Summary of Contents for Johnson Controls YORK OM Titan

- Page 1 oM TiTan™ MulTi-sTage Chiller operaTing insTruCTions NEW RELEASE Form 160.72-O1 (810) TiTan™ MulTisTage Chiller WiTh reTrofiT opTivieW ConTrol CenTer KiT and eleCTro-MeChaniCal sTarTer...

- Page 2 All wiring must be in accordance with Johnson Controls’ published specifications and must be performed only by a qualified electrician. Johnson Controls will NOT be responsible for damage/problems resulting from improper connections to the controls or application of improper control signals.

- Page 3 FORM 160.72-O1 (810) ChangeaBiliTY of This doCuMenT In complying with Johnson Controls’ policy for contin- Operating/service personnel maintains the responsi- uous product improvement, the information contained bility of the applicability of these documents to the in this document is subject to change without notice.

- Page 4 FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 5: Table Of Contents

Custom Setup Screen ..........................105 Security Log Screen ............................. 107 Security Log Details Screen ......................... 109 seCTion 3 - opTivieW ConTrol CenTer ....................111 seCTion 4 - general operaTing seQuenCe ................... 119 seCTion 5 - sYsTeM CoMMissioning ......................131 JOHNSON CONTROLS... - Page 6 TaBle 3 - Status Line Messages and Colors ....................... 112 TaBle 4 - Titan OptiView Analog Inputs .......................127 TaBle 5 - Titan OptiView Analog Outputs ......................128 TaBle 6 - Titan OptiView Digital Inputs and Outputs ...................128 TaBle 7 - SI Metric Conversion ...........................137 JOHNSON CONTROLS...

-

Page 7: Section 1 - Introduction

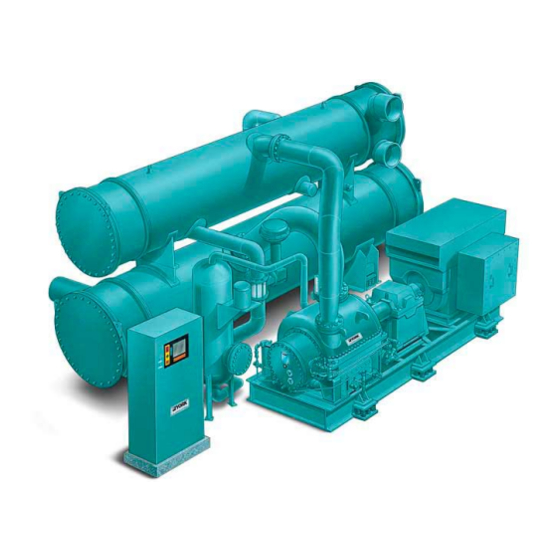

1 - inTroduCTion The following instructions outline the procedures to be Standard Johnson Controls operating instructions are followed for the operation of the YORK OM Titan™ included in this manual. Where the specific instruction retrofitted with OptiView Controls. is different than the standard instructions, the specific instruction should be followed. - Page 8 SECTION 1 - INTRODUCTION FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 9: Section 2 - Principles Of Operation

“head” or differential pressure con- ing gearbox) or a reciprocating gas engine (via a speed ditions. The valve is selected to fail open and opens increasing gearbox). on chiller shutdown, primarily to drain liquid from the JOHNSON CONTROLS... - Page 10 A collapsed or leaking ball (filled A manway with sight glasses allows for access to the with refrigerant) will cause the valve to remain closed. float valve assembly and adjusting arm. JOHNSON CONTROLS...

-

Page 11: Section 3 - Optiview Control Center

Service Instructions (Form 160.72-M1). These parameters affect chiller operation and should NEVER be modified by anyone other than a qualified Service Technician. They are shown in this manual for ref- erence only. JOHNSON CONTROLS... - Page 12 SECTION 3 - OPTIVIEW CONTROL CENTER FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

- Page 13 (such as proximity probe and vane cal- an entry form, the ‘X’ key is provided as a uni- ibration). In addition, the switch must be placed versal ‘Cancel’ symbol. in this state following a safety shutdown before JOHNSON CONTROLS...

- Page 14 ‘>’ symbol; if it is below the normal operating out returning to the Home Screen. After login, the user range, the low limit value will be displayed along with may then modify setpoints on that screen. JOHNSON CONTROLS...

- Page 15 If out of range, the value will The system will immediately refresh the display with not be accepted and the user is prompted to try the graphics for that screen. Following is a layout of all again. the screens and how they are connected. JOHNSON CONTROLS...

- Page 16 — Trend Screen (page 97) — Trend Setup Screen (page 99) — Trend Common Slots Screen (page 101) — Custom Screen (page 103) — Custom Setup Screen (page 105) — Security Log Screen (page 107) — Security Log Details Screen (page 109) JOHNSON CONTROLS...

