Table of Contents

Advertisement

Quick Links

Operating instructions

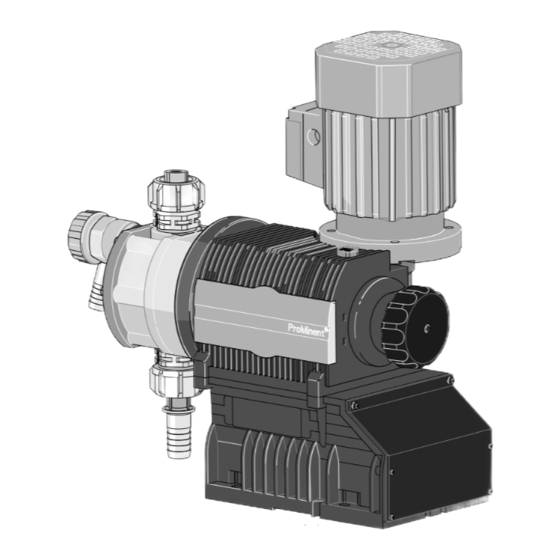

Diaphragm motor-driven metering pump

Sigma/ 1 Basic type S1Ba

EN

P_SI_0039

Target group: Minimally instructed personnel

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Part no. 985911

Original operating instructions (2006/42/EC)

Version: BA SI 106 06/22 EN

Advertisement

Table of Contents

Summary of Contents for ProMinent S1Ba 12017 PVT

- Page 1 Operating instructions Diaphragm motor-driven metering pump Sigma/ 1 Basic type S1Ba P_SI_0039 Target group: Minimally instructed personnel Please carefully read these operating instructions before use. · Do not discard. The operator shall be liable for any damage caused by installation or operating errors. The latest version of the operating instructions are available on our homepage.

- Page 2 Supplemental directives Supplementary information Read the following supplementary information in its entirety! Should you already know this information, you will benefit more from referring to the operating instructions. The following are highlighted separately in the document: Enumerated lists Fig. 1: Please read! Operating guidelines ð...

-

Page 3: Table Of Contents

Table of contents Table of contents Identity code..................5 Safety chapter................. 7 2.1 Markings and warning symbols..........7 2.2 Intended use................7 2.3 Personnel qualification............8 2.4 Safety information..............9 2.5 Isolating protective equipment..........11 2.6 Requirements if the motor is being installed independently.. 11 2.7 Safety information for ATEX designs........ - Page 4 Table of contents 15.5.3 Air humidity..............62 15.6 Installation height..............62 15.7 Motor data................62 15.8 Stroke actuator..............63 15.9 Stroke control drive............. 63 15.10 Diaphragm rupture sensor..........63 15.11 Stroke sensor "Sigma"............64 15.12 Relays................65 15.13 Sound pressure level............65 15.14 Supplementary information for modified versions.....

-

Page 5: Identity Code

Union nut and PVDF insert Union nut and SS insert Union nut and PVDF hose sleeve Union nut and SS hose sleeve Union nut and SS welding sleeve Aseptic clamp fitting DIN 11864-3 (Standard for hygienic design) Design with ProMinent-Logo (standard) without ProMinent logo... - Page 6 Identity code S1Ba Sigma 1 Basic type modified, order-specific design, see order paperwork for pump features Left liquid end Electric power supply Connection data - see motor nameplate no motor, with C 42 flange (NEMA) no motor, with B 5, size 56 (DIN) Degree of protection IP 55 (standard) Exe design ATEX-T3 ***...

-

Page 7: Safety Chapter

Safety chapter Safety chapter These operating instructions include notes and extracts from German reg‐ ulations relating to the operator's scope of responsibility. The notes and quotes do not in any way release the operator from his/her responsibility as operator. The notes and quotes are only intended to remind the oper‐ ator or make them aware of specific problem areas. -

Page 8: Personnel Qualification

Observe the general limitations with regard to viscosity limits, chem‐ ical resistance and density - see also the ProMinent Resistance List (in the Product Catalogue or at www.prominent.com)! All other uses or modifications are prohibited. -

Page 9: Safety Information

ProMinent or another authorised distribution partner. Service Service refers to service technicians who have received certified training and have been authorised by ProMinent to work on the system. 2.4 Safety information Safety information WARNING! - Page 10 – Take into account the resistance of the wetted mate‐ rials and the ProMinent Resistance List when selecting the feed chemical - see the ProMinent Product Catalogue or visit ProMinent. WARNING! Danger of injury to personnel and material damage The pump must only be opened at those points required to be opened by these operating instructions.

