Subscribe to Our Youtube Channel

Summary of Contents for Invertek Drives Eco Optidrive Series

- Page 1 Microlectra bv. User Guide www.microlectra.nl info@microlectra.nl AC Variable Speed Drives 0.75 - 250kW / 1HP - 350HP 200-600V 1 / 3 Phase Input Installation and Operating Instructions...

- Page 2 User Guide Revision 2.01 Invertek Drives Ltd adopts a policy of continuous improvement and whilst every effort has been made to provide accurate and up to date information, the information contained in this User Guide should be used for guidance purposes only and does not form the part of any contract.

-

Page 3: Table Of Contents

Optidrive Eco User Guide Revision 2.01 Introduction ..............................4 1.1. Important safety information ................................4 General Information and Ratings........................5 2.1. Drive model numbers .................................... 5 2.2. Identifying the Drive by Model Number ..............................6 Mechanical Installation ...........................7 3.1. Before Installation ....................................7 3.2. -

Page 4: Introduction

Ensure that all terminals are tightened to the appropriate torque setting Do not attempt to carry out any repair of the Optidrive. In the case of suspected fault or malfunction, contact your local Invertek Drives Sales Partner for further assistance. www.microlectra.nl... -

Page 5: General Information And Ratings

Optidrive Eco User Guide Revision 2.01 2. General Information and Ratings 2.1. Drive model numbers 2.1.1. IP20 Units 200 – 240 Volt, 1 Phase Input Frame Amps Model Code 0.75 ODV-3-220043-1F12-SN ODV-3-220070-1F12-SN 10.5 ODV-3-220105-1F12-SN 200 – 240 Volt, 3 Phase Input Frame Amps Model Code... -

Page 6: Identifying The Drive By Model Number

Optidrive Eco User Guide Revision 2.01 2.1.3. IP55 Enclosed Units 200 – 240 Volt, 3 Phase Input Frame Model Code ODV-3-420300-3F1N-TN ODV-3-420460-3F1N-TN ODV-3-520610-3F1N-TN ODV-3-520720-3F1N-TN ODV-3-620900-3F1N-TN ODV-3-621100-3F1N-TN ODV-3-621500-3F1N-TN ODV-3-621800-3F1N-TN ODV-3-722020-3F1N-TN ODV-3-722480-3F1N-TN 380 – 480 Volt, 3 Phase Input Frame Model Code ODV-3-440300-3F1N-TN ODV-3-440390-3F1N-TN ODV-3-440460-3F1N-TN... -

Page 7: Mechanical Installation

Optidrive Eco User Guide Revision 2.01 3. Mechanical Installation 3.1. Before Installation Carefully Unpack the Optidrive and check for any signs of damage. Notify the shipper immediately if any exist. Check the drive rating label to ensure it is of the correct type and power requirements for the application. ... - Page 8 Optidrive Eco User Guide Revision 2.01 3.3.2. IP66 Units ØI ØJ Drive Weight Size 10.12 8.67 7.87 28.4 1.12 9.41 7.40 6.93 0.17 0.33 10.6 10.12 8.67 7.87 28.4 1.12 10.24 7.40 6.93 0.17 0.33 12.1 12.20 276.5 10.89 251.5 9.90 33.4 1.31...

- Page 9 Optidrive Eco User Guide Revision 2.01 3.3.3. IP55 Units ØH ØI Drive Weight Size 17.32 16.46 16.65 0.31 9.92 6.73 4.33 4.25 0.17 0.30 25.4 21.26 20.28 20.47 0.31 10.63 9.25 6.89 4.25 0.17 0.30 23.1 50.9 34.06 32.68 33.07 0.39 12.99 12.99...

-

Page 10: Guidelines For Enclosure Mounting (Ip20 Units)

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate through the drive heatsink. Invertek Drives recommend the following minimum sizes for drives mounted in non-ventilated metallic enclosures:- Drive... -

Page 11: Guidelines For Mounting (Ip66 Units)

Optidrive Eco User Guide Revision 2.01 3.6. Guidelines for mounting (IP66 Units) Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in section 12.1 The drive must be mounted vertically, on a suitable flat surface ... -

Page 12: Removing The Terminal Cover

Optidrive Eco User Guide Revision 2.01 3.8. Removing the Terminal Cover All IP55 & IP66 enclosed models use quarter turn fasteners to secure the covers. The fastener positions are marked as shown below. The following diagrams show the open and closed (lock) position of the fasteners. Apply a slight pressure to the cover whilst turning the fastener to aid release. -

