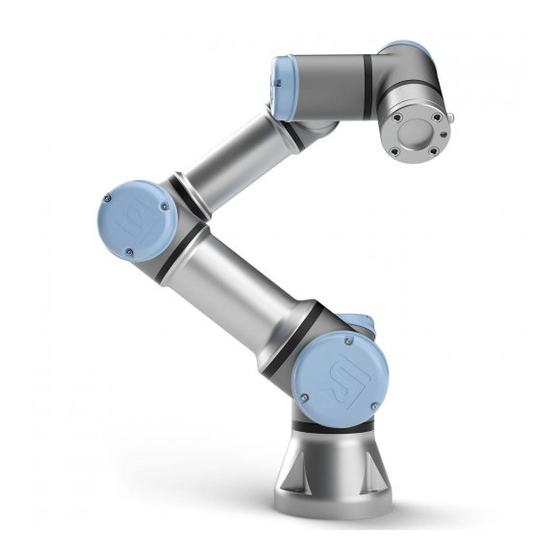

Universal Robots ur3 Original Instructions Manual

Collaborative table-top robot for light assembly tasks and automated workbench scenarios

Hide thumbs

Also See for ur3:

- Service manual (231 pages) ,

- Installation manual (12 pages) ,

- User manual (223 pages)

Summary of Contents for Universal Robots ur3

- Page 1 Service Manual Revision UR3_en_3.1.2 "Original instructions" Robot: UR3 with CB3-controller Valid from robot s/n 2014330001...

-

Page 2: Table Of Contents

2.2.1 Visual inspection of robot arm ......................8 3. Service and Replacement of parts ........................ 9 3.1 Robot arm ..............................9 3.1.1 Before returning any part to Universal Robots check: ..............9 3.1.2 Robot arm configuration ........................ 10 3.1.3 Brake release ..........................11 3.1.4 General guidance to separate joint from counterpart .............. - Page 3 3.1.19 Modify wrist 3 to Wrist 1 or wrist2 ....................43 3.2 Controller ............................... 45 3.2.1 Handling ESD-sensitive parts ......................45 3.2.2 Replacement of motherboard 3.1 ....................49 3.2.3 Replacement of Safety Control Board (SCB) ................... 52 3.2.4 Replacement of teach pendant ...................... 55 3.2.5 Replacement of 48V power supply ....................

-

Page 4: General Information

Universal Robots. Any improper use of the robot will invalidate the guarantee. Universal Robots recommends that you do not attempt repair, adjustment or other intervention in the mechanical or electrical systems of the robot unless a problem has arisen. Any unauthorized intervention will invalidate the guarantee. -

Page 5: Company Details

Fax +45 38 79 89 89 1.3 Disclaimer The information contained herein is the property of Universal Robots A/S and shall not be reproduced in whole or in part without prior written approval of Universal Robots A/S. The information herein is subject to change without notice and should not be construed as a commitment by Universal Robots A/S. -

Page 6: Preventive Maintenance

2. Preventive Maintenance 2.1 Controller 2.1.1 Inspection plan, Safety Functions The safety functions of the robots must be tested at least once a year to ensure correct function. The following tests must be performed. Test that the Emergency Stop button on the Teach Pendant functions: Press the Emergency Stop button on the Teach Pendant Observe that the robot stops and turns off the power to the joints Power the robot again... -

Page 7: Visual Inspection Of Controller

2.1.2 Visual inspection of controller Disconnect power cable from controller Open cabinet door Check connectors are properly inserted on printed circuit boards Check for any dirt/dust inside of controller If any dirt/dust is present: » Gently use a vacuum cleaner to remove particles »... -

Page 8: Robot Arm

2.2 Robot arm 2.2.1 Visual inspection of robot arm Of safety reasons confirm that the 4 rubber covers over the mounting screws are present on the Base mounting bracket. If you observe oil on the robot arm you simply clean it with a cloth. In very rare cases the grease is from the inside of the joint. -

Page 9: Service And Replacement Of Parts

Universal Robots cannot be held responsible for damage caused to non-UR equipment mounted on the robot. Backup all relevant files before sending the robot/part to UR. Universal Robots cannot be held responsible for loss of programs, data or files stored in the robot. ... -