-

Page 11: Isolating Protective Equipment

Safety chapter CAUTION! Danger from incorrectly operated or inadequately main‐ tained pumps Danger can arise from a poorly accessible pump due to incorrect operation and poor maintenance. – Ensure that the pump is accessible at all times. – Adhere to the maintenance intervals. Information in the event of an emergency In the event of an electrical accident, disconnect the mains cable from the mains/power supply or press the emergency cut-off switch fitted on the... -

Page 12: Safety Information For Atex Designs

Safety chapter As you have converted an "incomplete machine" into a complete machine, you must perform a conformity assessment, risk assess‐ ment, create a Declaration of Conformity, fit a company name‐ plate, ..Complete the pump documentation / operating instructions. Sound pressure level Sound pressure level LpA <... -

Page 13: Atex Safety Information

Safety chapter completed a relevant course of study or have a comparable technical qualification or another technical qualification combined with long-term experience of safety technology. The person must have knowledge of the relevant body of standards and regulations and have worked in the field for at least one year. The person needs to have opportunities for an exchange of experiences. - Page 14 Safety chapter Ignition hazard Protective measures to be observed by the customer Excessive surface pressure Limitation of the maximum temperature of the feed chem‐ ical Too low ambient temperature Limitation of the minimum ambient temperature Pump running hot The customer must monitor and maintain the pump in accordance with the “Maintenance”...

- Page 15 Safety chapter Ignition hazard Protective measures to be observed by the customer Ignition hazard with bought-in motor components Refer to the documentation for the motor. Comply with the monitoring intervals. The insulation resistance needs to be greater then 5 MOhm. Provide a time-delay residual current device.

- Page 16 Safety chapter WARNING! ATEX pump and flammable media The ignition temperature is reduced significantly below the ignition temperature at atmospheric pressure due to compression with the discharge stroke of the possibly ignitable vapour-air mixture. – Only use pumps with electrically conductive dosing heads.

-

Page 17: Potential Equalisation Lines And Other Features

Safety chapter WARNING! The following applies in areas at risk from explosion: – Note the details of the type examination certificate PTB 00 ATEX 2048 X for the Namur sensor NJ1.5-8GM-N as well. WARNING! ATEX pumps in areas at risk from explosion –... -

Page 18: Atex Features

WARNING! Stop the pump immediately in the event of any anoma‐ lies when inspecting the pump and rectify them immedi‐ ately. ProMinent Service may be needed if required. 2.7.5 ATEX features Maintenance Interval Maintenance work After 18,000 operating hours or 23,500 oper‐... -

Page 19: Safety Equipment

Safety chapter Power end and motor - ATEX Data Value Unit Ambient temperature during operation: -10 ... +40 °C TTT - ATEX liquid end Data Value Unit Max. temperature, long-term at max. oper‐ 50 °C ating pressure Minimum temperature. -10 °C SST - ATEX liquid end Data Value Unit... -

Page 20: Explanation Of The Atex Label

Safety chapter Select a suitable motor - the motor must correspond to the data for one of the motors from the “Motor data” table - see “Technical data” chapter. Have technical personnel fit the motor correctly on the flange. Observe the coupling operating instructions! With a claw coupling: Fix the claw on the motor shaft at the correct height –... - Page 21 Safety chapter Explanation of the pump’s ATEX labelling Sigma S1Ba Suffix X Special conditions - refer to the Declarations of Conformity and EC-type examination certificates WARNING! Example of EX-designation: Where may I use the ATEX version of the Sigma S1Ba? The pump designation is: "...

