KEB COMBIVERT S6 Series Instructions For Use Manual

Hide thumbs

Also See for COMBIVERT S6 Series:

- Instructions for use manual (74 pages) ,

- Installation manual (33 pages) ,

- Installation instructions (2 pages)

Summary of Contents for KEB COMBIVERT S6 Series

- Page 1 COMBIVERT S6 INSTRUCTIONS FOR USE | INSTALLATION S6 HOUSING 2 Translation of the original manual Document 20088319 EN 11...

-

Page 3: Preface

The hardware and software described in this document are products of KEB. The infor- mation contained in this document is valid at the time of publishing. KEB reserves the right to update this document in response to misprints, mistakes or technical changes. -

Page 4: Laws And Guidelines

The customer may use the instructions for use as well as further documents or parts from it for internal purposes. Copyrights are with KEB and remain valid in its entirety. This KEB product or parts thereof may contain third-party software, including free and/ or open source software. -

Page 5: Table Of Contents

TAbLe Of cONTeNTS Table of contents Preface ..............................3 Signal words and symbols ......................3 More symbols ..........................3 Laws and guidelines ........................4 Warranty and liability ........................4 Support ............................4 Copyright ............................4 Table of contents ........................... 5 List of figures ............................9 List of Tables ............................ - Page 6 TAbLe Of cONTeNTS 3.1.3 Chemical / mechanical active substances ................28 3.1.4 Electrical operating conditions .................... 29 3.1.4.1 Device classification ......................29 3.1.4.2 Electromagnetic compatibility ..................29 3.2 Dimensions and weights ......................30 3.2.1 Built-in version ........................30 3.2.2 Control cabinet installation ....................31 3.3 Mounting instructions for control cabinet installation ..............

- Page 7 TAbLe Of cONTeNTS 4.2.1.2 230 V devices ........................53 4.2.1.3 Mains terminal block X1A ....................54 4.2.2 Leakage currents ........................ 55 4.2.3 Protective earth and functional earth .................. 55 4.2.3.1 Protective earth ....................... 55 4.2.3.2 Functional earthing ......................56 4.2.4 AC connection ........................57 4.2.4.1 AC supply 230 V / 400 V 3-phase ..................

- Page 8 TAbLe Of cONTeNTS 5 Certification ..............73 5.1 ce-Marking ............................. 73 5.2 functional safety ........................... 73 5.3 Annex to the declaration of conformity ..................73 5.4 UL Marking ............................. 75 5.5 further informations and documentation ................... 78 6 revision History ............79...

-

Page 9: List Of Figures

LIST Of fIGUreS List of figures Figure 1: Nameplate........................25 Figure 2: Dimensions built-in version housing 2 ................30 Figure 3: Mounting distances ......................31 Figure 4: Control cabinet ventilation....................31 Figure 5: Installation depth ......................33 Figure 6: Switch-off time t depending on the overload I / IN (OL) 400 V devices ......41 Figure 7: Switch-off time t depending on the overload I / IN (OL) 230 V devices ...... -

Page 10: List Of Tables

LIST Of TAbLeS List of Tables Table 1: Type code ........................24 Table 2: Configurable options ......................26 Table 3: Climatic environmental conditions ................... 27 Table 4: Mechanical environmental conditions ................28 Table 5: Chemical / mechanical active substances ............... 28 Table 6: Device classification......................29 Table 7: Electromagnetic compatibility .................. -

Page 11: Glossary

(DIN 5008) IP xx Degree of protection (xx for level) Fieldbus system KEB product The KEB product is subject of this Cyclic duration factor manual Complete drive module including Silicium temperature sensor (pola- auxiliary equipment (control cabinet) - Page 12 GLOSSAry Term used in the safety technology (EN 61508-1...7) for the size of error probability per hour Programmable logic controller PT100 Temperature sensor with R0=100Ω PT1000 Temperature sensor with R0=1000Ω PTC-resistor for temperature detec- tion Pulse width modulation RJ45 Modular connector with 8 lines Synchronous sensorless closed loop SELV Safety Extra Low Voltage (<...

