Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Universal Robots UR5

- Page 1 User Manual UR5/CB3 Original instructions (en) US version...

- Page 3 User Manual UR5/CB3 Version 3.1 (rev. 17782) Original instructions (en) US Version Serial number UR5: Serial number CB3:...

- Page 4 The information contained herein is the property of Universal Robots A/S and shall not be reproduced in whole or in part without prior written approval of Universal Robots A/S. The information herein is subject to change without notice and should not be construed as a commitment by Universal Robots A/S.

-

Page 5: Table Of Contents

General purpose analog I/O..... I-28 4.3.7 Remote ON/OFF control ..... . I-30 Version 3.1 (rev. 17782) UR5/CB3... - Page 6 Getting Started ......II-3 10.1.1 Installing the Robot Arm and Control Box....II-3 UR5/CB3 Version 3.1 (rev. 17782)

- Page 7 12.14.2 Starting a Default Program ..... II-39 12.14.3 Auto Initialization ......II-39 Version 3.1 (rev. 17782) UR5/CB3...

- Page 8 13.30 Variables Tab ......II-83 13.31 Command: Variables Initialization ..... II-84 UR5/CB3 Version 3.1...

- Page 9 15.12 Safety I/O ......II-110 Glossary II-113 Index II-115 Version 3.1 (rev. 17782) UR5/CB3...

- Page 10 UR5/CB3 viii Version 3.1 (rev. 17782)

-

Page 11: Preface

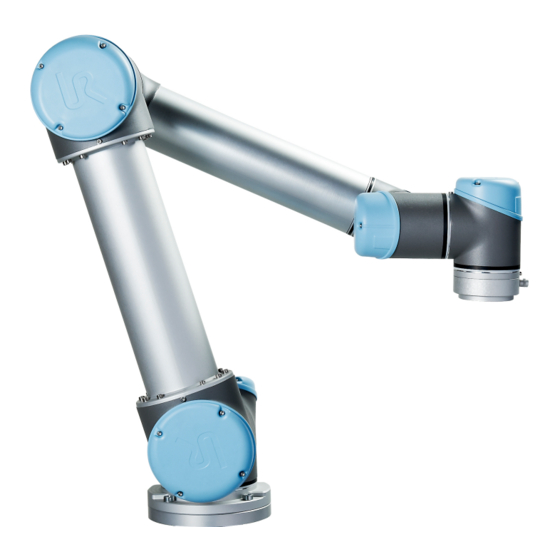

Preface Congratulations on the purchase of your new Universal Robot, UR5. The robot can be programmed to move a tool, and communicate with other machines using electrical signals. It is an arm composed of extruded aluminum tubes and joints. Using our patented programming interface, PolyScope, it is easy to program the robot to move the tool along a desired trajectory. -

Page 12: Important Safety Notice

It is also helpful, though not necessary, to be famil- iar with elementary concepts of programming. No special knowledge about robots in general or Universal Robots in particular is required. Where to Find More Information The support website (http://support.universal-robots.com/), available to all UR distributors, contains additional information, such as: •... -

Page 13: I Hardware Installation Manual

Part I Hardware Installation Manual... -

Page 15: Safety

• Marking the robot installation with relevant signs and contact information of the integrator; • Collecting all documentation in a technical file. Guidance on how to find and read applicable standards and laws is provided on http://support.universal-robots.com/ Version 3.1 (rev. 17782) UR5/CB3... -

Page 16: Limitation Of Liability

WARNING: This indicates a potentially hazardous hot surface which, if touched, could result in injury. CAUTION: This indicates a situation which, if not avoided, could result in dam- age to the equipment. UR5/CB3 Version 3.1 (rev. 17782) -

Page 17: General Warnings And Cautions

Other warnings and cautions are present throughout the manual. DANGER: Make sure to install the robot and all electrical equipment according to the specifications and warnings found in the Chapters 3 and 4. Version 3.1 (rev. 17782) UR5/CB3... - Page 18 10. Be aware of robot movement when using the teach pendant. 11. Do not enter the safety range of the robot or touch the robot when the system is in operation. UR5/CB3 Version 3.1 (rev. 17782)

- Page 19 13. Never modify the robot. A modification might create hazards that are unforeseen by the integrator. All authorized reassem- bling shall be done according to the newest version of all rele- vant service manuals. UNIVERSAL ROBOTS DISCLAIMS ANY LIABILITY IF THE PRODUCT IS CHANGED OR MODIFIED IN ANY WAY.

-

Page 20: Intended Use

It is recom- mended to test the robot program using temporary waypoints outside the workspace of other machines. Universal Robots can- not be held responsible for any damages caused to the robot or to other equipment due to programming errors or malfunction- ing of the robot. -

Page 21: Emergency Stop

(E.g. an enable device) to protect him while programming. Universal Robots has identified the potential significant hazards listed below as haz- ards which must be considered by the integrator. Note that other significant hazards might be present in a specific robot installation. -

Page 22: Movement Without Drive Power

2. If the brake is released manually, gravitational pull can cause the robot arm to fall. Always support the robot arm, tool and work item when releasing the brake. UR5/CB3 I-10 Version 3.1 (rev. 17782) -

Page 23: Transportation

Use proper lifting equipment. All regional and national guidelines for lifting shall be followed. Universal Robots cannot be held responsible for any damage caused by transportation of the equipment. 2. Make sure to mount the robot according to the mounting in- structions in chapter 3. - Page 24 UR5/CB3 I-12 Version 3.1 (rev. 17782)

-

Page 25: Mechanical Interface

Electrical installation instructions in chapter 4 must be observed. 3.1 Workspace of the Robot The workspace of the UR5 robot extends 850 mm from the base joint. It is important to consider the cylindrical volume directly above and directly below the robot base when a mounting place for the robot is chosen. -

Page 26: Mounting

Teach Pendant The teach pendant can be hung on a wall or on the control box. Extra brackets for mounting the teach pendant can be bought. Make sure that no one can trip over the cable. UR5/CB3 I-14 Version 3.1... - Page 27 Surface on which the robot is fitted. It should be flat within 0.05mm Outer diameter of robot mounting flange Cable exit 132 ±0,5 Figure 3.1: Holes for mounting the robot. Use four M8 bolts. All measurements are in mm. Version 3.1 (rev. 17782) I-15 UR5/CB3...

