Raven RS1 Installation Manual

With direcsteer

Hide thumbs

Also See for RS1:

- Calibration and operation manual (125 pages) ,

- Calibration & operation manual (100 pages) ,

- Guidance and steering installation manual (48 pages)

Table of Contents

Advertisement

Quick Links

Raven RS1™/SC1™ with DirecSteer

Installation Manual for Case IH

MXM, Farmall, JX U, TM, T50##, TL,

MXM 120, MXM 130, MXM 140, MXM

l

155, MXM 175, MXM 190

Farmall: 85U, 95U, 105U

l

JX 80U, JX 90U, JX 100U

l

JX 1080U, JX 1090U, JX 1110U

l

P/N 016-5030-301-A Jun 2023 E45532

Copyright © 2023

TL A, TS

Case IH

New Holland

TM 120, TM 130, TM 140, TM

l

155, TM 175, TM 190

T5040, T5050, T5060, T5070

l

TL70, TL80, TL90, TL100

l

TL70A, TL80A, TL90A, TL100A

l

TS90, TS100, TS110, TS115

l

Advertisement

Table of Contents

Summary of Contents for Raven RS1

- Page 1 Raven RS1™/SC1™ with DirecSteer Installation Manual for Case IH MXM, Farmall, JX U, TM, T50##, TL, TL A, TS Case IH New Holland TM 120, TM 130, TM 140, TM MXM 120, MXM 130, MXM 140, MXM 155, TM 175, TM 190...

- Page 2 Raven Industries shall not be held responsible for any modifications or repairs made outside our facilities, nor damages resulting from inadequate maintenance of this system.

-

Page 3: Table Of Contents

Table of Contents Disclaimer Table of Contents Important Safety Information Field Computers, Displays, and Control Consoles Hydraulic Safety Electrical Safety Touch Screen Recommendations and Best Practices Point of Reference Preparing for Install Aerials and Signal Interference Hose Routing Harness Routing Introduction Kit Components Updates... - Page 4 Install the DirecSteer System Components Mount the (Optional) Foot Switch Install the Field Computer Install RS1™ with DirecSteer Install the RS1™ Unit Insert a SIM Card in the RS1™ Assemble the Mounting Brackets Prepare the Roof Connect RS1™ Cabling to DirecSteer Best Mounting Practices Route the RS1™...

- Page 5 How can I get service? What will Raven Industries do? What is not covered by this warranty? Extended Warranty What does this warranty cover? Do I need to register my product to qualify for the extended warranty? Where can I register my product for the extended warranty?

-

Page 7: Important Safety Information

Review equipment operation with your local dealer and follow all safety information presented on this site. Contact a local Raven dealer for assistance with any portion of the installation, service, or operation of Raven equipment. Follow all safety labels affixed to system components. Be sure to keep safety labels in good condition and replace any missing or damaged labels. -

Page 8: Field Computers, Displays, And Control Consoles

The operator is responsible for disabling the system when a safe working dis- tance has diminished. Do not operate the implement on any public road with this Raven system enabled. Maintain control of the vehicle at all times during operation. For example, Remain in the operator seat while the system is enabled and disable auto- mated Raven controls before exiting the operator seat. -

Page 9: Electrical Safety

Electrical Safety Always verify that power leads are connected to the correct polarity as marked. Revers- ing the power leads could cause severe damage to the Raven system or other com- ponents. To prevent personal injury or fire, replace defective or blown fuses with only fuses of the same type and amperage. -

Page 10: Touch Screen

Chapter 1 Touch Screen Only touch the touch-screen with your finger or by using a special touch-screen stylus or pen. Operating the touch-screen with sharp objects may cause permanent damage to the screen. Only clean the screen using a damp cloth. Never use caustic or other aggressive sub- stances. -

Page 11: Recommendations And Best Practices

Important Safety Information Recommendations and Best Practices Point of Reference Instructions provided generally assume you are standing behind the machine facing toward the cab. More specific orientation may be provided as necessary to complete procedures. Preparing for Install Ensure there are no issues with the machine hydraulic system (e.g., pump issues, faulty hydraulic motors, fine metal deposits in the hydraulic hoses, etc.). -