-

Page 13: Standards For Drive Converters / Control Cabinets

STANDArDS fOr DrIVe cONVerTerS / cONTrOL cAbINeTS Standards for drive converters / control cabinets Product standards that apply directly to the drive converter EN 61800-2 Adjustable speed electrical power drive systems - Part 2: General requirements - Rating specifications for low voltage adjustable frequency a.c. power drive systems (VDE 0160-102, IEC 61800-2) EN 61800-3 Speed-adjustable electrical drives. Part 3: EMC requirements and specific test methods (VDE 0160-103, IEC 61800-3) -

Page 14: Standards That Are Used In The Environment Of The Drive Converter

STANDArDS fOr DrIVe cONVerTerS / cONTrOL cAbINeTS EN 61000-4-5 Electromagnetic compatibility (EMC) - Part 4-5: Testing and measurement techniques - Surge immunity test (IEC 61000-4-5); German version EN 61000-4-5 EN 61000-4-6 Electromagnetic compatibility (EMC) - Part 4-6: Testing and measurement techniques - Immunity to conducted disturbances, induced by radio-frequency fields (IEC 61000-4-6); German version EN 61000-4-6 EN 61000-4-34... -

Page 15: Basic Safety Instructions

► Read the instructions for use ! ► Observe the safety and warning instructions ! ► If anything is unclear, please contact KEB Automation KG ! 1.1 Target group This instruction manual is determined exclusively for electrical personnel. Electrical per- sonnel for the purpose of this instruction manual must have the following qualifications: •... -

Page 16: Installation

bASIc SAfeTy INSTrUcTIONS Drive converters contain electrostatic sensitive components. ► Avoid contact. ► Wear ESD-protective clothing. Do not store drive converters • in the environment of aggressive and/or conductive liquids or gases. • with direct sunlight. • outside the specified environmental conditions. 1.3 Installation DANGer Do not operate in an explosive environment! -

Page 17: Electrical Connection

If personnel protection is required during installation of the system, suitable protective devices must be used for drive converters. www.keb.de/fileadmin/media/Manuals/knowledge/04_techinfo/00_gene- ral/ti_rcd_0400_0002_gbr.pdf Installations which include drive converter shall be equipped with additional control and protective devices in accordance with the relevant applicable safety requirements, e.g. -

Page 18: Emc-Compatible Installation

According to it is permissible to disconnect already tested com- EN 60204-1 ponents. Drive converters of the KEB Automation KG are delivered ex works voltage tested to 100% according to product standard. 1.4.3 Insulation measurement An insulation measurement (in accordance with chapter 18.3) with DC... -

Page 19: Start-Up And Operation

If a drive converter with electrolytic capacitors in a DC link (see technical data) has not been in operation for more than one year, observe the following instructions. www.keb.de/fileadmin/media/Manuals/knowledge/04_techinfo/00_gene- ral/ti_format_capacitors_0400_0001_gbr.pdf continuous operation (S1) with load > 60 % or from a rated motor... -

Page 20: Maintenance

(mains on) (e.g. due to large rotating masses). Switching an the input For applications that require cyclic switching off and on of the drive converter, maintain an off-time of at least 5 min after the last switch on. If you require shorter cycle times please contact KEB Automation KG. Short-circuit resistance The drive converters are conditional short-circuit proof. After resetting the internal pro- tection devices, the function as directed is guaranteed. -

Page 21: Repair

1.8 Disposal Electronic devices of the KEB Automation KG are exclusively professional devices for further industrial processing (so-called B2B devices). Manufacturers of B2B devices are obliged to take back and recycle devices manufac- tured after 14.08.2018. -

Page 22: Product Description

The used semiconductors and components of the KEB Automation KG are developed and dimensioned for the use in industrial products. Restriction If the KEB COMBIVERT F5 is used in machines, which work under exceptional condi- tions or if essential functions, life-supporting measures or an extraordinary safety step must be fulfilled, the necessary reliability and security must be ensured by the machine builder. -