- Page 28 3.2 Mounting Figure 3.2: The tool output flange, ISO 9409-1-50-4-M6. This is where the tool is mounted at the tip of the robot. All measures are in mm. UR5/CB3 I-16 Version 3.1 (rev. 17782)

- Page 29 A wet control box could cause death. 2. The control box and teach pendant must not be exposed to dusty or wet environments that exceed IP20 rating. Pay special atten- tion to environments with conductive dust. Version 3.1 (rev. 17782) I-17 UR5/CB3...

- Page 30 3.2 Mounting UR5/CB3 I-18 Version 3.1 (rev. 17782)

-

Page 31: Electrical Interface

3. Some I/O inside the control box can be configured for either normal or safety-related I/O. Read and understand the com- plete section 4.3. Version 3.1 (rev. 17782) I-19 UR5/CB3... -

Page 32: Electrical Warnings And Cautions

EMC problems are found to happen usually in welding processes and are normally prompted by error mes- sages in the log. Universal Robots cannot be held responsible for any damages caused by EMC problems. 2. I/O cables going from the control box to other machinery and factory equipment may not be longer than 30m, unless extended tests are performed. -

Page 33: Controller I/O

• Safety I/O. • Configurable I/O. • General purpose I/O. It is very important that UR robots are installed according the electrical specifications, which are the same for all three different kinds of inputs. Version 3.1 (rev. 17782) I-21 UR5/CB3... - Page 34 [PWR - GND] Current [PWR - GND] External 24V input requirements Voltage [24V - 0V] Current [24V - 0V] The digital I/O are constructed in compliance with IEC 61131-2. The electrical specifi- cations are shown below. UR5/CB3 I-22 Version 3.1 (rev. 17782)

- Page 35 The two permanent safety inputs are the emergency stop and the safeguard stop. The emergency stop input is for emergency stop equipment only. The safeguard stop input is for all kinds of safety-related protective equipment. The functional difference is shown below. Version 3.1 (rev. 17782) I-23 UR5/CB3...

- Page 36 4.3.2.1 Default safety configuration The robot is shipped with a default configuration which enables operation without any additional safety equipment, see illustration below. Safety UR5/CB3 I-24 Version 3.1 (rev. 17782)

- Page 37 In this example the configured I/Os used are “CI0-CI1” and “CO0-CO1”. Configurable Outputs Configurable Outputs Configurable Inputs Configurable Inputs If more than two UR robot or other machines needs to be connected, a safety PLC is needed to control the emergency stop signals. Version 3.1 (rev. 17782) I-25 UR5/CB3...

- Page 38 If the safeguard interface is used to interface a light curtain, a reset outside the safety perimeter is required. The reset button must be a two channel type. In this example the I/O configured for reset is “CI0-CI1”, see below. UR5/CB3 I-26 Version 3.1...

- Page 39 This example shows how to connect a load to be controlled from a digital output, see below. Digital Outputs LOAD 4.3.4 Digital input from a button The example below shows how to connect a simple button to a digital input. Version 3.1 (rev. 17782) I-27 UR5/CB3...

- Page 40 “Power”. • Use of equipment that works in current mode. Current signals are less sensitive to interferences. Input modes can be selected in the GUI, see part II. The electrical specifications are shown below. UR5/CB3 I-28 Version 3.1 (rev. 17782)

- Page 41 Below is an example of how to control a conveyor belt with an analog speed control input. Analog Power 4.3.6.2 Using an Analog Input Below is an example of how to connect an analog sensor. Version 3.1 (rev. 17782) I-29 UR5/CB3...

-

Page 42: Remote On/Off Control

[ON / OFF] Activation time [ON] The following examples show how to use remote ON/OFF. NOTE: A special feature in the software can be used to load and start pro- grams automatically, see part II. UR5/CB3 I-30 Version 3.1 (rev. 17782) -

Page 43: Tool I/O

This connector provides power and control signals for grippers and sensors used on a specific robot tool. The following industrial cables are suitable: • Lumberg RKMV 8-354. The eight wires inside the cable have different colors. The different colors designate different functions, see table below: Version 3.1 (rev. 17782) I-31 UR5/CB3... -

Page 44: Tool Digital Outputs

The digital outputs are implemented as NPN. When a digital output is activated the corresponding connection is driven to GND, and when it is deactivated the corre- sponding connection is open (open-collector/open-drain). The electrical specifications are shown below: UR5/CB3 I-32 Version 3.1 (rev. 17782) -

Page 45: Tool Digital Inputs

Input resistance An example of how to use a digital input is shown in the following subsection. 4.4.2.1 Using the Tool Digital Inputs The example below shows how to connect a simple button. POWER Version 3.1 (rev. 17782) I-33 UR5/CB3... -

Page 46: Tool Analog Inputs

The example below shows how to connect an analog sensor with a differential output. Connect the negative output part to GND (0V) and it works in the same way as a non-differential sensor. POWER UR5/CB3 I-34 Version 3.1 (rev. 17782) -

Page 47: Ethernet

It is recommended to install a main switch to power of all equipment in the robot application as an easy means for lockout and tagout under service. The electrical specifications are shown in the table below. Version 3.1 (rev. 17782) I-35 UR5/CB3... -

Page 48: Robot Connection

The cable from the robot must be plugged into the connector at bottom of the control box, see illustration below. Ensure that the connector is properly locked before turning on the robot arm. Disconnecting the robot cable may only be done when the robot power is turned off. UR5/CB3 I-36 Version 3.1 (rev. 17782) - Page 49 4.7 Robot connection CAUTION: 1. Do not disconnect the robot cable when the robot arm is turned 2. Do not extend or modify the original cable. Version 3.1 (rev. 17782) I-37 UR5/CB3...

