Keysight X Series Security Features And Document Of Volatility

Signal analyzer

Hide thumbs

Also See for X Series:

- User & programmers manual (3096 pages) ,

- User reference (2852 pages) ,

- Programmer's reference manual (2650 pages)

Table of Contents

Summary of Contents for Keysight X Series

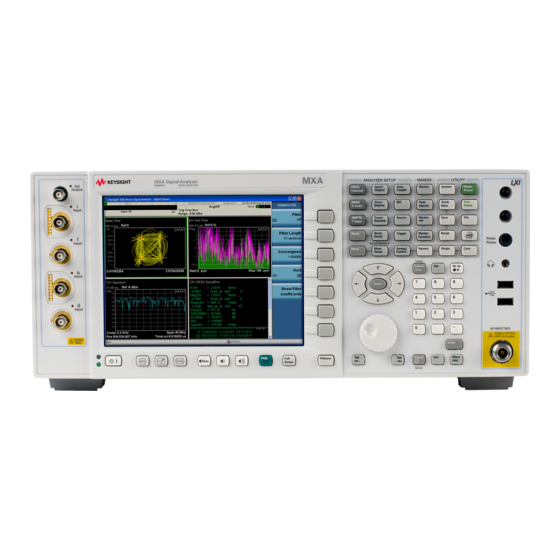

- Page 1 Keysight X-Series Signal Analyzers This manual provides documentation for the following analyzers: PXA Signal Analyzer N9030A MXA Signal Analyzer N9020A EXA Signal Analyzer N9010A CXA Signal Analyzer N9000A Security Features and Document of Volatility...

- Page 2 1400 Fountaingrove Parkway pursuant to the FAR and the DFARS Santa Rosa, CA 95403 and are set forth specifically in writing elsewhere in the EULA. Keysight shall Technology Licenses be under no obligation to update, A CAUTION notice denotes a hazard. It...

- Page 3 Support by Product box, enter the Product Number of your instrument (for example, N9030A) Model Number and click Find. To receive the latest updates by email, subscribe to Keysight Email Updates: http://www.keysight.com/find/emailupdates Information on preventing instrument damage can be found at: http://www.keysight.com/find/PreventingInstrumentRepair...

-

Page 4: Table Of Contents

Security Features and Document of Volatility Contents Table of Contents 1 Contacting Keysight Sales and Service Offices 2 Products Covered by this Document X-Series Processor and Disk Drive Configurations Processor Assembly Configuration Disk Drive Configuration Determining Instrument Configuration based on Product Name... - Page 5 Contents Software Revision A.01.55 or Lower Data Backup using XML File Data Restore using XML File Software Revision Greater than A.01.55 and Lower than A.02.00 Data Backup using Utility Program Data Restore using Utility Program Software Revision A.02.00 or Greater Data Backup or Restore using Alignment Data Wizard 6 Processor Assembly Removal Procedure 7 Disk Drive Removal Procedure...

-

Page 6: Contacting Keysight Sales And Service Offices

Keysight representative. N O T E In any correspondence or telephone conversation, refer to the instrument by its model number and full serial number. With this information, the Keysight representative can determine whether your unit is still within its warranty period. -

Page 7: Products Covered By This Document

Be sure that all information stored by the user in the instrument that needs to be saved is properly backed up before attempting to clear any of the instrument memory. Keysight Technologies cannot be held responsible for any lost files or data resulting from the clearing of memory. -

Page 8: X-Series Processor And Disk Drive Configurations

X-Series Processor and Disk Drive Configurations This document describes alternative Processor and Disk Drive Configurations for X-Series analyzers. Due to continuous improvement of the X Series Analyzer range, configurations may vary according to such factors as: manufacturing date, product name, and installed options. Processor and disk drive configurations are considered separately, due to the large number of possible combinations. -

Page 9: Disk Drive Configuration

Disk, by ordering Option PC6 or PC7 as appropriate. (Older CXA instruments may require Option PC5 instead of PC7. Before ordering, check with your Keysight Sales office, as described in “Contacting Keysight Sales and Service Offices” on page Note that... -

Page 10: Determining Instrument Configuration Based On Product Name

Products Covered by this Document Determining Instrument Configuration based on Product Name Determining Instrument Configuration based on Product Name Use the following procedures to determine the processor assembly and disk drive configurations of your instrument, starting from its Product Name. Processor Assembly Configuration The following procedure allows you to determine whether your instrument has Fixed Disk... - Page 11 Products Covered by this Document Determining Instrument Configuration based on Product Name Step Procedure Check the instrument’s installed options (see “Determining Installed Options” on page 13). — If the list includes N90X0A-IDE, your instrument has a 160 GB Removable Magnetic disk drive.

