Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for GCC Technologies LaserPro C180II

- Page 1 232001840G(08)

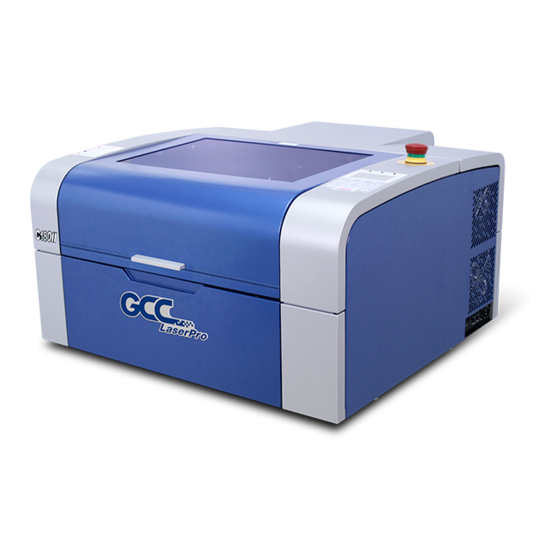

- Page 2 Dear Sir or Madam, Thank you for choosing GCC and the LaserPro C180II. You can be assured that this machine meets all of the highest safety standards while using technological innovations shared by no other laser engraver. The LaserPro C180II is backed by GCC, a truly international company that is dedicated to helping your business grow.

-

Page 3: Table Of Contents

5.2.2 Color Management .................... 78 5.2.3 Using the LaserPro C180II Print Driver ............. 78 5.2.3.1 LaserPro C180II Print Driver >> Option Page ......... 80 5.2.3.2 C180II Print Driver >> Pen Page ............. 86 5.2.3.3 C180II Print Driver >> Advance Page ............90 5.2.3.4 C180II Print Driver >>... - Page 4 8.3.1 Removing the Mirrors ..................132 8.3.2 Cleaning the Mirrors ..................135 8.3.3 Removing and Cleaning the Focal Lens ............136 Chapter 9 Basic Troubleshooting Chapter 10 Appendix 10.1 Glossary ........................140 10.2 LaserPro C180II Series Specification Sheet ............141...

-

Page 5: Safety

Chapter 1 Safety Principles of CO Laser Safety Ratings The Safety Interlock System Safety Labels Safety Measures Operating Environment 232001840G(08) -

Page 6: Principles Of A Co 2 Laser

One of the key safety features found on the LaserPro C180II is a Class 2 red beam safety guidance pointer (similar to a laser-pointer presentation pen) allowing the operator to see the exact location where the laser beam will fire. - Page 7 In compliance with CDRH standards, the required warning labels are affixed at the time of manufacture to the LaserPro C180II in the appropriate locations. These labels are not to be modified in any way or removed for any reason. Please familiarize yourself with the specific labels and their locations on the machine. Below is a list of all the safety labels and their locations on the machine.

- Page 8 Safety Label CDRH and CE regulations require that all laser manufacturers add warning labels in specific locations throughout the equipment. The following warning labels are placed on the laser system for your safety. Do not remove these labels for any reason. If the labels become damaged or have been removed for any reason, do not operate the laser system and immediately contact Great Computer Cooperation or e-mail us for a replacement.

- Page 9 CDRH Label This label indicates the class level of CDRH. CE Label This label identifies the classification of the Model in accordance with IEC 60825-1. It is located on the rear of the machine’s cabinet. Aperture warning stickers (mirror): This label indicates the laser path. Normally you can find this label inside of machine or laser exit. Please take extra caution of this area when you conduct maintenance or operate machine.

- Page 10 Warning Label Warning Label is written with all the necessary information to be aware of during operation. Invisible laser radiation when door open and interlock failed. Avoid eye or skin exposure direct to laser radiation. Do not leave the machine unattended during operation. Please clean the bearings and motion system tracks every day.

-

Page 11: Safety Measures

Emergency Stop Label This label indicates the emergency stop button. You can find this label on the right upper side of the machine. Protection Window Label This label indicates the protection wavelength. You can find this label in the lower right corner of window. -

Page 12: Operating Environment

• Avoid small, enclosed areas with poor ventilation. • Avoid areas with high levels of noise and electrical noise. • Select a location that is large enough to accommodate the LaserPro C180II, an exhaust system, a computer and a work or storage table. -

Page 13: Noise Test

Select a location in which there is a short, direct path to the fume exhaust system. • Set the LaserPro C180II on a floor surface that is completely even. • Make sure your smoke or fire detection system in the immediate area is functioning. -

Page 14: Machine Safety Information

The manufacturer GCC Great Computer 4F-1., No.236, Fude 2nd Rd., Xizhi Dist., New Taipei City 22151, Taiwan hereby declares that the following product GCC LaserPro C180II Model Number 12/30V/30C/40C has demonstrated conformity to the following guidelines: 2006/42/EC Machinery Directive 2006/95/EC Low Voltage Directive... -