Page 10: Robot Arm Configuration

3.1.2 Robot arm configuration 3.1.14 Tool flange – Wrist 3 joint 3.1.13 Wrist 3 joint – Wrist 2 joint Size 0 3.1.12 Wrist 2 joint – Wrist 1 joint Size 0 Size 0 3.1.11 Wrist 1 joint – Lower arm Size 1 Elbow counter part 3.1.9 Elbow joint –... -

Page 11: Brake Release

3.1.3 Brake release In an urgent situation the brake on Base, Shoulder and Elbow joints can be released without power connected. It is not possible to release the brakes on Wrist 1, 2 and 3 manually. IMPORTANT NOTICE: Before releasing a brake it is extremely important to dismount any dangerous parts to avoid any hazardous situations. -

Page 12: General Guidance To Separate Joint From Counterpart

3.1.4 General guidance to separate joint from counterpart Disassemble: 1. Check if you have the necessary tools before you start to repair the robot. 1.1. Service kit with torque tools, ESD Wristband, etc. 1.2. If you have to disassemble the robot arm you need: new flat rings, M3 and M4 tap tool for threads, pre coated screws or Loctite and normal. - Page 13 7. After disconnecting the wires gently remove black flexible flat ring with a tiny screwdriver and twist it around the joint housing. 8. Slide back the black teflon ring. (Marked with red) 6, 8 or 10 screws become visible Loosen the screws. 9.

- Page 14 Assemble: Important note: remove residues of old Loctite in screw holes with a M3 or M4 tap tool for threads before assembling the joint to get the correct torque on the new screws. Important note: Always use new pre-coated screws when it is possible. If you have to assemble with old screws carefully clean the screws and attach Loctite 648 on the screws before assembly.

- Page 15 6. Slide the black teflon ring (Indicated with red) into place and gently put the new flat ring back on top of the teflon ring. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 16 7. Connect the cables: Size 0 joint. Twist the communication cable 1.5 to 2 full rounds before connection Size 1 joint. Twist the communication cable 1.5 to 2 full rounds before connection Size 2 joint. Twist the communication cable 1.5 to 2 full rounds before connection Twist the communication cable 1.5 to 2 full rounds before connection.

-

Page 17: Torque Values

3.1.5 Torque values UR3 torque values CONNECTION TORQUE HEAD SIZE Base mounting bracket J0 Base 3.0Nm Torx T20 [J0] Base J[1] Shoulder 3.0Nm Torx T20 [J1] Shoulder Upper arm 3.0Nm Torx T20 Upper arm [J2] Elbow 1.3Nm Torx T10 [J2] Elbow Lower arm 1.3Nm... -

Page 18: Base Joint - Base Mounting Bracket

3.1.6 Base joint – Base mounting bracket Disassemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart 1. Shut down the controller. 2. Remove black flexible flat ring with a tiny screwdriver and twist it around the joint housing. 3. - Page 19 Base joint – Base mounting bracket: Assemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Important note: remove residues of old Loctite in screw holes with a M4 tap tool for threads before assembling the joint to get the correct torque on the new screws. Important note: Always use new pre-coated screws when it is possible.

-

Page 20: Shoulder Joint - Base Joint

3.1.7 Shoulder joint – Base joint Disassemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart 1. Shut down the controller. connect ESD wristband. 2. Remove blue lid on Base joint and 3. Disconnect wires between Base joint and Shoulder joint. Without bending the printed circuit board. -

Page 21: Upper Arm - Shoulder Joint

3.1.8 Upper arm – Shoulder joint Disassemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Shut down the controller. connect ESD wristband. 1. Remove blue lid on Shoulder joint and 2. Disconnect wires between Shoulder joint and Upper arm. Without bending the printed circuit board. -

Page 22: Elbow Joint - Upper Arm

3.1.9 Elbow joint – Upper arm Disassemble and assemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Shut down the controller. connect ESD wristband. 1. Remove blue lid on Elbow joint and 2. Disconnect wires between Elbow joint and Upper arm. Without bending the printed circuit board. -

Page 23: Elbow Counterpart - Elbow Joint

3.1.10 Elbow counterpart – Elbow joint Disassemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Shut down the controller. 1. Remove black flexible flat ring with a tiny screwdriver and twist it around the joint housing. 2. - Page 24 Elbow counterpart – Elbow joint: assemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Important note: remove residues of old Loctite in screw holes with a M3 tap tool for threads before assembling the joint to get the correct torque on the new screws. Important note: Always use new pre-coated screws when it is possible.