Page 12: Hose Routing

The word “hose” is used to describe any flexible, fluid carrying components. Use the following guidelines and recommendations when connecting and routing hoses while installing or maintaining this Raven system: Leave protective caps/covers over hose ends until connecting the end into the... -

Page 13: Harness Routing

The word “harness” is used to describe any electrical cables and leads, both bundled and unbundled. Use the following guidelines and recommendations when connecting and routing harnesses while installing or maintaining this Raven system: Leave protective caps/covers over harness connectors until needed to avoid dirt and... - Page 14 Chapter 1 Secure the harness to the frame or solid structural members at least every 12 in [30 cm]. Follow existing harness runs already routed on the implement as much as possible. Proper harness routing should: Secure harnessing and prevent the harness from hanging below the implement. Provide sufficient clearance from moving components and operational zones around shafts;...

- Page 15 Important Safety Information Inspect electrical components and connectors for corrosion, damaged pins or hous- ings, etc. Repair or replace components or harnessing as necessary. Ensure connectors are kept clean and dry. Apply dielectric grease to the sealing sur- faces of all connections exposed to moisture, dirt, debris, and other contaminates. Repair or replace harnessing as necessary.

- Page 16 Chapter 1...

-

Page 17: Introduction

Introduction NOTICE Depending upon the make and model of the machine, the steps required to complete the installation of the RS1™/SC1™ with DirecSteer auto-steer system may differ from the instructions provided in the following procedure. The DirecSteer steering system is designed to provide automated steering of agricultural equipment using an electric drive unit mounted to the steering column. - Page 18 Chapter 2 DirecSteer Steering Installation Kit for Case IH FARMALL/LUXXUM/MXM/JXU and New Hol- land T4/T5/T5000/TL/TM/TS/T6 (BRA) (P/N 117-5030-301 Rev. B) DirecSteer Steering Installation Kit with SC1™ and w/o IBBC (P/N 117-5030-310 Rev. A)

- Page 19 Introduction DirecSteer Steering Installation Kit with SC1™ and IBBC (P/N 117-5030-311 Rev. A) DirecSteer Steering Installation Kit with RS1™ and w/o IBBC (P/N 117-5030-312 Rev. A)

-

Page 20: Updates

DirecSteer Motor and Anti-Rotation Bracket Kit (P/N 117-5030-314 Rev. B) Updates Software and manual updates are available on the Raven Applied Technology website. https://portal.ravenprecision.com Sign up for email alerts and you will be automatically notified when updates for Raven products are available. - Page 21 Any comments or feedback (please include URLs, chapter, or page numbers as applicable). Let us know how long have you been using this or other Raven products. We will not share your email or any information you provide with anyone else. Your feedback is valued and extremely important to us.

-

Page 23: Install The Direcsteer System

Recommendations Raven Industries recommends the following best practices before installing or operating the system for the first time, at the start of the season, or when moving the system to another... -

Page 24: Tools Needed

Raven Industries recommends the following best practices when installing the system. Use part numbers to identify the parts. Do not remove the plastic wrap from a part until it is necessary for installation. -

Page 25: Remove The Steering Wheel

Install the DirecSteer System Remove the Steering Wheel NOTICE A steering wheel puller (not supplied) is required to complete the following procedure. Contact a local equipment dealer for assistance with any questions regarding the proper use of a steering wheel puller or removing the steering wheel. 1. - Page 26 Chapter 3 3. Use a steering wheel puller to remove the steering wheel from the steering column.

-

Page 27: Install The Anti-Rotation Bracket

Install the DirecSteer System Install the Anti-Rotation Bracket 1. Remove the 3 screws securing the cover on the front/top of the steering column. Note: Two of the screws are on either side of the cover. - Page 28 Chapter 3 2. Gently lift the cover from the steering column. Carefully remove the lever through the hole in the trim piece. 3. Secure the anti-rotation pin bracket (P/N 107-4050-103) to the steering column. Note: The bracket should be mounted as far away from the steering wheel as possible.

- Page 29 Install the DirecSteer System 4. Position the provided template (P/N 107-4050-149) inside the cover as shown below. Note: Line hole A (larger) with the existing hole in the cover. 5. Use the template to mark hole B (smaller) on the cover. 6.