- Page 17 AMPS Compressor Oil Cooler Water D/P "WG Gear Oil Cooler Water D/P "WG Condenser Oil Cooler Water D/P "WG Gear Supply Oil Temperature °F Chilled Water Entering Pressure PSIG Supply Air Pressure PSIG Condenser Water Entering Pressure PSIG JOHNSON CONTROLS...

- Page 18 Gear Lo Speed Shaft End Bearing Temperature °F Gear Lo Speed Blind End Bearing Temperature °F Motor Shaft End Bearing Temperature °F Motor Blind End Bearing Temperature °F Compressor Oil Temperature After Oil Cooler °F Chilled Water Leaving Pressure PSIG Compressor Motor kW 5000 JOHNSON CONTROLS...

-

Page 19: Home Screen

Displays the temperature of the liquid as it leaves the OPERATOR: The second access level is termed OP- evaporator. ERATOR and will allow the customer to change all of the setpoints required to operate the chiller system. JOHNSON CONTROLS... - Page 20 This screen provides access to a snapshot of system message indicating the cause of the shutdown. Using data at each of the last 10 shutdown conditions, all this key, the message can be cleared once the condition trending functions and custom screens. has been removed. JOHNSON CONTROLS...

-

Page 21: System Screen

Displays the present refrigerant pressure in the evapo- Condenser pressure rator. Displays the refrigerant pressure in the condenser. evaporator saturation Condenser saturation Displays the present saturation temperature in the Displays the present saturation temperature in the con- evaporator. denser. JOHNSON CONTROLS... - Page 22 Returns user to Home Screen. housing). If either of the transducers used to calculate this differential is out of range, the display field will show XX.X. % full load amps Displays the percentage of full load amps utilized by the compressor motor. JOHNSON CONTROLS...

-

Page 23: Evaporator Screen

Refrigerant Temperature -restart sensor input if the sensor is present, otherwise it will be Displays the Leaving Chilled Liquid Temperature at represented by the Evaporator Saturation temperature. which the chiller will restart after it has shut down due JOHNSON CONTROLS... - Page 24 34.0°F for the next 10 minutes. After ten (10) minutes 70.0°F (water). A remote device can provide an analog have elapsed, the shutdown threshold becomes the pro- signal (0-20mA or 4-20mA, 0-10VDC or 2-10VDC) grammed setpoint value. in Analog Remote mode or PWM signal in Digital JOHNSON CONTROLS...

- Page 25 80°F. The chiller will automatically re- start when this temperature is reached. This setpoint home can be used to reduce chiller cycling by delaying the Access Level Required: VIEW chiller restart until the cooling load has increased. Returns user to Home Screen. JOHNSON CONTROLS...

- Page 26 EVAPORATOR SCREEN FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 27: Condenser Screen

Options on the Configura- erant temperature and the Leaving Condenser Liquid tion screen. The service access level is required to en- temperature. The Condenser Refrigerant temperature able/disable this display. will be represented by the Condenser Saturation tem- perature. JOHNSON CONTROLS... - Page 28 Moves to the sub-screen allowing programming of the Condenser liquid pump (run / off) Refrigerant Level Control setpoints. Indicates whether Condenser Liquid Pump is operating. Condenser flow Displays the Condenser Water Flow, in GPM, if the sensor is present. JOHNSON CONTROLS...

-

Page 29: Refrigerant Level Control Screen

The ramp time will begin counting Manual - When the Level Control Valve is in manual at the end of the "Pulldown Time Remaining". During control position. the ramp time the level control valve will move from its start position to control position. JOHNSON CONTROLS... - Page 30 [level Control valve] lower (Manual) Condenser Access Level Required: SERVICE Access Level Required: VIEW This key allows the Service Technician to close the Returns user to the Condenser Screen. valve in increments of 1% or more from its current po- sition. JOHNSON CONTROLS...

-

Page 31: Compressor Screen

(Discharge temperature - Condenser Saturated field will show XX.X. temperature). Main oil Temperature intercooler refrigerant pressure Displays the temperature of the main oil supply feed- Displays the pressure of the refrigerant in its gaseous ing the compressor bearings. state in the intercooler. JOHNSON CONTROLS... - Page 32 CONFIGURATION Screen. Service Technicians refer [pre-rotation vanes] set (Manual) to the Service Instructions (Form 160.72-M1). Access Level Required: SERVICE This key allows the Service Technician to input a spe- cific value from 0 to 100 % to position the valve. JOHNSON CONTROLS...

