Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Prince Antec Controls Retrofit

- Page 1 VENTURI VALVE RETROFIT MANUAL v100...

-

Page 2: Table Of Contents

VVR - MANUAL TABLE OF CONTENTS INTRODUCTION ....................................2 General ......................................2 Product Overview..................................2 Safety Precautions ..................................2 GETTING STARTED WITH THE VVR ..............................3 In the Box ......................................3 Additional Components .................................6 Required Tools ....................................7 Installation and Calibration .................................7 When using a VVR with PACE ..............................7 When using a VVR with the FHC ...............................7 When using a VVR with the LMX ..............................7 MOUNTING THE RETROFIT ................................8... -

Page 3: Introduction

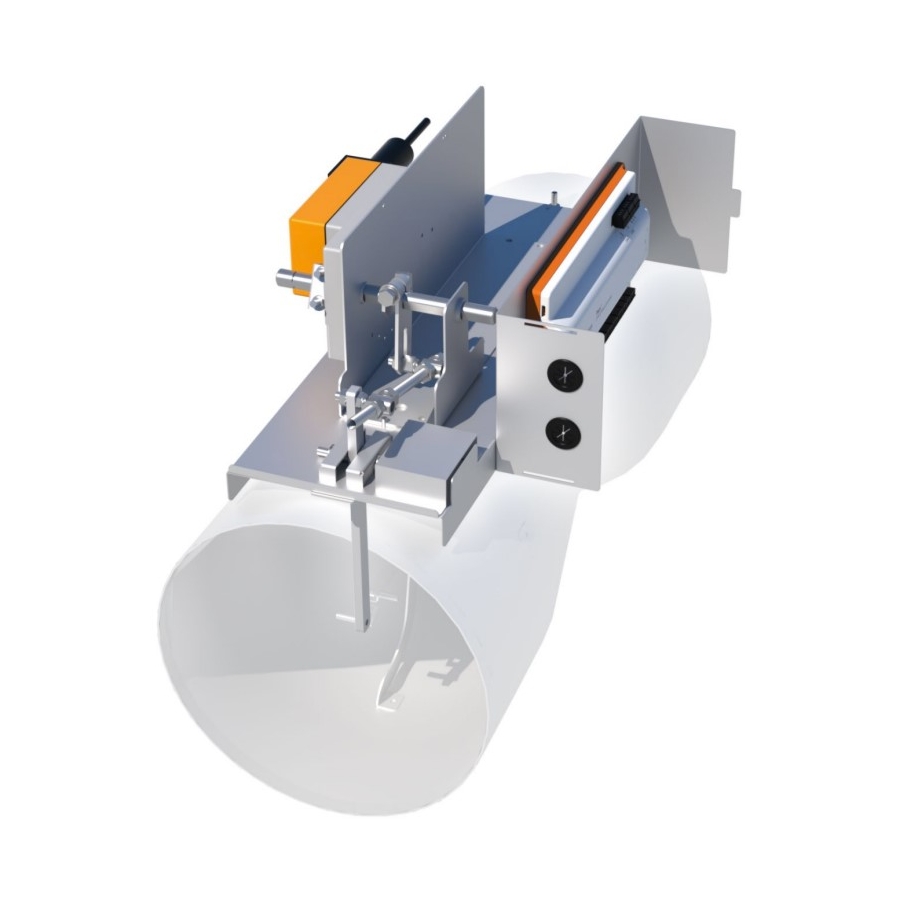

Product Overview For local area support, please contact your local Antec Controls Antec Controls Retrofit are designed to replace obsolete controls Representative on currently installed Venturi Valves. The VVR is built to mount directly onto the existing valves. Retrofits are designed to tether... -

Page 4: Getting Started With The Vvr

VVR - MANUAL GETTING STARTED WITH THE VVR CAUTION Please ensure all components are included in the box. Do not proceed if any components are missing, contact your local Antec Controls representative. In the Box For each of the available controllers the order includes the following components outlined in this section. PACE (Single Valve) The single venturi valve retrofit for PACE ships with several different components. - Page 5 VVR - MANUAL FHC (Single Valve) The single venturi valve retrofit for the FHC ships with several different components. The components are outlined in this section for a single venturi valve with an FHC. Component Quantity Description Single FHC controller. FHC Mounting Bracket used to mount the FHC to the controls Bracket...

- Page 6 VVR - MANUAL LMX (Single Valve) The single venturi valve retrofit for LMX ships with several different components. The components are outlined in this section for a single venturi valve with an LMX. Component Quantity Description Single LMX controller. LMX Mounting Bracket used to mount the LMX to the controls Bracket enclosure.