- Page 50 4.7 Robot connection UR5/CB3 I-38 Version 3.1 (rev. 17782)

-

Page 51: Safety-Related Functions And Interfaces

Violations of limits will hence only occur in exceptional cases. Nevertheless, if a limit is violated, the safety system issues a category 0 stop with the performance listed in the table: Version 3.1 (rev. 17782) I-39 UR5/CB3... -

Page 52: Limiting Safety-Related Functions

The system is considered de-energized when the 48 V bus voltage reaches an electrical potential below 7.3 V. The de-energizing time is the time from a detection of an event until the system has been de-energized. UR5/CB3 I-40 Version 3.1... -

Page 53: Safety Modes

Limiting Safety Function Limit Joint speed 30 / TCP speed TCP force 100 N Momentum kg m Power 80 W The safety system issues a category 0 stop if a violation of these limits appears. Version 3.1 (rev. 17782) I-41 UR5/CB3... -

Page 54: Safety-Related Electrical Interfaces

Additionally, for a category 1 stop, the safety system monitors that after the robot arm is at rest, the powering off is finalized within 600 ms. Furthermore, after a safeguard stop input, the robot arm is only allowed to start moving again after a positive edge UR5/CB3 I-42 Version 3.1... -

Page 55: Safety-Related Electrical Outputs

1250 ms System emergency stop 250 ms 1000 ms 1250 ms Safeguard stop 250 ms 1000 ms 1250 ms 5.3.2 Safety-related Electrical Outputs The table below gives an overview of the safety-related electrical outputs: Version 3.1 (rev. 17782) I-43 UR5/CB3... - Page 56 Safety Output Worst Case Reaction Time System emergency stop 1100 ms Robot moving 1100 ms Robot not stopping 1100 ms Reduced mode 1100 ms Not reduced mode 1100 ms UR5/CB3 I-44 Version 3.1 (rev. 17782)

-

Page 57: Maintenance And Repair

All UR distributors have access to this support site. Repairs shall only be performed by authorized system integrators or by Universal Robots. All parts returned to Universal Robots shall be returned according to the service man- ual. 6.1 Safety Instructions After maintenance and repair work, checks must be carried out to ensure the required safety level. -

Page 58: Safety Instructions

High voltages (up to 600 V) can be present inside these power supplies for several hours after the control box has been switched off. 5. Prevent water and dust from entering the robot arm or control box. UR5/CB3 I-46 Version 3.1 (rev. 17782) -

Page 59: Disposal And Environment

Fee for disposal and handling of electronic waste of UR robots sold on the Danish market is prepaid to DPA-system by Universal Robots A/S. Importers in countries covered by the European WEEE Directive 2012/19/EU must make their own regis- tration to the national WEEE register of their country. - Page 60 UR5/CB3 I-48 Version 3.1 (rev. 17782)

-

Page 61: Certifications

If the UR robot is used in a pesticide application, then note the presence of directive 2009/127/EC. The declaration of incorporation according to 2006/42/EC an- nex II 1.B. is shown in appendix B. Version 3.1 (rev. 17782) I-49 UR5/CB3... -

Page 62: Declarations According To Eu Directives

A CE mark is affixed according to CE marking directives above. Regarding waste of electric and electronic equipment see chapter 7. For information about standards applied during the development of the robot, see appendix C. UR5/CB3 I-50 Version 3.1 (rev. 17782) -

Page 63: Warranties

Warranty. Claims under the Warranty must be submitted within two months of the Warranty default becoming evident. Ownership of devices or components replaced by and returned to Universal Robots shall vest in Universal Robots. Any other claims resulting out of or in connection with the device shall be excluded from this Warranty. -

Page 64: Disclaimer

9.2 Disclaimer takes no responsibility for any errors or missing information. UR5/CB3 I-52 Version 3.1 (rev. 17782) -

Page 65: A Stopping Time And Stopping Distance

Stopping Distance (rad) Stopping time (ms) Joint 0 (BASE) 0.31 Joint 1 (SHOULDER) 0.70 Joint 2 (ELBOW) 0.22 Version 3.1 (rev. 17782) I-53 UR5/CB3... -

Page 66: Category 0 Stopping Distances And Times

A.1 CATEGORY 0 stopping distances and times UR5/CB3 I-54 Version 3.1 (rev. 17782) -

Page 67: B Declarations And Certificates

Denmark +45 8993 8989 hereby declares that the product described below Industrial robot UR5 Robot serial number Control box serial number may not be put into service before the machinery in which it will be incorporated is declared to comply with the provisions of Directive 2006/42/EC, as amended by Directive 2009/127/EC, and with the regulations transposing it into national law. -

Page 68: Safety System Certificate

B.2 Safety System Certificate B.2 Safety System Certificate UR5/CB3 I-56 Version 3.1 (rev. 17782) -

Page 69: Environmental Test Certificate

Conclusion The two robot arms UR5 and UR10 including their control box and teach pendant have been tested according to the below listed standards. The test results are given in the DELTA report listed above. The tests were carried out as specified and the test criteria for environmental tests as specified in Annex 1 of the report were fulfilled. -

Page 70: Emc Test Certificate

Other document(s) Conclusion The two robot arms UR5 and UR10 including their control box and teach pendant have been tested according to the below listed standards. Both systems meet the EMC requirements of the standards and the essential requirements of the European EMC directive 2004/108/EC. -

Page 71: C Applied Standards

EN ISO 13850:2008 (E) [Stop category 1 - 2006/42/EC] Safety of machinery – Emergency stop – Principles for design The emergency stop function is designed as a stop category 1 according to this standard. Stop category 1 is Version 3.1 (rev. 17782) I-59 UR5/CB3... - Page 72 • “5.10 Collaborative operation requirements”. The power and force limiting function of UR robots is always active. The visual design of the UR robots indicates that the robots are capable of being used for collaborative operations. The power and force limiting function is designed according to clause 5.10.5. UR5/CB3 I-60 Version 3.1...

- Page 73 This TS presents technologies and force-related safety limits for collaborative robots, where the robot and the human work together to perform a work task. Universal Robots is an active member of the international committee that develops this TS (ISO/TC 184/SC 2). A final version might be published in 2016.

- Page 74 The direct opening action and the safety lock mechanism of the emergency stop button comply with re- quirements in this standard. IEC 60529:2013 EN 60529/A2:2013 Degrees of protection provided by enclosures (IP Code) UR5/CB3 I-62 Version 3.1 (rev. 17782)

- Page 75 UR robots are constructed in compliance with this standard to provide protection against electrical shock. A protective earth/ground connection is mandatory, as defined in the Hardware Installation Manual. IEC 60068-2-1:2007 IEC 60068-2-2:2007 IEC 60068-2-27:2008 IEC 60068-2-64:2008 EN 60068-2-1:2007 EN 60068-2-2:2007 EN 60068-2-27:2009 EN 60068-2-64:2008 Environmental testing Version 3.1 (rev. 17782) I-63 UR5/CB3...