-

Page 33: Compressor Lubrication Screen

Displays the temperature of the main oil supply being Displays the pressure differential between the Shaft supplied to the compressor, after the oil cooler. Pump Discharge pressure transducer and the Post Fil- ter Pressure transducer in the oil line after the filter. JOHNSON CONTROLS... - Page 34 (led) Returns user to Home Screen. Indicates whether the Oil Pump is being commanded Compressor to operate. access level required: vieW oil heater (led) Returns user to the Compressor Screen. Indicates whether the Oil Heater output is energized. JOHNSON CONTROLS...

-

Page 35: Hot Gas Bypass Screen

Solenoid is energized. This should be energized when- shown 50% open. When actual position is 60% to 79%, ever the hot gas bypass valve is open. the valve is shown as 75% open. Positions greater than 79% are shown as full open. JOHNSON CONTROLS... - Page 36 Access Level Required: VIEW sition. Returns user to the Compressor Screen. [hot gas Bypass Control] set (Manual) Access Level Required: SERVICE This key allows the Service Technician to input a value from 0 to 100 % to position the valve immediately. JOHNSON CONTROLS...

-

Page 37: Interstage Valve Screen

If the sensor is present and enabled under pulldown before the Interstage valve control will mod- Options on the Configuration screen. The service ac- ulate to maintain the interstage pressure setpoint. cess level is required to enable/disable this display. JOHNSON CONTROLS... - Page 38 Access Level Required: VIEW sition. Returns user to the Compressor Screen. [interstage valve Control] set (Manual) Access Level Required: SERVICE This key allows the Service Technician to input a value from 0 to 100 % to position the valve immediately. JOHNSON CONTROLS...

-

Page 39: Motor Screen

(led) Displays the current limit value in use. This value could come from a 0-20mA, 4-20mA, 0-l0VDC or 2-10VDC Indicates when the safety contact in the starter is input in Analog Remote mode, PWM signal in Digital closed. JOHNSON CONTROLS... - Page 40 Instructions (Form 160.72-M1). local demand limit Access Level Required: OPERATOR Allows the operator to change the Demand Setpoint from 0 % to 100 %. This will be the Current Limit Setpoint or the Power Limit Setpoint depending on the JOHNSON CONTROLS...

-

Page 41: Gearbox Screen

Displays the temperature of the bearing at the shaft end of the high speed side of the gearbox, if present and supply oil pressure enabled. Displays the oil pressure after the oil cooler and filter that is supplied to the gear box bearings. JOHNSON CONTROLS... - Page 42 Access Level Required: OPERATOR This key puts the Oil Pump control in Manual Mode and forces it to RUN. Manual Oil Pump control is dis- abled (and the button hidden) during system prelube, system run, and system coastdown. JOHNSON CONTROLS...

-

Page 43: Anti-Recycle Setpoints Screen

Cold Start Uptime. values. Cold start recycle Time (2nd start) The time the motor must be given to cool down (anti- recycle) after the second cold start attempt assuming the chiller has not run for the Cold Start Uptime. JOHNSON CONTROLS... - Page 44 Allows a qualified Service Technician to change any Access Level Required: VIEW of the anti-recycle setpoints shown above. Refer to the Returns user to Home Screen. Service Instructions (Form 160.72-M1). Motor Access Level Required: VIEW Returns user to Motor Screen. JOHNSON CONTROLS...

-

Page 45: Capacity Controls Screen

Condenser setpoint – override limit Displays the minimum pre-rotation vane position Pressure at which the PRV's will begin to close to pre- setpoint required for stable operation at low head con- vent the chiller from tripping off or high condenser ditions. pressure. JOHNSON CONTROLS... - Page 46 Moves to the subscreen for the display of the Setpoints Displays the ramp rate for the Hot Gas Valve during Screens. the startup of the chiller. The system status will display CONTROLS RAMPING when this rate is in effect. JOHNSON CONTROLS...

-

Page 47: Pid Tuning Screen

Valve to maintain the leaving chilled liquid tem- set for each device configured for the system. All tun- perature setpoint. ing is to be performed by the Johnson Controls Ser- vice Technician at the time of chiller commissioning. Demand Limit These values should never be changed or entered by anyone other than a qualified Service Technician. - Page 48 Access Level Required: VIEW change Setpoints Returns to the Capacity Controls Screen. Allows a qualified Service Technician to change any of the setpoints shown above. Refer to the Service In- structions (Form 160.72-M1). JOHNSON CONTROLS...