Page 15: Unpacking & Contents

Chapter 2 Unpacking & Contents Unloading and Unpacking Contents and Accessories Checklist 232001840G (08) -

Page 16: Unloading And Unpacking

2.1 Unloading and Unpacking The LaserPro C180II is shipped in one crate that contains the machine, the software, and all of the necessary accessories. The following section contains detailed step-by-step instructions for unpacking and assembly of the machine. WARNING More than one person may be needed when loading and unloading the shipping crate in order to avoid body injury or damage to the machine .To prevent personal injury or damage to the... - Page 17 Unpack via the following steps: Move the shipping crate near the designated work area. Remove the packing tapes. Open the carton box. Carefully lift the machine out of the box with the help of another person. 232001840G (08)

-

Page 18: Install The Air Exhaust Connecting Box

2.2 Install the air exhaust connecting box 1) Fit the air exhaust connecting box into the top opening on the machine as shown in the picture below. 2) Tighten the 2 thumb screws by hand and the air exhaust connecting box installation is complete. How to re- p a ck the machine 1) Remove the exhaust connecting box from the machine and put the machine into the EPE foam first. - Page 19 2) Wrap the machine with the plastic bag carefully and place onto the bottom EPE foam 3) Place the top EPE on the machine and place the exhaust connecting box on to the EPE Use tape to secure the slider on the exhaust connection box.

- Page 20 4) Place the machine into the package box 5) Cover the lid and tighten by rope.

-

Page 21: Contents And Accessories Checklist

Lens Tissue PS2 Lubrication Grease Main Power Cord LAN Cable USB Cable CO 2 Goggles Focusing Tool Exhaust Connecting Box 2 inch Exhaust Tubing Installation CD ( LaserPro C180II user manual, driver ) Pencil Sample Quality Promise Card 232001840G (08) -

Page 22: Mechanical Overview

Chapter 3 Mechanical Overview Front View Top View Right (Profile) V iew Left (Profile) V iew Rear View 232001840G(06) -

Page 23: Front View

Please take some time to familiarize yourself with this section regarding the mechanical overview of the LaserPro C180II. References will be made back to the different parts of the LaserPro C180II in later sections. 3.1 Front View Lower Front Door 3.2 Top View... -

Page 24: Right (Profile) V Iew

3.3 Right (Profile) V iew Power Cable Inlet Printer Port 3.4 Left (Profile) V iew Air Exhaust Adjustment Bar 232001840G(06) -

Page 25: Rear View

3.5 Rear View Fume Extraction Connection Port Laser Access Panel Power Socket Air Valve USB Port Ethernet Port 232001840G (08) -

Page 26: Setup And Installation

Chapter 4 Setup and Installation Machine Setup Powering Up the Machine Power Cable Connection Connecting the Computer Graphics Software Setup Recommended Computer Configuration Installation of the LaserPro USB Driver Installation of the LaserPro Print Driver 232001840G(06) -

Page 27: Machine Setup

LCD adjustment wheel is located underneath the control panel 4.1.2 Connecting the Computer The LaserPro C180II Series can communicate with a computer through a USB Port or LAN Port connection interface. Regardless of the connection method chosen, you will need to connect the respective connection cable from the LaserPro C180II Series to your computer. - Page 28 Step 1. Connect LAN cable to the LAN port of GCC laser engravers and turn on machine Step 2. Navigate the control panel through <F4> Function <Machine Setting> <LAN Setup Wizard> IP Address. Step 3. Go to Windows <Control Panel> <Hardware and Sound>...

- Page 29 232001840G (08)

-

Page 30: Ethernet Connectivity Setup

4.1.2.1 Ethernet Connectivity Setup GCC laser engraver is built-in with LAN port to transmit data from PC to laser engraver with ease and higher speed instead of USB port option. Step 1. Connect LAN cable to the LAN port of GCC laser engravers and turn on machine Step 2. - Page 31 Step 5. Go to <Control Panel Network and Internet Network Connections> of computer, right click mouse on the connected internet device, and choose <Properties> Step 6. Choose the <Internet Protocol Version 4(TCP/IPv4)> and click <Properties> to open up the setting window. 232001840G (08)

- Page 32 Step 7. Enter the IP address and Subnet mask setting values, and choose <OK> Note the IP address 192.168.3.X (X value can be 1~255, while can’t be the same number as machine control panel setting in step 4) Step 8. Go to <Control Panel> <Device and Printers>...