-

Page 25: Wrist 1 Joint - Lower Arm

3.1.11 Wrist 1 joint – Lower arm Disassemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart 1. Shut down the controller. connect ESD wristband. 2. Remove blue lid on Wrist 1 joint and 3. Disconnect wires between Wrist 1 joint and Lower arm. Without bending the printed circuit board. - Page 26 Wrist 1 joint – Lower arm Assemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Important note: remove residues of old Loctite in screw holes with a M3 tap tool for threads before assembling the joint to get the correct torque on the new screws. Important note: Always use new pre-coated screws when it is possible.

-

Page 27: Wrist 2 Joint - Wrist 1 Joint

3.1.12 Wrist 2 joint – Wrist 1 joint Disassemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart 1. Shut down the controller. connect ESD wristband. 2. Remove blue lid on Wrist 2 and 3. Disconnect wires between Wrist 1 joint and Wrist2 joint without bending the printed circuit board. - Page 28 Wrist 2 joint – Wrist 1 joint: Assemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Important note: remove residues of old Loctite in screw holes with a M3 tap tool for threads before assembling the joint to get the correct torque on the new screws.

-

Page 29: Wrist 3 Joint - Wrist 2 Joint

3.1.13 Wrist 3 joint – Wrist 2 joint Disassemble and assemble Procedure for separating Wrist 3 joint from Wrist 2 is similar to separation of Wrist 2 joint and Wrist 1 joint, consult chapter 3.1.12 Wrist 2 joint – Wrist 1 joint 3.1.14 Tool flange –... - Page 30 Tool flange – Wrist 3 joint: Assemble For details and photos please see: 3.1.4 General guidance to separate joint from counterpart Connect ESD wristband. Important note: remove residues of old Loctite in screw holes with a M3 tap tool for threads before assembling the joint to get the correct torque on the new screws.

-

Page 31: Dual Robot Calibration And Joint Calibration

3.1.15 Dual Robot Calibration and Joint calibration. Dual Robot Calibration kit (Part no: 185500) Dual Robot Calibration is a calibration that calibrates the robot in the full work space. All robots are Dual Robot Calibrated when they are produced. If a joint has been replaced on a calibrated robot the calibration is not correct anymore. There are 2 options: Performing a Dual Robot Calibration after replacement of a joint will let the robot continue in the production line without modifying waypoints in the robot program. -

Page 32: Instructions For Calibrating A Joint

3.1.16 Instructions for calibrating a joint If it is not possible to make a dual robot calibration you can make a calibration of joints. After this you must expect to adjust the most important waypoints. Make sure that the base of the robot is horizontal. ... - Page 33 Enter password lightbot and press OK. lightbot You are now in Expert Mode, press Low Level Control. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 34 Press Turn power on for enabling power to joints. Press Go to Idle for enabling the joints ready mode. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 35 Select the desired joint by directly clicking the status line for that joint. Press Arm current joint to release the brake on the selected joint. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 36 Use the Up and Down buttons in the Move window to navigate the joint to the correct zero position according to the following illustrations. Press STOP when the joint is in the correct position. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 37 Zero position illustrations Base: Shoulder, Elbow, Wrist 1: Base zero position is aligned so that the Shoulder, Elbow and Wrist 1 zero output flange is output flange is offset 180 degree from vertical aligned (if Base if horizontal). the slot for cable in back of robot base. Make sure that base of robot is horizontal, use spirit level to align joints.

- Page 38 Select Calibration tab and press Zero current joint position to calibrate the joint. Press Back to exit Low Level Control. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 39 Press Return to Normal. Verify zero position by moving the robot to HOME. If not satisfied with the zero position, perform the procedure once again. All rights reserved Servicemanual_UR3_en_rev3.1.2...