-

Page 49: Auto / Manual Control Screen

In addition, the Anti-Surge setpoints are also displayed. anti-surge-pressure delta See the Anti-Surge setpoints section for a detailed ex- Condenser pressure minus Evaporator pressure. planation. anti-surge Max.pressure delta pre-rotation vanes Maximum compressor differential pressure in PSID Displays the current PRV position. for stable operation. JOHNSON CONTROLS... - Page 50 This key allows the Service Technician to open the Access Level Required: VIEW valve 1% from its current position. Returns user to Capacity Controls Screen. lower (Manual) Access Level Required: SERVICE This key allows the Service Technician to close the valve 1% from its current position. JOHNSON CONTROLS...

-

Page 51: Setpoints Screen

Current – By CT’s on the motor leads temperature required to begin automatic control of the Power - KW meter Pre Rotation Vanes (PRV’s) to maintain setpoint. pre-rotation vane Minimum startup position The minimum position for the vanes at startup JOHNSON CONTROLS... - Page 52 SETPOINTS SCREEN FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 53: Temperature Setpoints Screen

This screen displays the temperature setpoints. These the output that controls the motor cooling valve. points will be configured at commissioning by a quali- fied Johnson Controls Service Technician. Motor Water valve Maximum Temperature displaY onlY The temperature which will generate a 20 mA signal to the output that controls the motor cooling valve. - Page 54 Returns user to Home Screen. Misc setpoints Access Level Required: VIEW setup Moves directly to the Miscellaneous Setpoints Screen. Access Level Required: VIEW Returns to the Setup Screen. pressure setpoints Access Level Required: VIEW Moves directly to the Pressure Setpoints Screen. JOHNSON CONTROLS...

-

Page 55: Pressure Setpoints Screen

This screen displays the pressure setpoints. These Service Technicians refer to the Service points will be configured at commissioning by a quali- Instructions (Form 160.72-M1) for opera- fied Johnson Controls Service Technician. tion instructions and explanation of all programmable setpoints and displayed displaY onlY values. - Page 56 Temperature setpoints Misc alarms/Trips Access Level Required: VIEW Access Level Required: VIEW Moves directly to the Temperature Setpoints Screen. Moves directly to the Miscellaneous Setpoints Screen. Time setpoints Access Level Required: VIEW Moves directly to the Time Setpoints Screen. JOHNSON CONTROLS...

-

Page 57: Time Setpoints Screen

Displays the delay time on startup before control of the This screen displays the time setpoints. These points Interstage valve is initiated. will be configured at commissioning by a qualified Johnson Controls Service Technician. override off delay displaY onlY Displays the delay time required for pressure overrides to be cleared. - Page 58 Access Level Required: VIEW Moves directly to the Miscellaneous Setpoints Screen. Change setpoints Allows a qualified Service Technician to change any of the setpoints shown above. Refer to the Service In- structions (Form 160.72-M1). JOHNSON CONTROLS...

-

Page 59: Miscellaneous Setpoints Screen

This screen displays the miscellaneous setpoints. These The minimum position for the Pre-Rotation vanes at points will be configured at commissioning by a quali- startup. fied Johnson Controls Service Technician. level Control valve Min position displaY onlY The minimum position for the subcooler level valve at prv ramp rate startup. - Page 60 Moves directly to the Time Setpoints Screen. Access Level Required: VIEW Returns to the Setup Screen. page down Access Level Required: VIEW Temperature setpoints Moves to the Anti-Recycle Setpoints Screen. Access Level Required: VIEW Moves directly to the Temperature Setpoints Screen. JOHNSON CONTROLS...

-

Page 61: Setup Screen

Base Leaving Chilled Liquid Temperature value is displayed. setpoint. This offset may be defined up to 10.0°F or 20.0°F above the Base setpoint (see the Remote Leaving Chilled JOHNSON CONTROLS... - Page 62 Chilled liquid Temperature Cycling diagnostics offset –– restart Access Level Required: SERVICE Access Level Required: OPERATOR Returns user to Diagnostics Screen. This value allows the user to specify the Leaving Chilled Liquid Temperature at which the chiller will restart af- JOHNSON CONTROLS...

-

Page 63: Configuration Screen

If within range, the value will be accepted. If out of range, the user is prompted for the information again. At this point the user may retry the date entry or cancel the programming attempt. JOHNSON CONTROLS... - Page 64 Access Level Required: VIEW sales order Returns user to Home Screen. Access Level Required: OPERATOR Moves to the Sales Order Screen. setup Access Level Required: OPERATOR operations Moves to the Setup Screen. Access Level Required: OPERATOR Moves to the Operations Screen. JOHNSON CONTROLS...

-

Page 65: User Screen

ü key when the Password values. Each Password will then require a cor- dialog box appears during the selection process. The responding User ID and User Level. Service Technicians refer to the Service Instructions (Form 160.72-M1). JOHNSON CONTROLS... - Page 66 User Access Levels. Each Access Level will Returns user to Home Screen. then require a corresponding Password and User ID. Service Technicians refer to the Service Instructions Configuration (Form 160.72-M1). Access Level Required: VIEW Return to the Configuration Screen. JOHNSON CONTROLS...