Page 23: Product Features

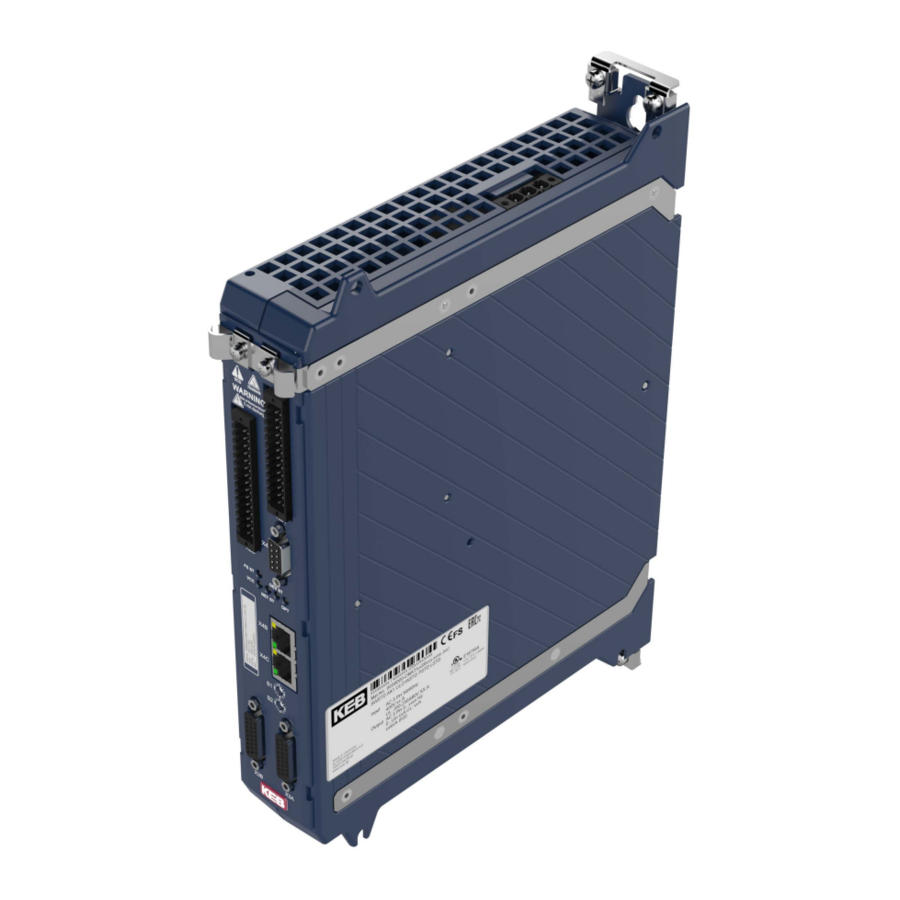

PrODUcT DeScrIPTION 2.3 Product features This instruction manual describes the power circuits of the following devices: Device type: Drive controller Series: COMBIVERT S6 Power range: 0.75...2.2 kW 400 V 3-phase 0.75...1.5 kW 230 V 1-phase Housing: The COMBIVERT S6 is characterized by the following features: •... -

Page 24: Type Code

PrODUcT DeScrIPTION 2.4 Type code x x S 6 x x x - x x x x Reserved 0: Reserved Reserved 0: Reserved cOMPAcT 1: Multi Encoder Interface, EtherCAT 2: Multi Encoder Interface, VARAN APPLIcATION 1: Realtime Ethernet Module, Multi Encoder Interface Type of control 1: Multi Encoder Interface / Ethernet-Fieldbus-Interface no Encoder / Ethernet-Fieldbus-Interface / Safe... -

Page 25: Nameplate

EQ. 5D72 ③ Output AC 3 PH 0...2000Hz 0...Uin 5.8A UL: 4.8A Made in Germany ⑧ 4kVA IP20 by KEB Automation KG 32683 Barntrup www.keb.de Legend Manufacturer identification Technical data input Technical data output Material number, basic device =>... -

Page 26: Configurable Options

PrODUcT DeScrIPTION 2.5.1 Configurable options features feature values Description Software SWxxx Software version of the drive controller Axxx Selected accessories Accessories No accessories Limitation to 599 Hz Clearing output frequency > 599 Hz available WSTD Warranty - standard Warranty Wxxx Warranty extension PSTD Parameterization - standard... -

Page 27: Technical Data

OPerATING cONDITIONS 3 Technical Data Unless otherwise indicated, all electrical data in the following chapter refer to a 3-phase AC voltage supply. 3.1 Operating conditions 3.1.1 climatic environmental conditions Storage Standard class Descriptions Ambient temperature -25…55 °C EN 60721-3-1 Relative humidity EN 60721-3-1 5…95 % (without condensation) Storage height... -

Page 28: Mechanical Environmental Conditions

OPerATING cONDITIONS 3.1.2 Mechanical environmental conditions Storage Standard class Descriptions Vibration amplitude 1.5 mm (2…9 Hz) Vibration limits EN 60721-3-1 Acceleration amplitude 5 m/s² (9…200 Hz) Shock limit values 40 m/s²; 22 ms EN 60721-3-1 Transport Standard class Descriptions Vibration amplitude 3.5 mm (2…9 Hz) Vibration limits Acceleration amplitude 10 m/s²... -