-

Page 12: Rear Panel Configurations

Products Covered by this Document Determining Instrument Configuration based on Product Name Rear Panel Configurations Figure 2-1 Rear Panel of Instrument with Fixed Magnetic Disk Security Features & Document of Volatility... -

Page 13: Determining Installed Options

Products Covered by this Document Determining Instrument Configuration based on Product Name Figure 2-2 Rear Panel of Instrument with Removable Magnetic Removable Solid-State Disk Determining Installed Options Use the following procedure to determine whether your instrument has a magnetic or solid-state disk drive, and whether any of Options PC2 through PC7 are installed. - Page 14 Products Covered by this Document Determining Instrument Configuration based on Product Name Figure 2-3 Show System Display: Option Listing 3. The entries under the heading have the significance described in Table 2-3. Option 4. To dismiss the display, press any other front-panel or menu key. Show System Table 2-3 Interpretation of Option Items...

- Page 15 Products Covered by this Document Determining Instrument Configuration based on Product Name a. "X" is a digit between 0 and 3, according to the Model Number Security Features & Document of Volatility...

-

Page 16: Security Terms And Definitions

“Media Sanitization Matrix” in Appendix T of the Defense Security Service (DSS) Assessment and Authorization Process Manual (DAAPM). Secure Erase Secure Erase is a term that is used to refer to either the clearing or sanitization features of Keysight instruments. -

Page 17: Instrument Memory & Volatility

Security Features and Document of Volatility Instrument Memory & Volatility Instrument Memory & Volatility This chapter summarizes all memory types in the instrument, for the following processor assembly and disk drive configurations: Fixed Disk processor assemblies, Removable Disk processor assemblies. For definition of terms, and to determine the configuration of your instrument, based on its Product Name and installed options, see “X-Series Processor and... -

Page 18: Non-Volatile Memory

Instrument Memory & Volatility Non-Volatile Memory Non-Volatile Memory This section contains information on the memory components available in your instrument. — “Components for All Instruments” on page 19 — “Additional Components for PXA and some MXA Instruments” on page 24 —... -

Page 19: Components For All Instruments

Instrument Memory & Volatility Non-Volatile Memory Components for All Instruments Table 4-1 Summary of Non-Volatile instrument memory - All Instruments (Single-Core and Dual-Core Processors) Memory Purpose/Contents Data Input Method Location in Sanitization Component, Instrument and Procedure Type and Size Remarks 1. - Page 20 Instrument Memory & Volatility Non-Volatile Memory Table 4-1 Summary of Non-Volatile instrument memory - All Instruments (Single-Core and Dual-Core Processors) Memory Purpose/Contents Data Input Method Location in Sanitization Component, Instrument and Procedure Type and Size Remarks 4. Config & Cal Header EEPROM used to Programmed A14 Synthesizer...

- Page 21 Instrument Memory & Volatility Non-Volatile Memory Table 4-1 Summary of Non-Volatile instrument memory - All Instruments (Single-Core and Dual-Core Processors) Memory Purpose/Contents Data Input Method Location in Sanitization Component, Instrument and Procedure Type and Size Remarks 10. Config & Cal Header EEPROM used to Programmed A3 Digital IF...

- Page 22 Instrument Memory & Volatility Non-Volatile Memory Table 4-1 Summary of Non-Volatile instrument memory - All Instruments (Single-Core and Dual-Core Processors) Memory Purpose/Contents Data Input Method Location in Sanitization Component, Instrument and Procedure Type and Size Remarks 16. Digital Contains default data to Programmed A16 Reference None.