-

Page 40: Change Joint Id

3.1.17 Change joint ID Each joint has a unique ID no. It is NOT possible to have two joints with the same ID no. on the same robot. Joint Base Shoulder Elbow Wrist 1 Wrist 2 Wrist 3 Example: Wrist 1 (J3) has to be replaced. Spare joint is a Wrist 3 (J5) ... - Page 41 Select J5 (The one to be changed) Uncheck “Exchange IDs” box In dropdown box, select ID no. 3 Press Set it Confirm Change ID After you have turned power on you can see the joint J5 has changed to J3. All rights reserved Servicemanual_UR3_en_rev3.1.2...

-

Page 42: Joint Spare Part Adaptation

3.1.18 Joint spare part adaptation The UR3 constructed of 3 joint sizes and have to be setup on the robot: Recommended spare joints for UR3 are marked with: Robot: To use a wrist 3 joint as wrist 1 or wrist 2 it is Wrist 3: ID =5 Size 0 necessary to modify the joint. -

Page 43: Modify Wrist 3 To Wrist 1 Or Wrist2

3.1.19 Modify wrist 3 to Wrist 1 or wrist2 Mechanical parts has to be replaced. The orientation of the output flange has to be changed The joint ID has to be modified. Use the ESD guidelines for the modification of the wrist see: 3.2.1 Handling ESD-sensitive parts The Wrist 3 has the slipring for infinite turning of the tool mounting bracket. - Page 44 The removed slipring with screws Parts for wrist 1 and wrist 2 Attach the plastic protection. Put the wires through the joint and attach and assemble the connectors for the communication and power. There is no cable tie for this joint. NB! Pull gently in each wire to be sure the connector is attached correct in the plastic part of the connector.

-

Page 45: Controller

3.2 Controller 3.2.1 Handling ESD-sensitive parts To prevent damage to ESD-sensitive parts, follow the instructions below in addition to all the usual precautions, such as turning off power before removing logic cards: Keep the ESD-sensitive part in its original shipping container. (a special "ESD bag") until the part is ready to be installed Put the ESD wrist strap on your... - Page 46 Step 2: Step 1: Take NEW board out of ESD bag. Put OLD board into spare ESD bag. Hold the ESD-sensitive part by its edges. Do not touch its pins. If a pluggable module is being removed, then use the correct tool. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 47 Do not place the ESD-sensitive part on nonconductive material or on a metal table. If the ESD-sensitive part needs to be put into down for any reason, then first put it special ESD bag Machine covers and metal tables are electrical grounds. They increase the risk of damage because they make a discharge path from your body through the ESD-sensitive part.

- Page 48 Prevent ESD-sensitive parts from being accidentally touched by other personnel and do not put unprotected ESD-sensitive parts on a table. Be extra careful in working with ESD-sensitive parts when cold-weather and heating is used because low humidity increases static electricity. All rights reserved Servicemanual_UR3_en_rev3.1.2...

-

Page 49: Replacement Of Motherboard 3.1

3.2.2 Replacement of motherboard 3.1 Take care of ESD handling 3.2.1 Handling ESD-sensitive parts How to replace motherboard 3.1 Shut down the controller and disconnect the power cable, open the controller cabinet and loosen the 3 Torx screws Remove the aluminum cover plate All rights reserved Servicemanual_UR3_en_rev3.1.2... - Page 50 Disconnect cable connections from motherboard: 1. White plug with white, brown, yellow and green wires. 12 V Power 2. DVI-cable for TP screen 3. Ethernet cable to Safety control board SCB 4. Ethernet cable to external connector 5. Black USB cable for TP USB connector 6.

- Page 51 8. Replace Motherboard. 9. Insert the 6 cables in correct connectors. 10. Re-install USB stick for UR system SW. 11. Carefully put back the aluminum cover plate, make sure to mount it correct and fix it with the 3 screws All rights reserved Servicemanual_UR3_en_rev3.1.2...