- Page 30 Chapter 3 8. Install the spacer in the hole closest to the steering wheel: For Farmall U and T50x0 Series Tractors Use the supplied 17.5mm spacer (P/N 107-4050-148) and a 6mm x 35mm bolt. For MXM, TM, TL, and TS Series Tractors Use the supplied 13mm spacer (P/N 107-4050-147) and a 6mm x 35mm bolt.

- Page 31 Install the DirecSteer System 11. Use the supplied M5 hardware to secure the anti-rotation bearing (P/N 325-0000-048) on the bracket. Note: To make installing the DirecSteer unit easier, do not fully tighten the anti- rotation pin bearing. Note: The factory steering wheel and components will not be used with the DirecSteer system.

-

Page 32: Install The Direcsteer Assembly

Chapter 3 Install the DirecSteer Assembly Prepare the DirecSteer Assembly 1. Use two M5x16 bolts (P/N 311-4070-091) to secure the anti-rotation pin bracket (P/N 107-4050-104) to the bottom of the DirecSteer assembly (P/N 063-4001-040). Note: The anti-rotation pin bracket may be secured using any two of the mounting threaded holes on the bottom of the DirecSteer casing. -

Page 33: Attach The Direcsteer Assembly To The Steering Column

Install the DirecSteer System 2. By hand, remove the center cover from the DirecSteer assembly. 3. Install the spline adapter (P/N 107-4050-013) into the center of the DirecSteer assembly and secure using the six provided M5x12 bolts (P/N 311-4070-090). Attach the DirecSteer Assembly to the Steering Column 1. - Page 34 Chapter 3 2. Put the DirecSteer assembly over the spline and turn the anti-rotation pin into the anti- rotation bracket attached to the DirecSteer assembly. Note: The anti-rotation pin should be inserted in the bracket hole closest to the steering column.

- Page 35 Install the DirecSteer System 3. Use the previously removed nut to secure DirecSteer to the steering column spline and tighten with a 22 mm socket.

- Page 36 Chapter 3 4. Put the cover on the steering wheel.

-

Page 37: Install The Direcsteer System Components

Install the DirecSteer System Components NOTICE Depending upon the make and model of the machine, the steps required to complete the installation of the RS1™/SC1™ with DirecSteer auto-steer system may differ from the instructions provided in the following procedure. Mount the (Optional) Foot Switch... -

Page 38: Install The Field Computer

Chapter 4 2. Use the base plate of the foot switch as a template to drill holes for mounting the foot switch. 3. Secure the foot switch to the floor using the supplied screws through the base plate. Install the Field Computer Several options exist for compatible displays for field computers for the DirecSteer system. - Page 39 7. Connect the power cable and any other necessary cabling to the connections on the back of the device. Note: Refer to "Connect RS1™ Cabling to DirecSteer" on page 38 or "Connect SC1™ Cabling to DirecSteer" on page 59 for more detailed information on cable connections with DirecSteer.

- Page 40 Chapter 4...

-

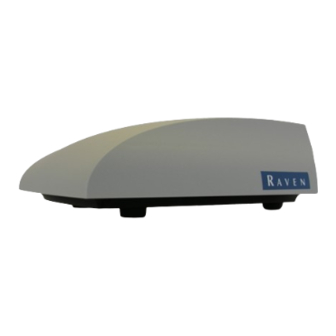

Page 41: Install Rs1™ With Direcsteer

Chapter 5: Install RS1™ with DirecSteer Note: This section only applies to DirecSteer kits with RS1™ guidance. For SC1™/TC1™ information, see "Install SC1™/TC1™ with DirecSteer" on page 55. CAUTION Do not connect the system power cable to the vehicle ignition or battery until all system components are mounted and all elec- trical connections are completed. -

Page 42: Install The Rs1™ Unit

1. Remove the four screws on the bottom of the RS1™. 2. Remove the SIM slot cover. 3. Insert the SIM card into the SIM slot. Note: The SIM card must be inserted into the J11 slot or the RS1™ will not connect to wireless or a CORS network. -

Page 43: Assemble The Mounting Brackets

RS1™ must mounted at least 50 cm [20 in.] from other GNSS, cellular, or radio antennas or equipment. Align the RS1™ on the center line of the tractor in front of the rear axle or toward the front of the cab. -