- Page 22 Safety chapter WARNING! Example 2 - EX-designation: Where may I use the ATEX version of the Sigma S1Ba? The pump designation is " ... II 2G Ex h IIC T4 Gb X". The pump label corresponds to “Unit group” II: the pump may only be used in overground production systems, which are not at risk from firedamp.

-

Page 23: Storage, Transport And Unpacking

The "Decontamination Declaration Form" can be found at www.prominent.com. CAUTION! Danger of material damage The device can be damaged by incorrect or improper storage or transportation! –... -

Page 24: Overview Of Equipment And Control Elements

Overview of equipment and control elements Overview of equipment and control elements P_SI_0017_SW Fig. 3: Overview of equipment and control elements S1Ba Drive motor Drive unit Stroke length adjustment knob Liquid end with relief valve Diaphragm rupture sensor P_SI_0088_SW_2 Fig. 4: Sigma control elements Relief valve Diaphragm rupture sensor (visual) - Page 25 Overview of equipment and control elements P_SI_0096_SW Fig. 5: Adjusting the stroke length 100% = 2 rotations 50% = 1 rotation 1% = 1 scale mark on stroke adjustment dial PG11 P_SI_0036 Fig. 6: Front cover for version with pacing relay Pacing relay cable Supply voltage cable for pacing relay PCB...

-

Page 26: Functional Description

Functional description Functional description 5.1 Pump The metering pump is an oscillating diaphragm pump, the stroke length of which is adjustable. An electric motor drives the pump. 5.2 Liquid end The diaphragm (2) hermetically shuts off the pump volume of the dosing head (4) towards the outside. -

Page 27: Multi-Layer Safety Diaphragm

Functional description P_SI_0019 Fig. 8: Integral relief valve Spring, large Ball Rotary dial Spring, small Hose connection 5.4 Multi-layer safety diaphragm With visual diaphragm rupture sensors, in the event of a diaphragm rup‐ ture, the lowered red cylinder (6) springs forward beneath the transparent cover (7) so that it then becomes clearly visible - see Fig. -

Page 28: Assembly

Assembly Assembly Compare the dimensions on the dimensional drawing with those of the pump. 6.1 Assembly of the motor - with designs without motor Select a suitable motor. The motor must correspond to the data for one of the motors from the "Motor data" table - see Chapter "Tech‐ nical Data". -

Page 29: Base

Assembly Model size Motor flange B 5/140 * (26) Dimensions in mm - unless otherwise indicated. * Motor is fitted directly onto the motor flange without intermediate flange and claw coupling. 6.2 Base The pump can break through the base or slide off it Ensure that the base is horizontal, flat and permanently load-bearing. -

Page 30: Fastening

Assembly 6.4 Fastening Liquid end alignment Dosing rate too low. The valves of the liquid end cannot close correctly if the valves of the liquid end are not upright. Ensure that the discharge valve is upright. Vibrations can disturb the liquid end valves. Secure the metering pump so that no vibrations can occur. -

Page 31: Installation, Hydraulic

Installation, hydraulic Installation, hydraulic Disregarding the technical data during installation can lead to personal injury or damage to property. Observe the technical data - refer to the Chapter "Technical data" and, where applicable, the operating instructions for the accessories. WARNING! ATEX pumps in areas at risk from explosion –... - Page 32 The pump is supplied with PTFE moulded composite seals with a flare, which are used for the pump connectors, and which seal the connectors between grooved pump valves and ProMinent grooved inserts - see Fig. 15. Use an elastomer flat seal in the event that an unflared insert is used (e.g.

- Page 33 Installation, hydraulic CAUTION! Danger due to incorrect use of the integral relief valve The integral relief valve can only protect the motor and the gear, and then only against impermissible positive pressure that is caused by the metering pump itself. It cannot protect the system against positive pressure.

