Table of Contents

Advertisement

Quick Links

General Operating Instructions

®

ProMinent

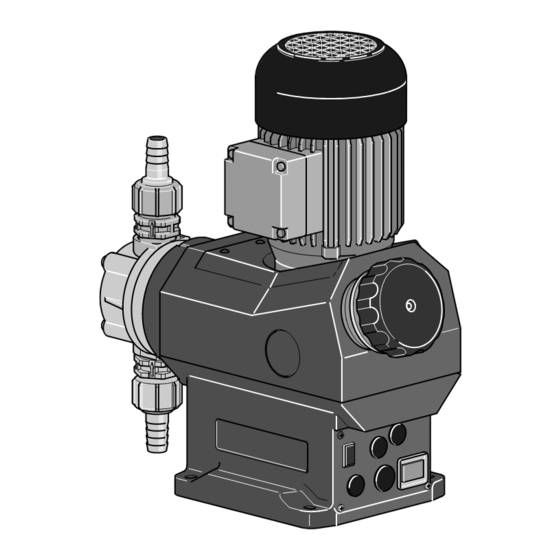

Motor-Driven Metering Pumps

and Hydraulic Accessories

Sigma

Vario

alpha

Hydro

Meta

Makro/ 5

Makro TZ

Two sets of operating instructions are necessary to ensure safe operation of the metering pumps corresponding to their

intended purpose: The product-specific operating instructions (e.g. for Sigma) and the general operating instructions

®

for ProMinent

motor-driven metering pumps.

Both are only applicable in conjunction with each other.

Please completely read through these operating instructions first! Do not discard!

The warranty shall be invalidated by damage caused by operating errors!

Part No. 987702

ProMinent Dosiertechnik GmbH

69123 Heidelberg

Germany

BA MOZ 013 07/03 GB

•

•

Advertisement

Table of Contents

Need help?

Do you have a question about the alpha and is the answer not in the manual?

Questions and answers