- Page 33 Step 9. Select <Add Pot> under Ports tab, and follow the instruction to enter the TCP/IP information in laser machine’s control panel in step 4. 232001840G (08)

- Page 34 232001840G(06)

- Page 35 232001840G (08)

-

Page 36: Graphics Software Setup

• ECP – Cable (Less than 1.8 meters) Software Compatibility • The LaserPro C180II drivers are designed for Windows Vista, 7, 8, or newer operating systems. When you have the mass cutting production, we will suggest that you can select AutoCAD to work with the LaserPro C180II to have better output performance. -

Page 37: Installation Of The Laserpro Print Driver

No if you want to use this printer as the default printer and click Next to continue. NOTE When working with the LaserPro C180II Print Driver within your graphics software, you will need to have the C180II set as the default printer to get proper output. If you select to not... -

Page 38: Parallels Desktops For Mac Users

4.2.3 Parallels Desktops for MAC Users MAC users can use GCC LaserPro machines by purchasing the Parallels Desktop software which allows you to install Windows OS in MAC computers and run Windows based software under MAC computer and output with GCC print driver. - Page 39 4) Enter your Mac OS X User Name and Password then press “OK” 5) Press “Active” 6) Press “OK” when activation is complete. 232001840G(08)

- Page 40 7) Register Parallels Desktop 8) Press “Register” and “OK” to complete the installation of Parallels Desktop. 9) Open Parallels Desktop (in the Applications folder) then choose File → New 10) Press “Install Windows from DVD or image file” then press “continue” to install windows OS 232001840G(08)

- Page 41 11) Select CD-ROM drive with the Windows installation CD 12) Enter the Windows OS product key 232001840G(08)

- Page 42 13) Select how you would like to run your Windows program. 14) After the prior setting is complete the windows OS installation procedure will start automatically. 15) Windows OS installation is complete then you can refer to “4.2.4 Installation of the LaserPro Print Driver”...

-

Page 43: Using Autocad Inventor With Gcc Lasers

4.2.4 Using AutoCAD Inventor with GCC Lasers 1. Start drawing. 2. Delete border and title block by right clicking on sheet1 and selecting delete. 3. Set sheet size to match working area of engraver. Engraver working area can be found on the paper tab of the windows driver. - Page 44 4. Start sketch. 5. Engraving a. Finish sketch. b. Right click on sketch and select properties. c. Line Type: By Layer d. Line Weight: By Layer e. Set color to match one of the 16 colors available in the pen tab of the windows driver. 232001840G(08)

-

Page 45: Using Ecut With Gcc Lasers

6. Cutting a. Finish sketch. b. Right click on sketch and select properties. c. Line Type: Continuous d. Line Weight: .001 in. e. Set color to match one of the 16 colors available in the pen tab of the windows driver. NOTE All objects created in one particular sketch will have the same properties meaning all will engrave or all will cut. -

Page 46: Operating The Laserpro C180Ii

- Page Setup and Orientation - Color Management - Using the LaserPro C180II Print Driver - LaserPro C180II Print Driver >> Options Page - LaserPro C180II Print Driver >> Pen Page - LaserPro C180II Print Driver >> Advanced Page - LaserPro C180II Print Driver >> Paper Page - LaserPro C180II Print Driver >>... -

Page 47: Using The Hardware

5.1.2 Graphic Control Panel Overview (Description) The Control Panel The control panel on the LaserPro C180II provides easy access to all of the manual controls needed for cutting and engraving. The liquid crystal display (LCD), functional, directional and selection buttons make navigating through the machine’s manual controls easy to do. - Page 48 LED INDICATOR LIGHTS Three indicator lights on the LaserPro C180II’s control panel are part of the system’s safety interlock system. • DOOR - The door light will illuminate when either the top lid or external pass through doors on the LaserPro C180II are open or improperly closed.

-

Page 49: Graphic Control Panel Navigation Chart

and the material, you can use the buttons to do so. Doing so will adjust the vertical height (z- axis) of the worktable. 5.1.3 Graphic Control Panel Navigation Chart Main Work Page Functions Page File Management Page Information Machine Setting Advanced Option Page Select Lens Save Position... - Page 50 Main Work Page The main work page is the page that the LaserPro C180II will default to upon startup and will be the “home base” for when navigating through the various functions of the control panel. This will be the page that is displayed when you are processing your jobs.

- Page 51 Carriage / Work Table Adjustment Page Navigating to this page: Main Work Page Press or F3 Carriage / Work Table Carriage / Work Table Adjustment Page Adjustment Page The Carriage / Work Table Adjustment Page allow you to manually increase and decrease the height of the work table (Z-axis).

- Page 52 SmartCENTER Page Navigating to this page: Main Work Page Main Work Page press F3 SmartCENTER Page Under SmartCENTER mode the job will begin after the system positions the carriage to the center position between two points or four points indicated by the user. The SmartCENTER mode has to be enabled through the driver.

- Page 53 Menu Page • File Management Page – this page allows you to manage the files that you have loaded onto the LaserPro C180II • Machine Setting Page – this page allows you to access and modify various machine settings, including: Set Lens, Tune Auto Focus, Set Table Down, Set Red Beam, Carriage Lock, Set Command Mode, Save Position, Flash Memory, Set File Save Mode, Set Vector Mode, Tune Image Power, Set Laser Wattage, Set Fine Mode, Other, Reset.

- Page 54 The File Management Page allows you to manage the files that you have loaded onto the LaserPro C180II. You can scroll through your jobs, delete a selected job, delete all jobs, and go to the Link / DLink Page to set and arrange multiple loaded jobs into a single job queue for processing.