-

Page 67: Comms Screen

Define the number of data bits at which the panel shall eter to be changed. With the selection box around the communicate through the modem port. desired parameter, press the ENTER (ü) key. A dialog box is displayed permitting data entry. JOHNSON CONTROLS... - Page 68 Access Level Required: VIEW communicate through the modem port. Returns user to the Printer Setup Screen. navigaTion Comm2 setup home Access Level Required: SERVICE Access Level Required: VIEW Returns user to the Comm2 Setup Screen. Returns user to Home Screen. JOHNSON CONTROLS...

-

Page 69: Printer Screen

Access Level Required: OPERATOR value of the system schedule times) or a Sales Order Data report (information provided on the Sales Order Define the interval at which log printing will occur. screen). A print report is generated upon completion of selection. JOHNSON CONTROLS... - Page 70 Access Level Required: OPERATOR Access Level Required: VIEW Generate a report of the system data at the time of all Return to the Configuration Screen. stored shutdowns. navigaTion home Access Level Required: VIEW Returns user to Home Screen. JOHNSON CONTROLS...

-

Page 71: Sales Order Screen

Define the date at which the chiller was commissioned. panel serial number Factory defined serial number for the micropanel. Job name Chiller serial number Access Level Required: SERVICE Factory defined serial number for the chiller system. Refine the job name where the chiller is located. JOHNSON CONTROLS... - Page 72 Access Level Required: VIEW located. Returns user to Home Screen. print Configuration Access Level Required: VIEW Access Level Required: VIEW Generates a listing of the Sales Order data. Return to the Configuration Screen. Change Access Level Required: ADMIN JOHNSON CONTROLS...

-

Page 73: Operations Screen

Digital Remote, Analog Remote, Modem Remote fer to the Service Instructions (Form 160.72-M1). or BAS Remote. number of starts Access Level Required: ADMIN Displays the number of the starts the chiller has initi- ated. This may be reprogrammed to a desired value, JOHNSON CONTROLS... - Page 74 OPERATIONS SCREEN FORM 160.72-O1 (810) navigaTion home Access Level Required: VIEW Returns user to Home Screen. Configuration Access Level Required: VIEW Return to the Configuration Screen. JOHNSON CONTROLS...

-

Page 75: Options Screen

Type None – Gauge - Differential Displays Water or Brine Compressor oil Cooler Water Temperature sensor refrigerant selection Displays Disabled or Enabled Displays R-22, and R134a Depending on existence of sensor hot gas Bypass Displays Disabled or Enabled JOHNSON CONTROLS... - Page 76 Refer to the Service Instructions (Form 160.72-M1). navigaTion home Access Level Required: VIEW Returns user to Home Screen. setup Access Level Required: VIEW Returns to the Setup Screen. drive options Access Level Required: VIEW Returns to the Drive Options JOHNSON CONTROLS...

- Page 77 Temperature sensor Returns to the Setup Screen. Displays Disabled or Enabled drive options Depending on existence of sensor Access Level Required: VIEW subcooler refrigerant sensor Returns to the Drive Options Displays Disabled or Enabled Depending on existence of sensor JOHNSON CONTROLS...

- Page 78 OPTIONS SCREEN FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 79: Drive Options Screen

Depending on existence of starter contacts setup This is an additional safety contact from starter in most Access Level Required: VIEW cases is not required. Returns to the Setup Screen. Motor power (KW) sensor Displays Disabled or Enabled Depending on existence of sensors JOHNSON CONTROLS... - Page 80 DRIVE OPTIONS SCREEN FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 81: Temperature Alarms And Trips Screen

Shaft end of the high speed gear, if the (warning) or a trip (shutdown) or both. These points sensors are present and enabled. will be configured at commissioning by a qualified Johnson Controls Service Technician. gearbox low speed Blind end Bearing high Temperature displaY onlY... - Page 82 Access Level Required: VIEW set alarms Moves to the second screen of the Temperature Alarms Allows a qualified Service Technician to change any and Trips Screen. of the alarm points shown above. Refer to the Service Instructions (Form 160.72-M1). JOHNSON CONTROLS...

- Page 83 36° for water or the value set for points will be configured at commissioning by a quali- brine. fied Johnson Controls Service Technician. restart offset displaY onlY Temperature that will permit a restart of the chiller that...

- Page 84 Access Level Required: VIEW Moves to the first display of the Pressure Alarms and Returns to the Temperature Alarm and Trips Screen. Trips Screen. pressure alarms/Trips Access Level Required: VIEW Moves directly to the Pressure Alarms and Trips Screen. JOHNSON CONTROLS...

