Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for WAGNER PER-X1

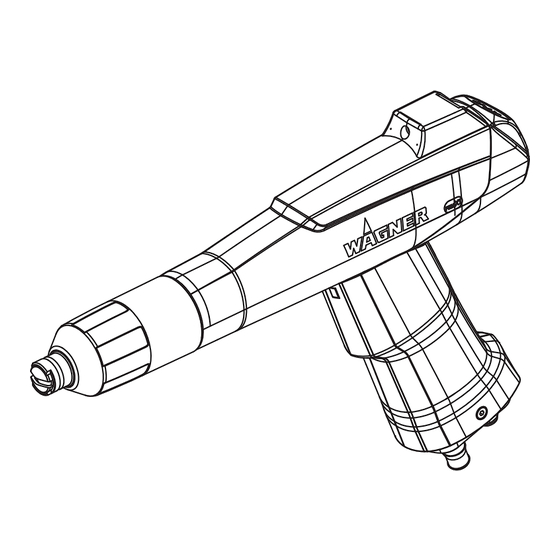

- Page 1 P_04900 Robot powder spray gun PER-X1 Translation of the Original Operating Manual 0102 II 2 D 2 mJ For professional use. Always observe the information in this manual, particularly the safety instructions and the warning instructions. Store the manual in a safe place. Edition: 10/2022...

-

Page 3: Table Of Contents

Operating manual Robot powder spray gun PER-X1 Table of Contents TABLE OF CONTENTS About these Instructions Preface Warnings, Notices and Symbols in these Instructions Languages Abbreviations Terminology for the Purpose of this Manual Using in Accordance with the Instructions Device Type... - Page 4 Operating manual Robot powder spray gun PER-X1 Table of Contents 6.6.1 PER-X1 Single Outside (SO) 6.6.2 PER-X1 Single Inside (SI) 6.6.3 PER-X1 Twin Outside (TO) 6.6.4 PER-X1 Twin Inside (TI) Grounding 6.7.1 Grounding the powder coating system Safety Checks Operation...

- Page 5 How to Order Spare Parts 13.2 Notes on the Use of Spare Parts 13.3 PER-X1 Corona Robot Spray Gun with a Flat Jet Nozzle 13.4 PER-X1 Corona Robot Spray Gun with a Round Jet Nozzle 13.5 X1 R Electrode Holder 13.6...

-

Page 6: About These Instructions

Operating manual Robot powder spray gun PER-X1 1 About these Instructions 1 ABOUT THESE INSTRUCTIONS 1.1 PREFACE The operating manual contains information about safely operating, maintaining, cleaning and repairing the device. The operating manual is part of the device and must be available to the operating and service personnel. -

Page 7: Abbreviations

Operating manual Robot powder spray gun PER-X1 1 About these Instructions 1.4 ABBREVIATIONS Order no. Order number Spare part Marking in the spare parts lists Position Number of pieces Item not available as spare part Item does not exist 1.5 TERMINOLOGY FOR THE PURPOSE OF THIS MANUAL... -

Page 8: Using In Accordance With The Instructions

EN 16985 or under equivalent ventilation conditions. The device may only be operated under the following conditions: 4 Use the device only to work with the materials recommended by WAGNER. 4 Do not deactivate safety fixtures. 4 Use only WAGNER original spare parts and accessories. -

Page 9: Identification

Incorrect use! Risk of injury and damage to the device. 4 Only connect the powder spray gun to original WAGNER devices. The PER-X1 robot powder spray gun may only be used with the following control units: Guns Control units PER-X1 (with accessories) - Page 10 Operating manual Robot powder spray gun PER-X1 3 Identification Guns Control units EPG-Sprint XE EPG-Sprint EPG S2 HVM-DP EPG-DP5 EPG-SL5 For accessories, see chapter Accessories [8 51] Order number 2444998 | Edition 10/2022...

