Table of Contents

Advertisement

Quick Links

3002526/03

INSTALLER GUIDE

C1

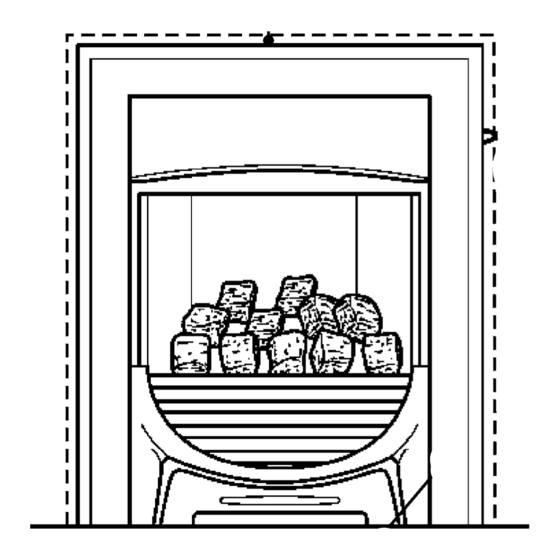

INSET LIVE FUEL EFFECT GAS FIRE

(GC No. 32-032-46)

INCORPORATING THE

CONTROL

(Manufacturer ref. 640)

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20)

WHEN CONVERTED USING CONVERSION KIT NO. 0591301 THIS

APPLIANCE IS FOR USE WITH PROPANE GAS (G31)

THIS APPLIANCE IS FOR USE IN THE UNITED KINGDOM (GB) AND THE

REPUBLIC OF IRELAND (IE) ONLY.

INSTALLER: Please leave this guide with the owner

Manufactured exclusively for British Gas & Scottish Gas by Valor Heating

For Service Phone 0845 960 5040

Because our policy is one of constant development and improvement, details may vary

slightly from those given in this publication.

© Valor Heating

Advertisement

Table of Contents

Summary of Contents for Valor C1 superflame

- Page 1 REPUBLIC OF IRELAND (IE) ONLY. INSTALLER: Please leave this guide with the owner Manufactured exclusively for British Gas & Scottish Gas by Valor Heating For Service Phone 0845 960 5040 Because our policy is one of constant development and improvement, details may vary slightly from those given in this publication.

-

Page 2: Table Of Contents

INSTALLER’S GUIDE CONTENTS SAFETY ...............................3 APPLIANCE DATA ........................4 GENERAL INSTALLATION REQUIREMENTS................5 PACK CONTENTS ........................12 FIREPLACE CHECK .........................14 IGNITION CHECK ........................16 GAS SUPPLY CONNECTION ....................17 PREPARING APPLIANCE FOR INSTALLATION ..............18 CONVECTION BOX INSTALLATION ..................20 BURNER & SUPPLY PIPE INSTALLATION................24 9.1 Burner & Supply Pipe Installation ................ 24 9.2 Preliminary Burner Checks ................... -

Page 3: Safety

INSTALLER’S GUIDE S A F E T Y Installer • Before continuing any further with the installation of this appliance please read the following guide to manual handling • The lifting weight of this appliance is 15.5 kg. One person should be sufficient to lift the fire. -

Page 4: Appliance Data

INSTALLER’S GUIDE 1 A P P L I A N C E D A T A This product uses fuel effect pieces, burner compartment walls and gaskets containing Refractory Ceramic Fibres (RCF), which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause irritation to eyes, skin and respiratory tract. -

Page 5: General Installation Requirements

INSTALLER’S GUIDE 2 G E N E R A L I N S T A L L A T I O N R E Q U I R E M E N T S The installation must be in accordance with these instructions. For the user’s protection, in the United Kingdom it is the law that all gas appliances are installed by competent persons in accordance with the current edition of the Gas Safety (Installation and Use) Regulations. - Page 6 INSTALLER’S GUIDE the Environment for Northern Ireland. In the republic of Ireland the installation must also conform to the relevant parts of: The current edition of IS 813 All relevant national and local rules in force. 2.2 In the United Kingdom, as supplied, the appliance can be installed in the following situations: -...