Page 29: Electrical Operating Conditions

OPerATING cONDITIONS 3.1.4 electrical operating conditions 3.1.4.1 Device classification requirement Standard class Descriptions – EN 61800-5-1 Overvoltage category EN 60664-1 – Non-conductive pollution, occasional conden- Pollution degree EN 60664-1 sation when PDS is out of service. Table 6: Device classification 3.1.4.2 Electromagnetic compatibility An external filter is required for devices without an internal filter in order to comply with the following limits. -

Page 30: Dimensions And Weights

DIMeNSIONS AND WeIGHTS 3.2 Dimensions and weights 3.2.1 built-in version 226,3 24,5 Housing Weight 1.9 kg Dimensions All dimensions in mm Figure 2: Dimensions built-in version housing 2... -

Page 31: Control Cabinet Installation

DIMeNSIONS AND WeIGHTS 3.2.2 control cabinet installation Power dissipation for the control cabinet dimension => „3.6.5 Power dissipation 400 V devices“. A lower value can be used here depending on the operating mode / load. Installation of the drive controller For reliable operation, the drive controller must be installed without clearance on a smooth, closed, bare metal mounting plate. -

Page 32: Mounting Instructions For Control Cabinet Installation

MOUNTING INSTrUcTIONS fOr cONTrOL cAbINeT INSTALLATION 3.3 Mounting instructions for control cabinet installation For mounting the drive controllers, the following fastening materials with the correspond- ing quality were tested by KEB. required material Tightening torque 3.2 Nm Screw assembly ISO 7045 - M6 - 8.8... -

Page 33: Installation Depth

MOUNTING INSTrUcTIONS fOr cONTrOL cAbINeT INSTALLATION 3.3.1 Installation depth For the various connections, it is recommended to keep the specified distance to upstream components. The values given are approximate values. The actual installation depth must be checked individually by the user. X2A/ X4B/ X3A/X3B Housing Dimensions All dimensions in mm Figure 5: Installation depth... -

Page 34: Device Data Of The 400 V Devices

3.4.1 Overview of the 400 V devices The technical data are for 2/4-pole standard motors. With other pole numbers the drive controller must be dimensioned onto the motor rated current. Contact KEB for special or medium frequency motors. Device size... -

Page 35: Voltage And Frequency Specifications Of The 400 V Devices

DeVIce DATA Of THe 400 V DeVIceS 3.4.3 Voltage and frequency specifications of the 400 V devices Input voltage and frequencies Rated input voltage Rated input voltage UL 230 / 480 N_UL Input voltage range 184…550 Mains phases Mains frequency / Hz 50 / 60 Mains frequency tolerance... -

Page 36: Input And Output Currents / Overload Of The 400 V Devices

DeVIce DATA Of THe 400 V DeVIceS 3.4.4 Input and output currents / overload of the 400 V devices Input currents 400 V devices Device size Rated input current @ U = 400 V Rated input current UL @ U = 480 V N _UL in_UL... -

Page 37: Device Data Of The 230 V Devices

3.5.1 Overview of the 230 V devices The technical data are for 2/4-pole standard motors. With other pole numbers the drive controller must be dimensioned onto the motor rated current. Contact KEB for special or medium frequency motors. Device size... -

Page 38: Voltage And Frequency Specifications Of The 230 V Devices

DeVIce DATA Of THe 230 V DeVIceS 3.5.3 Voltage and frequency specifications of the 230 V devices Input voltage and frequencies Rated input voltage 120...230 Rated input voltage UL 120...230 N_UL Input voltage range 184...265 Mains phases Mains frequency / Hz 50 / 60 Mains frequency tolerance / Hz... -

Page 39: Input And Output Currents / Overload Of The 230 V Devices

DeVIce DATA Of THe 230 V DeVIceS 3.5.4 Input and output currents / overload of the 230 V devices Input currents 230 V devices Device size Rated input current @ U = 230 V Rated input current UL @ U = 230 V N _UL in_UL... -