- Page 76 The electrical circuitry of UR robots is designed in compliance with this standard. EUROMAP 67:2015, V1.10 Electrical Interface between Injection Molding Machine and Handling Device / Robot UR robots equipped with the E67 accessory module to interface injection molding machines comply with this standard. UR5/CB3 I-64 Version 3.1 (rev. 17782)

-

Page 77: D Technical Specifications

Power supply 100-240 VAC, 50-60 Hz Calculated operating life 35,000 hours Cabling Cable between robot and control box (6 m / 236 in) Cable between touchscreen and control box (4.5 m / 177 in) Version 3.1 (rev. 17782) I-65 UR5/CB3... - Page 78 UR5/CB3 I-66 Version 3.1 (rev. 17782)

-

Page 79: Polyscope Manual

Part II PolyScope Manual... -

Page 81: Introduction

10 Introduction The Universal Robot arm is composed of extruded aluminum tubes and joints. The joints with their usual names are shown in Figure 10.1. The Base is where the robot is mounted, and at the other end (Wrist 3) the tool of the robot is attached. By coordinat- ing the motion of each of the joints, the robot can move its tool around freely, with the exception of the area directly above and directly below the base. -

Page 82: Turning The Control Box On And Off

10.1 Getting Started Figure 10.1: Joints of the robot. A: Base, B: Shoulder, C: Elbow and D, E, F: Wrist 1, 2, 3 10.1.2 Turning the Control Box On and Off The control box is turned on by pressing the power button at the front side of the panel with the touch screen. -

Page 83: The First Program

10.1 Getting Started 1. Press the Emergency Stop button on the front side of the teach pendant. 2. Press the power button on the teach pendant. 3. Wait a minute while the system is starting up, displaying text on the touch screen. 4. -

Page 84: Polyscope Programming Interface

10.2 PolyScope Programming Interface 2. Touch the Next button (bottom right) so that the <empty> line is selected in the tree structure on the left side of the screen. 3. Go to the Structure tab. 4. Touch the Move button. 5. - Page 85 10.2 PolyScope Programming Interface The picture above shows the Welcome Screen. The bluish areas of the screen are but- tons that can be pressed by pressing a finger or the backside of a pen against the screen. PolyScope has a hierarchical structure of screens. In the programming environment, the screens are arranged in tabs, for easy access on the screens.

-

Page 86: Welcome Screen

10.3 Welcome Screen 10.3 Welcome Screen After booting up the controller PC, the welcome screen is shown. The screen offers the following options: • Run Program: Choose and run an existing program. This is the simplest way to operate the robot arm and control box. •... -

Page 87: Initialization Screen

10.4 Initialization Screen 10.4 Initialization Screen On this screen you control the initialization of the robot arm. Robot arm state indicator The status LED gives an indicaton of the robot arm’s running state: • A bright red LED indicates that the robot arm is currently in a stopped state where the reasons can be several. - Page 88 10.4 Initialization Screen Similarly, the name of the installation file that is currently loaded is shown in the grey text field. A different installation can be loaded by tapping the text field or by using the Load button next to it. Alternatively, the loaded installation can be customized using the buttons next to the 3D view in the lower part of the screen.

-

Page 89: On-Screen Editors

11 On-screen Editors 11.1 On-screen Keypad Simple number typing and editing facilities. In many cases, the unit of the typed value is displayed next to the number. Version 3.1 (rev. 17782) II-11... -

Page 90: On-Screen Keyboard

11.2 On-screen Keyboard 11.2 On-screen Keyboard Simple text typing and editing facilities. The Shift key can be used to get some additional special characters. II-12 Version 3.1 (rev. 17782) -

Page 91: On-Screen Expression Editor

11.3 On-screen Expression Editor 11.3 On-screen Expression Editor While the expression itself is edited as text, the expression editor has a number of buttons and functions for inserting the special expression symbols, such as for mul- tiplication and for less than or equal to. The keyboard symbol button in the top right of the screen switches to text-editing of the expression. -

Page 92: Robot

11.4 Pose Editor Screen Robot The current position of the robot arm and the specified new target position are shown in 3D graphics. The 3D drawing of the robot arm shows the current position of the robot arm, and the “shadow” of the robot arm shows the target position of the robot arm controlled by the specified values on the right hand side of the screen. -

Page 93: Feature And Tool Position

11.4 Pose Editor Screen Feature and tool position In the top right corner of the screen, the feature selector can be found. The feature selector defines which feature to control the robot arm relative to Below the feature selector, the name of the currently active Tool Center Point (TCP) is displayed. - Page 94 11.4 Pose Editor Screen Cancel button Clicking the Cancel button leaves the screen discarding all changes. II-16 Version 3.1 (rev. 17782)

- Page 95 12 Robot Control 12.1 Move Tab On this screen you can always move (jog) the robot arm directly, either by translat- ing/rotating the robot tool, or by moving robot joints individually. 12.1.1 Robot The current position of the robot arm is shown in 3D graphics. Push the magnifying glass icons to zoom in/out or drag a finger across to change the view.

-

Page 96: Move Tool

12.1 Move Tab The tool orientation boundary limit is visualized with a spherical cone together with a vector indicating the current orientation of the robot tool. The inside of the cone represents the allowed area for the tool orientation (vector). When the robot TCP no longer is in the proximity of the limit, the 3D representation disappears. -

Page 97: I/O Tab

12.2 I/O Tab WARNING: 1. Make sure to use the correct installation settings (e.g. Robot mounting angle, weight in TCP, TCP offset). Save and load the installation files along with the program. 2. Make sure that the TCP settings and the robot mounting set- tings are set correctly before operating the Freedrive button. -

Page 98: Modbus Client I/O

12.3 MODBUS client I/O Configurable I/O’s can be reserved for special safety settings defined in the safety I/O configuration section of the installaton (see 15.12); those which are reserved will have the name of the safety function in place of the default or user defined name. Configurable outputs that are reserved for safety settings are not togglable and will be displaed as LED’s only. -

Page 99: Automove Tab

12.4 AutoMove Tab 12.4 AutoMove Tab The AutoMove tab is used when the robot arm has to move to a specific position in its workspace. Examples are when the robot arm has to move to the start position of a program before running it, or when moving to a waypoint while modifying a program. -

Page 100: Installation Load/Save

12.5 Installation Load/Save Auto Hold down the Auto button to move the robot arm as shown in the animation. Note: Release the button to stop the motion at any time! Manual Pushing the Manual button will take you to the MoveTab where the robot arm can be moved manually. -

Page 101: Installation Tcp Configuration

12.6 Installation TCP Configuration Load/Save text on the left side of the Installation tab. Saving an installation can be done by pressing the Save or Save As... button. Al- ternatively, saving a program also saves the active installation. To load a different in- stallation file, use the Load button. -