-

Page 11: Basic Safety Instructions

Operating manual Robot powder spray gun PER-X1 4 Basic Safety Instructions 4 BASIC SAFETY INSTRUCTIONS 4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR 4 Keep this operating manual at hand near the device at all times. 4 Always follow existing regulations concerning occupational safety and accident prevention regulations. -

Page 12: Personnel Qualifications

Operating manual Robot powder spray gun PER-X1 4 Basic Safety Instructions 4 Protective clothing including gloves, must correspond to EN 1149-5. The measured insulation resistance must not exceed 100 MΩ. 4 Ensure that there are no ignition sources such as naked flames, sparks, glowing wires, or hot surfaces in the spray booth. -

Page 13: Safe Handling Of Wagner Powder Spray Devices

Operating manual Robot powder spray gun PER-X1 4 Basic Safety Instructions 4 For sufficient health and environmental protection, only operate the device with technical ventilation (extraction) switched on. 4.2.2 Safe Handling of WAGNER Powder Spray Devices Danger due to dust formation! 4 Do not point spray guns at people. -

Page 14: Electrical Connection Cables

4.2.7 Maintenance and Repair Danger due to improper maintenance and repair! Danger to life and equipment damage. 4 Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. Order number 2444998 | Edition 10/2022... -

Page 15: Protective And Monitoring Equipment

4 Use only WAGNER original spare parts and accessories. 4 WAGNER assumes no liability for changes to the product made by the operating company without the knowledge of WAGNER. Any adjustments to the documentation and the market release are the responsibility of the operating company. - Page 16 Operating manual Robot powder spray gun PER-X1 4 Basic Safety Instructions Pos Designation Nozzle Electrode Luminous discharge Work piece With the high voltage switched on, a luminous or corona discharge occurs at the electrode tip; this can only be seen in the dark. This physical effect can be seen when the electrode is brought near the grounded work piece.

-

Page 17: Description

Operating manual Robot powder spray gun PER-X1 5 Description 5 DESCRIPTION 5.1 DESIGN OF THE ROBOT GUN P_04902 6 5 4 Pos Designation Handle Spray gun body Union nut Electrical connection Atomizer air connection Powder hose connection Flat jet nozzle... -

Page 18: Mode Of Operation Of The Robot Spray Gun

Identification: "Attention! Positive cascade" Note: For the conversion of an existing gun, the Wagner customer service must be contacted! 5.3 MODE OF OPERATION OF THE ROBOT SPRAY GUN The high voltage is activated in the robot spray gun when the gun is electronically actuated! The powder supply and air supply to the gun are activated at the same time. -

Page 19: Dimensions

Operating manual Robot powder spray gun PER-X1 5 Description Dimensions: Polarity Negative / positive (special ac- cessories) Pneumatic: Input air pressure (atomizing air volume) Maximum 3 bar; 0.3 MPa, 43.51 Powder discharge quantity Maximum 450 g/min; maximum 0.99 lbs/min WARNING Exhaust air containing oil! Risk of poisoning if inhaled. -

Page 20: Accessories

Operating manual Robot powder spray gun PER-X1 5 Description 5.6 ACCESSORIES Only the accessories listed in chapter Accessories [8 51] of this operating manual may be connected to the PER-X1 robot powder spray gun. Order number 2444998 | Edition 10/2022... -

Page 21: Assembly And Commissioning

Operating manual Robot powder spray gun PER-X1 6 Assembly and Commissioning 6 ASSEMBLY AND COMMISSIONING 6.1 TRAINING OF ASSEMBLY/COMMISSIONING PERSONNEL 4 The assembly and commissioning personnel must have the technical skills to safely commission the device. 4 When assembling, commissioning and carrying out all work, read and follow the operating manuals and safety regulations for the additionally required system components. - Page 22 Operating manual Robot powder spray gun PER-X1 6 Assembly and Commissioning Nozzle Application Distance to Powder dis- charge (g/min) Work piece (mm) Universal 120 – 300 50 – 300 Deep and complex part geome- tries P_01664 Parts with large surfaces The spray width can be adjusted by the sliding ring.

-

Page 23: Connecting The Robot Spray Gun

Operating manual Robot powder spray gun PER-X1 6 Assembly and Commissioning Deflector cone Application Distance to work piece (mm) ⌀ 18 mm 100 – 300 Smaller flat parts P_01665 ⌀ 25 mm 100 – 300 Medium sized flat parts P_01666 ⌀... - Page 24 Operating manual Robot powder spray gun PER-X1 6 Assembly and Commissioning Work steps: 1. Switch off the high-voltage generation on the control unit. 2. Before connecting the robot spray gun, check that all components, such as the nozzle system and union nut, are correctly fitted.