Page 13: Electrical Installation

4.1. Grounding the Drive This manual is intended as a guide for proper installation. Invertek Drives Ltd cannot assume responsibility for the compliance or the non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated equipment. - Page 14 Optidrive Eco User Guide Revision 2.01 4.1.6. Shield Termination (Cable Screen) – IP55 Units For best EMC performance and compliance with EMC directives when using enclosed drives, the power and motor cable shields should be connected to the cable shield / gland plate using a suitable EMC gland, ensuring direct metal to metal contact between the cable shield and the gland.

- Page 15 Optidrive Eco User Guide Revision 2.01 4.1.7. Recommended installation for EMC compliance – Panel Mount Units 4.1.8. Wiring Precautions Connect the Optidrive according to section 4.7, ensuring that motor terminal box connections are correct. There are two connections in general: Star and Delta. It is essential to ensure that the motor is connected in accordance with the voltage at which it will be operated. For more information, refer to section 4.4.

-

Page 16: Incoming Power Connection

Optidrive Eco User Guide Revision 2.01 4.2. Incoming Power Connection Power should be connected to the L1 and L2 terminals for single phase drives, L1, L2 and L3 for three phase drives. Phase sequence is not important. For compliance with CE and C Tick EMC requirements, a symmetrical shielded cable is recommended. ... -

Page 17: Control Terminal Wiring

Optidrive Eco User Guide Revision 2.01 4.5.2. Motor Thermistor Connection Where a motor thermistor is to be used, it should be connected as follows :- Control Terminals Additional Information Compatible Thermistor : PTC Type, 2.5kΩ trip level Use a setting of P1-13 that has Input 5 function as External Trip, e.g. -

Page 18: Safe Torque Off

Optidrive Eco User Guide Revision 2.01 4.8. Safe Torque Off Safe,Torque,OFF,will,be,referred,to,as,“STO”,through,the,remainder,of,this,section 4.8.1. Responsibilities The overall system designer is responsible for defining the requirements of,the,overall,“Safety,Control,System”,within,which,the,drive,will,be, incorporated; furthermore the system designer is responsible for ensuring that the complete system is risk assessed,and,that,the,“Safety, Control,System”,requirements,have,been,entirely,met and that the function is fully verified, this must include confirmation testing of the “STO”,function,before,drive,commissioning... - Page 19 Optidrive Eco User Guide Revision 2.01 “STO”FaultCodes Fault Code Description Corrective Action Code Number A fault has been detected within either of the “Sto-F” Refer to your Invertek Sales Partner internal,channels,of,the,“STO”,circuit 4.8.6. “STO” Function response time The total response time is the time from a safety related event occurring to the components (sum of) within the system responding and becoming safe.

- Page 20 Optidrive Eco User Guide Revision 2.01 4.8.2. External Power supply Specification. Voltage Rating (Nominal) 24Vdc STO Logic High 18-30Vdc (Safe torque off in standby) Current Consumption (Maximum) 100mA 4.8.3. Safety Relay Specification. The safety relay should be chosen so that at minimum it meets the safety standards in which the drive meets. Standard Requirements SIL2 or PLd SC3 or better (With Forcibly guided Contacts) Number of Output Contacts...

-

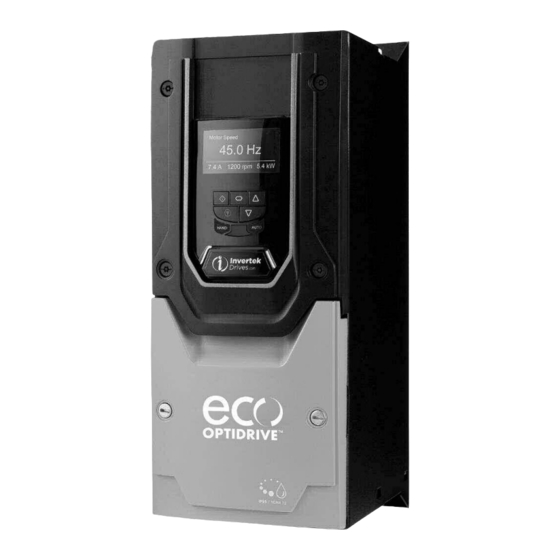

Page 21: Using The Oled Keypad (Standard On Ip55 & Ip66 Units)