Page 44: Connect Rs1™ Cabling To Direcsteer

3. Use the two adhesive strips to secure the bottom bracket assembly to the roof of the tractor. Attach the RS1™ brackets so that the RS1™ 4. Secure the RS1™, already connected to the latch plate, onto the fixed plate. 5. Mount the round adhesive plate for the Laird cellular antenna (P/N 121-000-042) within 50 cm [20 in.] from the RS1™... -

Page 45: Best Mounting Practices

Install RS1™ with DirecSteer Implement Ready Power Harness (P/N 115-8000-060/315) with a ISObus IBBC connector Basic Power Harness (P/N 115-8000-141) The Implement Ready Power Harness is the only harness with the ISObus IBBC connector, and should be mounted on the back of the tractor. -

Page 46: Route The Rs1™ Cabling To Direcsteer

Chapter 5 Tie down the harnesses so they are free from vibration and friction. Route the RS1™ Cabling to DirecSteer 1. Locate the battery of the tractor, normally located on the right side of the tractor, below the door/window. 2. Leave the black and red wires of the DirecSteer power cable (P/N 115-8000-473) near the battery to ensure the system can connect to power later. - Page 47 Install RS1™ with DirecSteer If Installing a Kit with IBBC: a. Starting from the battery, route the implement ready power harness (P/N 115- 8000-060/315) through the machine so the IBBC connectors end up near the back of the machine. b. Ensure the 12-pin connector can still be routed into the cab of the machine.

- Page 48 A harness extension cable (P/N 115-8000-214) is available if needed. 5. In the cab, route the RS1™ T-cable (P/N 115-8000-330) from the side console to the roof. The cable can be routed to the roof through the pillar (recommended) or outside of the cab and attached to the pillar cab post.

- Page 49 Install RS1™ with DirecSteer 7. In the cab, connect the gray 12-pin connector of the RS1™ T-cable (P/N 115-8000-330) to the mating connector of the DirecSteer power harness (P/N 115-8000-060/315 or 115-8000-141). 8. Route cabling behind the lining. 9. Connect the 2-pin Deutsch connector from the DirecSteer power cable (P/N 115-8000- 473) to the mating 2-pin connector on the DirecSteer main harness (P/N 115-8000- 474).

- Page 50 Chapter 5 12. Route the road switch connector from the DirecSteer main cable (P/N 115-8000-474) through the open cavity and connect it to the road switch. Note: Use the provided adapter for the switch if needed.

- Page 51 Install RS1™ with DirecSteer 13. Press the switch assembly into the cavity to seat the switch. Note: If needed, use the supplied switch adapter (P/N 412-8000-037) when installing in a larger sized cavity. 14. Route the DirecSteer motor cable (P/N 115-4001-257) from the DirecSteer assembly...

- Page 52 DirecSteer main cable (P/N 115-8000-474) located in the side console. 16. Connect the DirecSteer motor cable (P/N 115-4001-257) to the DirecSteer assembly. 17. Connect the 12-pin connector of the field computer harness to the mating connector of the RS1™ T-cable (P/N 115-8000-330).

- Page 53 Install RS1™ with DirecSteer 18. Connect the field computer cable to the mating connectors on the back of the display. Note: Refer to System Diagrams for cable part numbers and refer to https://ravenindustries.mcoutput.com/fieldcomp/en-us/Content/0-General/CRX_ DeviceOverview.htm for specific device connections. 19. Once everything is installed and connected, hide the cabling behind the lining...

-

Page 54: Connect To Power

Chapter 5 Connect to Power CAUTION Do not connect the system power cable to the vehicle ignition or battery until all system components are mounted and all elec- trical connections are completed. 1. Locate the battery terminal rings on the DirecSteer power cable (P/N 115-8000-473) and power harness (P/N 115-8000-060/315 or 115-8000-141). -

Page 55: Rs1™ And Direcsteer System Diagrams

4. Connect the red lead(s) to the positive battery terminal and the black lead(s) to the negative battery terminal. RS1™ and DirecSteer System Diagrams The following sections contain example diagrams of various systems which may interface with the auto-steer system. - Page 56 Chapter 5 DirecSteer System Diagram w/ RS1™ and CR12™ w/o IBBC (P/N 054-5030-312 Rev. A, Pg. 1)