- Page 55 Link / DLink Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Manage- ment>from the menu File Management Page press F2 Link / DLink Page The Link / DLink Page allows you to set, arrange, and remove loaded jobs to and from a job queue for processing.

- Page 56 File Information Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Manage- ment>from the menu File Management Page Select a job file and press E nt e r File Information Page The File Information Page allows you to view the speed, power, DPI, and PPI settings of the selected job.

- Page 57 File Management Edit Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Manage- ment>from the menu File Management Page Select a job file and press E nt e r File Information Page press F4 File Management Edit The File Management Edit Page allows you the choice to modify your raster or vector settings for the selected job, as well as setting the number of times to repeat the process of the selected job (Repeat Num).

- Page 58 SmartACT for the selected job. These settings correspond to the same settings found on the LaserPro C180II driver. This page allows you to easily adjust these values to make immediate adjustments while processing your loaded jobs, even when you have disconnected your computer from the LaserPro C180II •...

- Page 59 File Edit Vector Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Manage- ment>from the menu File Management Page Select a job file and press E nt e r File Information Page press F4 File Information Page Select<...

- Page 60 Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Manage- ment>from the menu Machine Setting Page The Machine Setting Page allows you to access and modify various machine settings, including: Set Lens, Tune Auto Focus, Set Table Down, Carriage Free, Set Command Mode, File Save Mode, Scaling, Other, and Reset.

- Page 61 Remember to save your settings after you have made the proper changes. Now by pressing the Auto Focus button, the LaserPro C180II will conduct auto focus accordingly using the new lens. The LaserPro C180II default setting is <2.0">...

- Page 62 Tune Auto Focus Page Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Setting>from the Machine Setting Page Select<Tune Auto Focus>from the menu Tune Auto Focus Page The Tune Auto Focus Page allows you to manually set the default auto focus distance / vertical height of the worktable (Z-axis) when the Auto Focus button is pushed.

- Page 63 Pressing the Enter key at this point will confirm the prompt to move the work table to its lowest position. If the Table Down is set to <NO>, then the LaserPro C180II will not display this warning prompt at system startup.

- Page 64 Carriage Free Page Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Setting>from the Machine Setting Page Select<Ca rri a g e Lock >from the menu Carriage Free Page The Carriage Lock Page allows you to set whether the laser carriage is to be locked or free. If the Carriage Free setting is set to <YES>, then you will be able to manually move the laser carriage along the X and Y axis by hand with the top door open.

- Page 65 Command Mode Page Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Setting>from the Machine Setting Page Select<Set C omm a nd Mode>from the menu Set Command The Command Mode Page allows you to configure vector settings when outputting in Default or HPGL mode.

- Page 66 M od e >from the menu Set File Save Mode Page The Set File Save Mode Page allows you to set whether or not the LaserPro C180II automatically deletes each job file after processing. Setting File Save to <NO> will automatically and immediately delete each job file from the LaserPro C180II after the engraving or cutting process.

- Page 67 LAN Setup Wizard Page Navigating to this page: Main Work Page press F4 Functions Page Select<Ma chin e Se tting >from the menu Machine Setting Page Select<LAN setup wizard> from the menu LAN Setup Wizard Page The LAN Setup Wizard Page allows you to connect the laser machine with ethernet to transmit files from computer to laser machine for processing jobs.

- Page 68 LAN Setup Wizard Page Relevant Buttons Function F1 (Back) Back to previous page F4 (Save) Save your current settings Cycle DHCP between NO/ OFF, or move between Directional tabs on IP address settings Scroll between menu options, or change the Directional numbers of IP address settings.

- Page 69 Scaling Page Navigating to this page: Main Work Page press F4 Functions Page Select<Ma chin e Se tting >from the menu Machine Setting Page Select<Scaling> from the menu Scaling Page The Scaling Page allows you to fine tune the laser machine output scale to precisely fit the original graphic file design scale when precision output is requried to your application.

- Page 70 Others Page Navigating to this page: Main Work Page press F4 Functions Page Select<Ma chin e Se tting >from the menu Machine Setting Page Select<O th e rs > from the menu Others Page The Others Page allows you to change various settings that correspond to the control panel. The Language setting will allow users to change available languages displayed on the control panel.

- Page 71 Reset Page Navigating to this page: Main Work Page press F4 Functions Page Select<Ma chin e Se tting >from the menu Machine Setting Page Select<O th e rs > from the menu Others Page The Reset Page will restore machine settings back to factory default. Press ENTER to confirm the change, and restart the machine.

- Page 72 Save Position Function Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Setting>from the Advanced Option Page Select<Sa v e Position >from the Save Position Page The Save Position Function allows you to save the current X-axis and Y-axis positions of the laser carriage and sets this position to be the origin for subsequent jobs.

- Page 73 SmartGUARD Page Navigating to this page: Main Work Page press F4 Functions Page Select< Adv a nc e d O ptions >from the Advanced Option Page Select<S m a rt GU A RD> from the menu SmartGUARD Page After optional SmartGUARD hardware installation, please enter the function menu on the control panel to enable the SmartGUARD fire alarm.