Page 102: Adding, Modifying And Removing Tcps

12.6 Installation TCP Configuration 12.6.1 Adding, modifying and removing TCPs To define a new TCP, hit the New button. The created TCP then automatically receives a unique name and becomes selected in the drop-down menu. The translation and rotation of the selected TCP can be modified by tapping the re- spective white text fields and entering new values. -

Page 103: Teaching Tcp Orientation

12.6 Installation TCP Configuration 1. Tap the Position button. 2. Choose a fixed point in the workspace of the robot. 3. Use the buttons on the right side of the screen to move the TCP to the chosen point from at least three different angles and to save the corresponding positions of the tool output flange. -

Page 104: Payload

12.7 Installation Mounting 3. Use the button below to move to a position in which the orientation of the tool corresponding to the TCP coincides with the coordinate system of the selected feature. 4. Verify the calculated TCP orientation and set it onto the selected TCP using the Set button. -

Page 105: Installation Mounting

12.7 Installation Mounting Here the mounting of the robot arm can be specified. This serves two purposes: 1. Making the robot arm look right on the screen. 2. Telling the controller about the direction of gravity. The controller uses an advanced dynamics model to give the robot arm smooth and precise motions, and to make the robot arm hold itself when in Freedrive mode. -

Page 106: Installation I/O Setup

12.8 Installation I/O Setup 12.8 Installation I/O Setup Input and output signals can be given names. This can make it easier to remember what the signal does when working with the robot. Select an I/O by clicking on it, and set the name using the on screen keyboard. You can set the name back by setting it to only blank characters. -

Page 107: Installation Safety

12.9 Installation Safety 12.9 Installation Safety See chapter 15. 12.10 Installation Variables Variables created here are called installation variables and can be used just like nor- mal program variables. Installation variables are special because they keep their value even if a program is stopped and then started again, and when the robot arm and/or control box is powered down and powered up again. - Page 108 12.11 Installation MODBUS client I/O Setup It is possible to change the value of an installation variable by highlighting the variable in the list and then clicking on Edit Value. To delete a variable, select it in the list, then click Delete. After configuring the installation variables, the installation itself must be saved to keep this configuration, see 12.5.

-

Page 109: Installation Modbus Client I/O Setup

12.11 Installation MODBUS client I/O Setup Delete unit Push this button to delete the MODBUS unit and all signals on that unit. Set unit IP Here the IP address of the MODBUS unit is shown. Press the button to change it. Add signal Push this button to add a signal to the corresponding MODBUS unit. - Page 110 12.11 Installation MODBUS client I/O Setup Signal value Here, the current value of the signal is shown. For register signals, the value is ex- pressed as an unsigned integer. For output signals, the desired signal value can be set using the button. Again, for a register output, the value to write to the unit must be supplied as an unsigned integer.

-

Page 111: Installation Features

12.12 Installation Features 12.12 Installation Features Customers that buy industrial robots generally want to be able to control or ma- nipulate a robot arm, and to program the robot arm, relative to various objects and boundaries in the surroundings of the robot arm, such as machines, objects or blanks, fixtures, conveyers, pallets or vision systems. - Page 112 12.12 Installation Features The meaning of such and similar questions is very straightforward to an average cus- tomer who intends to use a robot arm for instance at various stations in a production plant, and it may seem annoying and incomprehensible to the customer to be told that there may not be a simple answer to such relevant questions.

- Page 113 12.12 Installation Features Add Point Push this button to add a point feature to the installation. The position of a point feature is defined as the position of the TCP at that point. The orientation of the point feature is the same as the TCP orientation, except that the feature coordinate system is rotated 180 degrees about its x-axis.

- Page 114 12.12 Installation Features Add Plane Push this button to add a plane feature to the installation. A plane is defined by three sub point features. The position of the coordinate system is the same as the position for the first sub point. The z-axis is the plane normal, and the y-axis is directed from the first point towards the second.

-

Page 115: Conveyor Tracking Setup

12.13 Conveyor Tracking Setup 12.13 Conveyor Tracking Setup When using a conveyor, the robot can be configured to track the movement of the conveyor. The Conveyor Tracking Setup provides options for configuring the robot to work with absolute and incremental encoders, and linear and circular conveyors. Conveyor Parameters Incremental encoders can be connected to digital inputs 0 to 3. - Page 116 12.14 Installation Default Program The value of Ticks per meter must be the number of ticks the encoder generates when the conveyor moves one meter. ticks per revolution of encoder Ticks per meter (12.1) radius of encoder disc[m] Circular conveyors When tracking a circular conveyor, the center point of the conveyor (circle) must be defined.

-

Page 117: Installation Default Program

12.14 Installation Default Program 12.14.1 Loading a Default Program A default program can be chosen to be loaded when the control box is powered up. Furthermore, the default program will also be auto loaded when the Run Program screen (see 10.3) is entered and no program is loaded. 12.14.2 Starting a Default Program The default program can be auto started in the Run Program screen. -

Page 118: Log Tab

12.16 Load Screen 12.15 Log Tab Robot Health The top half of the screen displays the health of the robot arm and control box. The left part shows information related to the control box of the robot, while the right part shows information about each robot joint. Each robot joint shows information for temperaure of the motor and electronics, the load of the joint and the voltage at the joint. - Page 119 12.16 Load Screen NOTE: Running a program from a USB drive is not recommended. To run a program stored on a USB drive, first load it and then save it in the local programs folder using the Save As... option in the File menu.

- Page 120 12.16 Load Screen By selecting a folder name in the list, the load dialog changes to that directory and displays it in the file selection area 12.16. File selection area In this area of the dialog the contents of the actual area is present. It gives the user the option to select a file by single clicking on its name or to open the file by double clicking on its name.