- Page 7 INSTALLER’S GUIDE appliance is suitable for installations under all circumstances unless there is a history of cracking problems. Remember that faults such as cracking may be caused by poorly built and restrictive flues, e.g. mortar extrusions, too many bends, flue heights below three metres, restrictive terminations etc.

- Page 8 INSTALLER’S GUIDE BS EN 1806. This system is only suitable if the conditions stated in section 2.2.2 are met. The flue must conform to BS 5440: Part 1 in design and installation. The flue, measured from the bottom of the fireplace opening to the bottom of the terminal, shall be not less than 3m in actual vertical height.

- Page 9 INSTALLER’S GUIDE Graph 1. Combustible shelf clearances 2.12 The minimum height from the top surface of the hearth to the underside of any shelf made from wood or other combustible materials is shown in graph 1. 2.13 Note that soft wall coverings (e.g. embossed vinyl, etc.) are easily affected by heat. They may scorch or become discoloured when close to a heating appliance.

- Page 10 INSTALLER’S GUIDE 2.17 Propane gas appliances must not be installed in a room that is built entirely below ground level (See BS 5871 Part 2). 2.18 If the appliance is to be fitted against a wall with combustible cladding, the cladding must be removed from the area covered by the outer surround.

- Page 11 INSTALLER’S GUIDE 2.19 The minimum allowable distance from the outside of the appliance case to a corner wall having combustible material or any other combustible surface which projects beyond the front of the appliance is shown in figure 5. A 10mm access clearance from a non-combustible surface is necessary at the left side. See figure 5.

-

Page 12: Pack Contents

INSTALLER’S GUIDE 3 P A C K C O N T E N T S Pack contains: Burner & Convection box Unit Nut & olive for 8mm inlet pipe Flue restrictor plate Screws (For flue restrictor) Screws (For Fireback spacing brackets) Screws (For Rear Ceramic wall support bracket) Screw (For Surround securing brackets) Ceramic back wall... - Page 13 INSTALLER’S GUIDE Figure 6. Pack contents Page 13...

-

Page 14: Fireplace Check

INSTALLER’S GUIDE 4 F I R E P L A C E C H E C K 4.1.1 Fireplace size The fireplace must comply with the requirements described in section 2.2. This will probably entail removing the fireback and infill material behind the fireback. - Page 15 INSTALLER’S GUIDE otherwise impractical. N.B. It is unwise to attempt to drill into marble without the proper tools and equipment. If method 1 is chosen, make sure that the front surround area is sound enough to take the rawlplugs and woodscrews. If necessary, make sound with a suitable cement. If method 2 is chosen, make sure that the areas at the back and towards the centre of the fireplace floor are sound enough to take the eyebolts and screws.

-

Page 16: Ignition Check

INSTALLER’S GUIDE 5 I G N I T I O N C H E C K Before attempting to install, it is worth checking that the electronic ignition system performs satisfactorily. Fit the battery to the ignition block ● located below the burner tray at the left side (see figure 8). -

Page 17: Gas Supply Connection

INSTALLER’S GUIDE 6 G A S S U P P L Y C O N N E C T I O N A nut and olive are provided for an 8mm pipe inlet connection to the elbow at the bottom front of the appliance. -

Page 18: Preparing Appliance For Installation

INSTALLER’S GUIDE 7 P R E P A R I N G A P P L I A N C E F O R I N S T A L L A T I O N IMPORTANT Before continuing with the installation of this gas fire the aeration setting on the burner must be checked. - Page 19 INSTALLER’S GUIDE figure 13. Secure the fireback spacers using the screws removed previously and the two supplied with the fire. This appliance is supplied with a flue restrictor for use where the flue draught is excessive. The restrictor must NOT be fitted where a precast flue or a flue liner is used.

-

Page 20: Convection Box Installation

INSTALLER’S GUIDE Fit the two surround securing brackets to the convection box side flanges with the screws supplied. Note the different orientation of the brackets at left and right sides (See figure 16) Left Right Figure 16. Surround securing brackets. 8 C O N V E C T I O N B O X I N S T A L L A T I O N 8.1 Method 1 - Front Fixing to Fireplace Surround 1. - Page 21 INSTALLER’S GUIDE Method 2 - Cable Retention and Floor Fixing. Make sure that the relevant areas at the fireplace back or floor are sound enough to take the eyebolts and screws. If these areas have deteriorated due to prolonged use they should be made sound with a suitable cement.