-

Page 52: Replacement Of Safety Control Board (Scb)

3.2.3 Replacement of Safety Control Board (SCB) Take care of ESD handling 3.2.1 Handling ESD-sensitive parts How to replace Safety Control Board in Controller box Check that the software on the robot is as new as the firmware version on the SCB. If the software on the robot is too old then you get an error C203A0. - Page 53 Shut down the controller and disconnect the power cable, open the controller cabinet. Carefully remove all plugs and connectors Loosen the 5 Torx screws and remove the aluminum cover. All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 54 Carefully remove all plugs and connectors. Remove 14 screws holding the Safety Control Board. Replace Safety Control Board with new one and tighten the 14 screws to hold the board Insert all connectors and plugs in correct positions. Eventually see section 5.4.1 Schematic overview Carefully attach the aluminum cover, make sure to mount it correct and fix it with the 5 screws.

-

Page 55: Replacement Of Teach Pendant

3.2.4 Replacement of teach pendant Take care of ESD handling 3.2.1 Handling ESD-sensitive parts How to replace Teach Pendant on Controller Note: use the same procedure for power down and removing the aluminum cover plates as in chapter 3.2.2 Replacement of motherboard 3.1 3.2.3 Replacement of Safety Control Board (SCB) 1. -

Page 56: Replacement Of 48V Power Supply

3.2.5 Replacement of 48V power supply Take care of ESD handling 3.2.1 Handling ESD-sensitive parts How to replace 48V power supply in Controller box Note: use the same procedure for power down and removing the aluminum covers as in Chapter 3.2.2 Replacement of motherboard 3.1 3.2.3 Replacement of Safety Control Board (SCB) 1. - Page 57 5. Power supplies are located in the rack under the controller module, the two 48V power supplies are the lower ones in the rack. (UR3 and UR5 have one and the UR10 have two 48V power supplies) Before dismounting the 48V power supply, mark and disconnect the cables from that supply.

- Page 58 6. Remove the screws respectively of the defective 48V power supply from the side of the rack. 7. Replace 48V power supply with new one. 8. Reconnect the wires for the 48V power supply. 9. Re-install Controller module in reverse order and connect the 2 wires for the fan and cables for the teach pendant.

-

Page 59: Replacement Of 12V Power Supply

3.2.6 Replacement of 12V power supply Take care of ESD handling 3.2.1 Handling ESD-sensitive parts How to replace 12V power supply in Controller box Note: use the same procedure for power down and removing the aluminium cover and cables for teach pendant as in chapter 3.2.4 Replacement of teach pendant To replace the 12V power supply follow exactly the same steps as for the procedure in chapter... -

Page 60: Replacement Of Current Distributor

3.2.7 Replacement of current distributor Take care of ESD handling 3.2.1 Handling ESD-sensitive parts How to replace current distributor in Controller box Note: use the same procedure for power down and removing the aluminum cover and cables for teach pendant as in chapter 3.2.4 Replacement of teach pendant 1. -

Page 61: Software

4. Software 4.1 Update software Universal Robots software is named PolyScope. Read This Prior to Updating Your Software: Updating the software may cause changes or restrictions to functionality. Do not downgrade the software to earlier version than the version the robot was produced with. - Page 62 6. In left side menu, select Update Robot. 7. Press button Search for searching after software update on USB-stick. 8. Select the found software update and press UPDATE. 9. Press YES to update the software. 10. Wait for update to complete, after successful update controller will automatically power off. 11.

-

Page 63: Update Joint Firmware

After replacement of a joint on a UR3 the firmware is updated. 4.3 Using Magic files For easy backup, Universal Robots provides Magic files to automatically copy data from controller to USB- stick. These files are available: Function: ... -

Page 64: Troubleshooting

5. Troubleshooting In the error codes different words have been used for the same thing: On the Safety Control Board: Processor A = A uP = SafetySys1 On the Safety Control Board: Processor B = B uP = SafetySys2 PSU = Power Supply PC = Controller Open log files with Support Log Reader. - Page 65 CODE_4A6 Communication with primary If either processor A or a) Check Euromap67 EUROMAP67 uP lost processer B is communicating, connection between Euromap67 or cable between Motherboard and the Motherboard and Euromap67. b) Exchange Euromap is defect Euromap67 CODE_4A7 Communication with If either processor A or a) Check Euromap67 secondary EUROMAP67 uP...