-

Page 34: Basic Installation Notes

Installation, hydraulic 7.1 Basic installation notes Safety information Rupturing hydraulic components Hydraulic components can rupture if the maximum permissible oper‐ ating pressure of the hydraulic parts is exceeded. Never allow the metering pump to run against a closed shut-off device. With metering pumps without integral relief valve: Install a relief valve in the pressure line. -

Page 35: Installation, Electrical

Never change the “Motor voltage” and “Cycle frequency” parameters with motor designs with integral frequency converter. The parameters on delivery from ProMinent do not correspond to the motor manufacturer’s factory settings. If other parameters are to be changed, then we recommend speaking to... - Page 36 Installation, electrical What requires electrical installation?: Motor External fan (optional) Stroke control drive (optional) Stroke adjusting drive (optional) Diaphragm rupture sensor (optional) Stroke sensor (optional) Pacing relay (option) Frequency converter (optional) Earthing wires (to be provided on site) Potential equalisation line (to be provided on site, prescribed in the area at risk from explosion) Motor ATEX pumps in areas at risk from explosion...

- Page 37 For further information on the motor with identity – code specification "S", refer to our website www.prominent.com. Motor data sheets can be requested for all other motors. With motors other than those with identity code –...

- Page 38 Installation, electrical Stroke sensor (identity code specification "Stroke sensor": 3) Connect the stroke sensor to a suitable monitoring device according to the technical data provided with the monitoring device and that of the stroke sensor - see chapter "Technical data". Make sure that the monitoring/feed equipment installed by the cus‐...

- Page 39 Installation, electrical Earthing lines Connect the electrical components of the entire installation supplied cleanly and permanently to an electrically clean earthing point, e.g. with an earthing bar on site - see earthing diagrams in the appendix. Potential equalisation lines, required in The entire installation supplied is provided ex works with the necessary areas at risk from explosion potential equalisation lines.

-

Page 40: Start Up

Start up Start up Safety information WARNING! ATEX pumps in areas at risk from explosion – Make sure that a suitably competent person checks whether the appropriate installation information from the "Installation" chapter has been implemented cor‐ rectly. – Make sure that a "recognised competent person" checks the electrical installation and in particular the intrinsically safe power circuits. - Page 41 Start up Diaphragm rupture sensor Unnoticed diaphragm rupture If the pump has been ordered with an electric diaphragm rupture sensor, then the diaphragm rupture sensor must also be installed. Screw the enclosed diaphragm rupture sensor into the liquid end. Unnoticed diaphragm rupture From approx.

- Page 42 Start up Turn the rotary dial on the integral relief valve in a clockwise direc‐ tion up to the "close" stop. ð The pump can be started. When operating the integral relief valve close to the opening pressure, a minimal overflow into the overflow line can occur.

-

Page 43: During Operation

During operation During operation WARNING! Personnel injury and material damage may occur During use all units, protective equipment, additional devices must be fitted, operational and tightly closed. WARNING! Sparking caused by dry running If the bearings in the power end run dry, sparks can be formed. -

Page 44: Maintenance

Maintenance Maintenance 11.1 Safety information ATEX pumps in areas at risk from explosion Carry out a general check to ensure that the system is working prop‐ erly, particularly the power end and bearings, by regular monitoring (for leaks, noises, temperatures, smell ...). Do not allow the pump to run hot due to a lack of oil. -

Page 45: Inspection, Daily

WARNING! In the area at risk from explosion: Stop the pump safely and as quickly as possible and rectify these anomalies. ProMinent Service may be needed if required. 11.3 Standard liquid ends Under heavy loading (e.g. continuous operation) shorter maintenance intervals are recommended than those given. - Page 46 Maintenance * With normal loading (approx. 30% of continuous operation). Under heavy loading (e.g. continuous operation, aggressive feed chemi‐ cals etc.): shorter intervals. Check the condition of the metering dia‐ The diaphragm is a wearing part, the service life of which is dependent on phragm the following parameters: System back pressure...

-

Page 47: Repair

Only use original spare parts. Use the correct spare parts kits. If in doubt, refer to the exploded views and order information in the appendix or on our website www.prominent.com. Only with "Physiologically safe" design: WARNING! Product can be dangerously contaminated Only use the spare parts from the "Physiologically safe"... - Page 48 Repair CAUTION! Warning of feed chemical spraying around PTFE seals, which have already been used / com‐ pressed, can no longer reliably seal a hydraulic connec‐ tion. – New, unused PTFE seals must always be used. P_SI_0013_SW Fig. 21: Ball valve, simple, cross-section Flat seal Valve body Valve ball...