- Page 22 INSTALLER’S GUIDE Thread the cables through the eyebolts. Return the cables through the holes near the bottom of the convection box back panel, (For precast or clay block flue systems return the cables through the slotted holes in the side of the convection box), and through the “V”...

- Page 23 INSTALLER’S GUIDE Inspect the installation of the convection box against the fireplace surround. If the convection box is aligned squarely and the sealing is satisfactory, fully tighten the cable retainers. If the convection box is not correctly aligned, release the tension on the cables by slackening the screws and turning the hexagonal adjusters fully anticlockwise.

-

Page 24: Burner & Supply Pipe Installation

INSTALLER’S GUIDE 9 B U R N E R & S U P P L Y P I P E I N S T A L L A T I O N Burner & Supply Pipe Installation Refit the burner unit to the convection box with two screws. Connect the supply line to the appliance. -

Page 25: Reference Pressure Check

INSTALLER’S GUIDE Reference Pressure Check The appliance is pre-set to give the correct heat input at the inlet pressure shown in section 1 of this manual. No adjustment is necessary. Check the burner pressure by fitting a pressure gauge at the test point. The test point is on the pipe situated below the bottom right corner of the burner unit. -

Page 26: Ceramic Walls Installation

INSTALLER’S GUIDE 1 0 C E R A M I C W A L L S I N S T A L L A T I O N Fit the rear ceramic wall support bracket to the rear of the convection box using two screws. -

Page 27: Front Surround & Control Linkage Installation

INSTALLER’S GUIDE 1 1 F R O N T S U R R O U N D & C O N T R O L L I N K A G E I N S T A L L A T I O N 11.1 Slide the control button upwards as far as it will go. -

Page 28: Ceramic Coals Installation

INSTALLER’S GUIDE 1 2 C E R A M I C C O A L S I N S T A L L A T I O N Place the ceramic base coal in the burner compartment. The bottom rear face of the coal should rest on the angled ledges at the back of the burner compartment. - Page 29 INSTALLER’S GUIDE Install the 12 loose coals as follows. The underside of each coal is marked with a letter ‘A’ to ‘L’ and an arrow. The coals should be positioned so that the arrows always point towards the back of the firebox.

- Page 30 INSTALLER’S GUIDE Hold coal ‘D’ upright with the arrow pointing to the top. Locate coal ‘D’ as shown in figure 36. Hold coal ‘E’ upright with the arrow pointing to the top. Locate coal ‘E’ as shown in figure 37. Hold coal ‘F’...

- Page 31 INSTALLER’S GUIDE Locate coals ‘G’ to ‘K’ so that they are firmly seated in the valleys in the coal base. Hold coal ‘G’ upright with the arrow pointing to the top. Locate coal ‘G’ as shown in figure 39. Figure 39. Third row “Coal G” Hold coal ‘H’...

- Page 32 INSTALLER’S GUIDE Hold coal ‘J’ upright with the arrow pointing to the top. Locate coal ‘J’ as shown in figure 42 Hold coal ‘K’ upright with the arrow pointing to the top. Locate coal ‘K’ as shown in figure 43 Hold coal ‘L’...

-

Page 33: Front Castings Installation

INSTALLER’S GUIDE 1 3 F R O N T C A S T I N G S I N S T A L L A T I O N 13.1 Check that the two screws in the back of the fire front casting are in the outer threaded holes. -

Page 34: Full Operating Checks

INSTALLER’S GUIDE 1 4 F U L L O P E R A T I N G C H E C K S 14.1 Check the Control Settings The control position markings on the front surround are shown in figure 48. Please note: •... -

Page 35: Check For Spillage

INSTALLER’S GUIDE 14.2 Check For Spillage A spillage check must be made before leaving the installed appliance with the customer. Make this with all the ceramic coals in position. Close all doors and windows in the room containing the appliance. Light the appliance and set the slide control to the maximum burning position. - Page 36 INSTALLER’S GUIDE 1. Light the appliance. Set the slide control to the maximum burning position and leave for one minute. 2. Set the control to the Low burning position. Isolate the gas supply at the inlet elbow. The pilot and main burner will go out. Note the time when the pilot goes out. Listen for a snap sound at the gas tap.