-

Page 25: Assembly Of The Variants

P_04914 Assembly: 1. Screw the PER-X1 SO elbow onto the robot arm using the screws (6x). 2. Guide the connection cable as well as the powder and atomizing air hose through the clamping ring and the PER-X1 SO elbow and connect to the spray gun. -

Page 26: Per-X1 Single Inside (Si)

2. Unscrew the RSI robot flange from the robot spray gun. 3. Pull the connection cable, powder and atomizing air hose off of the gun. 4. Replace PER-X1 robot spray gun and assemble it again as described in Assembly. Order number 2444998 | Edition 10/2022... -

Page 27: Per-X1 Twin Outside (To)

6.6.3 PER-X1 Twin Outside (TO) WARNING Improper settings! The following requirements must be ensured for the operation of the PER-X1 Twin spray gun: 4 Both spray guns must always be operated with the same settings for high voltage, current limitation and characteristic curve quality. -

Page 28: Per-X1 Twin Inside (Ti)

6.6.4 PER-X1 Twin Inside (TI) WARNING Improper settings! The following requirements must be ensured for the operation of the PER-X1 Twin spray gun: 4 Both spray guns must always be operated with the same settings for high voltage, current limitation and characteristic curve quality. -

Page 29: Grounding

3. Unscrew the gun connection from the guns. 4. Replace the PER-X1 robot spray gun and assemble it again as described in Assembly. 6.7 GROUNDING For safety reasons, the control unit must be properly grounded. The grounding connection... -

Page 30: Grounding The Powder Coating System

Operating manual Robot powder spray gun PER-X1 6 Assembly and Commissioning 6.7.1 Grounding the powder coating system P_04905 1. Only use mains cables with grounding strand! 2. Connect the control unit's grounding cable with the signal ground! 3. Connect grounding cable to an uncoated metal part of the booth! 4. -

Page 31: Operation

Operating manual Robot powder spray gun PER-X1 7 Operation 7 OPERATION 7.1 TRAINING THE OPERATING PERSONNEL – The operating personnel must be qualified to operate the entire system. – The operating staff must be familiar with the potential risks associated with improper behavior as well as the necessary protective devices and measures. -

Page 32: Switching Off The Automatic Gun In The Event Of Faults Or Emergencies

Operating manual Robot powder spray gun PER-X1 7 Operation Work steps for an example with powder injector as powder conveyor: 1. The atomizing air has to remain open to prevent powder from penetrating into the atomizing air channels and the cascade compartment during the flushing process. -

Page 33: Cleaning And Maintenance

8.1.2 Cleaning Procedures The cleaning intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. If in doubt, we recommend contacting WAGNER's specialist personnel. 8.1.3 Performing a Paint Change WARNING Dust formation! Risk of poisoning if inhaled. -

Page 34: Maintenance

DANGER Incorrect maintenance/repair! Danger to life and equipment damage. 4 Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. 4 Use only WAGNER original spare parts and accessories. 4 Only repair and replace parts that are listed in the spare parts chapter and that are assigned to the device. -

Page 35: Replacing The Robot Spray Gun

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance Maintenance work Time stamp Per shift Weekly Blow out gun and check for sintering Check gun settings Blow out powder hoses Check grounding Check compressed air quality Check gun voltage Check powder hoses for bends and sintering 8.3 ... -

Page 36: Fitting The Flat Jet Nozzle

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance 4. Remove powder residues from the removed parts and spray gun. Note: Never place spray gun, or parts of it, in cleaning agent. As a rule, the protective wedge needs to be checked for wear and replaced if necessary. -

Page 37: Changing The Round Jet Nozzle

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance 8.5 CHANGING THE ROUND JET NOZZLE 8.5.1 Removing the Round Jet Nozzle P_01677 1. Pull off deflector cone. 2. Unscrew the union nut from gun housing. 3. Remove the union nut with the nozzle system from the gun body. -

Page 38: Fitting The Round Jet Nozzle

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance 8.5.2 Fitting the Round Jet Nozzle P_01678 1. Before inserting the electrode holder, the spring contact of the gun body and contact surface of the electrode holder should be checked. -

Page 39: Installing The Protective Wedge

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance P_01675 Wedge tool Electrode holder (shown with a cut-away view to improve comprehension) Protective wedge (when positioned) 1. Guide wedge tool 1 into electrode holder 2 up to stop. -

Page 40: Changing Nozzle Types

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance P_01676 1. Guide protective wedge into wedge tool. 2. Move both parts up to stop in the opening of the electrode holder. If it is not possible to push the wedge tool in as far as the X mark, rotate the wedge tool a little until it can be pushed up to the mark. - Page 41 Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance CAUTION Electrode tip! Risk of injury and damage to the device. 4 Take care when fitting the electrode holder. Note: If changing from the flat jet nozzle to the deflector cone, or the other way around, the depth control must be adjusted.