-

Page 121: Run Tab

12.17 Run Tab 12.17 Run Tab This tab provides a very simple way of operating the robot arm and control box, with as few buttons and options as possible. This can be usefully combined with password protecting the programming part of PolyScope (see 14.3), to make the robot into a tool that can run exclusively pre-written programs. - Page 122 12.17 Run Tab II-44 Version 3.1 (rev. 17782)

-

Page 123: Programming

13 Programming 13.1 New Program A new robot program can start from either a template or from an existing (saved) robot program. A template can provide the overall program structure, so only the details of the program need to be filled in. Version 3.1 (rev. -

Page 124: Program Tab

13.2 Program Tab 13.2 Program Tab The program tab shows the current program being edited. 13.2.1 Program Tree The program tree on the left side of the screen displays the program as a list of com- mands, while the area on the right side of the screen displays information relating to the current command. -

Page 125: Program Execution Indication

13.2 Program Tab 13.2.2 Program Execution Indication The program tree contains visual cues informing about the command currently being executed by the robot controller. A small indicator icon is displayed to the left of the command icon, and the name of the executing command and any commands of which this command is a sub-command (typically identified by the command icons) are highlighted with blue. -

Page 126: Program Dashboard

13.2 Program Tab 13.2.4 Program Dashboard The lowest part of the screen is the Dashboard. The Dashboard features a set of but- tons similar to an old-fashioned tape recorder, from which programs can be started and stopped, single-stepped and restarted. The speed slider allows you to adjust the program speed at any time, which directly affects the speed at which the robot arm moves. -

Page 127: Variables

13.3 Variables 13.3 Variables A robot program can make use of variables to store and update various values during runtime. Two kinds of variables are available: Installation variables: These can be used by multiple programs and their names and values are persisted together with the robot installation (see 12.10 for further de- tails);... -

Page 128: Command: Move

13.5 Command: Move Program commands need to be inserted here. Press the Structure button to go to the structure tab, where the various selectable program lines can be found. A program cannot run before all lines are specified and defined. 13.5 Command: Move The Move command controls the robot motion through the underlying waypoints. - Page 129 13.5 Command: Move path. The shared parameters that can be set for this movement type are the de- sired tool speed and tool acceleration specified in mm/s and mm/s , respectively, and also a feature. The selected feature will determine in which feature space the tool positions of the waypoints are represented in.

- Page 130 13.5 Command: Move Cruise Deceleration Acceleration Time Figure 13.1: Speed profile for a motion. The curve is divided into three segments: acceleration, cruise and deceleration. The level of the cruise phase is given by the speed setting of the motion, while the steepness of the acceleration and deceleration phases is given by the acceleration parameter.

-

Page 131: Command: Fixed Waypoint

13.6 Command: Fixed Waypoint 13.6 Command: Fixed Waypoint A point on the robot path. Waypoints are the most central part of a robot program, telling the robot arm where to be. A fixed position waypoint is given by physically moving the robot arm to the position. Setting the waypoint Press this button to enter the Move screen where you can specify the robot arm’s po- sition for this waypoint. - Page 132 13.6 Command: Fixed Waypoint Note on I/O Timing If a waypoint is a stop point with an I/O command as the next command, the I/O command is executed when the robot arm stops at the waypoint. However, if the waypoint has a blend radius, the following I/O command is executed when the robot arm enters the blend.

-

Page 133: Command: Relative Waypoint

13.7 Command: Relative Waypoint 13.7 Command: Relative Waypoint A waypoint with the position given relative to the robot arm’s previous position, such as “two centimeters to the left”. The relative position is defined as the difference be- tween the two given positions (left to right). Note that repeated relative positions can move the robot arm out of its workspace. -

Page 134: Command: Variable Waypoint

13.8 Command: Variable Waypoint 13.8 Command: Variable Waypoint A waypoint with the position given by a variable, in this case calculated pos. The variable has to be a pose such as var=p[0.5,0.0,0.0,3.14,0.0,0.0]. The first three are x,y,z and the last three are the orientation given as a rotation vector given by the vector rx,ry,rz. -

Page 135: Command: Wait

13.9 Command: Wait 13.9 Command: Wait Waits for a given amount of time or for an I/O signal. Version 3.1 (rev. 17782) II-57... -

Page 136: Command: Set

13.10 Command: Set 13.10 Command: Set Sets either digital or analog outputs to a given value. Can also be used to set the payload of the robot arm, for example the weight that is picked up as a consequence of this action. Adjusting the weight can be neccesary to prevent the robot from triggering a protective stop unexpectedly, when the weight at the tool is different from the expected one. -

Page 137: Command: Popup

13.11 Command: Popup 13.11 Command: Popup The popup is a message that appears on the screen when the program reaches this command. The style of the message can be selected, and the text itself can be given using the on-screen keyboard. The robot waits for the user/operator to press the “OK” button under the popup before continuing the program. -

Page 138: Command: Halt

13.12 Command: Halt 13.12 Command: Halt The program execution stops at this point. II-60 Version 3.1 (rev. 17782) -

Page 139: Command: Comment

13.13 Command: Comment 13.13 Command: Comment Gives the programmer an option to add a line of text to the program. This line of text does not do anything during program execution. Version 3.1 (rev. 17782) II-61... -

Page 140: Command: Folder

13.14 Command: Folder 13.14 Command: Folder A folder is used to organize and label specific parts of a program, to clean up the program tree, and to make the program easier to read and navigate. A folder does not in itself do anything. II-62 Version 3.1 (rev. -

Page 141: Command: Loop

13.15 Command: Loop 13.15 Command: Loop Loops the underlying program commands. Depending on the selection, the underly- ing program commands are either looped infinitely, a certain number of times or as long as the given condition is true. When looping a certain number of times, a dedi- cated loop variable (called loop 1 in the screen shot above) is created, which can be used in expressions within the loop. -

Page 142: Command: Subprogram

13.16 Command: SubProgram 13.16 Command: SubProgram A Sub Program can hold program parts that are needed several places. A Sub Program can be a seperate file on the disk, and can also be hidden to protect against accidental changes to the SubProgram. II-64 Version 3.1 (rev. - Page 143 13.16 Command: SubProgram Command: Call SubProgram A call to a sub program will run the program lines in the sub program, and then return to the following line. Version 3.1 (rev. 17782) II-65...