Page 40: General Data

GeNerAL DATA 3.6 General data 3.6.1 Overload characteristic (OL) All COMBIVERT S6 can be operated time-limited at rated switching fre- quency even in overload.Further information can be found in the diagrams „Figure 6: Switch-off time t depending on the overload I / IN (OL) 400 V devices“ „Figure 7: Switch-off time t depending on the overload I / IN (OL) 230 V devices“. -

Page 41: Switch-Off Time Depending On The Overload At 400 V Devices

GeNerAL DATA 3.6.1.1 Switch-off time depending on the overload at 400 V devices Overload characteristic (Oc Level 300%) ① Motor current / drive controller rated currrent in % Detail view in the range from 200 % to 300 % ② Motor current / drive controller rated currrent in % Legend 1 Thermal overload limit 2 Limitation by current controller limit (adjustable via software) -

Page 42: Switch-Off Time Depending On The Overload At 230 V Devices

GeNerAL DATA 3.6.1.2 Switch-off time depending on the overload at 230 V devices Overload characteristic (Oc Level 240%) ① Motor current / drive controller rated currrent in % Detail view in the range from 150 % to 250 % ② Motor current / drive controller rated currrent in % Legend 1 Thermal overload limit 2 Limitation by current controller limit (adjustable via software) -

Page 43: Maximum Current (Ol2)

GeNerAL DATA 3.6.1.3 Maximum current (OL2) It can be adjusted in the drive controller parameters if error (OL2) shall be triggered when exceeding the maximum currents, or if the switching frequency is automatically reduced (derating). The following tables indicate the permissible maximum current for 6 output frequency val- ues. -

Page 44: Table 24: Frequency-Dependent Maximum Current For Device Size 07 400 V Devices

GeNerAL DATA frequency-dependent maximum current 400 V devices Device size rated switching frequency 8 kHz Output frequency / Hz 12.5 4 kHz frequency-dependent maximum current @ f 8 kHz out_max Basic Time Period = 62.5 µs (Parameter is22=0) 16 kHz frequency-dependent maximum current @ f 7 kHz out_max... -

Page 45: Table 27: Frequency-Dependent Maximum Current For Device Size 07 230 V Devices

GeNerAL DATA frequency-dependent maximum current 230 V devices Device size rated switching frequency 8 kHz Output frequency / Hz 12.5 4 kHz frequency-dependent maximum current @ f 8 kHz out_max Basic Time Period = 62.5 µs (Parameter is22=0) 16 kHz frequency-dependent maximum current @ f 7 kHz out_max... -

Page 46: Switching Frequency And Temperature

GeNerAL DATA 3.6.2 Switching frequency and temperature The drive controller cooling is designed by way that the heat sink overtemperature threshold is not exceeded at rated conditions. A switching frequency higher than the rat- ed switching frequency also produces higher losses and thus a higher heat sink heating. If the heat sink temperature reaches a critical threshold (T ) the switching frequency can be reduced automatically step by step, in order to prevent that the drive controller... -

Page 47: Protection Of The Drive Controller

GeNerAL DATA 3.6.3 Protection of the drive controller 3.6.3.1 400 V units, 3-phase At 400V operation, 3-phase Alternatively fuse in A Motor protection switch Device size = 400 V = 480 V eaton gG (Iec) class „cc“ or „J“ (UL) PKZM0 10-e (UL) Sccr 30 kA Sccr 30 kA... -

Page 48: Dc Link / Braking Transistor Function

GeNerAL DATA 3.6.4 Dc link / braking transistor function 3.6.4.1 DC link / braking transistor function of the 400 V devices Device size DC link rated voltage @ U = 400 V N_dc DC link rated voltage @ U = 480 V N_dc_UL DC link voltage working voltage range 260…750 ±0... -

Page 49: Power Dissipation 400 V Devices

Activation of the braking transistor function The function must be activated with parameter "is30 braking transistor func- tion" in order to use the braking transistor. Further information can be found in the download area of www.keb.de under the search term „S6 Programming manual“. -

Page 50: Fan

GeNerAL DATA 3.6.7 fan Device size Number Heat sink fan Speed-variable — NOTICE Destruction of the fan ! ► Take care that no foreign substances drop into the fan ! 3.6.7.1 Switching behaviour of the fan The fan has different switch-on and switch-off points. The switching point for the switch- on temperature ① of the fan is adjustable. The switching point for the switch-off temper- ature ② cannot be changed and is always 5°C below the switch-on temperature. -