- Page 66 CODE_4A77 Lost package from uPA to joints 1 package lost - warning CODE_4A78 Lost package from uPA to teach pendant 1 package lost - warning CODE_4A79 Lost package from uPA to uPB 1 package lost - warning CODE_4A80 Lost package from uPB 1 package lost - warning CODE_4A81 Packet counter disagreement...

- Page 67 CODE_10A1 Lost packet from PC Eventually update the software CODE_10A101 PC packet received too early Eventually update the software CODE_10A102 Packet counter does not Eventually update the match software CODE_10A103 PC is sending packets too often Eventually update the software CODE_11 Bad CRC error Check black 2-wire...

- Page 68 CODE_38 Online RAM test failed Replace Item CODE_38A1 Data-bus test failed Replace Item CODE_38A2 Address-bus stuck-high test failed Replace Item CODE_38A3 Address-bus stuck-low test failed Replace Item CODE_38A4 Address-bus shorted test failed Replace Item CODE_38A5 Memory-cell test failed Replace Item CODE_39 Logic and Temporal Monitoring Fault...

- Page 69 CODE_44A3 Joint 3 CRC check failure on Serial communication problem Replace joint 3 primary bus with joint or secondary bus node CODE_44A4 Joint 4 CRC check failure on Serial communication problem Replace joint 4 primary bus with joint or secondary bus node CODE_44A5 Joint 5 CRC check failure on...

- Page 70 CODE_50A16 The Teach Pendant does not Check the cable or change respond Loose wire or incorrect safety in the Safety Configuration configuration. Message comes of the Installation the from Safety Control Board miscellaneous settings CODE_50A17 The Euromap67 interface does Check the cable or change not respond in the Safety Configuration Loose wire or incorrect safety...

- Page 71 CODE_50A53 58V generator deviation error CODE_50A54 5V regulator too low CODE_50A55 5V regulator too high CODE_50A56 -4V generator too low CODE_50A57 -4V generator too high CODE_50A80 Last CPU reset caused by Low- Power-Reset CODE_50A81 Last CPU reset caused by Window-Watchdog-Reset CODE_50A82 Last CPU reset caused by Independent-Watchdog-Reset...

- Page 72 Board CODE_55A23 Safety relay error (minus Current distributor error Fault: Cable SCB-Current connection) distributor or 48V Power supply or Current distributor. CODE_55A24 Safety relay error (plus Current distributor error Fault: Cable SCB-Current connection) distributor or 48V Power supply or Current distributor.

- Page 73 CODE_57 Brake release failure Check Brake, solonoide, Payload, TCP and Mount CODE_57A1 Joint did not move or motor Check Brake, solonoide, encoder is not functioning Payload, TCP and Mount CODE_57A2 Large movement detected Check Brake, solonoide, during brake release Payload, TCP and Mount CODE_57A3 Robot was not able to brake Check Brake, solonoide,...

- Page 74 CODE_71A52 Current sensor test failed Sensors reported different Replace the joint. Defect currents when probed Printed circuit board CODE_72 Power Supply Unit failure 48 V Power problem CODE_72A1 0 PSUs are active PSU was not able to deliver Check power connection 48V (In UR10: No 48V) between power supply and Safety Control Board...

- Page 75 CODE_74A8 Supply voltage is out of range Error: The argument is the sum Check previous error of C75 errors CODE_74A16 Temperature is out of range Error: The argument is the sum Check previous error of C75 errors CODE_75A32 Signal lost =Misaligned Error: The argument is the sum Replace joint readhead or damaged ring...

- Page 76 CODE_104 Error=Empty command sent to robot CODE_111 Something is pulling the robot Check Payload setting CODE_115 Unknown robot type The robot type specified in the configuration is unknown CODE_116 Realtime part warning Possible CPU-overload due to Restructure user program structure of user program CODE_117 Restart SCB failed The Safety Control Board...

- Page 77 CODE_161 Protective stop: Large 1. Verify that the robot movement of the robot position in the 3D graphics detected while it was powered matches the real robot, to off. The joints were moved ensure that the encoders while it was powered off, or function before releasing the the encoders do not function.