-

Page 37: Final Review

INSTALLER’S GUIDE 1 5 F I N A L R E V I E W If a gap is visible between the inner sides of the front surround and the ceramic side walls, gently slide the walls forward. Visually inspect the appliance. Clean off any marks incurred during installation. Advise the customer how to operate the appliance. -

Page 38: Servicing & Parts Replacement

INSTALLER’S GUIDE 1 6 S E R V I C I N G & P A R T S R E P L A C E M E N T Always turn off the gas supply before commencing any servicing (The appliance inlet “T”... -

Page 39: To Remove The Ignition Microswitch

INSTALLER’S GUIDE • Check that the appliance is clean and that soot or debris is not blocking the gaps between the coals causing an imperfect flame. • Check that soot or debris is not impairing the electrode spark or pilot burner. •... -

Page 40: To Remove The Fire Front Surround

INSTALLER’S GUIDE Detach the microswitch cover by removing one screw and pulling clear of the location lug. See figure Loosen the thermocouple nut to free the microswitch leads and pull the leads clear of the thermocouple interrupter block. See figure 53. Detach the bridging bracket, microswitch assembly and insulation pad by removing two screws. -

Page 41: To Replace The Control Slide Unit

INSTALLER’S GUIDE 16.5 To Replace the Control Slide Unit Remove the front surround - See section 16.3. Detach the slide unit by removing two screws securing the plastic slide mechanism to the rear of the front surround – See figure 57. Replace in the reverse order. -

Page 42: To Remove The Thermocouple Interrupter Block

INSTALLER’S GUIDE burner unit. This will avoid damage to the brackets and the work surface (see figure 59) Remove the spark lead Unscrew the pipe clamp and two support bracket screws. The generator and its support bracket can now be moved forward. -

Page 43: To Remove The Pilot Unit

INSTALLER’S GUIDE Refit in the reverse order. If the microswitch leads cannot be easily attached to the interrupter block when it is fully tightened to the gas shut-off tap, slacken it and rotate to allow the leads to be fitted. Retighten making sure that the leads remain in place in the interrupter block. -

Page 44: To Remove The Shut-Off Tap

INSTALLER’S GUIDE 16.11 To Remove the Shut-Off Tap See figure 63. Remove the burner unit - See section 16.6. Unscrew and remove the two ceramic support brackets from the top of the burner unit. This will avoid damage to the brackets and the worksurface (see figure 63) Turn the burner unit upside down. -

Page 45: To Remove The Gas Flow Rate Controller

INSTALLER’S GUIDE 16.12 To Remove the Gas Flow Rate Controller See figure 64. Remove the burner unit - See section 16.6. If lying the burner on its back, unscrew and remove the two ceramic support brackets from the top of the burner unit. -

Page 46: To Replace Burner Plaques

INSTALLER’S GUIDE If lying the burner on its back, unscrew and remove the two ceramic support brackets from the top of the burner unit. This will avoid damage to the brackets and the worksurface (see figure 59) Disconnect the main burner pipe from the injector at the venturi end. If necessary, loosen the pipe at the flow rate controller end to swing the pipe clear of the injector. -

Page 47: To Remove The Appliance From The Fireplace

INSTALLER’S GUIDE Place the new right hand plaque in position. Make sure that the centre section of the combination gasket is between the two plaques. If there is any play between the plaques and the end retaining flanges, push the plaques firmly to the left squeezing the centre section of the combination gasket between the two plaques. -

Page 48: Short List Of Spares

INSTALLER’S GUIDE 1 7 S H O R T L I S T O F S P A R E S Page 48... - Page 49 INSTALLER’S GUIDE DESCRIPTION MAKER’S PART NO. Shut-off tap 730K146 Gas flow rate controller 730K147 Thermocouple interrupter block 720A142 Ignition microswitch 720A269 Gas shut-off microswitch 020K931 Pilot unit - For Natural Gas Appliances 720A249 Pilot unit - For Propane Gas Appliances 720A300 Injector Bray cat 18U size 420 - For 720A072...

Need help?

Do you have a question about the C1 superflame and is the answer not in the manual?

Questions and answers