Page 51: Installation And Connection

INSTALLATION AND cONNecTION 4 Installation and connection 4.1 Overview of the cOMbIVerT S6 representation by the example of an APPLIcATION control board Mains input Motor output / Connection for braking resistor Temperature monitoring, brake control Strain relief Control terminal block Safety functions / DC 24 V supply CAN bus / analog inputs and outputs LED1...5... - Page 52 INSTALLATION AND cONNecTION Instructions for use COMBIVERT S6 control board APPLICATION www.keb.de/fileadmin/media/Manuals/dr/ma_dr_s6-cu-a-inst-20109645_en.pdf Instructions for use COMBIVERT S6 control board COMPACT www.keb.de/fileadmin/media/Manuals/dr/ma_dr_s6-cu-k-inst-20087885_en.pdf Instructions for use COMBIVERT S6 control board www.keb.de/fileadmin/media/Manuals/dr/ma_dr_s6-cu-p-inst-20156056_en.pdf...

-

Page 53: Connection Of The Power Unit

cONNecTION Of THe POWer UNIT 4.2 connection of the power unit 4.2.1 connection of the voltage supply 4.2.1.1 400 V devices The COMBIVERT S6 can be supplied both by mains and via DC terminals. The starting current limiting is arranged before the DC link. When using as DC output, parallel con- nected drive controllers must have their own starting current limiting at the DC voltage input. -

Page 54: Mains Terminal Block X1A

cONNecTION Of THe POWer UNIT Minimum waiting time between two switch-on procedures 5 min- NOTICE utes ! Cyclic switching on and off of the unit leads to temporary high resistance of the resistor (PTC) in the input. A restart without limitation is possible after cooling. 5 min NOTICE Destruction of the drive controller ! Never exchange connections mains input and motor output ! 4.2.1.3 Mains terminal block X1A L1 L2... -

Page 55: Leakage Currents

cONNecTION Of THe POWer UNIT 4.2.2 Leakage currents Calculated maximum leakage currents depending on voltage and frequency. Leakage current / Mains phases rated input voltage / V frequency / Hz Leakage current / 1-phase Maximum input voltage / V frequency / Hz Table 36: Leakage currents 1-phase Leakage current /... -

Page 56: Functional Earthing

The use of the functional earth (FE) is not required if the frequency inverter is EMC-technically wired. The functional earth may not be wired green / yellow! Notes on EMC-compatible installation can be found here. www.keb.de/fileadmin/media/Manuals/emv/0000neb0000.pdf... -

Page 57: Ac Connection

EN 61800-3 HF filter without internal filter KEB COMBIVERT Figure 16: Connection of the mains supply 3-phase devices The service life of drive controllers with voltage DC link depends on the DC voltage, surrounding temperature and the current load of the electrolytic capacitors in the DC link. -

Page 58: Ac Supply 230 V 1-Phase

EN 61800-3 HF filter without internal filter KEB COMBIVERT Figure 17: Connection of the mains supply 1-phase devices The service life of drive controllers with voltage DC link depends on the DC voltage, surrounding temperature and the current load of the electrolytic capacitors in the DC link. -

Page 59: Supply Cable

400 V devices DC voltage 260...375 V 260…750 V Type aR Fuses Pay attention to the permissible voltage range ! KEB COMBIVERT Figure 18: Connection at DC voltage supply 4.2.5.2 Terminal block X1B DC connection Name function cross-section ++, -- DC connection 0.5...2.5 mm²... -

Page 60: Connection Of The Motor

400 V 3-phase Table 38: Maximum motor cable length at AC supply The use of motor chokes or filters can significantly increase the cable length. KEB recommends the use of motor chokes or filters for a line length upto 50 m. Motor chokes or filters are absolutely necessary upto 100 m. 4.2.6.3 Motor cable length at operation with DC voltage The maximum motor cable length at DC operation is basically dependent on the capaci- ty of the motor cable. The internal filter is not active at DC operation. External measures must be taken if necessary. The following data apply for operation under nominal rating conditions. -

Page 61: Motor Cable Length For Parallel Operation Of Motors

cONNecTION Of THe POWer UNIT 4.2.6.4 Motor cable length for parallel operation of motors The resulting motor cable length for parallel operation of motors, or parallel installation with multiple cables arises from the following formula: resulting motor cable length = ∑single cable length x √Number of motor cables 4.2.6.5 Motor cable cross-section The motor cable cross-section is dependent •... -