-

Page 49: Replacing The Diaphragm

Only use original spare parts. Use the correct spare parts kits. If in doubt, refer to the exploded views and order information in the appendix or on our website www.prominent.com. Personnel: Technical personnel Requirements: Put in place protective measures, if necessary. - Page 50 Should this not work, remove dirt or swarf from the thread and screw the diaphragm correctly onto the drive axle this time. ð If this is still unsuccessful, contact ProMinent-ProMaqua Service. Place the dosing head with the screws onto the diaphragm - the suction connector should be pointing downwards when the pump is subsequently installed.

- Page 51 Repair Optical diaphragm rupture sensor Unscrew the transparent cover from the diaphragm rupture sensor. Press the red cylinder into the diaphragm rupture sensor until the cylinder engages. Press the piston on the other side of the diaphragm rupture sensor into the dosing head (approximately 4 mm) using a blunt, smooth object until it triggers.

- Page 52 Repair P_SI_0038 Fig. 24: Cross-section through the liquid end Suction valve Diaphragm Discharge valve Dosing head Backplate 13 Safety diaphragm Tightening torques Data Value Unit Tightening torques for dosing head 4.5 ... 5.0 Nm screws:...

-

Page 53: Troubleshooting

Troubleshooting Troubleshooting Before commencing all work WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Please ensure when handling hazardous substances that you have read the latest safety data sheets provided by the manufacture of the hazardous substance. The actions required are described in the safety data sheet. - Page 54 All other faults. Other causes. Call ProMinent Service. * If necessary use the cross-section drawing of the integral relief valve in the "Functional Description" chapter. WARNING! Warning of eye injuries When opening the relief valve, a spring under high ten‐...

- Page 55 Troubleshooting Leaking feed chemical When dosing combustible feed chemicals or in areas at risk from explosion, under no circumstances must the second diaphragm also rupture. If the diaphragm rupture sensor triggers, stop the pump safely and as quickly as possible. Only restart the pump once a new multi-layer safety diaphragm is fitted.

-

Page 56: Decommissioning

Decommissioning Decommissioning Before commencing all work WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Please ensure when handling hazardous substances that you have read the latest safety data sheets provided by the manufacture of the hazardous substance. The actions required are described in the safety data sheet. - Page 57 Decommissioning (Temporary) decommissioning Disconnect the pump from the mains/power supply. Depressurise and vent the hydraulic system around the pump. Drain the liquid end by turning the pump upside down and allowing the feed chemical to run out. Flush the liquid end with a suitable medium, observing the material safety data sheet.

-

Page 58: Technical Data

Technical data Technical data Only with "M - modified" design: WARNING! Risk of personal injuries Please observe the ”Supplement for modified version“ at the end of the chapter! It replaces and supplements the technical data! -

Page 59: Performance Data

Technical data 15.1 Performance data S1Ba with 50 Hz operation Type Minimum pump capacity at maximum Maximum Suction lift Permissible Connector back pressure stroke rate priming pres‐ size sure, suction side ml/stroke Strokes/min m water G-DN column 12017 PVT 3/4 male - 12017 SST 3/4 male - 12035 PVT... - Page 60 Technical data S1Ba with 60 Hz operation Type Minimum pump capacity at maximum back pres‐ Maximum Suction lift Permissible Connector sure stroke priming size rate pressure, suction side Strokes/mi m water G-DN column 12017 PVT 3/4 male - 12017 SST 3/4 male - 12035 PVT 11.1...