- Page 23 Instrument Memory & Volatility Non-Volatile Memory Table 4-1 Summary of Non-Volatile instrument memory - All Instruments (Single-Core and Dual-Core Processors) Memory Purpose/Contents Data Input Method Location in Sanitization Component, Instrument and Procedure Type and Size Remarks 21. A12 Config Header EEPROM used to Programmed A12 YTF None.

-

Page 24: Additional Components For Pxa And Some Mxa Instruments

Instrument Memory & Volatility Non-Volatile Memory Additional Components for PXA and some MXA Instruments Table 4-2 below, refer to the footnotes to determine to which model number a particular component applies. Table 4-2 Summary of Non-Volatile instrument memory - Additional Components for all PXA Instruments and some MXA Instruments Memory Purpose/Contents... - Page 25 Instrument Memory & Volatility Non-Volatile Memory Table 4-2 Summary of Non-Volatile instrument memory - Additional Components for all PXA Instruments and some MXA Instruments Memory Purpose/Contents Data Input Method Location in Sanitization Component, Instrument and Procedure Type and Size Remarks 6.

-

Page 26: Additional Components For Instruments With Pc4, Pc5, Pc6(S)/Pc7(S) Processor Assemblies

Present only in instruments with PC4, PC5, PC6(S), and PC7(S) Processors. b. Accessible only via a Keysight-provided utility, which permits only storage and retrieval of calibration data. c. Present only in instruments with PC6S or PC7S Processors. -

Page 27: Disk Drive Partitioning

Instrument Memory & Volatility Non-Volatile Memory Disk Drive Partitioning The instrument’s disk drive is divided at the factory into three visible partitions, labeled C:, D: and E:, plus a fourth hidden partition. The sizes of each partition vary according to the instrument’s Disk Drive Configuration. -

Page 28: Volatile Memory

Instrument Memory & Volatility Volatile Memory Volatile Memory The volatile memory in the instrument does not have battery backup. It does not retain any information when AC power is removed. Removing power from this memory meets the memory sanitization requirements specified in the “Media Sanitization Matrix” in Appendix T of the Defense Security Service (DSS) Assessment and Authorization Process Manual (DAAPM). - Page 29 Instrument Memory & Volatility Volatile Memory Table 4-5 Summary of Volatile Instrument Memory - Instruments with Single-Core and Dual-Core Processors Memory Type Purpose/Contents Data Input Method Location in Sanitization and Size Instrument and Procedure Remarks 4. SDRAM Contains measurement Programmed by A26 Wideband Turn off data from data...

-

Page 30: Memory Sanitization And Removal Procedures

Security Features and Document of Volatility Memory Sanitization and Removal Procedures Memory Sanitization and Removal Procedures This section explains how to clear, sanitize, and remove memory from your instrument, for all types of non-volatile memory that can be written to during normal instrument operation. - Page 31 Memory Sanitization and Removal Procedures Table 5-2 CPLD, CMOS Programmable Logic Devices Description and These memory devices are used to execute timing, control, and measurement functions. No purpose user data is contained in these devices. This memory cannot be written to during instrument operation.

- Page 32 Memory Sanitization and Removal Procedures Table 5-4 SD Memory Card Description and The intended purpose of the SD Memory Card is for backing up the instrument calibration database purpose file. The backup and restore process used by the instrument will default to this location. Users can also write to this memory, since it appears as another disk drive to the instrument.

-

Page 33: Instrument Sanitization Procedures

Memory Sanitization and Removal Procedures Instrument Sanitization Procedures Instrument Sanitization Procedures This section includes flowcharts that describe how to sanitize an instrument by physical removal and replacement of either the Processor Assembly or Disk Drive. — For Fixed Disk instruments, see “Replacement of Processor Assembly”... -

Page 34: Replacement Of Disk Drive (Instruments Without Pc6S/Pc7S)

Memory Sanitization and Removal Procedures Instrument Sanitization Procedures Step Task Physically deploy instrument into controlled area. Use instrument inside controlled area until cal or repair is needed. Remove main Processor Assembly #1 and retain in controlled area. For details of how to remove the Processor Assembly, see “Processor Assembly Removal Procedure”... -