- Page 57 Install RS1™ with DirecSteer DirecSteer System Diagram w/ RS1™ and CR7™ w/o IBBC (P/N 054-5030-312 Rev. A, Pg. 2)

- Page 58 Chapter 5 DirecSteer System Diagram w/ RS1™, CR12™, and IBBC (P/N 054-5030-313 Rev. A, Pg. 1)

- Page 59 Install RS1™ with DirecSteer DirecSteer System Diagram w/ RS1™, CR7™, and IBBC (P/N 054-5030-313 Rev. A, Pg. 2)

- Page 60 Chapter 5...

-

Page 61: Install Sc1™/Tc1™ With Direcsteer

Chapter 6: Install SC1™/TC1™ with DirecSteer Note: This section only applies to DirecSteer kits with SC1™/TC1™ guidance. For RS1™ information, see "Install RS1™ with DirecSteer" on page 35. CAUTION Do not connect the system power cable to the vehicle ignition or battery until all system components are mounted and all elec- trical connections are completed. -

Page 62: Install The Sc1™/Tc1™ Unit

Chapter 6 Install the SC1™/TC1™ Unit NOTICE Depending upon the make and model of the machine, the steps required to complete the installation of the RS1™/SC1™ with DirecSteer auto-steer system may differ from the instructions provided in the following procedure. Note: Contact an authorized dealer for assistance with ordering or installing the SC1™... - Page 63 Install SC1™/TC1™ with DirecSteer 4. Install the mounting bracket (P/N 107-8000-125/157) using the bolts removed in the previous step.

-

Page 64: Install The Antenna

Chapter 6 Install the Antenna Install the 500S™ Receiver 500S™ only allows for the following installation options. To install the antenna: 1. Use the provided screws to secure the antenna mounting base to the antenna. Verify the power and signal notch on the antenna mounting base faces towards the power and signal connection on the bottom of the antenna. -

Page 65: Install The 700S™ Receiver

Install SC1™/TC1™ with DirecSteer 5. Thread the antenna onto the mounting base antenna until snug. Note: Hand-tighten only. Damage resulting from over-tightening is not covered by the warranty. 6. Connect the power cable (P/N 115-0172-588) to the power port of the 500S™ unit. 7. -

Page 66: Best Mounting Practices

Chapter 6 The Implement Ready Power Harness is the only harness with the ISObus IBBC connector, and should be mounted on the back of the tractor. Best Mounting Practices Ensure the installer follows all of the following guidelines for best mounting practices: Mount the relays in fixed position on a clean, dry, easily accessible spot. -

Page 67: Route The Sc1™ Cabling To Direcsteer

Install SC1™/TC1™ with DirecSteer Route the SC1™ Cabling to DirecSteer 1. Locate the battery of the tractor, normally located on the right side of the tractor, below the door/window. 2. Leave the black and red wires of the DirecSteer power cable (P/N 115-8000-473) near the battery to ensure the system can connect to power later. - Page 68 Chapter 6 If Installing a Kit with IBBC: a. Starting from the battery, route the implement ready power harness (P/N 115- 8000-060/315) through the machine so the IBBC connectors end up near the back of the machine. b. Ensure the 12-pin connector can still be routed into the cab of the machine. c.

- Page 69 Install SC1™/TC1™ with DirecSteer 4. Route the 12-pin connector from the DirecSteer power cable (P/N 115-8000-473) and DirecSteer power harness (P/N 115-8000-060/315 or 115-8000-141) into the cab of the machine. Note: A harness extension cable (P/N 115-8000-214) is available if needed. 5.

- Page 70 Chapter 6 6. Connect the two 4-pin Deutsch connector from the DirecSteer main cable (P/N 115- 8000-474) to the mating CAN 2 connectors on the SC1™ in-cab harness (P/N 115- 8000-475). 7. Locate an open or free console cavity for the road switch and remove the blank. 8.

- Page 71 Install SC1™/TC1™ with DirecSteer 9. Press the switch assembly into the cavity to seat the switch. Note: If needed, use the supplied switch adapter (P/N 412-8000-037) when installing in a larger sized cavity.