-

Page 61: Viscosity

Technical data * - when installed correctly, under constant conditions, at least 30% stroke length and water at 20 °C 15.2 Viscosity Tab. 5: The liquid ends are suitable for the following viscosity ranges: Design Stroke rate, max. Viscosity Strokes/min mPas Standard 0 ... -

Page 62: Media Temperatures

Technical data 15.5.2 Media temperatures Liquid end PVT, PVF Data Value Unit Max. temperature, long-term at max. oper‐ 65 °C ating pressure Max. temperature, for 15 minutes at max. 100 °C 2 bar Minimum temperature. -10 °C TTT liquid end Data Value Unit Max. -

Page 63: Stroke Actuator

For further information on the motor with identity – code specification "S", refer to our website www.prominent.com. Motor data sheets can be requested for all other motors. – With motors other than those with identity code specifications "S", "M"... -

Page 64: Stroke Sensor "Sigma

Technical data Tab. 6: Contact loading, max. a) Contact (standard with identity code specification "Displacement mechanism“: with voltage Maximum current 30 V DC The diaphragm rupture sensor is an N/C. For safety reasons we recommend connection to protective low voltage, e.g. in accordance with EN 60335-1 (SELV). The cable can be connected as required. -

Page 65: Relays

Technical data b) Namur sensor (identity code specifica‐ Install the sensor in accordance with the chapter "Installation, electrical". tion "Stroke sensor": 3) Refer to its documentation. Sensor name: NJ1.5-8GM-N. 5–25 V DC, in accordance with Namur or DIN 60947-5-6, potential-free design. -

Page 66: Diagrams For Adjusting The Capacity

Diagrams for adjusting the capacity Diagrams for adjusting the capacity S1Ba (50 Hz) S1Ba (50 Hz) C [l/h] C [l/h] 70.0 60.0 10050 60.0 07065 50.0 12035 * 10044 12017 * 50.0 10022 40.0 40.0 30.0 30.0 20.0 20.0 10.0 10.0 S [%] S [%]... - Page 67 Diagrams for adjusting the capacity S1Ba (60Hz) S1Ba (60Hz) C [l/h] C [l/h] 90.0 70.0 80.0 60.0 10050 07065 70.0 10044 12035 * 10022 50.0 60.0 12017 * 40.0 50.0 40.0 30.0 30.0 20.0 20.0 10.0 10.0 S [%] S [%] C [l/h] C [l/h] 90.0...

-

Page 68: Dimensional Drawings

Dimensional drawings Dimensional drawings Compare the dimensions on the dimension sheet – and pump. All dimensions are in mm. – Dimensional drawing for Sigma/ 1, S1Ba max.40 P_SI_0033 Fig. 27: Dimensional drawing of Sigma/ 1, S1Ba - Drawing is not strictly binding. Hose nozzle relief valve d16 S with thread DIN ISO 228-G3/4 A Tab. - Page 69 Dimensional drawings Type Connector Sigma 07042, 04085, DN15 04120 PVT / TTT male Sigma 07042, 04085, DN15 04120 PVT-relief valve- male A/sv-a Sigma 07042, 04085, DN15 04120 SST male Sigma 07042, 04085, DN15 04120 SST-relief valve- male A/sv-a Tab. 8: Dimensions in mm Standard motor Motor, controllable EExe motor...

- Page 70 Dimensional drawings Dimensional drawing of Sigma/ 1, S1Ba, rotated P_SI_0155_SW Fig. 28: Dimensional drawing of Sigma/ 1, S1Ba, rotated - Drawing is not strictly binding. Hose nozzle relief valve d16 S with thread DIN ISO 228-G3/4 A Tab. 9: Dimensions in mm Type Connector Sigma 12017,12035,...

- Page 71 Dimensional drawings Type Connector Sigma 07042, 04085, DN15 04120 SST male Sigma 07042, 04085, DN15 04120 SST-relief valve- male A/sv-a Tab. 10: Dimensions in mm Standard motor Motor, controllable EExe motor Motor with fre‐ 1-phase motor quency converter Dimensional drawing of Sigma/ 1, S1Ba, motor flange, actuator P_SI_0034_2 61_01-101_00_55-73...

- Page 72 Dimensional drawings Dimensional drawing of Sigma 1, S1Ba with EExde motor P_SI_0156_SW Fig. 30: Dimensional drawing of Sigma/ 1, S1Ba, with EExde motor - Drawing is not strictly binding. Tab. 12: Dimensions in mm Type Connector Sigma 12017,12035, DN10 G 3/4 10050 PVT / TTT male Sigma 12017,12035,...