Page 35: Items Required

Memory Sanitization and Removal Procedures Instrument Sanitization Procedures If the non–classified drive receives a software upgrade, or if the non-classified drive is replaced with a drive that contains a newer revision of software than that of the classified drive, the classified drive will require a software upgrade (inside the controlled area) to match the non-classified drive. - Page 36 Memory Sanitization and Removal Procedures Instrument Sanitization Procedures Step Task Back up (archive) the instrument factory calibration data to the USB memory device. For details of the procedure, see “Archiving and Restoring Factory Calibration Data Files” on page Remove the Disk Drive and SD Memory Card (if present) from the instrument. See “SD Memory Card Removal Procedure”...

-

Page 37: Replacement Of Disk Drive (Instruments With Pc6S/Pc7S)

Memory Sanitization and Removal Procedures Instrument Sanitization Procedures Step Task Install secondary non-classified Disk Drive #2, which was previously prepared in Step 12. Power on instrument. When the instrument has booted up, press System, Show System, and confirm that the Instrument Software Revision is the same as noted in Step 16. If not, upgrade the instrument software to the same version as recorded in Step 16. -

Page 38: Items Required

Memory Sanitization and Removal Procedures Instrument Sanitization Procedures If the non–classified drive receives a software upgrade, or if the non-classified drive is replaced with a drive that contains a newer revision of software than that of the classified drive, the classified drive will require a software upgrade (inside the controlled area) to match the non-classified drive. - Page 39 Memory Sanitization and Removal Procedures Instrument Sanitization Procedures Step Task Remove the Disk Drive and SD Memory Card (if present) from the instrument. See “SD Memory Card Removal Procedure” on page Replace the original instrument disk drive (Disk Drive #1) with the spare disk drive (Disk Drive #2) that was obtained previously.

- Page 40 Memory Sanitization and Removal Procedures Instrument Sanitization Procedures Step Task Instrument is now operational with original calibration data. Deliver to service center for cal/repair. Service center may or may not generate new calibration files on Disk Drive, depending on whether an adjustment is performed. This procedure assumes that new cal data was generated.

- Page 41 Memory Sanitization and Removal Procedures Instrument Sanitization Procedures Step Task A further dialog appears, as shown in Figure 5-2 below, asking you to confirm that you want to overwrite the current calibration data (presently on the Disk Drive) with the backup data stored in the internal Flash memory.

-

Page 42: Archiving And Restoring Factory Calibration Data Files

Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files Archiving and Restoring Factory Calibration Data Files This section describes how to archive ("back up") the instrument’s factory calibration data to an external memory device, or restore the calibration data from an external USB Memory Device. -

Page 43: Determining Instrument Software Revision

Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files Determining Instrument Software Revision 1. On the instrument front panel, press System > Show > System. 2. The display appears, as shown in Figure 5-3 below. Look for the Show System Software Revision number specified in the entry. -

Page 44: Software Revision A.01.55 Or Lower

Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files When you have obtained the Instrument Software Revision number, refer to Table 5-5 on page 44 below for the appropriate backup or restore procedure. Table 5-5 Backup & Restore Procedures for all Instrument Software Revisions Instrument Software Backup Procedure Restore Procedure... -

Page 45: Software Revision Greater Than A.01.55 And Lower Than A.02.00

Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files CurrentDataSet.xml 5. Select the calibration data file, then copy it to the Windows clipboard by selecting Edit > Copy from the Windows Explorer pull-down menu. 6. Navigate to the folder below and paste the file by selecting Edit > Paste from the Windows Explorer pull-down menu: E:\AlignDataStorage 7. -

Page 46: Data Restore Using Utility Program

Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files 7. In the group box use the mouse to press Specify Backup Folder or File Name the “...” button to open the “Browse For Folder” dialog. 8. In the dialog, select or create the desired folder on the USB Browse For Folder memory device, then press OK. -

Page 47: Data Backup Or Restore Using Alignment Data Wizard

Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files Data Backup or Restore using Alignment Data Wizard The Alignment Data Wizard is launched directly from the instrument application software interface, so you do not need to exit the application software before proceeding. - Page 48 Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files Figure 5-6 Alignment Data Wizard Dialog If the instrument has a PC6S or PC7S Processor Assembly, then the Alignment dialog contains the selections shown in Figure 5-7 below. Data Wizard Security Features &...