- Page 74 Whereas Quality Vector Mode offers the highest quality, sacrificing output speed. Keep in mind that speed and quality are usually at a tradeoff. The system’s default is Fine Vector mode, sacrificing some speed for higher quality. The LaserPro C180II default setting is <Fine Vector>.

- Page 75 Machine Information Page Navigating to this page: Main Work Page press F4 Functions Page Select<Information> from the menu Machine Setting Information Page The Machine Information Page allows you to view information regarding the system such as the GCC logo, machine name, firmware version, and other information. Machine Information Page Relevant Buttons Function...

-

Page 76: The Laserpro C180Ii Print Driver

Please make sure the LaserPro C180II is set to the default printer before proceeding to the page and layout setup. Ensure that the LaserPro C180II has been selected as the DEFAULT PRINTER. You can do so by going into your Windows Control Panel → Printers and Faxes. - Page 77 From the navigation bar on the left, click DOCUMENT → PAGE → SIZE. Ensure that NORMAL PAPER and LANDSCAPE are selected. Ensure the Paper Width and Height dimensions match the LaserPro C180II’s work table dimensions of 458 mm (18 inches) and 305 mm (12 inches).

-

Page 78: Color Management

Now after you have properly set the Page and Layout and Color Management of your graphics software, you are ready to configure the details of your actual job through the LaserPro C180II Print Driver. The LaserPro C180II print driver allows you to adjust your engraving / cutting options. After you have setup your image, design, or text to be engraved in your software application, you can access the LaserPro C180II print driver by going to FILE →... - Page 79 NOTE For this screenshot example, CorelDRAW was used as the software application. The LaserPro C180II Print Driver consists of seven primary sections (pages) in which you will be able to choose various engraving / cutting options and settings: • Option Page •...

-

Page 80: Laserpro C180Ii Print Driver >> Option Page

(the black pen from the PEN menu. Please refer to the next section of the manual for details regarding the PEN functions). The LaserPro C180II print driver will interpret colored and shaded areas as different shades of gray by producing a halftone effect while engraving. Instead of engraving only solid lines, gray/halftone areas will be a collection of dots with varying density. - Page 81 White mode. NOTE Selecting the Black & White mode will enable the Raster page on the LaserPro C180II Print Driver, allowing you to adjust advanced stamp-related settings. Manual Color Fill: Select this mode when you would like to designate specific power and speed settings and link them to certain colors of your image.

- Page 82 Checking this will instruct the LaserPro C180II to immediately begin the laser engraving process, when you select Print from your graphic software program. If Print Immediately is not checked, then selecting Print will transfer the job file to the LaserPro C180II system and will need to be initialized from the LaserPro C180II control panel.

- Page 83 area will be extended as well. T ip There is a greater performance gain when enabling SmartACT for designs that are vertically longer than they are horizontally wide, as the SmartACT optimization modifies the movement of the X-axis of the lens carriage. Preview (Options Page) [DEFAULT SETTING: Unselected] Users can use the Preview function to check a simulated output of the job.

- Page 84 After entering the filename and pressing <ok>, the Preview screen will be shown. The output file can be previewed and an estimated working time of the job is also displayed. File Function (Option Page): The file function section allows you to manage various laser parameters. This section is useful when performing repeat jobs on a variety of objects, allowing you to save your frequently used laser parameters and load them in the future.

- Page 85 LaserPro material database settings allow you easy to load the several parameters. If you are loading LaserPro parameter database as your operating parameter, please direct load from several build-in parameter folders. 232001840G(08)

-

Page 86: C180Ii Print Driver >> Pen Page

5.2.3.2 C180II Print Driver >> Pen Page The LaserPro C180II incorporates the use of 16 different colors to represent 16 different laser power and speed settings when cutting and engraving. These colors are referred to as “Pen”. Think of each pen as a designated laser setting, rather than as a color. As an example, a black and white image will use only one power and speed laser setting (Black). - Page 87 NOTE The LaserPro C180II print driver cannot store more than 16 pen colors or different laser parameter settings per file. 232001840G(08)

- Page 88 Speed (Pen Page) [DEFAUL T SETTING: 4 0] The speed slider controls the laser’s speed during operation (engraving speed) with settings ranging from 0.1 – 100%.Only when moving in straight line with enough distance, the carriage can achieve 100% speed. On the other hand, the machine will automatically slow down when processing curves so the speed % indicator only presents maximum speed % that laser can achieve but not equal to actual laser carriage moving speed.

- Page 89 This checkbox sets the Auto Focus for that particular job. With the Auto Focus button checked, the LaserPro C180II will automatically initialize the auto focus procedure before starting the job. This will ensure the focal distance is properly set based on the particular material you are working with and the focal lens you have installed.

-

Page 90: C180Ii Print Driver >> Advance Page

5.2.3.3 C180II Print Driver >> Advance Page Scaling (Advance Page) [DEFAUL T SETTING: 0] In some cases you may find a slight output inaccuracy in the actual output compared to what you have set in the computer. This margin of error or offset is extremely small (approximately 1/300). What this means that there may be a 1-unit offset for every 300 unit increments. - Page 91 (front end to rear end of the work table) (Normally, the LaserPro C180II engraves from left to right, top to bottom. Selecting Bottom Up will force the machine to start from the bottom and work its way to the rear of the working table.