- Page 78 CODE_171A13 Overlapping Blends in a Decrease the blend radius MoveL, a waypoint was or choose waypoints that skipped are further apart. CODE_171A14 Overlapping Blends in a Decrease the blend radius MoveL, a waypoint was or choose waypoints that skipped are further apart. CODE_172 Illegal control mode CODE_184...

- Page 79 CODE_191A18 Robot not stopping output violation CODE_191A19 Invalid safety IO configuration Fault in config file, when no GUI is used CODE_191A20 Configuration information or limit sets not received CODE_191A21 The other safety processor detected a violation CODE_191A22 Received unknown command Check Firmware from Controller CODE_191A23...

- Page 80 CODE_192A9 TCP speed disagreement Reduce payload, check for encoder problems CODE_192A10 TCP position disagreement Reduce payload, check for encoder problems CODE_192A11 TCP orientation disagreement Reduce payload, check for encoder problems CODE_192A12 Power disagreement Power calculation: uP-A and Joint error: Check previous uP-B disagreement error codes from the same joint and evaluate...

- Page 81 CODE_192A36 Online RAM test failed CODE_192A37 Not all safety related functionalities are running CODE_192A38 Package too short for CRC calculation CODE_192A39 Three position switch input disagreement CODE_192A40 Operation mode switch input disagreement CODE_193 One of the nodes is in fault SCB has detected an error See previous error or mode...

- Page 82 CODE_194A5 Joint 5 is not booted or not SCB has detected an error present CODE_194A6 Tool is not booted or not SCB has detected an error present CODE_194A7 Screen 1 is not booted or not SCB has detected an error present CODE_194A8 Screen 2 is not booted or not...

- Page 83 CODE_200A1 Hardware ID is wrong SCB: uP-A has detected an error: Wrong SCB CODE_200A2 MCU type is wrong SCB: uP-A has detected an error CODE_200A3 Part ID is wrong SCB: uP-A has detected an error CODE_200A4 RAM test failed SCB: uP-A has detected an Replace Safety Control error Board (SCB)

- Page 84 CODE_200A24 It took too long to stabilize Safety Control Board External 24 V problem or 24V IO error(SCB) replace SCB CODE_200A25 24V voltage is too high Safety Control Board Replace Safety Control error(SCB) Board (SCB) CODE_200A26 24V IO voltage is too high Disconnect I/O or replace CODE_201 Setup of safety board failed...

- Page 85 CODE_206A1 Target joint speed does not match target joint position - Joint 1 (Shoulder) CODE_206A2 Target joint speed does not match target joint position - Joint 2 (Elbow) CODE_206A3 Target joint speed does not match target joint position - Joint 3 (Wrist 1) CODE_206A4 Target joint speed does not match target joint position -...

-

Page 86: Led Indicators And Fuses On Safety Control Board

5.2 LED indicators and Fuses on Safety Control Board Safety Control Board (SCB) The 5 A fuse “48 V” protects all 48 V for over current in the system inclusive Euromap. This information is only for troubleshooting. Do NOT replace the fuse on any circumstances. Do ONLY replace the SCB with a new tested board. - Page 87 Normal startup sequence on a CB3.x UR3: 1. When the power plug connected and the robot is not turned on the 12 V LED is on. 2. After the power on button is activated the power up sequence starts. 3. In this sequence The 48 V LED indicator and the "R" LED indicator is on in about 1 second. This is done to test that the 48V power supply is working and to test that the robot arm is connected.

-

Page 88: Error Phenomena

5.3 Error phenomena 5.3.1 ControlBox: NO CONTROLLER displayed in Initializing ControlBox = NO CONTROLLER displayed at INITIALIZING screen Replace Ethernet cable between motherboard Defective Ethernet cable and Safety Control Board and verify problem is solved Replace Safety Control Board and verify problem Defective Safety Control is solved Board... -

Page 89: No Cable Displayed During Power Up

5.3.2 NO CABLE displayed during power up NO CABLE displayed during power up > controller shuts off after few seconds Measure that 230V AC is present on power input Replace current distributor connector on 12V power supply Check that 12V PSU LED is lid. The top LED in the row in the right side of the Safety Control Board. -