- Page 73 Dimensional drawings Type Connector Sigma 07042, 04084, DN15 04120 SST male Sigma 07042, 04084, DN15 04120 SST-relief valve- male A/sv-a...

-

Page 74: Potential Equalisation Drawings For Sigma Basic Type

Potential equalisation drawings for Sigma Basic Type Potential equalisation drawings for Sigma Basic Type P_SI_0169_SW Fig. 31: Potential equalisation drawing for Sigma S1Ba Potential equalisation of motor Potential equalisation of motor flange Potential equalisation of liquid end Positions 1, 2 and 3 must be connected to a protective earth cable. -

Page 75: Motor Data Sheet Standard Motor

This information is supplied without liability. Les données techniques correspondent au descriptif du fabricant des moteurs. Les données techniques des moteurs similaires chez d’ autres fabricants varient très peu. Données sont d’ ordre général. ProMinent Dosiertechnik GmbH . 69123 Heidelberg . Germany No. MD-1018432, 1018433, 1018455 Datum/Date April 2011... -

Page 76: Exploded Drawings Sigma/ 1

Exploded drawings Sigma/ 1 Exploded drawings Sigma/ 1 Liquid end for Sigma/ 1 050 and 065 PVT P_SI_0024 Fig. 32: Liquid end for Sigma/ 1 050 and 065 PVT Pos. Description Type 12035, 12017, Type 07065, 10044, 10050 10022 Spring Ball Ball seat Diaphragm rupture sensor, optical... - Page 77 Exploded drawings Sigma/ 1 Liquid end for Sigma/ 1 120 PVT P_SI_0024 Fig. 33: Liquid end for Sigma/ 1 120 PVT Pos. Description Type 04084, 04120, 07042 Spring Ball Ball seat Diaphragm rupture sensor, optical 1033323 Valve 792517* Multi-layer diaphragm 1035828* * The items listed are included in the spare parts kit.

- Page 78 Exploded drawings Sigma/ 1 Sigma/ 1 PVT relief valve-A P_SI_0086_SW Fig. 34: Sigma/ 1 PVT relief valve-A Pos. Description Type 12035, Type 10050, Type 07065, Type 04084, 12017 10044, 10022 07042 04120 Relief valve, complete 12 bar PVA 1018572 Relief valve, complete 10 bar PVA 1018947 Relief valve, complete 7 bar PVA 740811...

- Page 79 Exploded drawings Sigma/ 1 Liquid end for Sigma/ 1 050 and 065 TTT P_SI_0175_SW Fig. 35: Liquid end for Sigma/ 1 050 and 065 TTT Pos. Description Type 12035, 12017, Type 07065, 10044, 10050 10022 Spring Ball Ball seat Diaphragm rupture sensor, optical 1033323 1033323 Valve...

- Page 80 Exploded drawings Sigma/ 1 Liquid end for Sigma/ 1 120 TTT P_SI_0175_SW Fig. 36: Liquid end for Sigma/ 1 120 TTT Pos. Description Type 04084, 04120, 07042 Spring Ball Ball seat Diaphragm rupture sensor, optical 1033323 Valve 809403 Multi-layer diaphragm 1035828* * The items listed are included in the spare parts kit.

- Page 81 Exploded drawings Sigma/ 1 Liquid end for Sigma/ 1 050 and 065 SST P_SI_0025_SW Fig. 37: Liquid end for Sigma/ 1 050 and 065 SST Pos. Description Type 12035, 12017, Type 07065, 10044, 10050 10022 Spring Ball Ball seat Diaphragm rupture sensor, optical 1033323 1033323 Valve...

- Page 82 Exploded drawings Sigma/ 1 Liquid end for Sigma/ 1 120 SST P_SI_0025_SW Fig. 38: Liquid end for Sigma/ 1 120 SST Pos. Description Type 04084, 04120, 07042 Spring Ball Ball seat Diaphragm rupture sensor, optical 1033323 Valve 809404 Multi-layer diaphragm 1035828* * The items listed are included in the spare parts kit.