-

Page 85: Pressure Alarms And Trips Screen

Displays the Condenser High Pressure alarm and trip Displays the Gear High Differential Oil Pressure points. alarm. evaporator low pressure Compressor low sump oil pressure Displays the Evaporator Low Pressure alarm and trip Displays the Compressor Low Oil Supply Pressure points. alarm point. JOHNSON CONTROLS... - Page 86 Refer to the Service and Trips Screen. Instructions (Form 160.72-M1). page down navigaTion Access Level Required: VIEW home Moves to the second screen of the Pressure Alarms and Access Level Required: VIEW Trips Screen. Returns user to Home Screen. JOHNSON CONTROLS...

- Page 87 (warning) or a trip (shutdown) or both. These points will be configured at commissioning by a qualified set Trips Johnson Controls Service Technician. Allows a qualified Service Technician to change any displaY onlY of the trip points shown above. Refer to the Service Instructions (Form 160.72-M1).

- Page 88 Access Level Required: VIEW Moves directly to the Miscellaneous Alarms and Trips Moves to the Time Alarms and Trips Screen. Screen. page up Access Level Required: VIEW Moves to the first screen of the Pressure Alarms and Trips Screen. JOHNSON CONTROLS...

-

Page 89: Time Alarms And Trips Screen

(warning) or a trip (shutdown) or both. These points will be configured at commis- Motor start Contact delay sioning by a qualified Johnson Controls Service Tech- nician during the manufacturing of the chiller. Displays the Motor Start Contact Delay trip point, if enabled. - Page 90 Refer to the Service page down Instructions (Form 160.72-M1). Access Level Required: VIEW navigaTion Moves to the Miscellaneous Alarms and Trips Screen. home Access Level Required: VIEW Returns user to Home Screen. JOHNSON CONTROLS...

-

Page 91: Miscellaneous Alarms And Trips Screen

(warning) or a trip (shutdown) Instructions (Form 160.72-M1). or both. These points will be configured at commis- sioning by a qualified Johnson Controls Service Tech- set Trips nician during the manufacturing of the chiller. Allows a qualified Service Technician to change any displaY onlY of the trip points shown above. - Page 92 MISCELLANEOUS ALARMS AND TRIPS SCREEN FORM 160.72-O1 (810) Misc alarms/Trips Access Level Required: VIEW Moves directly to the Miscellaneous Alarms and Trips Screen. page up Access Level Required: VIEW Moves to the Time Alarms and Trips Screen. JOHNSON CONTROLS...

-

Page 93: History Screen

This generates a report listing the status of the chill- scription of the last normal shutdown. A normal shut- er parameters at the time of each of the stored shut- down is defined as: downs. • Local (Panel rocker switch) • Remote (Digital, Analog or BAS) JOHNSON CONTROLS... - Page 94 Access Level Required: VIEW Moves user to a sub-screen allowing the user to view trending data on selected chiller parameters. Custom view Access Level Required: VIEW Moves user to a sub-screen allowing the user to view the Custom Setup Screen. JOHNSON CONTROLS...

-

Page 95: History Details Screen

This is the on-screen printout of the system parameters. Returns user to Home Screen. prograMMaBle history Access Level Required: VIEW page down/page up Returns user to History Screen. Access Level Required: VIEW Scroll up or down in the displayed data (if applicable). JOHNSON CONTROLS... - Page 96 HISTORy SCREEN FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 97: Trend Screen

Y-axis label minimum for that param- played on the trending screen. The START key must be eter, the value will be plotted at the minimum value. pressed to initiate a new trend screen. Similarly, if the actual value is greater than the Y-axis JOHNSON CONTROLS... - Page 98 Selections are ALL DATA or DATA POINT X (1-6). Only displayed if the trending is stopped. Causes a jump to a subscreen for configuring the trending display. JOHNSON CONTROLS...

-

Page 99: Trend Setup Screen

900 seconds, with the last 112.5 hours Selects CONTINUOUS, ONE SCREEN or TRIG- (4.7 days) of data viewable on the screen. Therefore, GERED type of graph. the selected interval is a compromise between resolu- tion and full screen time display. JOHNSON CONTROLS... - Page 100 To change, use the SELECT key as described above and enter the desired value. The value must always be set to a value less than the Data JOHNSON CONTROLS...