Page 90: Force Limit Protective Stop

5.3.3 Force limit protective stop Force Limit Protective Stop Payload and tcp settings in Installation\TCP Adjust payload and tcp Configuration must correspond with actual tool. settings Are settings incorrect? Adjust center of mass using Is center of mass very different from tcp point? script code set_payload() Are waypoints positioned very close to cylindrical Adjust waypoints away... -

Page 91: Power On Failure In Initializing

5.3.4 Power on failure in Initializing If power turns off a few seconds after Robot Power is turned On in the Initializing window, there are many possible causes for this phenomenon. Most likely it is a control box failure or a communication failure with a joint or the tool. Control box failure Check log history for error messages and consult the section Error Codes for detailed explanation... - Page 92 Communication failure with a joint or the tool connector Check log history for error messages and consult the section Error Codes for detailed explanation Go to LOW LEVEL CONTROL in EXPERT MODE (consult chapter 4.2 for how to access EXPERT MODE) Unmount tool and check Go to tab General and press “TURN POWER ON”...

- Page 93 Continued Go to tab General and press “TURN POWER ON” Remove blue lid of joint and and “Go to Idle” and “Arm robot”. Does state of check black comm. all joints J0-J5 switch from “Power OFF” to connector is fully inserted READY? Does state of joint switch to READY?

-

Page 94: Checklist After A Collision

5.3.5 Checklist after a collision Checklist after a collision Check log history for error messages and consult the section Error Codes for detailed explanation Stop robot program and eventually press the Emergency button prior to entering the work cell Visually inspect robot arm. Remove lid and inspect Are any parts visually damaged, like damages on parts inside of joint... -

Page 95: Electrical Drawing

5.4 Electrical drawing 5.4.1 Schematic overview Diagrams in pdf or in E-plan format, can be found on the support site http://www.universal-robots.com/support/ All rights reserved Servicemanual_UR3_en_rev3.1.2... - Page 96 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 97 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 98 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 99 All rights reserved Servicemanual_UR3_en_rev3.1.2...

-

Page 100: E-Plan Diagrams

5.4.2 E-Plan diagrams Diagrams in pdf or in E-plan format, can be found on the support site. http://www.universal-robots.com/support/ All rights reserved Servicemanual_UR3_en_rev3.1.2... - Page 101 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 102 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 103 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 104 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 105 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 106 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 107 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 108 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 109 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 110 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 111 All rights reserved Servicemanual_UR3_en_rev3.1.2...

- Page 112 All rights reserved Servicemanual_UR3_en_rev3.1.2...

-

Page 113: Spare Parts

Controller excl. Teach Pendant CB3.1 UR3 (With cabinet) 124903 Controller OEM CB3.1 UR3 (Without Teach Pendant and cabinet) 122091 Teach Pendant incl. Touch Screen & power cable UR3, UR5 & UR10 180001 Stylus Pen 171010 USB Flash 2 GB for UR system SW 122650 Motherboard kit CB3.1... -

Page 114: Service Kit

Lid Tool protective cap Alu. For tool connector 139033 Bracket for Mounting Teach Pendant 103203 Cover plug kit for UR3 base: 4 x covering screw holes + 1 x cover for cable hole 132407 Bracket for Mounting Controller 107000 Safety Control board Terminal kit... -

Page 115: Packing Of Robot

7 Packing of robot Packing of robot and controller box for shipment Remove any external tooling and external electrical connections. Download the Put_Into_Box program to a USB stick. Download it from: http://www.universal-robots.com/support/ Load program Put_into_box_ur3.urp on the robot and follow instructions while removing mounting bolts. -

Page 116: Changelog

8 Changelog 8.1 Changelog Date Revision Action Changes 20. Marts 2015 UR3_en_3.1.1 Added Revision 3.1.1 released December 2015 UR3_en_3.1.2 Added More details for replacements of parts, additional error codes, Updated Electrical drawings, Torque value for elbow changed, All rights reserved Servicemanual_UR3_en_rev3.1.2...

Need help?

Do you have a question about the ur3 and is the answer not in the manual?

Questions and answers