- Page 49 Memory Sanitization and Removal Procedures Archiving and Restoring Factory Calibration Data Files Figure 5-7 Alignment Data Wizard Dialog for PC6S/PC7S In this case, the storage location options are as follows: — Internal Flash is the Calibration Backup memory in the A4 Processor assembly.

-

Page 50: Processor Assembly Removal Procedure

Security Features and Document of Volatility Processor Assembly Removal Procedure Processor Assembly Removal Procedure To remove the processor board assembly, follow the procedure below, while referring to Figure 6-1, which shows the rear panel of instruments with Fixed Disk processor assemblies. The procedure for instruments with Removable Disk processor assemblies is... - Page 51 Processor Assembly Removal Procedure 1. Locate and remove the Processor Assembly from the instrument, by removing the 6 rear panel screws (part number 0515-0372, M3 x 0.5, 8 mm long). 2. The assembly can be removed from the chassis by pulling it straight out. Use the two ejector arms to remove the Assembly from the instrument Security Features &...

-

Page 52: Disk Drive Removal Procedure

Security Features and Document of Volatility Disk Drive Removal Procedure Disk Drive Removal Procedure This chapter describes the procedures for physical removal of the disk drive from: Instruments with Non-Removable Drives (generally, older MXA, EXA and CXA instruments), Instruments with Removable Drives (generally, all PXA instruments, and newer MXA, EXA and CXA instruments). -

Page 53: Instruments With Non-Removable Drives

Disk Drive Removal Procedure Instruments with Non-Removable Drives Instruments with Non-Removable Drives To remove the disk drive, follow the procedure below, while referring to Figure 7-1. The numbered items in the figure correspond to the step numbers in the procedure. Before commencing this procedure, remove the complete Processor Assembly from the instrument, following the procedure described in the chapter Processor Assembly Removal... - Page 54 Disk Drive Removal Procedure Instruments with Non-Removable Drives 4. Disconnect the drive cable from the disk drive. Security Features & Document of Volatility...

-

Page 55: Instruments With Removable Drives

Disk Drive Removal Procedure Instruments with Removable Drives Instruments with Removable Drives To remove the disk drive, follow the procedure below. You do not need to remove the Processor Assembly from the instrument before removing the drive. The numbered items in the figures below correspond to the step numbers in the procedure. - Page 56 Disk Drive Removal Procedure Instruments with Removable Drives Figure 7-3 Removable Disk Drive Unit partially extracted (shows SD Memory Card for PC6/PC7 Assemblies only) 4. Pull the U-shaped handle attached to the drive unit, to remove the drive from the Processor Assembly, as shown in Figure 7-3.

-

Page 57: Sd Memory Card Removal Procedure

Security Features and Document of Volatility SD Memory Card Removal Procedure SD Memory Card Removal Procedure The SD Memory Card is present only in instruments with the PC6 and PC7 processor assemblies. See “Determining Installed Options” on page 13 details. When present, the SD Memory Card is located on the A4 Processor assembly. - Page 58 SD Memory Card Removal Procedure Figure 8-1 Instrument Rear Panel, showing Removable Disk Drive Assembly and SD Memory Card 3. Reinstall the disk drive assembly. Removing the SD Memory Card does not interfere with normal operation of the instrument operating system or the instrument application software. Security Features &...

