- Page 98 16. Table 2 ISO 10218-1 Technique Explanation UR e-Series Collaborative Speed and SSM is the robot maintaining a To facilitate SSM, UR Operation 2011 separation separation distance from any robots have the edition, clause monitoring operator (human). This is done capability of switching 5.10.4 (SSM) safety by monitoring of the distance...

- Page 99 16. Table 2 ISO 10218-1 Technique Explanation UR e-Series Collaborative Power and How to accomplish PFL is left to UR robots are power Operation 2011 force limiting the robot manufacturer. The and force limiting edition, clause (PFL) by robot design and/or safety robots specifically 5.10.5 inherent...

- Page 100 16. Table 2 UR5e Hardware Manual...

- Page 101 17. Index 17. Index Base 65 Bracket 29 Configurable I/O 33 Control Box 26, 29, 32, 41-42, 79 Conveyor Tracking 32 Elbow 65 Ethernet 29 EtherNet/IP 29 Freedrive 20 General purpose I/O 33 I/O 29, 34 integrator 10 Hardware Manual UR5e...

- Page 102 17. Index Mini Displayport 29 MODBUS 29 Modes 20 PolyScope 20 Recovery mode 20 Reduced mode 20 risk assessment 5, 10, 13, 17 Robot arm 79 Robot Arm 29 robot cable 44-45 Safety Configuration 11 Safety functions 15-16 Safety I/O 15, 19, 33-34 Safety instructions 53 Safety Settings 5 Shoulder 65...

- Page 103 17. Index Tool I/O 45 Warning signs 6 Hardware Manual UR5e...

Need help?

Do you have a question about the e Series and is the answer not in the manual?

Questions and answers