-

Page 101: Trend Common Slots Screen

Returns user to Home Screen. displaY onlY Trend setup Returns user to Trend Setup Screen. slot numbers These are the slot numbers of the most commonly used parameters. prograMMaBle page down Access Level required: OPERATOR Scroll down in the displayed data. JOHNSON CONTROLS... - Page 102 TREND COMMON SLOTS SCREEN FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 103: Custom Screen

None Access Level required: SERVICE prograMMaBle Causes a jump to the sub-screen that allows selection of the parameters to be displayed. print Access Level Required: VIEW This generates a listing of the parameters displayed on this screen. JOHNSON CONTROLS... - Page 104 CUSTOM SCREEN FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 105: Custom Setup Screen

Clear display Scroll up through list of available parameters. Pressing this key clears all selected parameters from the Custom View screen. page down Scroll down through list of available parameters. JOHNSON CONTROLS... - Page 106 CUSTOM SETUP SCREEN FORM 160.72-O1 (810) navigaTion home Access Level Required: VIEW Returns user to Home Screen. Custom view Access Level Required: SERVICE Returns user to Custom View Screen. JOHNSON CONTROLS...

-

Page 107: Security Log Screen

Displays the value entered at the time of the setpoint description change. Displays the setpoint/category that was changed. prograMMaBle Time print Displays the time the setpoint was changed. Generates a report of change parameters displayed on this screen. JOHNSON CONTROLS... - Page 108 SECURITy LOG SCREEN FORM 160.72-O1 (810) navigaTion hoMe Access Level Required: SERVICE Returns user to Home Screen. security log Access Level Required: SERVICE Returns user to Security Log Screen. JOHNSON CONTROLS...

-

Page 109: Security Log Details Screen

Scroll up in the displayed data (if applicable). Category page down Displays the category of the setpoint (motor, evapora- Scroll down in the displayed data (if applicable). tor, condenser, etc.) setpoint Displays the setpoint that was changed. JOHNSON CONTROLS... - Page 110 Returns user to Home Screen. history Access Level Required: SERVICE Returns user to History Screen. view details Access Level Required: SERVICE Moves user to a sub-screen containing the details of the setpoint change selected with the Log Entry key. JOHNSON CONTROLS...

-

Page 111: Section 3 - Optiview Control Center

Gear Shaft Pump Oil Pressure 2353 Gear Supply Oil Temperature 2369 Gear Oil Cooler Leaving Water Temperature 2370 Gearbox Oil Cooler Water D/P 2420 % FLkW 19481 Intercooler Refrigerant Pressure 19483 Intercooler Refrigerant Liquid Temperature 1296 Condenser Temperature (Compressor Discharge) JOHNSON CONTROLS... - Page 112 One of the Anti-Surge parameters is causing the Ca- brication is being performed. The Pre-lube duration is pacity Controls to function in an Anti-Surge override configured by a qualified Service Technician during condition. commissioning and will be up to 150 seconds. JOHNSON CONTROLS...

- Page 113 The OptiView Control Center has detected a Motor ducer after the chiller has been running for 10 minutes. Start Contact signal from the motor starter while the This is indicative of a Condenser or Evaporator Trans- chiller is shutdown. As long as this condition exists, JOHNSON CONTROLS...

- Page 114 Analog I/O Boards or the Digital I/O Board the oil temperature minus the condenser saturation has been interrupted for at least 20 seconds. Message temperature is < 40°F. automatically clears when communications are re- stored. JOHNSON CONTROLS...

- Page 115 When detecting concentration of the Brine solution. The Brine shut- a fault condition that places the starter or motor at risk, down threshold is programmed at the YORK Factory. JOHNSON CONTROLS...

- Page 116 <23.7 der to initiate a shutdown, the difference must be outside PSIA and the COMPRESSOR switch is placed in the the acceptable range continuously for 10 minutes. For STOP/RESET (O) position. JOHNSON CONTROLS...

- Page 117 20.0 PSID during the last 5 seconds of the SYSTEM PRELUBE period. The differential oil pressure is the difference between the output of the Sump Oil Pressure Transducer (system low pressure) and the output of the Pump Oil Pressure Transducer (system high pressure). JOHNSON CONTROLS...

- Page 118 SECTION 3 - OPTIVIEW CONTROL CENTER FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

-

Page 119: Section 4 - General Operating Sequence

The switch is spring-loaded to the compressor and gearbox, if applicable, low oil return to the run position. pressure signals and low pressure cutout switch- es are checked. The chilled and condenser water low differential pressure cutout switches are also checked. JOHNSON CONTROLS... - Page 120 After the ramp-up is completed, the capacity con- trols operate to control chiller capacity in response to chilled water outlet temperature. JOHNSON CONTROLS...

- Page 121 These actions are taken to re- iary oil pumps will be turned off. duce backspin of the compressor on shutdown. If the chiller is shutdown by a stop command, an or- JOHNSON CONTROLS...