-

Page 7: Additional Components

VVR - MANUAL Additional Components The additional components for each available option are outlined in this section. Controls Enclosure The venturi valve retrofit has an option to order a controls enclosure. The controls enclosure comes with two different components. Component Quantity Description Enclosure Bracket... -

Page 8: Required Tools

VVR - MANUAL Required Tools See below for a list of required tools when performing a VVR installation. Installation and Calibration When installing the controls enclosure and calibrating the linkage, the installer will require the following tools: • #8 x 5/16” screws •... -

Page 9: Mounting The Retrofit

VVR - MANUAL MOUNTING THE RETROFIT Pre-Installation Checks The following checks are required prior to installation: • Visually inspect the valve for damage – If damage is found DO NOT INSTALL. Please contact a Price representative. • Visually inspect the Retrofit for damage – if damage is found DO NOT INSTALL. Please contact Antec Field Support. -

Page 10: Mounting Instructions For A Single Valve

VVR - MANUAL Mounting Instructions for a Single Valve STEP 1 Make a mark 2.25” from the middle of the control arm shaft. 2.25 2.25 STEP 2 Align the groove so that it's in-line with the pressure tap. Ensure that the bracket is lined up with the 2.25”... - Page 11 VVR - MANUAL STEP 4 Secure the mounting bracket to the mounting plate of the valve using four 3/8” self-tapping screws. Pick two holes from the discharge side and two from the inlet side. NOTE: Self-tapping screws are not provided with the VVR. The recommended size is a 3/8” self-tapping screw for metal.

- Page 12 VVR - MANUAL STEP 7A Mount the PACE below the top tab insert on the encloure. There must be a minor gap so the lid of the enclosure can slide on after. STEP 7B Pressure ports must be mounted facing the right hand side of the enclosure. PACE is mounted a minimum of 3”...

- Page 13 VVR - MANUAL STEP 8 To mount the FHC, use the mounting bracket and install 4 self-tapping screws. To mount the FHC in the correct location please ensure the following: The controller leaves enough room for the pressure tubing to be connected. There is sufficient space for the 3-pole terminal block to be mounted and wired in.

- Page 14 VVR - MANUAL STEP 11 Connect the wiring to the PACE, FHC, or LMX. For PACE wiring proceed to Step 11A. For FHC wiring proceed to Step 11B. For LMX wiring proceed to Step 11C. STEP 11A Wire the: Actuator signal wire into AO4 on PACE. POT cable in the POT1 terminal on PACE.

- Page 15 VVR - MANUAL STEP 11C Wire the: Actuator signal wire to AO1 on the LMX. POT cable to the Venturi POT terminal on the LMX. Flow and pressure signal into the FLO SIG and PRESSURE SIG terminal blocks, respectively. Power into the power terminal block on the LMX. Flow Signal Power Venturi POT...

-

Page 16: Mounting Instructions For A Dual Valve

VVR - MANUAL Mounting Instructions for a Dual Valve STEP 1 The airflow direction and location of the control arm will determine where the VVR is mounted. The VVR will be mounted following the airflow direction on the left hand side valve as shown in the figure. - Page 17 VVR - MANUAL STEP 3 Align the edge of the actuator mounting bracket with the edge of the base plate so they are parallel. STEP 4 Secure the mounting bracket to the mounting plate of the valve using four self-tapping screws.

- Page 18 VVR - MANUAL STEP 6B DUAL (V-type Base Channels): Align the front edge of the VVR 2.25 inches from the control arm (as mentioned in the steps above (STEP 2). Align VVR baseplate onto base channels such that the angled portion of the base plate sits flush against the base channel and the 2 crank arm assemblies are positioned approximately in-line with the 2 control arms.

- Page 19 VVR - MANUAL STEP 8B Pressure ports must be mounted facing the right-hand side of the enclosure. PACE is mounted a minimum of 3” from the right side of the enclosure. 3” STEP 8C PACE is mounted above the base channnel on the valve. STEP 9 To mount the FHC, use the mounting bracket and install 4 self-tapping screws.

- Page 20 VVR - MANUAL STEP 11 Mount the 3-pole terminal block with two self-tapping screws. NOTE: Self-tapping screws are not provided with the VVR. The recommended size is a 3/8” self-tapping screw for metal. STEP 12A Wire the: Actuator signal wire into AO4 on PACE. POT cable in the POT1 terminal on PACE.

- Page 21 VVR - MANUAL STEP 12B Wire the: Actuator signal wire to AO1 on the FHC. POT cable to the Venturi POT terminal on the FHC. Power into the power terminal block on the FHC. Actuator Venturi POT Power STEP 12C Wire the: Actuator signal wire to AO1 on the LMX.

- Page 22 VVR - MANUAL STEP 14 Route the other end of the pressure tubing through the knockout holes to the Pace pressure taps. Connect the red tubing to the high pressure side (H) and the green tubing to the low pressure side (L). STEP 15 Once power is turned on to the unit, please proceed to the POT Curves...

-

Page 23: Potentiometer Curves

VVR - MANUAL POTENTIOMETER CURVES Potentiometer (POT) curves are required any time a VVR is installed on an existing venturi valve in the field. If provided by the original manufacturer or the building owner, this curve can be configured by the factory prior to shipping the VVR. If the POT curve has been configured by the factory, please skip to the Calibration Section of this manual. - Page 24 VVR - MANUAL STEP 4 Click on PACE to enter the PACE section of the software. STEP 5 Toolbox will begin by loading linestrings. After this is complete, all PACE controllers detected on the Room Information Network (RIN) will be displayed on the home screen. NOTE: If configuring POT curves for the whole room, all valves should be visible.