- Page 92 Use Cluster (Advance Page) [DEFAUL T SETTING: Unselected] This setting allows you to change how the LaserPro C180II interprets and processes individual / independent areas of an image in order to minimize job-processing times. The Cluster function is only applicable when multiple areas of an image are broken down and isolated from each other (areas not touching each other, blank space in-between).

-

Page 93: C180Ii Print Driver >> Paper Page

T rue Image Mode (Advance Page) [DEFAUL T SETTING: Unselected] This setting allows you to improve the engraving quality by reordering the line by line output sequence and by doing so masking the banding problems. This feature is only suitable for engraving large sized graphics. - Page 94 Paper Size (Paper Page) The paper size represents your total work area. Ensure that the paper size is never set greater than the C180II’s worktable area of 18" x 12" (458 mm x 305 mm). The X value represents the length and the Y value represents the width.

- Page 95 Rotary Fixture (Paper Page) [DEFAUL T SETTING: Unselected] NOTE This option is only to be used with the Rotary Attachment optional accessory properly set up. For instructions on how to set up the Rotary Attachment, please refer to Chapter VII of this manual. You will need to select the option when processing a job with the optional rotary attachment system to engrave on rounded or cylindrical objects.

- Page 96 5.2.3.5 C180II Print Driver >> Language Page This page allows you to specify the language displayed by the C180II Print Driver. Available language options include: English, Spanish, French, Japanese, German, Simplified Chinese, and Traditional Chinese. 232001840G(08)

-

Page 97: C180Ii Print Driver >> Raster Page

5.2.3.6 C180II Print Driver >> Raster Page NOTE The Raster Page is only available when Black & White Mode Setting is selected from the Option Page, this page offers a number of advanced Raster Engraving output options. Contrast (Raster Page) [DEFAUL T SETTING: 0] A quick and easy way to immediately adjust the contrast of an engraved image. - Page 98 Halftone (Raster Page) [DEFAUL T SETTING: Dithering] This option controls the way a raster-engraved image is processed. The “digital image to engraved output” process can be processed via two methods: Dithering or Error Diffusion. Each offer additional output options yielding different output effects, style, and quality. •Dithering: Interprets and outputs the raster engraving via the dithering method.

- Page 99 Floyd Stucki Jarvis There is no "correct" or "best" setting when using the Raster options. The most appropriate settings will be based on a variety of factors: your design, the material you are engraving on, the results you wish to achieve, etc. Please take some time to experiment with the multitude of raster options to get the one you feel is the best for your piece.

-

Page 100: C180Ii Print Driver >> Stamp Page

5.2.3.7 C180II Print Driver >> Stamp Page Producing stamps require different operational steps than your standard engraving or cutting jobs. The Stamp page offers dynamic options allowing you to customize your stamp production process. NOTE The Stamp page will only appear and be accessible when you have selected the Stamp Mode from the Options Page. - Page 101 Adjustment Bar / Power Level (Stamp Page) Another important aspect of creating a stamp is setting the slope level of the shoulder. The shoulder is the section from the "contact section" of the stamp to its base. This function allows you to adjust the slope for the shoulder sections of your stamp.

-

Page 102: Engraving And Cutting Techniques

Chapter 6 Engraving and Cutting Techniques Raster Engraving Vector Cutting Vector and Raster 3D Tips To Modified Image Settings of a Picture for Better Engraving Quality 232001840G(08) -

Page 103: Raster Engraving

6.1 Raster Engraving A laser engraver can process text, scanned image, digital picture, or design by "laser firing" grids / dots of individual pixels into a raster image. Think of this as simply "printing" your job onto any particular material. An example of a raster engraved piece would be a photo engraving on tile, as shown in the picture below. -

Page 104: Vector And Raster

In these situations when there are raster engraving and vector cutting operations on a single project, the LaserPro C180II driver will interpret between raster sections and vector sections by the types of lines and line widths of your design. Areas of your design with line widths set between 0.001" (0.025 mm), 0.004" (0.1 mm) will be designate for vector cutting, and the other areas will be designated for raster engraving. -

Page 105: Tips

6.4 3D Tips 3D Mode is one of the functions of LaserPro laser engraver. Instead of traditional two dimensional graphic processing, 3D Mode allows the naked eyes to visualize the curvatures of the 3D effect by applying 200 power levels technology to create different depth of engraving. Although it is easy to produce 3D samples with LaserPro Engraver, production of the 3D graphic can be a hassle for our users. - Page 106 Concept illustration of 3D graphic production with Laser Professional AP After the graphic is completed, you can output the 3D graphic directly to the laser machine through GCC LaserPro driver, which is very handy. Or you can also export the 3D graphics as JPG or BMP format and edit with frequently used CorelDRAW or Illustrator software, then output the graphic to GCC laser system.