- Page 122 Thus, the net chilling capac- ity is reduced (albeit not efficiently). The minimum suction flow or minimum com- pressor PRV position will vary. As the differential JOHNSON CONTROLS...

- Page 123 JOHNSON CONTROLS...

- Page 124 To hot gas bypass whenever possible. The anti-surge attempt to keep the chiller online, the High Dis- output signal to HSR provides a minimum closure JOHNSON CONTROLS...

- Page 125 The PRV signal will then track the primary The control output signal is selected by signal LSR output signal until the next chiller start. selector SS five minutes after start-up when the ramped valve control signal has decreased to JOHNSON CONTROLS...

- Page 126 Chilled Water Out Temperature rising above the are also shown. These values will change any time new setpoint during the override operation. ramp times are entered. JOHNSON CONTROLS...

- Page 127 4-20ma Gear Hi Speed Shaft End Bearing Temperature 30-250 °F 4-20ma Gear Hi Speed Blind End Bearing Temperature 30-250 °F 4-20ma Gear Lo Speed Shaft End Bearing Temperature 30-250 °F 4-20ma Gear Lo Speed Blind End Bearing Temperature JOHNSON CONTROLS...

- Page 128 Hardwired Gear Low Oil Pressure Switch (ALM=OPN) Gear AOP Motor Starter Run Interlock Compressor Motor Starter Fault (CLO=ALM) Hardwired Evaporator Low Refrig Pres Switch (ALM=0PN) Spare Vibration Monitor Trip Compressor Motor Starter Run Interlock Vibration Monitor Alarm Vane Motor Close Switch JOHNSON CONTROLS...

- Page 129 Intercooler refrigerant liquid Temperature TT-111 Evaporator refrigerant liquid Temperature TT-112 compressor Suction Temperature TT-113 compressor Discharge Temperature TT-114 Subcooler refrigerant liquid Temperature TT-115 condenser refrigerant liquid Temperature TT-140 compressor Supply oil Temperature TT-142 compressor Shaft End Bearing oil return Temperature JOHNSON CONTROLS...

- Page 130 Compressor Motor Full Voltage Run Contacts Compressor Motor Protection Device Contacts ZS-100A Vane Motor Switch analOg Outputs DEViCE DEsCriptiOn pass LY-114 Subcooler Liquid Level Control Valve PDY-115 Interstage Valve TY-100A Compressor Pre-Rotation Vanes TY-100C Hot Gas Bypass Valve JOHNSON CONTROLS JOHNSON CONTROLS...

-

Page 131: Section 5 - System Commissioning

_____ consecutive normal working hours, and we agree that a charge of _______ per diem plus travel expenses will be made to Johnson Controls if services are required for longer than ______ consecutive normal hours or if repeated calls are required, through no fault of YORk/Johnson Controls. - Page 132 Close Percentage ..........1. eVaporator screen Minimum Load ........... Record the following setpoints: Manual or Auto Control (as desired) ....Leaving Chilled Liquid Temp (except BAS remote mode) ......... Leaving Chilled Liquid Temp Remote Range (except BAS remote mode) ......... JOHNSON CONTROLS...

- Page 133 If it is not desired to change any of the listed setpoints, proceed to the SETUP Screen below. Remote Analog Input Range ....... JOHNSON CONTROLS JOHNSON CONTROLS...

- Page 134 … pass and liquid injection systems and oil ANALOG REMOTE). return systems 6. Set the Leaving Chilled Liquid Temperature … … (f) Verify the compressor pre-rotation vanes are … … Setpoint. closed to unload the motor during starting. JOHNSON CONTROLS...

- Page 135 A Cycling Shutdown message will appear on the display if the contacts are open. The start sequence shall initiate. The display will in- dicate the operating state of the chiller as it transitions from start-up to run mode. JOHNSON CONTROLS...

- Page 136 SECTION 5 - SySTEM COMMISSIONING FORM 160.72-O1 (810) This page inTenTionallY lefT BlanK JOHNSON CONTROLS...

- Page 137 (°C), subtract 32° and multiply by 5/9 or 0.5556. Example: (45.0°F - 32°) x 0.5556 = 27.2°C To convert a temperature range (i.e., a range of 10°F) from Fahrenheit to Celsius, multiply by 5/9 or 0.5556. Example: 10.0°F range x 0.5556 = 5.6 °C range JOHNSON CONTROLS...

- Page 138 Tele. 800-861-1001 P.O. Box 1592, York, Pennsylvania USA 17405-1592 Subject to change without notice. Printed in USA www.york.com Copyright © by Johnson Controls 2010 ALL RIGHTS RESERVED Form 160.72-O1 (810) Supersedes: Nothing...

Need help?

Do you have a question about the YORK OM Titan and is the answer not in the manual?

Questions and answers