- Page 25 VVR - MANUAL STEP 8 The edit airflow menu will appear as zeros for all airflow and voltage values. Enter the 8 airflow and voltage values for the original POT curve. This information should come from the previous manufacturer. If this is not NOTE: available, please skip to Creating a New POT...

- Page 26 VVR - MANUAL STEP 10 Select save and exit the menu. NOTE: A message should appear in the snack bar “Curve for POT 1 sent to VALVE TAG succesfully” 25 | VVR– Manual | AntecControls.com...

-

Page 27: Configuring A Pot Curve For Fhc

VVR - MANUAL Configuring a POT Curve for FHC STEP 1 Ensure the unit has power. NOTE: Please see the FHC Manual for power requirements STEP 2 Using the Ethernet cable described in the Required Tools, connect the RJ45 end to the NET OUT port on the FHC and wire the 3-wire connection to the BCT using the following wiring: BCT Terminal... - Page 28 VVR - MANUAL STEP 5 The program will automatically detect a COM port that is communicating with the FHC. If a COM port is not automatically detected, use the Scan COMs button to scan again. If connection is still not detected, please proceed to the Troubleshooting section of the manual.

- Page 29 VVR - MANUAL STEP 11 Review your entry and once satisfied click the Flash Module button. A pop-up will display informing the result of the flash. 28 | VVR– Manual | AntecControls.com...

-

Page 30: Configuring A Pot Curve For Lmx

VVR - MANUAL Configuring a POT Curve for LMX STEP 1 Ensure the unit has power. NOTE: Please see the LMX Product Submittal for power requirements STEP 2 Connect the RJ12 cable to the SERVICE port on the LMX. STEP 3 Connect the Linker2 to the laptop using the USB-A to USB-B cable. - Page 31 VVR - MANUAL STEP 6 After a module is found, confirm the Module Type is shown as LMX. STEP 7 Select whether the valve has One POT Curve or Two POT Curves. STEP 8 Select the operating range of the valve. NOTES: •...

-

Page 32: Creating A New Pot Curve

VVR - MANUAL Creating a New POT Curve If the original curve is not available, then it may be necessary to create a new POT curve to use for the valve control. STEP 1 Begin with the actuator in the minimum position (2 VDC). Adjust the crank arm and position nuts so that the valve is capable of achieving the minimum rated airflow. -

Page 33: Calibrating The Retrofit

VVR - MANUAL CALIBRATING THE RETROFIT Calibration is the process of adjusting the valve’s linkage assembly to ensure that the minimum position of the actuator provides the minimum airflow of the valve, and the maximum position of the actuator provides the maximum airflow of the valve. - Page 34 VVR - MANUAL STEP 4 Select the valve you would like to calibrate. Configure the airflow device and actuator in the PACE MANAGER screen. STEP 5 Enter the balancing menu underneath the Airflow tab. STEP 6 With the valve in the minimum airflow position (2VDC to actuator), loosen the ½” nuts around the swivel nut and fasten it to the control arm on of the valve.

- Page 35 VVR - MANUAL STEP 7 Override the valve from full closed (2 VDC to actuator) to full open (10 VDC to actuator) to see if it matches the full operating range of the valve. NOTE: This should reach the full operating range, not just the scheduled maximum airflow. If it matches the range, you have successfully completed the calibration.

-

Page 36: Potentiometer Replacement

VVR - MANUAL POTENTIOMETER REPLACEMENT In some cases, it may be appropriate to change the potentiometer on the valve. Potentiometer Replacement (Option #1) STEP 1 Loosen the shaft coupler by loosening the 2 hex screws. Slide the Shaft Coupler onto the rotating pin. - Page 37 VVR - MANUAL STEP 4 Align the control arm of the Venturi Valve so that it is straight vertical and verify that the potentiometer is at the center of its rotation. Do this by rotating the potentiometer (POT) shaft CW and then CCW to find its limits. Return the POT shaft to its center point, before proceeding to step 5.

-

Page 38: Curve Sheets

VVR - MANUAL CURVE SHEETS This page can be printed to record the potentiometer curves for all valves on the project if the old curves will not be available after the retrofit installation is completed. POTENTIOMETER CURVE POTENTIOMETER CURVE ANTEC ORDER #: ANTEC ORDER #: POINT VPOT... -

Page 39: Troubleshooting

VVR - MANUAL TROUBLESHOOTING Technical Support If technical support is required, please contact us: By Email @ FieldSupport@AntecControls.com By Phone @ 866-884-3524 Hours of Operation: Monday – Friday, 8am to 4:30pm CST NOTE: If you will need support outside of the above hours, please contact us 48 hours in advance. 38 | VVR–... - Page 40 Product Improvement is a continuing endeavour at Antec Controls by Price. Therefore, specifications are subject to change without notice. Consult your Sales Representative for current specifications or more detailed information. Not all products may be available in all geographic areas. All goods described in this document are warranted as described in the Limited Warranty.

Need help?

Do you have a question about the Antec Controls Retrofit and is the answer not in the manual?

Questions and answers