- Page 107 232001840G(08)

- Page 108 LaserPro requests your attention If you need to produce circular 3D graphics, you only need to select Radial as the gray level type in the pull-down menu of Type. Then, a circular 3D graphic may be produced. Step 2. Produce three-dimensional characters 232001840G(08)

- Page 109 232001840G(08)

- Page 110 Step 3. Edit the characters for the website Step 4. Combine the 3D images After finishing the production for each of the objects, you may proceed with the combination of the objects. The combined graphic may be output with the laser engraver. Output the 3D graphic After selecting the graphic to be output, set the Mode as 3D Mode in the driver.

- Page 111 Tips for engraving 3D graphics LaserPro Application Lab provides a few reminders that may require your attention during the 3D engraving in order to improve the result of the engraving. Turn on the Air Assist function When the engraving is done along with Air Assist, the depth of the engraving would be deeper. Set Air assist inside the driver by checking the box.

-

Page 112: Modify Image Settings Of A Picture For Better Engraving Quality

6.5 Modify Image Settings of a Picture for Better Engraving Quality Connect your digital camera to the computer by USB cable. Download the picture from the digital camera to the computer Select the picture that you want to engrave. Import the image from the folder where the picture is located by selecting File/Import Convert the image to Bitmap by selecting the image and click on Bitmaps/Convert to Bitmap 232001840G(08) - Page 113 Change the Bitmap settings by setting “Color” to Grayscale (8-bit) and “Resolution” to 300 dpi and click OK. Finally, Invert the image by selecting Effects/Transform/Invert 232001840G(08)

- Page 114 Now you are ready to output the modified image by clicking File/Print 232001840G(08)

- Page 115 NOTE This instruction is a simple example for general use. There are many tips and tricks to achieve a good engraving quality. It takes a lot of practice and experience to achieve a good engraving quality. Different picture may need different modifications and different material may need different parameters.

-

Page 116: Optional Items

Chapter 7 Optional Items Fume Extraction System Option Air Compressor Option Items Honeycomb Table Option Focus Lens Option SmartAIR Nozzle (Fine/Ultra) SmartGUARD Fire Alarm Option Rotary Attachment Option 232001840G(08) -

Page 117: Fume Extraction System Option

When purchasing the LaserPro C180II from your local authorized GCC distributor, you will be provided a chance to purchase optional items to enhance your experience with your system. If anytime after the purchase of your LaserPro C180II, would you like to purchase any optional item, please contact your local authorized GCC distributor. -

Page 118: Fume Extraction Exhaust Adjustment Bar

7.1.2 Fume Extraction exhaust adjustment bar Fume Extraction exhaust adjustment bar Back view C180II added fantastic adjustment function for air exhaust system. When user pull the bar to the left side “Bottom Suction” will increase gradually; on the contrary when user pull the bar to the right side, the “Top Suction will increase. -

Page 119: Air Compressor Option

7.2 Air Compressor Option Specifically designed for laser engravers, the air compressor utilizes an oil-free diaphragm. The air compressor helps eliminate harmful and potentially damaging moisture from the laser optics, maximizing laser optic life. In addition the air compressor provides the optimal air flow to the SmartAIR nozzles to minimize flaming, suppress working temperatures, and blow away dust and particle byproducts generated from the laser process. - Page 120 Connect a ¼" tubing to the air tube fastener valve on the air compressor. NOTE It is important that the ¼" air tubing has clean, straight cuts on each end. Jagged or slanted cuts will not produce adequate sealing capabilities. Take the unattached end of the ¼"...

-

Page 121: Honeycomb Table Option

7.3 Honeycomb Table Option Honeycomb tables are important to tune out a beautiful output when working with cutting operations. C180II has a very easy to install honeycomb table. Simply lay it on top and against the upper left corner of the working area for use. -

Page 122: Smartair Nozzle (Fine/Ultra)

7.5 SmartAIR Nozzle (Fine/Ultra) The optional SmartAIR Fine Nozzle is recommended for engraving or cutting thin materials such as textile. The smaller caliber nozzle is positioned closer to the object for a concentrated blast directed over a small area to eliminate burning on the cutting edge. The perfectly-vertical design of the SmartAIR Fine Nozzle pro- duces a concentrated airflow to blow away dust and unwanted residue, leaving a clean product surface. -

Page 123: Smartguard Fire Alarm Option

7.6 SmartGUARD Fire Alarm Option Laser cutting and engraving operations using the SmartGUARD device protects the operator, machine, produced and the work products from potential fire hazards. During the engraving process, flames may be produced when working with combustible or easily-flammable materials, such as paper or wood. The SmartGUARD is an optional item that can be set to notify the operator through audio warnings and automatically shut down the laser firing as a safety precaution. - Page 124 Connect the cable shown OPERATION MENU: Navigating to this page: Main Work Page press F4 Functions Page Select< Adv a nc e d O ptions >from the Machine Setting Page Select<S m a rt GU A RD Se tting > from the menu SmartGUARD Setting Page After hardware installation, please enter the function menu on the control panel to enable the SmartGUARD fire alarm.