-

Page 144: Command: Assignment

13.17 Command: Assignment 13.17 Command: Assignment Assigns values to variables. An assignment puts the computed value of the right hand side into the variable on the left hand side. This can be useful in complex programs. II-66 Version 3.1 (rev. 17782) -

Page 145: Command: If

13.18 Command: If 13.18 Command: If An “if...else” construction can make the robot change its behavior based on sensor inputs or variable values. Use the expression editor to describe the condition under which the robot should proceed to the sub-commands of this If. If the condition is evaluated to True, the lines inside this If are executed. -

Page 146: Command: Script

13.19 Command: Script 13.19 Command: Script This command gives access to the underlying real time script language that is exe- cuted by the robot controller. It is intended for advanced users only and instructions on how to use it can be found in the Script Manual on the support website (http: //support.universal-robots.com/). -

Page 147: Command: Event

13.20 Command: Event 13.20 Command: Event An event can be used to monitor an input signal, and perform some action or set a variable when that input signal goes high. For example, in the event that an output signal goes high, the event program can wait for 200ms and then set it back to low again. -

Page 148: Command: Thread

13.21 Command: Thread 13.21 Command: Thread A thread is a parallel process to the robot program. A thread can be used to control an external machine independently of the robot arm. A thread can communicate with the robot program with variables and output signals. II-70 Version 3.1 (rev. -

Page 149: Command: Pattern

13.22 Command: Pattern 13.22 Command: Pattern The Pattern command can be used to cycle through positions in the robot program. The pattern command corresponds to one position at each execution. A pattern can be given as one of four types. The first three, “Line”, “Square” or “Box” can be used for positions in a regular pattern. -

Page 150: Command: Force

13.23 Command: Force A “Box” pattern uses three vectors to define the side of the box. These three vectors are given as four points, where the first vector goes from point one to point two, the second vector goes from point two to point three, and the third vector goes from point three to point four. - Page 151 13.23 Command: Force a workpiece. Force mode also supports applying certain torques around predefined axes. Note that if no obstacles are met in an axis where a non-zero force is set, the robot arm will try to accelerate along/about that axis. Although an axis has been selected to be compliant, the robot program will still try to move the robot along/around that axis.

- Page 152 13.23 Command: Force • Simple: Only one axis will be compliant in force mode. The force along this axis is adjustable. The desired force will always be applied along the z-axis of the selected feature. However, for Line features, it is along their y-axis. •...

-

Page 153: Command: Pallet

13.24 Command: Pallet • Non-compliant: The limit is the maximum deviation from the program trajectory which is allowed before the robot protective stops. Units are [mm] and [deg]. Test force settings The on/off button, labeled “Test”, toggles the behavior of the Freedrive button on the back of the Teach Pendant from normal Freedrive mode to testing the force command. -

Page 154: Command: Seek

13.25 Command: Seek Programming a Pallet Operation The steps to go through are as follows; 1. Define the pattern. 2. Make a “PalletSequence” for picking up/placing at each single point. The se- quence describes what should be done at each pattern position. 3. - Page 155 13.25 Command: Seek When programming a seek operation for working on a stack, one must define s the starting point, d the stack direction and i the thickness of the items in the stack. On top of this, one must define the condition for when the next stack position is reached, and a special program sequence that will be performed at each of the stack positions.

- Page 156 13.25 Command: Seek Destacking When destacking, the robot arm moves from the starting position in the given direc- tion to search for the next item. The condition on the screen determines when the next item is reached. When the condition becomes satisfied, the robot remembers the po- sition and performs the special sequence.

- Page 157 13.25 Command: Seek Direction The direction is given by two positions, and is calculated as the position difference from the first positions TCP to the second positions TCP. Note: A direction does not consider the orientations of the points. Next Stacking Position Expression The robot arm moves along the direction vector while continuously evaluating whether the next stack position has been reached.

-

Page 158: Command: Start/Stop Conveyor Tracking

13.28 Graphics Tab 13.26 Command: Start/Stop Conveyor Tracking When using a conveyor, the robot can be configured to track the movement of the con- veyor. Two program nodes are available for tracking a conveyor, Start Conveyor Tracking and Stop Conveyor Tracking. When the Conveyor Tracking defined in the installation is configured correctly, a linear or circular conveyor can be tracked. - Page 159 13.28 Graphics Tab the current position of the robot arm, and the “shadow” of the robot arm shows how the robot arm intends to reach the waypoint selected in the left hand side of the screen. If the current position of the robot TCP comes close to a safety or trigger plane, or the orientation of robot tool is near the tool orientation boundary limit (see 15.11), a 3D representation of the proximate boundary limit is shown.

-

Page 160: Structure Tab

13.29 Structure Tab 13.29 Structure Tab The program structure tab gives an opportunity for inserting, moving, copying and removing the various types of commands. To insert new commands, perform the following steps: 1) Select an existing program command. 2) Select whether the new command should be inserted above or below the selected command. -

Page 161: Variables Tab

13.30 Variables Tab 13.30 Variables Tab The Variables tab shows the live values of variables in the running program, and keeps a list of variables and values between program runs. It only appears when it has information to display. The variables are ordered alphabetically by their names. The variable names on this screen are shown with at most 50 characters, and the values of the variables are shown with at most 500 characters. -

Page 162: Command: Variables Initialization

13.31 Command: Variables Initialization 13.31 Command: Variables Initialization This screen allows setting variable values before the program (and any threads) start executing. Select a variable from the list of variables by clicking on it, or by using the variable selector box. For a selected variable, an expression can be entered that will be used to set the variable value at program start. -

Page 163: Setup Screen

14 Setup Screen • Initialize Robot Goes to the initialization screen, see 10.4. • Language and Units Configure the language and units of measurements for the user interface, see 14.1. • Update Robot Upgrades the robot software to a newer version, see 14.2. •... -

Page 164: Language And Units

14.1 Language and Units 14.1 Language and Units Language and units used in PolyScope can be selected on this screen. The selected language will be used for the text visible on the various screens of PolyScope as well as in the embedded help. Tick off “English programming” to have the names of com- mands within robot programs written in English. -

Page 165: Update Robot

14.2 Update Robot 14.2 Update Robot Software updates can be installed from USB flash memory. Insert an USB memory stick and click Search to list its contents. To perform an update, select a file, click Update, and follow the on-screen instructions. WARNING: Always check your programs after a software upgrade. -

Page 166: Set Password

14.3 Set Password 14.3 Set Password Two passwords are supported. The first is an optional System password which pre- vents unauthorized modification of the setup of the robot. When the System password is set, programs can be loaded and executed without the password, but the user must enter the correct password in order to create or change programs. -

Page 167: Calibrate Screen

14.4 Calibrate Screen 14.4 Calibrate Screen Calibrating the touch screen. Follow the on-screen instructions to calibrate the touch screen. Preferably use a pointed non-metallic object, such as a closed pen. Patience and care help achieve a better result. Version 3.1 (rev. -

Page 168: Setup Network

14.5 Setup Network 14.5 Setup Network Panel for setting up the Ethernet network. An Ethernet connection is not necessary for the basic robot functions, and is disabled by default. II-90 Version 3.1 (rev. 17782) -