- Page 83 Exploded drawings Sigma/ 1 Sigma/ 1 SST relief valve-A P_SI_0087 Fig. 39: Sigma/ 1 SST relief valve-A Pos. Description Type 12035, Type 10050, Type 07065, Type 04084, 12017 10044, 10022 07042 04120 Relief valve, complete 12 bar SSA 1005625 Relief valve, complete 10 bar SSA 1018573 Relief valve, complete 7 bar SSA 740815...

- Page 84 Exploded drawings Sigma/ 1 Pos. Type Quantity Article Order no. 1.000 Liquid end Sigma 1 - 50 SSTH 1036541 1.000 Liquid end Sigma 1 - 65 SSTH 1036542 1.000 Liquid end Sigma 1 - 120 SSTH 1036543 1.000 Hyg.dos. head, complete 96.0 x 42.0 LK80 1035627 1.000 Hyg.

-

Page 85: Wear Parts For Sigma/ 1

Wear parts for Sigma/ 1 Wear parts for Sigma/ 1 21.1 Standard Tab. 13: Spare parts kits types 12017, 12035, 10050 Liquid ends Wetted materials Remark Order no. FM 50 - DN10 1035964 FM 50 - DN10 with 2 valves, assembled 1077570 FM 50 - DN10 1035966... -

Page 86: Physiological Safety

Wear parts for Sigma/ 1 21.2 Physiological safety Spare parts kits Tab. 16: Scope of delivery with PVT material version 1 x diaphragm, 2 x valve balls, 1 x suction valve complete, 1 x discharge valve complete 1 x elastomer sealing set (EPDM) 2 x ball seat housings, 2 x ball seat discs, 4 x composite seals 1x sealing washer (for bleed valve or relief valve) Tab. - Page 87 Wear parts for Sigma/ 1 Wetted materials – "Physiologically safety with regard to wetted materials" design Material version Liquid end Suction / pressure Seals* / ball seat Balls Integrated bleed connector valve or relief valve PVDF PVDF PTFE / PVDF Ceramic PVDF / EPDM Stainless steel...

-

Page 88: Declaration Of Conformity For Machinery

Appendix I, No. 1.5.1 of the Machinery Directive 2006/42/EC EMC Directive (2014/30/EU) Harmonised standards applied, in EN ISO 12100:2010 particular: EN 809:1998 + A1:2009 + AC:2010 EN 61000-6-2:2005 + AC:2005 EN 61000-6-4:2007 + A1:2011 + AC:2012 Date: 20.04.2016 You can download the Declaration of Conformity at www.prominent.com. -

Page 89: Declaration Of Incorporation For Machinery

Compliance with the protection targets of the Low Voltage Directive 2014/35/EU according to Appendix I, No. 1.5.1 of the Machinery Directive 2006/42/EC Harmonised standards applied, in EN ISO 12100:2010 particular: EN 809:1998 + A1:2009 + AC:2010 Date: 20.04.2016 You can download the Declaration of Conformity at www.prominent.com. -

Page 90: Declaration Of Conformity For Machinery Atex

* With regard to “Special conditions” - refer also to the “Safety chapter” - “Safety information for ATEX designs” - “Special conditions for ATEX”. You can download the Declaration of Conformity at www.prominent.com. The Declarations of Conformity, the EC type-examination certificates and the operating instructions for the individual components are also enclosed with the pump. -

Page 91: Declaration Of Conformity For Atex Machinery

* “Special conditions” - also refer to the chapter entitled “Special conditions for ATEX”. You can download the Declaration of Conformity at www.prominent.com. The Declarations of Conformity, the EC type-examination certificates and the operating instructions for the individual components are also enclosed... -

Page 92: Index

Index Index Identity code versions for areas at risk from explosion ........90, 91 Actuator . - Page 93 Index Spare parts ......65 Special conditions ......12 Start up .

- Page 96 ProMinent GmbH Im Schuhmachergewann 5-11 69123 Heidelberg Germany Telephone: +49 6221 842-0 Fax: +49 6221 842-419 Email: info@prominent.com Internet: www.prominent.com 985911, 7, en_GB © 2022...

Need help?

Do you have a question about the S1Ba 12017 PVT and is the answer not in the manual?

Questions and answers