-

Page 125: Rotary Attachment Option

176mm (6.9 inches) INSTALLATION: Open the front panel of the LaserPro C180II, lower the working platform to the bottom Turn off the power of the laser engraver When placing the rotary attachment on the working table, the rotary attachment can only apply the... - Page 126 7) Close the front door panel. Rotary Attachment Port 8) The rotary attachment is now properly installed. Power on the LaserPro C180II and the rotary attachment will be automatically detected and the engraving table will automatically move to its lowest position.

- Page 127 X / Y location on the object you will be engraving and position the auto focus pin over the area to be engraved on your work piece. Hit the Auto Focus button and the LaserPro C180II will now properly focus at the location to be engraved.

- Page 128 B. Detach the circular cylindrical cone by moving it in the direction of the arrow as shown below. C. Assemble the smaller conical fixture onto the rotary attachment as shown below. D. Use the flat surface as shown in picture below as a reference point and tighten the first screw against it.

-

Page 129: Basic Maintenance

Chapter 8 Basic Maintenance Suggested Cleaning and Maintenance Supplies Maintaining the Work table and Motion System Cleaning the Work table and Motion System Lubrication of the Rails Cleaning the Optics System - Removing the Mirrors - Cleaning the Mirrors - Removing and Cleaning the Focal Lens 232001840G(07) -

Page 130: Suggested Cleaning And Maintenance Supplies

Keeping your LaserPro C180II clean and well maintained will ensure quality output, consistent reliability, and extended product life. Smoke, dust or residue build-up inside the laser system or the mechanical components can cause a reduction in the laser power, irregularities in the motion system, reduced product life cycle, and a host of other avoidable problems. -

Page 131: Maintaining The Worktable And Motion System

8.2 Maintaining the Worktable and Motion System 8.2.1 Cleaning the Worktable and Motion System Clean the working table and the motion system on weekly basis through the following steps: 1) Turn the power off and unplug the C180II before cleaning. 2) Use a vacuum cleaner with a flexible nozzle to remove dust and debris from the worktable and motion system. -

Page 132: Cleaning The Optics System

This mirror is located inside the bottom cover of the LaserPro C180II. 1) Use a Screwdriver to remove the back cover located on the bottom side of the LaserPro C180II. 2) Loosen the thumbscrew and screw to the dust cover securing the mirror. (As shown in the picture below). - Page 133 Mirror 2 Unscrew and remove the black dust cover covering mirror 2. Unscrew the thumbscrew holding mirror 2 in place. Clean the lens in the proper manner. Re-install mirror 2 after cleaning. Tighten the thumbscrew. Replace and secure the dust cover. 232001840G(07)

- Page 134 Mirror 3, 4 These mirrors are accessible on the worktable area of the LaserPro C180II. Mirror3 Mirror 3 Unscrew the thumbscrew holding mirror 3 in place. Clean the lens in the proper manner. Re-install mirror 3 after cleaning. Tighten the thumbscrew.

-

Page 135: Cleaning The Mirrors

Repeat the cleaning processes if the mirror is not completely clean after the first attempt. Make sure that the mirror is completely dry before reinstalling it. CAUTION If the center of the mirror is scratched, contact your LaserPro C180II dealer for a replacement. 232001840G(07) -

Page 136: Removing And Cleaning The Focal Lens

8.3.3 Removing and Cleaning the Focal Lens 1) Unscrew the three thumbscrews (front face of the laser head) securing the laser carriage panel and remove the laser carriage panel to reveal the focal lens. 2) Carefully pull out the focal lens (as indicated in the picture below). Clean the focal lens with a cotton swab and lens cleaner solution. -

Page 137: Basic Troubleshooting

Chapter 9 Basic Troubleshooting 232001840G(08) - Page 138 Quality Problems • Check focal length setting under Menu function key > Machine Setting > Set Focus Lens to see if it matches the type of the lens installed. • Check if the focal lens is installed correctly or if focal lens is not fixed properly. •...

-

Page 139: Appendix

Chapter 10 Appendix Glossary LaserPro C180II Series Specification Sheet 232001840G(08) -

Page 140: Glossary

10.1 Glossary Color Fill – Term within the awards and engraving industry used to describe the variety of techniques used to add color or contrast to engraving. DPI – Dots Per Inch or Pixels Per Inch. The resolution of an image as defined by the amount of dots/pixels included in an inch. -

Page 141: Laserpro C180Ii Series Specification Sheet

10.2 LaserPro C180II Series Specification Sheet LaserPro C180 II Work Area 18x12 in. (458 x305 mm) Maximum Part Size 19.8 x 12.2 x 6 in.(505 x 309 x 170 mm) Table Size 20.4 x 14.7 in.(520 x 375 mm) Dimensions 29.1 x 30.7 x 16.1 in.(740 x 780 x 410 mm)

Need help?

Do you have a question about the LaserPro C180II and is the answer not in the manual?

Questions and answers