Page 169: Set Time

14.6 Set Time 14.6 Set Time Set the time and date for the system and configure the display formats for the clock. The clock is displayed at the top of the Run Program and Program Robot screens. Tap- ping on it will show the date briefly. The GUI needs to be restarted for changes to take effect. - Page 170 14.6 Set Time II-92 Version 3.1 (rev. 17782)

-

Page 171: Safety Configuration

15 Safety Configuration The robot is equipped with an advanced safety system. Depending on the particu- lar characteristics of its workspace, the settings for the safety system must be config- ured to guarantee the safety of all personnel and equipment around the robot. For details on the safety system, see the Hardware Installation Manual. -

Page 172: Changing The Safety Configuration

15.1 Changing the Safety Configuration ments of the robot arm, and of safety function settings for the configurable inputs and outputs. They are defined in the following subtabs of the safety screen: • The General Limits subtab defines the maximum force, power, speed and mo- mentum of the robot arm. -

Page 173: Safety Synchronization And Errors

15.2 Safety Synchronization and Errors 15.2 Safety Synchronization and Errors The state of the applied Safety configuration in comparison to what robot installation the GUI has loaded, is depicted by the shield icon next to the text Safety on the left side of the screen. -

Page 174: Safety Checksum

15.5 Safety Modes The Safety System receives the values from the input fields, and detects any violation of these values. The Robot Arm attempts to prevent any violations of the safety system and gives a protective stop by stopping the program execution when the limit minus the tolerance is reached. -

Page 175: Freedrive Mode

15.6 Freedrive Mode WARNING: Note that limits for joint position, TCP position and TCP orientation are disabled in Recovery mode, so take caution when moving the robot arm back within the limits. The subtabs of the Safety Configuration screen enable the user to define separate sets of safety limits for Normal and Reduced mode. -

Page 176: Apply

15.9 General Limits 15.8 Apply When unlocking the safety configuration, the robot arm will be powered off while changes are being made. The robot arm cannot be powered on until the changes have been applied or reverted, and a manual power on is performed from the initialization screen. - Page 177 15.9 General Limits Power: A limit for the maximum mechanical work produced by the robot on the envi- ronment, considering that the payload is part of the robot and not of the environ- ment. Speed: A limit for the maximum linear speed of the robot TCP. Momentum: A limit for the maximum momentum of the robot arm.

- Page 178 15.9 General Limits Here, each of the general limits, described in 15.9, can be modified independently of the others. This is done by tapping the corresponding text field and entering the new value. The highest accepted value for each of the limits is listed in the column titled The force limit can be set to a value between 100 N and 250 N, and the Maximum.

-

Page 179: Joint Limits

15.10 Joint Limits Switching to Basic Settings Pressing the Basic Settings... button switches back to the basic general limits screen and all general limits are reset to their Default preset. Should this cause any customized values to be lost, a popup dialog is shown to confirm the action. -

Page 180: Boundaries

15.11 Boundaries Note that the fields for limits in Reduced mode are disabled when neither a safety plane nor a configurable input is set to trigger it (see 15.11 and 15.12 for more details). Fur- thermore, the limits for Reduced mode must not be higher than their Normal mode counterparts. -

Page 181: Selecting A Boundary To Configure

15.11 Boundaries WARNING: Defining safety planes only limits the TCP and not the overall limit for the robot arm. This means that although a safety plane is speci- fied, it does not guarantee that other parts of the robot arm will obey this restriction. -

Page 182: Visualization

15.11 Boundaries Click the button to toggle the 3D visualization of the boundary limit on/off. If a boundary limit is active, the safety mode (see 15.11.3 and 15.11.4) is indicated by one of the following icons 15.11.2 3D visualization The 3D View displays the configured safety planes and the orientation boundary limit for the robot tool together with the current position of the robot arm. - Page 183 15.11 Boundaries Name The Name text field allows the user to assign a name to the selected safety plane. Change the name by tapping the text field and entering a new name. Copy Feature The position and normal of the safety plane is specified using a fea- ture (see 12.12) from the current robot installation.

- Page 184 15.11 Boundaries Safety mode The drop down menu on the right hand side of the Safety Plane Properties panel is used to choose the safety mode for the safety plane, with the following modes available: The safety plane is never active. Disabled When the safety system is in Normal mode, a Normal...

- Page 185 15.11 Boundaries mal or Reduced mode and the movements of the robot arm are limited by the respective limit set. By default, the safety system is in Normal mode. It transitions into Reduced mode when- ever one of the following situations occurs: a) The robot TCP is positioned beyond some Trigger Reduced mode plane, i.e.

-

Page 186: Tool Boundary Configuration

15.11 Boundaries 15.11.4 Tool Boundary configuration The Tool Boundary Properties panel at the bottom of the tab defines a limit on the orientation of robot tool composed of a desired tool orientation and a value for the maximum allowed deviation from this orientation. Deviation The Deviation text field shows the value for the maximum allowed de- viation of the orientation of the robot tool from the desired orientation. - Page 187 15.11 Boundaries feature has changed, this is indicated by a icon positioned over the feature selector. Click the button next to the selector to update the limit with the current orientation of the feature. The icon is also displayed if the selected feature has been deleted from the installation.

- Page 188 15.12 Safety I/O 15.12 Safety I/O This screen defines the Safety functions for configurable inputs and outputs (I/Os). The I/Os are divided between the inputs and outputs, and are paired up so that each function is providing a Category 3 and PLd I/O. Each Safety function can only control one pair of I/Os.

-

Page 189: Safety I/O

15.12 Safety I/O category 0 stop. The transition back to Normal mode happens in the same manner. Note that safety planes can also cause a transition to Reduced mode (see 15.11.3 for more details). • Safeguard Reset: If Safeguard Stop is wired in the safety I/Os, then Safeguard Reset is used to ensure the Safeguard Stopped state continues until a reset is triggered. - Page 190 15.12 Safety I/O II-112 Version 3.1 (rev. 17782)

-

Page 191: Glossary

Glossary Category 0 stop: Robot motion is stopped by immediate removal of power to the robot. It is an uncontrolled stop, where the robot can deviate from the programmed path as each joint brake as fast as possible. This protective stop is used if a safety- related limit is exceeded or in case of a fault in the safety-related parts of the control system. - Page 192 15.12 Safety I/O II-114 Version 3.1 (rev. 17782)

-

Page 193: Index

Index Version 3.1 (rev. 17782) II-115...

Need help?

Do you have a question about the UR5 and is the answer not in the manual?

Questions and answers