Subscribe to Our Youtube Channel

Summary of Contents for LinMot P01-48-HP Series

- Page 1 Installation Guide Linear Motors P01-48-HP EX protected NTI AG / LinMot Dok-Nr. 0185-0125-E_1V1_IG_P01-48-HP-EX_Linear_Motors...

-

Page 2: Table Of Contents

Warning signs ............................ 6 Additional ATEX safety instructions ....................8 Product description..........................9 Structure ............................9 3.1.1 Linear Motor ........................... 9 3.1.2 LinMot Servo Drive ........................9 3.1.3 Temperature relay ........................10 3.1.4 Circuit breaker..........................10 Exterior view ............................ 10 Interior view............................11 Technical data .......................... - Page 3 Cleaning agent ..........................37 Stator checking ..........................37 Storage, transport, installation height ....................39 Declaration of Conformity ........................40 IECEx Conformity certificate ......................... 41 EC Type examination certificate ...................... 45 NTI AG / LinMot P01-48-HP EX protected Page 3 / 47...

-

Page 4: General Information

1.4 Liability NTI AG (as manufacturer of LinMot and MagSpring products) excludes all liability for damages and expenses caused by incorrect use of the products. This also applies to false applications, which are caused by NTI AG's own data and notes, for example in the course of sales, support or application activities. -

Page 5: Safety Instructions

The linear motors of the types described here are used exclusively to carry out linear movements. The direct drives are intended for use in industrial plants. The motors are only operated with original LinMot servo drives. For external temperature monitoring, 2 temperature sensors and a temperature relay are used, which interrupts the power supply in the event of a fault. -

Page 6: Warning Signs

Before working, make sure that there are no high voltages. Fast-moving machine parts The sliders of LinMot linear motors are fast-moving machine parts. All necessary precautions must be taken to prevent persons approaching the moving elements during operation (provide covers, guards, etc.). - Page 7 When machining magnets, the drilling dust could easily ignite. Machining the sliders and the magnets they contain is not permitted. Burn hazard The sliders of LinMot motors can reach temperatures of 80 °C, which may cause burns upon contact. Grounding All metal parts that are exposed to contact during any user operation or servicing and likely to become energized shall be reliably connected to the means for grounding.

-

Page 8: Additional Atex Safety Instructions

Maintenance and service work may be performed only in a clean room with no explosive atmosphere. Dangerous ignition sources may arise when disassembling component parts. Only original parts from LinMot may be used for commissioning and maintenance work. The stator is grounded via the motor cable. The connector must be firmly tightened. -

Page 9: Product Description

2 to 4 temperature sensors on the windings depending on the length. These sensors can be used with a series x1100 or x1200 LinMot drive to read and analyze the absolute temperature. This allows the winding temperature to be determined and the motor to be switched off if the motor runs too hot. If the drive can no longer communicate with the motor, then it will shift to a fault state. -

Page 10: Temperature Relay

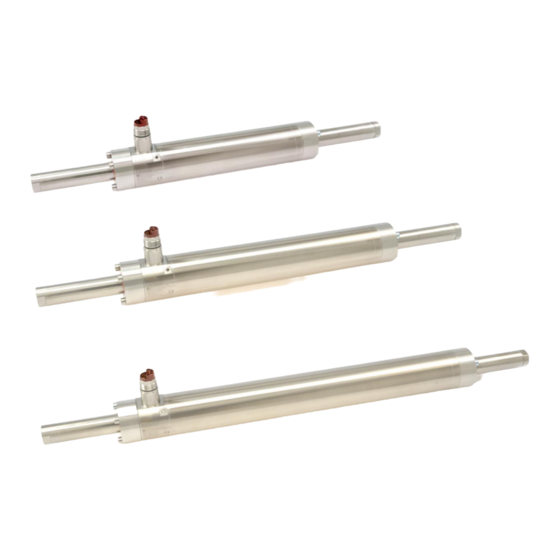

Interrupts the system power supply if the maximum surface temperature setting is exceeded. 3.2 Exterior view Water cooling Pt1000 sensors under connection stainless steel housing Copper tubing for water cooling Stator with windings (encapsulated) Page 10 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 11: Interior View

(5.58) (6.44) (7.30) (8.44) (9.30) (11.31) (13.03) (lb) Repeatability ±0.05 (±0.0020) (in) Linearity ±0.10 Repeatability with EPS ±0.01 (±0.0004) (in) Linearity with EPS ±0.01 (±0.0004) (in) * on request NTI AG / LinMot P01-48-HP EX protected Page 11 / 47... - Page 12 PL01-27x1220/1140 Slider 'high clearance' 1220 (48.03) 0150-1587 PL01-27x1400/1320 Slider 'high clearance' 1400 (55.12) 0150-1588 Item Description Item-No. PB01-48x25-80-E-SSC Bearing for PS01-48x...-SSC (Stainless) 0150-4190 PB03-48x25-80-E-SSC Bearing for PS01-48x...-SSC (Stainless) 0150-4191 Page 12 / 47 P01-48-HP EX protected NTI AG / LinMot...