- Page 72 Chapter 6 10. Connect the female 12-pin connector of the SC1™/TC1™ cable (P/N 115-8000-475) to the 12-pin connector of the DirecSteer power harness (P/N 115-8000-060/315 or 115- 8000-141) coming into the cab of the tractor. Note: This can be done behind the covers behind the seat in most tractors. Make sure the green and gray connectors can be removed from behind the covers to insert them in the SC1™...

- Page 73 Install SC1™/TC1™ with DirecSteer 12. Connect the terminal connectors of the field computer harness (P/N 115-8000- 064/327) to the back of the terminals. Note: Refer to System Diagrams for cable part numbers and refer to https://ravenindustries.mcoutput.com/fieldcomp/en-us/Content/0-General/CRX_ DeviceOverview.htm for specific device connections.

- Page 74 Chapter 6 13. Connect the green and the gray 12-pin connectors from the in-cab SC1™ harness cable (P/N 115-8000-475) to the SC1™ unit. 14. Route the DirecSteer motor cable (P/N 115-4001-257) from the DirecSteer assembly down through the housing of the steering column and to the pedals. 15.

-

Page 75: Connect The 500S™/700S™ Antenna

Install SC1™/TC1™ with DirecSteer 16. Connect the DirecSteer motor cable (P/N 115-4001-257) to the DirecSteer assembly. 17. Once everything is installed and connected, hide the cabling behind the lining whenever possible, and tie down the cabling where appropriate to avoid loose cabling. Connect the 500S™/700S™... - Page 76 Chapter 6 1. Locate the battery terminal rings on the DirecSteer power cable (P/N 115-8000-473) and power harness (P/N 115-8000-060/315 or 115-8000-141). 2. Locate and open the battery compartment. Note: Generally, the battery compartment is located on the right side of the tractor, in front of the rear tire and below or beside the tractor cab.

-

Page 77: Sc1™ And Direcsteer System Diagrams

Install SC1™/TC1™ with DirecSteer SC1™ and DirecSteer System Diagrams The following sections contain example diagrams of various systems which may interface with the auto-steer system. DirecSteer System Diagram w/ SC1™ and CR12™ w/o IBBC (P/N 054-5030-310 Rev. A, Pg. 1) - Page 78 Chapter 6 DirecSteer System Diagram w/ SC1™ and CR7™ w/o IBBC (P/N 054-5030-310 Rev. A, Pg. 2)

- Page 79 Install SC1™/TC1™ with DirecSteer DirecSteer System Diagram w/ SC1™, CR12™, and IBBC (P/N 054-5030-311 Rev. A, Pg. 1)

- Page 80 Chapter 6 DirecSteer System Diagram w/ SC1™, CR7™, and IBBC (P/N 054-5030-311 Rev. A, Pg. 2)

-

Page 81: Limited And Extended Warranties

Bring the defective part and proof of purchase to your Raven dealer. If the dealer approves the warranty claim, the dealer will process the claim and send it to Raven Industries for final approval. The freight cost to Raven Industries will be the customer’s responsibility. The Return Materials Authorization (RMA) number must appear on the box and all documentation (including completed RMA form, Certificate of Decontamination, and retail... - Page 82 Extended Warranty What does this warranty cover? This warranty covers all defects in workmanship or materials in your Raven Applied Technology Division product under normal use, maintenance, and service when used for intended purpose. Do I need to register my product to qualify for the extended warranty? Yes.

- Page 83 Bring the defective part and proof of purchase to your Raven dealer. If the dealer approves the warranty claim, the dealer will process the claim and send it to Raven Industries for final approval. The freight cost to Raven Industries will be the customer’s responsibility. The Return Materials Authorization (RMA) number must appear on the box and all documentation (including completed RMA form, Certificate of Decontamination, and...

- Page 84 Software downloads and updates. Tamper-Evident label broken or customer disassembly. Any customer modification to the original product outside normal calibration and adjustments, without written approval. Intentional modification to cables. Failures due to lack of cleaning or preventive maintenance, and any condition, mal- function or damage not resulting from defects in material or workmanship.

Need help?

Do you have a question about the RS1 and is the answer not in the manual?

Questions and answers