Page 62: Wiring Of The Motor

➁ ➂ ④ Control P A/K Legend KEB COMBIVERT Motor cable Three-phase motor Temperature monitoring Figure 21: Wiring of the motor Apply the shield at both ends over a large area on the functional earth (shielding plate or mounting plate) Temperature monitoring is optionally available, =>... -

Page 63: Connection Of A Braking Resistor

Only intrinsically safe braking resistors permitted ! Only "intrinsically safe" braking resistors are permitted for this opera- tion, since these resistors interrupt themselves at fault such as safety fuse without fire risk. Instructions for use „Installation of an intrinsically safe braking resistor“ www.keb.de/fileadmin/media/Manuals/dr/ma_dr_safe-braking-resis- tors-20106652_en.pdf... -

Page 64: Use Of Non-Intrinsically Safe Braking Resistors

► Only use braking resistors with temperature sensor. ► Evaluate temperature sensor. ► Trigger fault on the drive controller (e.g. external input). ► Switch off input voltage (e.g. input contactor). ► Connection examples for non-intrinsically safe braking resistors => Instructions for use „Installation Braking Resistors“. Instructions for use „Installation Braking Resistors“ www.keb.de/fileadmin/media/Manuals/dr/ma_dr_braking-resis- tors-20116737_en.pdf... -

Page 65: Brake Control And Temperature Detection For K- And A- Control

brAKe cONTrOL AND TeMPerATUre DeTecTION fOr K- AND A- cONTrOL 4.3 brake control and temperature detection for K- and A- control Name Notes Brake control / output + Brake control / output - Reserved Reserved Temperature detection / input+ Temperature detection / input- Figure 24: Assignment of the terminal block X1C for K- and A-control 4.3.1 Specification and connection of the brake control... -

Page 66: Specification And Connection Of The Temperature Detection

► Cables of the motor temperature sensor inside the motor cable only permissible with double shielding ! A switchable KTY84/PTC evaluation is implemented in the KEB COMBIVERT. The de- sired operating mode can be adjusted by software (dr33). Operating mode (dr33) -

Page 67: Operation Without Temperature Detection

brAKe cONTrOL AND TeMPerATUre DeTecTION fOr K- AND A- cONTrOL 4.3.3 Operation without temperature detection Use of the COMBIVERT without evaluation of the temperature input: • Deactivate the evaluation (pn33 =7) • Install bridge between terminal X1C.5 and X1C.6 (dr33=1) 4.3.4 connection of a KTy sensor NOTICE No protection of the motor winding in case of wrong connection. -

Page 68: Connection Of Ptc, Temperature Switch Or Pt1000

brAKe cONTrOL AND TeMPerATUre DeTecTION fOr K- AND A- cONTrOL 4.3.5 connection of PTc, temperature switch or PT1000 Thermal contact (NC contact) ① Temperature sensor (PTC) or PT1000 ① Mixed sensor chain ① Name function Stetting dr33=1; PTC or tempera- TA1 (X1C.5);... -

Page 69: Brake Control And Temperature Detection For P- Control

brAKe cONTrOL AND TeMPerATUre DeTecTION fOr P- cONTrOL 4.4 brake control and temperature detection for P- control Name Notes Brake control / output Brake control / output for supply of the feedback inputs P24Vin - 0.5 V / max. 1 A 24Vout (BR+ and 24Vout in addition 2 A) DIBR1... -

Page 70: Specification And Connection Of The Temperature Detection

brAKe cONTrOL AND TeMPerATUre DeTecTION fOr P- cONTrOL 4.4.2 Specification and connection of the temperature detection DANGer Use only sensors with base insulation or safe separation ! Danger to life due to electric shock ! NOTICE Malfunctions due to incorrect cable or laying! Malfunctions of the control due to capacitive or inductive coupling. -

Page 71: Operation Without Temperature Detection

brAKe cONTrOL AND TeMPerATUre DeTecTION fOr P- cONTrOL 4.4.2.1 Operation without temperature detection Use of the COMBIVERT without evaluation of the temperature input: • Deactivate the evaluation (pn12 = 7). • Install bridge between terminal TA1 (X1C.9) and TA2 (X1C.10) (dr33 = 1). 4.4.2.2 Connection of a KTY sensor NOTICE No protection of the motor winding in case of wrong connection. -