- Page 13 0150-1471 PL01-27x800/720 Slider 'high clearance' 800 (31.50) 0150-1472 PL01-27x920/840 Slider 'high clearance' 920 (36.22) 0150-1447 PL01-27x1010/930 Slider 'high clearance' 1010 (39.76) 0150-1473 PL01-27x1220/1140 Slider 'high clearance' 1220 (48.03) 0150-1587 NTI AG / LinMot P01-48-HP EX protected Page 13 / 47...

- Page 14 Installation Guide Linear Motors PL01-27x1400/1320 Slider 'high clearance' 1400 (55.12) 0150-1588 Item Description Item-No. PB01-48x25-80-E-SSC Bearing for PS01-48x...-SSC (Stainless) 0150-4190 PB03-48x25-80-E-SSC Bearing for PS01-48x...-SSC (Stainless) 0150-4191 Page 14 / 47 P01-48-HP EX protected NTI AG / LinMot...

- Page 15 0150-1472 PL01-27x920/840 Slider 'high clearance' 920 (36.22) 0150-1447 PL01-27x1010/930 Slider 'high clearance' 1010 (39.76) 0150-1473 PL01-27x1220/1140 Slider 'high clearance' 1220 (48.03) 0150-1587 PL01-27x1400/1320 Slider 'high clearance' 1400 (55.12) 0150-1588 NTI AG / LinMot P01-48-HP EX protected Page 15 / 47...

-

Page 16: Performance Characteristic

The nominal sensor operating temperature is 90°C. At 95 °C a warning is given and at 100 °C the drive goes into error state. The LinMot-Designer program provides concrete information on the motion designs. Logging in is necessary to view these parameters. - Page 17 Logging in is necessary to view these parameters. • User-ID: «SERVICE» • Password: without (in default state) It is recommended to set a service password to prevent unintentional changes. T6 Setting Max. Sensor Temperature NTI AG / LinMot P01-48-HP EX protected Page 17 / 47...

-

Page 18: Higher-Level Temperature Monitoring

The table below must be consulted for setting the temperature relay. Setting of Temperature Relais Temperature class Sensor Max. surface temperature Pt1000 135 °C Pt1000 85 °C Page 18 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 19: Dimensions

Installation Guide Linear Motors 3.7 Dimensions 3.7.1 PS01-48x150 with bearing PB01 in mm NTI AG / LinMot P01-48-HP EX protected Page 19 / 47... -

Page 20: Ps01-48X150 With Bearing Flange Pb03

Installation Guide Linear Motors 3.7.2 PS01-48x150 with bearing flange PB03 in mm Page 20 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 21: Ps01-48X240 With Bearing Pb01

Installation Guide Linear Motors 3.7.3 PS01-48x240 with bearing PB01 in mm NTI AG / LinMot P01-48-HP EX protected Page 21 / 47... -

Page 22: Ps01-48X240 With Bearing Flange Pb03

Installation Guide Linear Motors 3.7.4 PS01-48x240 with bearing flange PB03 in mm Page 22 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 23: Ps01-48X360 With Bearing Pb01

Installation Guide Linear Motors 3.7.5 PS01-48x360 with bearing PB01 in mm NTI AG / LinMot P01-48-HP EX protected Page 23 / 47... -

Page 24: Ps01-48X360 With Bearing Flange Pb03

Installation Guide Linear Motors 3.7.6 PS01-48x360 with bearing flange PB03 in mm Page 24 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 25: Marking

Installation Guide Linear Motors 3.8 Marking LinMot ATEX linear motors are identified as follows: II 2G Ex eb IIC T6…T4 Gb 1258 II 2D Ex tb IIIC T85 °C…T135 °C Db 1258 Example of marking for item no. 0150-4365 3.9 Connector assignment... -

Page 26: Motor Cable

Trailing Chain Cable KS10-EX-Y-Fe/E6k-, Custom length 0150-3642 Item Description Item-No. MC01-Y-Fe/m Motor Connector Y-Fe/m 0150-3289 MC01-E6k/f-EX Connerctor with hexagonal union nut 0150-3538 KS10-05/05/04-EX Motor cable for EX applications per m 0150-9010 Page 26 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 27: Cabling

The maximum switch-off temperature to be set on the temperature relay is 85 °C or 135 °C, depending on the temperature class. • The max. installation altitude is 2'000 m (for higher values contact LinMot) above sea level. • From 1'000 m, derating of 1 °C per 100 m is to be considered for air cooling. -

Page 28: Mounting The Motor

4. If fluid cooling is used, remove headless screws. For the stator variant with liquid cooling, the headless screws must be removed and replaced with the corresponding threaded plugs. See additional details in Paragraph 4.8.5 Page 28 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 29: Mounting The Flange