-

Page 42: Mounting The Double Adapter

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance P_01690 5. Before inserting the electrode holder, the spring contact of the gun body and contact surface of the electrode holder should be checked. The spring contact must be clean and move easily, the gun body must also be clean and free of powder deposits. -

Page 43: Installation Of The Double Adapter

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance P_01673 1. Unscrew the union nut from gun housing. 2. Remove the union nut with the nozzle system from the gun body. The nozzle system remains inserted in the union nut. -

Page 44: Cleaning The Double Adapter

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance 1. Install electrode holder 3 together with nozzle 2 in nozzle insert 4 and tighten union nut 1. 2. Place the double adapter 5 on the gun body and tighten it. -

Page 45: Assembly Of The Coronastar

Operating manual Robot powder spray gun PER-X1 8 Cleaning and Maintenance 2. Pull out electrode holder 3 and nozzle 2. 3. Gently turn cylindrical union nut 5 (bayonet fitting) and pull it off. 4. Unscrew contact ring 6. 5. Pull off O-ring 4. -

Page 46: Troubleshooting And Rectification

4 WAGNER devices, protective systems and safety, monitoring and control equipment may only be serviced/repaired as defined in Directive 2014/34/EC (ATEX) by trained WAGNER service personnel or skilled persons in accordance with TRBS 1203! Note national regulations! 4 Service, repair or replacement of devices or parts of devices may only be performed... -

Page 47: Inspections In Accordance With Din En 50177: 2009

Operating manual Robot powder spray gun PER-X1 10 Inspections in Accordance with DIN EN 50177: 2009 10 INSPECTIONS IN ACCORDANCE WITH DIN EN 50177: 2009 If the system is used for electrostatic coating with ignitable coating powders, the test must be performed in accordance with EN 50177:2009+A1:2012 according to the following... -

Page 48: Overview Table

10.2 OVERVIEW TABLE Section Type of inspection Requirements Inspection Type of inspection Inspection in- terval Checking the effectiveness Checking the effectiveness of technical ventila- TP/SP Continuously of technical ventilation tion Measurements of air flow speed/ air quantities Check the differential pressure in- dicator. - Page 49 Section Type of inspection Requirements Inspection Type of inspection Inspection in- terval Ground leaking resistance The ground leaking resistance of the attachment ME/CM Weekly from the work piece attach- point of every work piece may be 1 megohm at Measure the ground leaking resis- ment point most (measuring voltage must be 500 V or tance (ground potential of the...

-

Page 50: Disassembly And Disposal

4 WAGNER or one of our dealers will take back your used WAGNER electric or electronic equipment and will dispose of it for you in an environmentally-friendly way. -

Page 51: Accessories

Operating manual Robot powder spray gun PER-X1 12 Accessories 12 ACCESSORIES 12.1 ROBOT FLANGE VARIANTS Order no. Designation 2434468 Robot mounting bracket, PER-X1 SO P_04910 2434364 Robot mounting bracket, PER-X1 SI P_04911 2434678 Robot mounting bracket, PER-X1 TO P_04112 2434467... -

Page 52: Flat Jet Nozzles System X1

Operating manual Robot powder spray gun PER-X1 12 Accessories 12.2.1 Flat Jet Nozzles System X1 Order no. Designation 2429073 ♦ X1 electrode holder, cpl. ET (white) P_01691 Can be combined with: 2420243 X1 flat jet nozzle, F1 ♦ P_04985 2428515 X1 cross nozzle, 90°... -

Page 53: X1 R Round Jet Nozzles System

Operating manual Robot powder spray gun PER-X1 12 Accessories 12.2.3 X1 R Round Jet Nozzles System Order no. Designation 2322490 ♦ X1 electrode holder, X1 R ET (yellow) P_01692 2322493 ♦ Electrode holder, X1 R (yellow) + nozzles P_01692 Can be combined with: 2321981 ♦... -

Page 54: Double Adapter

Operating manual Robot powder spray gun PER-X1 12 Accessories 12.2.4.1 Flat Jet Nozzles System Order no. Designation 2323401 ♦ Nozzle insert, X1 VL F (yellow) P_04993 Can be combined with: 2324147 ♦ Flat jet nozzle, X1 VL ET P_04995 ♦ = Wearing parts 12.2.4.2 ... - Page 55 Operating manual Robot powder spray gun PER-X1 12 Accessories Order no. Designation 2429073 ♦ X1 electrode holder, cpl. ET (white) P_01691 2420243 X1 flat jet nozzle, F1 ♦ P_04985 2428515 X1 cross nozzle, 90° ♦ P_04987 2428283 X1 angular nozzle, 30°...