Optidrive Eco User Guide Revision 2.01 5. Using the OLED Keypad (Standard on IP55 & IP66 Units) The drive is configured and its operation monitored via the built in seven button keypad (Start, Stop, Navigate, Up, Down, Hand, Auto) keypad and multi-line OLED text display. 5.1. -

Page 22: Accessing And Changing Parameter Values

Optidrive Eco User Guide Revision 2.01 5.4. Accessing and Changing Parameter Values Maximum Speed Limit Maximum Speed Limit Maximum Speed Limit STOP P1-01 50.0Hz 45.0Hz 200.0 0.0 200.0 0.0 37kW 400V 50.0Hz P1-01 P1-01 Hold navigate button in for >1 Use up and down keys to scroll to Presss / release navigate button Use up and down keys to edit... -

Page 23: Selecting Between Hand And Auto Control

Optidrive Eco User Guide Revision 2.01 5.7. Selecting between Hand and Auto Control STOP STOP 37kW 400V 37kW 400V A = Auto H = Hand The active control source is Hand mode permits drive control shown on the OLED display. directly from the drive keypad. -

Page 24: Using The Keypad & Led Display On Ip20 Frame Size 2 & 3

Optidrive Eco User Guide Revision 2.01 6. Using the Keypad & LED Display on IP20 Frame Size 2 & 3 The drive is configured and its operation monitored via the keypad and display. 6.1. Keypad Layout and Function – Standard LED Keypad Used to display real-time information, to access and exit NAVIGATE parameter edit mode and to store parameter changes... -

Page 25: Advanced Keypad Operation Short Cuts

Optidrive Eco User Guide Revision 2.01 6.3. Advanced Keypad Operation Short Cuts Function When Display shows... Press... Result Example Display shows The next highest Parameter xxx Press group is selected Fast Selection of Parameter Groups ... -

Page 26: Commissioning

Optidrive Eco User Guide Revision 2.01 7. Commissioning 7.1. General The following guidelines apply to all applications 7.1.1. Entering the motor nameplate information Optidrive Eco uses the information from the motor nameplate to Operate the motor with the best possible efficiency level ... -

Page 27: Parameters

Optidrive Eco User Guide Revision 2.01 8. Parameters 8.1. Parameter Set Overview The Optidrive Eco Extended Parameter set consists of 7 groups as follows: Group 1 – Basic Parameter Set Group 2 – Extended Parameter Set Group 3 – User PID Control Parameter Set ... - Page 28 Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P1-12 Control Mode Select 0: Terminal Control. The drive responds directly to signals applied to the control terminals. 1: Uni-directional Keypad Control. The drive can be controlled in the forward direction only using the internal or remote Keypad 2: Uni-directional Keypad Control.

-

Page 29: Digital Input Functions

Optidrive Eco User Guide Revision 2.01 9. Digital Input Functions 9.1. Digital Input Configuration Parameter P1-13 P1-13 Local (Hand) Digital Input 1 Digital Input 2 Digital Input 3 Analog Input 1 Analog Input 2 Notes *(2) Control Function (Terminal 2) (Terminal 3) (Terminal 4) (Terminal 6) -

Page 30: Extended Parameters

Optidrive Eco User Guide Revision 2.01 10.Extended Parameters 10.1. Parameter Group 2 - Extended parameters Parameter Name Minimum Maximum Default Units P2-01 Preset Speed 1 -P1-01 P1-01 50.0 (60.0) Hz / Rpm P2-02 Preset Speed 2 -P1-01 P1-01 40.0 Hz / Rpm P2-03 Preset Speed 3 -P1-01... - Page 31 Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P2-13 Analog Output 2 Function (Terminal 11) Digital Output Mode. Logic 1 = +24V DC Settings 4 to 7 use the adjustable limit parameters P2-19 and P2-20. The Output switches to Logic 1(24 Volt DC) when the chosen analog value exceeds the Upper Threshold (P2-19) and resets to Logic 0 (0 Volt DC) when the chosen analog value reduces below the Lower Threshold (P2-20).

- Page 32 Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P2-18 Relay Output 2 Function (Terminals 17 & 18) Selects the function assigned to Relay Output 2. The relay has two output terminals, Logic 1 indicates the relay is active, and therefore terminals 17 and 18 will be linked together.