It is important to avoid torsional stress on slider (note figure below). Slider Thread Max. torque for screw 27 mm M 10 47 Nm NTI AG / LinMot P01-48-HP EX protected Page 29 / 47... -

Page 30: Moving Slider" Installation

Slider mounting kit fixed bearing) are used to connect to the load. The mounting kit of slider and an oversized hole for the screw make it possible to adjust a radial and angle offset. Mounted payload with radial and angle offset Page 30 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 31: Electrical Connection Of The Motor

Pos. 9: Pt1000 temperature signals Pos. 5: Power The motor is connected to the temperature relay and the LinMot control unit as shown in the diagram above. The terminal assignment of the control unit and the temperature relay can be found in the respective operating instructions. -

Page 32: Check Before Commissioning

• T_Water -> Pv_Max (Continuous power dissipation) -> Q_Water -> Δp The design is illustrated by an example in the following. Page 32 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 33: Determination Of The Max. Possible Amount Of Cont. Power Dissipation Pv_Max

Water = 0.7 l / min ➔ Water To achieve a very regular cooling of the motor, the max. difference between flow and return temperature should not exceed 10 ° C. NTI AG / LinMot P01-48-HP EX protected Page 33 / 47... -

Page 34: Determination Of Water Pressure Δp

Two threaded connections are used for the inflow and outflow of the cooling medium to and from the stator (see illustration above). The connection can be implemented as an M5 thread. Page 34 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 35: Accessories

5.2 Cooling Flange The motor can also be mounted using a cooling flange. You will find the mounting diagram below. Ordering Information Item Description Item-No. PF01-48x330-SSC Flange 48x330mm-SSC 0150-4350 NTI AG / LinMot P01-48-HP EX protected Page 35 / 47... -

Page 36: Maintenance And Test Instructions

Ease of movement If friction is noticeable during the movement of the rotor, the motor must be switched off immediately. Check the alignment of the load guide and the rotor. Page 36 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 37: Cleaning In Assembled State

Klüberfood NH1 4-002 Spray* (250 ml) 0150-2394 * LinMot Spray LU06 corresponds to KLÜBERFOOD NH1 4-002 which was developed for the food processing industry. 6.5 Stator checking The following tables show the resistive value between the different connector pins for each stator type. If the value is not within a range of +/- 10% the stator may be damaged (temperature of the stator for all measurements: 20°C). - Page 38 Pin A - 10 / Housing > 20 M 1080 @ 20 °C Pt1000 1 Pin 7, 8 1080 @ 20 °C Pt1000 2 Pin 9, 10 Page 38 / 47 P01-48-HP EX protected NTI AG / LinMot...

-

Page 39: Storage, Transport, Installation Height

• Sliders are to be stored and transported only in the plastic containers (with cardboard inlay) provided for this purpose, or already installed and secured in LinMot P stators. • Remove the slider from this plastic containers only for assembling. -

Page 40: Declaration Of Conformity

EN IEC 60079-7: 2015 EN IEC 61000-6-2: 2016 EN IEC 61000-6-4: 2007+A1: 2011 EN IEC 61000-6-7: 2015 Spreitenbach, 14.08.2020 Dr.-Ing. Ronald Rohner Dr.-Ing. Marco Hitz CEO NTI AG RESPONSIBLE FOR DOCUMENTATION Page 40 / 47 P01-48-HP EX protected NTI AG / LinMot... -

Page 41: Iecex Conformity Certificate

Installation Guide Linear Motors 9 IECEx Conformity certificate NTI AG / LinMot P01-48-HP EX protected Page 41 / 47... - Page 42 Installation Guide Linear Motors Page 42 / 47 P01-48-HP EX protected NTI AG / LinMot...

- Page 43 Installation Guide Linear Motors NTI AG / LinMot P01-48-HP EX protected Page 43 / 47...

- Page 44 Installation Guide Linear Motors Page 44 / 47 P01-48-HP EX protected NTI AG / LinMot...

-

Page 45: Ec Type Examination Certificate

Installation Guide Linear Motors 10 EC Type examination certificate NTI AG / LinMot P01-48-HP EX protected Page 45 / 47... - Page 46 Installation Guide Linear Motors Page 46 / 47 P01-48-HP EX protected NTI AG / LinMot...

- Page 47 ALL LINEAR MOTION FROM A SINGLE SOURCE Europe / Asia Headquarters North / South America Headquarters NTI AG - LinMot & MagSpring LinMot USA Inc. Bodenaeckerstrasse 2 N1922 State Road 120, Unit 1 CH-8957 Spreitenbach Lake Geneva, WI 53147 Switzerland Sales / Administration: +41 56 419 91 91 Sales / Administration: 262.743.2555...

Need help?

Do you have a question about the P01-48-HP Series and is the answer not in the manual?

Questions and answers