-

Page 56: Corrugated Tubes

Operating manual Robot powder spray gun PER-X1 12 Accessories IMPORTANT: For both variants, always use powder tube D10-12 (order no. 2431552). Also for the HC1 variants. 12.4 CORRUGATED TUBES Order no. Designation 2423435 Corrugated tube 2419989 Corrugated tube, divisible 12.5 RETROFIT SET CORONASTAR P_01695 Order no. -

Page 57: Powder Hose

Operating manual Robot powder spray gun PER-X1 12 Accessories 12.8 POWDER HOSE Order no. Designation 2310699 ♦ Powder hose, Ø 10 mm 2307502 ♦ Powder hose, Ø 11 mm Wearing parts = ♦ 12.9 ATOMIZING AIR HOSE Order no. Designation 9982079 Atomizing air hose, black, Ø... -

Page 58: Spare Parts

DANGER Incorrect maintenance/repair! Danger to life and equipment damage. 4 Only a WAGNER service center or a specially trained person may carry out repairs and replace parts. 4 Use only WAGNER original spare parts and accessories. 4 Only repair and replace parts that are listed in the spare parts chapter and that are assigned to the device. -

Page 59: Per-X1 Corona Robot Spray Gun With A Flat Jet Nozzle

Operating manual Robot powder spray gun PER-X1 13 Spare Parts 13.3 PER-X1 CORONA ROBOT SPRAY GUN WITH A FLAT JET NOZZLE P_04908 Order no. Designation 2423084 Corona robot spray gun, PER-X1 ♦ SeeAcces- Connection cable, PER-X1 sories [8 51] 2434666 Handle, complete... -

Page 60: Per-X1 Corona Robot Spray Gun With A Round Jet Nozzle

Operating manual Robot powder spray gun PER-X1 13 Spare Parts 13.4 PER-X1 CORONA ROBOT SPRAY GUN WITH A ROUND JET NOZZLE P_04909 Order no. Designation 2423084 * Corona robot spray gun, PER-X1 ♦ SeeAcces- Connection cable, PER-X1 sories [8 51] 2434666... -

Page 61: X1 R Electrode Holder

Operating manual Robot powder spray gun PER-X1 13 Spare Parts 13.5 X1 R ELECTRODE HOLDER P_01700 Order no. Designation 2322493 Electrode holder, X1 R, with nozzle ♦ ♦ 2322490 Electrode holder, X1 R ET ♦ 2429695 X1 replacement protective wedge ♦... -

Page 62: X1 Double Adapter

Operating manual Robot powder spray gun PER-X1 13 Spare Parts 13.6 X1 DOUBLE ADAPTER 1a / 1b 3a / 3b P_05467 Order no. Designation 1a ♦ 2436638 X1 double adapter 1b ♦ 2436625 X1 double adapter, HC1 2428235 Union nut, 55 mm ⋆... -

Page 63: Declaration Of Conformity

Declaration of Conformity The declaration of conformity is enclosed with this product. If needed, further copies can be ordered through your WAGNER dealer by specifying the product name and serial number. Order number: 2427643 Order number 2444998 | Edition 10/2022... - Page 64 Operating manual Robot powder spray gun PER-X1 14 Declaration of Conformity Order number 2444998 | Edition 10/2022...

- Page 65 Operating manual Robot powder spray gun PER-X1 14 Declaration of Conformity Order number 2444998 | Edition 10/2022...

- Page 66 Operating manual Robot powder spray gun PER-X1 14 Declaration of Conformity Order number 2444998 | Edition 10/2022...

- Page 68 Order number 2444998 Edition 10/2022 Germany J. Wagner GmbH Otto-Lilienthal-Strasse 18 Postfach 1120 D-88677 Markdorf Telephone: +49 (0)7544 5050 Fax: +49 (0)7544 505200 E-mail: ts-powder@wagner-group.com Switzerland Wagner International AG Industriestrasse 22 CH-9450 Altstätten Telephone: +41 (0)71 757 2211 Fax: +41 (0)71 757 2222 More contact addresses on the internet at: www.wagner-group.com Subject to changes without notice...

Need help?

Do you have a question about the PER-X1 and is the answer not in the manual?

Questions and answers