-

Page 59: User And Remote Interface Security Measures

Security Features and Document of Volatility User and Remote Interface Security Measures User and Remote Interface Security Measures This chapter discusses options that are available to you to control and configure remote access to the instrument, including: — SCPI/GPIB Control of Interfaces —... -

Page 60: Determining The Instrument's Operating System

Running any third-party program while making measurements may adversely affect the instrument’s performance. Details of all these features are provided in the "Windows Security" chapter of Keysight X-Series Signal Analyzer: Getting Started Guide. Determining the Instrument’s Operating System You can easily determine your instrument’s operating system version as follows: 1. -

Page 61: Windows 7

User and Remote Interface Security Measures USB Interfaces Windows 7 If your instrument has the Windows 7 operating system, you can disable or enable AutoPlay via the Control Panel. Open the Control Panel and select Hardware and Sound > AutoPlay, then uncheck or check the "Use AutoPlay for all media and devices"... - Page 62 User and Remote Interface Security Measures USB Interfaces Figure 9-1 AutoRun Flag Definitions for NoDriveTypeAutoRun Registry entry As shown in Figure 9-1 above, the default Windows XP (post-SP2) and Windows 7 value for this entry is (under the entry 0x91 HKCU\...\NoDriveTypeAutoRun).

- Page 63 User and Remote Interface Security Measures USB Interfaces a. For Windows XP, select Run... from the Windows Start menu. Then, type into the Windows Run dialog box, as shown in Figure regedit below, and click OK. Figure 9-2 Windows XP Run Dialog b.

-

Page 64: Configuring Usb For Read-Only

1. If you are not currently logged on to the instrument as the Administrator, you must log off. If you are currently logged on to the instrument as the Administrator, and the Keysight XSA application is already running, go to Step 4. - Page 65 Figure 9-5 Windows 7 Log off Control 3. After you have logged on to the instrument as the Administrator, restart the Keysight XSA application. 4. When the XSA application has fully initialized (that is, when the main results view and softkey menu are visible), press the System front-panel key.

-

Page 66: Procedure For Declassifying A Faulty Instrument

Security Features and Document of Volatility Procedure for Declassifying a Faulty Instrument Procedure for Declassifying a Faulty Instrument Even if the instrument is not able to power on, it may be declassified by: 1. Removing the disk drive from the instrument, using the appropriate procedure as described in “Disk Drive Removal Procedure”... -

Page 67: Special Options

Security Features and Document of Volatility Special Options Special Options You can install certain special options that provide security-related functionality. The following available options are described in this chapter. — “Option SF1” on page 68 — “Option SF2” on page 69 To determine which of these options, if any, are installed in your instrument, use the procedure described in “Determining Installed Options”... -

Page 68: Option Sf1

Special Options Option SF1 Option SF1 Option SF1 is a license key-enabled special option that addresses the requirements of security-conscious users. Installing Option SF1 in the instrument causes changes to available functionality in certain menus, and suppression of certain SCPI commands, to prevent the launching of Windows programs from the instrument application. -

Page 69: Option Sf2

Option SF2 installed), an advisory dialog appears, describing how to disable the page files. The X-Series application will not start until memory page files are disabled. For details of how to run SF2RegSetup.reg, refer to Installation Note: Keysight X-Series Signal Analyzers Option SF2. Menu & Command Changes Installing Option SF2 causes several menu and command changes in the instrument, as follows. -

Page 70: File Menu

Special Options Option SF2 — Save N O T E Save and Recall are often used with the N9069C Noise Figure Measurement Application to allow multiple noise sources to be used without the need to re-enter ENR values or to perform the noise source calibration each time a different noise source is connected. - Page 71 Special Options Option SF2 — :MMEMory:LOAD:AXConfig — :MMEMory:LOAD:CAPTured — :MMEMory:LOAD:CCORrection — :MMEMory:LOAD:CHTable — :MMEMory:LOAD:CORRection — :MMEMory:LOAD:CORRection:DDIRectory — :MMEMory:LOAD:CORRection:GROup — :MMEMory:LOAD:DLISt — :MMEMory:LOAD:DPD:REFerence:DATa — :MMEMory:LOAD:DPD:REFerence:SRATe? — :MMEMory:LOAD:DTRaces — :MMEMory:LOAD:ENR — :MMEMory:LOAD:EVMSetup — :MMEMory:LOAD:FMT — :MMEMory:LOAD:FREQuency — :MMEMory:LOAD:IQRef — :MMEMory:LOAD:LIMit — :MMEMory:LOAD:LIMit:DDIRectory —...