Page 72: Connection Of Ptc, Temperature Switch Or Pt1000

brAKe cONTrOL AND TeMPerATUre DeTecTION fOr P- cONTrOL 4.4.2.3 Connection of PTC, temperature switch or PT1000 Thermal contact (NC contact) ① Temperature sensor (PTC) or PT1000 ① Mixed sensor chain ① Name function Stetting dr33=1; PTC or tempera- TA1 (X1C.9); ture switch Temperature sensor input TA2 (X1C.10) -

Page 73: Certification

EN 61800-5-1 EN 61800-3 Further information can be found in the download area of under www.keb.de the search term „Declaration of conformity“. 5.2 functional safety Drive controllers with functional safety are marked with the FS logo on the nameplate. -

Page 74: Table 43: Applied Standards

ANNeX TO THe DecLArATION Of cONfOrMITy eN - Norm Name reference EN 61800-5-1 Electrical power drive systems with adjustable speed: Safety VDE 0160-105-1 requirements EN 61800-2 Basic determinations for AC drive controller VDE 0160-102 EN 61800-3 Electrical power drive systems with adjustable speed. EMC VDE 0160-103 requirements Especially for systems with functional safety additionally:... -

Page 75: Ul Marking

UL MArKING 5.4 UL Marking Acceptance according to UL is marked at KEB drive controllers with the adjacent logo on the nameplate. To be conform according to UL for use on the North American and Canadian Market the following additionally instructions must be observed (original text of the UL-File): •... - Page 76 COURANT DANS UN RELAIS DE SURCHARGE, LE RELAIS TOUT ENTIER DOIT ÊTRE REMPLACÉ. Devices 07, 09 and 10 / 480V – housing 2 have been evaluated for connecting to DC voltage, supplied by other KEB inverters to a DC bus capacitance as follows: cat. No. Housing Min.

- Page 77 UL MArKING II) Listed (NKHJ, NKHJ7/CSA Certified), Type E Self Protected Manual Motor Control- lers, Type and manufacturer and electrical ratings as specified below: 120-230V/1ph S6 Models: Manual Motor Controller; not more than 5000 rms Symmetrical Amperes (SCCR 5kA): cat. No. Housing Manufacturer Type rating 07S6 115V/1ph, 1.5 hp Eaton PKZM0 20-E 09S6 230V/1ph, 3 hp 200-230V/3ph S6 Models: Manual Motor Controller; not more than 30000 rms Symmetrical Amperes (SCCR 30kA): cat.

-

Page 78: Further Informations And Documentation

INfOrMATIONS AND DOcUMeNTATION 5.5 further informations and documentation You find supplementary manuals and instructions for the download under www.keb.de/de/service/downloads General instructions • EMC and safety instructions • Manuals for additional control boards, safety modules, fieldbus modules, etc. Instruction and information for construction and development • Input fuses in accordance with UL • Programming manual for control and power unit •... -

Page 79: Revision History

reVISION HISTOry 6 revision History Version Date Description 2014-08 Preliminary version 2014-12 1st released version 2015-01 Fuse type class cc added to UL description 2015-05 Devices without internal filter registered; preface changed General technical data completely revised, power dissipation added, UL description 2015-11 extended Change to new CI-optics, revision of the device data, change of the overview, adjust- 2017-07 ment of the backup data 2018-11 230 V variant added, terminal block X1C included... - Page 80 NOTES...

- Page 81 Tel: +33 149620101 Fax: +33 145767495 c / Mitjer, Nave 8 - Pol. Ind. LA MASIA E-Mail: info@keb.fr Internet: www.keb.fr 08798 Sant Cugat Sesgarrigues (Barcelona) Spain Tel: +34 93 8970268 Fax: +34 93 8992035 E-Mail: vb.espana@keb.de Germany Geared Motors KEB Antriebstechnik GmbH...

- Page 82 Automation with Drive www.keb.de KEB Automation KG Suedstrasse 38 32683 Barntrup Tel. +49 5263 401-0 E-Mail: info@keb.de...

Need help?

Do you have a question about the COMBIVERT S6 Series and is the answer not in the manual?

Questions and answers

Upon attempted installation of the S6-A Model servo inverter (See attached image for exact model) Error message is displayed "Service Mode-Too Many Attempts Made" Is this something we can alter or fix in our facility or does this fault message require a repair from KEB? The units in question we have received back from KEB as refurbished parts prior to this instance of faulting.