- Page 72 Special Options Option SF2 — :MMEMory:LOAD:STATe:VSA — :MMEMory:LOAD:T2Config — :MMEMory:LOAD:TMMConfig — :MMEMory:LOAD:TRACe — :MMEMory:LOAD:TRACe:DATA — :MMEMory:LOAD:TRACe:REGister — :MMEMory:LOAD:VSASetup — :MMEMory:LOAD:ZMAP — :MMEMory:MSIS — :MMEMory:NAME — :MMEMory:NFIGure:LOAD:ENR — :MMEMory:NFIGure:LOAD:FREQuency — :MMEMory:NFIGure:LOAD:LOSS — :MMEMory:NFIGure:STORe:ENR — :MMEMory:NFIGure:STORe:FREQuency — :MMEMory:NFIGure:STORe:LOSS — :MMEMory:REGister:STATe:LABel — :MMEMory:REGister:STATe:LABel:MAXimum? —...

- Page 73 Special Options Option SF2 — :MMEMory:RMEDia:LIST? — :MMEMory:RMEDia:SIZE? — :MMEMory:RMEDia:WPRotect? — :MMEMory:SELect[:ITEM]:ALL — :MMEMory:SELect[:ITEM]:DEFault — :MMEMory:SELect[:ITEM]:HWSettings — :MMEMory:SELect[:ITEM]:LINes:ALL — :MMEMory:SELect[:ITEM]:NONE — :MMEMory:SELect[:ITEM]:SCData — :MMEMory:SELect[:ITEM]:TRACe[:ACTive] — :MMEMory:SELect[:ITEM]:TRANsducer:ALL — :MMEMory:STORe:ALIMit — :MMEMory:STORe:ALISt — :MMEMory:STORe:ATRace — :MMEMory:STORe:AXConfig — :MMEMory:STORe:CAPTured — :MMEMory:STORe:CHTable — :MMEMory:STORe:CORRection —...

- Page 74 Special Options Option SF2 — :MMEMory:STORe:RECording — :MMEMory:STORe:RESults — :MMEMory:STORe:RESults:DATA — :MMEMory:STORe:RESults:MTABle — :MMEMory:STORe:RESults:PTABle — :MMEMory:STORe:RESults:SNGLS — :MMEMory:STORe:RESults:SPECtrogram — :MMEMory:STORe:RESults:TABLe:CUMulative — :MMEMory:STORe:RESults:TABLe:CURRent — :MMEMory:STORe:RESults:TABLe:PDW — :MMEMory:STORe:RESults:TABLe:PDW:FULL — :MMEMory:STORe:RESults:TABLe:PULSe — :MMEMory:STORe:RESults:TABLe:PULSe:FULL — :MMEMory:STORe:RESults:TABLe:VPDW — :MMEMory:STORe:RESults:TABLe:VPDW:FULL — :MMEMory:STORe:SCAN — :MMEMory:STORe:SCONfig — :MMEMory:STORe:SCReen —...

- Page 75 Special Options Option SF2 — :MMEMory:TRACe:OPERator:STATe — :MMEMory:TRACe:PDEScription — :MMEMory:TRACe:PDEScription:STATe — :MMEMory:TRACe:TITLe — :MMEMory:TRACe:TITLe:STATe SYSTem Subsystem — :SYSTem:PON:TYPE — :SYSTem:PRESet:SAVE — :SYSTem:PRESet:TYPE — :SYSTem:PRESet:USER — :SYSTem:PRESet:USER:ALL — :SYSTem:PRESet:USER:SAVE — :SYSTem:PRINt:THEMe Security Features & Document of Volatility...

-

Page 76: Appendix A References

Keysight X-Series Signal Analyzer: Getting Started Guide Keysight Technologies 2008-2019. Part Number: subject to change as document is revised. A printed copy of this document is supplied with each Keysight X-Series Analyzer. It is also available in Acrobat (PDF) form: —... - Page 77 This information is subject to change without notice. © Keysight Technologies 2009-2019 Edition 5, October 2019 N9020-90124 www.keysight.com...

Need help?

Do you have a question about the X Series and is the answer not in the manual?

Questions and answers