- Page 33 Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P2-28 Slave Speed Scaling Active in Keypad mode (P1-12 = 1 or 2) and Slave mode (P1-12=4) only. The keypad reference can be multiplied by a preset scaling factor or adjusted using an analog trim or offset. 0 : Disabled.

-

Page 34: Parameter Group 3 - Pid Control

Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P2-37 Hand / Keypad / Fieldbus Starting Mode Options 0 to 3 are only active when P1-12 = 1 or 2 (keypad Mode). With these settings, the drive waits for the keypad start button to be pressed before running. -

Page 35: Parameter Group 4 - High Performance Motor Control

Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P3-09 PID Output Limit Select 0 : Digital Output Limits. The output range of the PID controller is limited by the values of P3-07 & P3-08 1 : Analog Input 1 Provides a Variable Upper Limit. The output range of the PID controller is limited by the values of P3-08 & the signal applied to Analog Input 1 2: Analog Input 1 Provides a Variable Lower Limit. -

Page 36: Parameter Group 5 - Communication Parameters

Optidrive Eco User Guide Revision 2.01 P4-02 Auto-tune Enable When set to 1, the drive immediately carries out a non-rotating auto-tune to measure the motor parameters for optimum control and efficiency. Following completion of the auto-tune, the parameter automatically returns to 0. P4-03 Vector Speed Controller Proportional Gain 400.0... -

Page 37: Parameter Group 8 - Application Function Specific Parameters

Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P5-09 BACnet Device Instance Number (Low) 65535 P5-10 BACnet Device Instance Number (High) When using BACNet MS/TP, these parameter together allow a unique Device Instance Number to be programmed into the drive. For further information on using BACnet MS/TP, refer to section 11.3 P5-11 BACnet Maximum Masters... - Page 38 Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P8-06 Load Monitor Enable This parameter enables the Load Profile Monitoring Function (load current monitoring), which can be used to detect belt failure in belt driven fan applications, or Dry Pump, Pump Blockage or broken impeller in Pump applications. 0: Disabled 1: Low Load Detection Enabled (Belt Failure / Dry Pump / Broken Impeller) 2: High Load Detection Enabled (Pump Blockage)

-

Page 39: Parameter Group 0 - Monitoring Parameters (Read Only)

Optidrive Eco User Guide Revision 2.01 Parameter Name Minimum Maximum Default Units P8-17 Assist Pump Start Speed P8-18 P1-01 49.0 Hz / RPM This,parameter,defines,the,speed,at,which,an,“;ssist”,Pump,is,started,when,using,the,Pump,Cascade,or,Optiflow,feature. When the drive output increases beyond this threshold the next Staging pump is switch on. The Pump staging settle time must then expire before additional staging pumps can be brought on or off line. - Page 40 Optidrive Eco User Guide Revision 2.01 Parameter Name Units P0-24 Time Ambient >80° C HH:MM:SS Two entry display: First display shows hours. Second display shows minutes and seconds Displays the amount of time in hours and minutes that the Optidrive has operated for during its lifetime with an ambient temperature in excess of 80°C.

-

Page 41: Serial Communications

Optidrive Eco User Guide Revision 2.01 Parameter Name Units P0-48 DSP comms fault counter Displays the number of communication errors detected by the Power Stage processor in messages received from the I/O processor since the last power up P0-49 Modbus RTU / BACnet Fault Counter This parameter is incremented every time an error occurs on the Modbus RTU communication link. -

Page 42: Modbus Rtu Communications

Optidrive Eco User Guide Revision 2.01 11.2. Modbus RTU Communications 11.2.1. Modbus Telegram Structure The Optidrive Eco supports Master / Slave Modbus RTU communications, using the 03 Read Multiple Holding Registers and 06 Write Single Holding Register commands. Many Master devices treat the first Register address as Register 0; therefore it may be necessary to convert the Register Numbers detail in section 11.2.2 by subtracting 1 to obtain the correct Register address. -

Page 43: Bacnet Mstp

Optidrive Eco User Guide Revision 2.01 Register Upper Byte Lower Byte Read Notes Number Write Pre Ramp Speed Reference Internal drive frequency set-point DC Link Voltage Measured DC Link Voltage VDC (P0-20) Drive temperature Measured Heatsink Temperature in °C (P0-21) kWh Meter (User Resettable) User resettable energy meter kWh (P0-26) MWh Meter (User Resettable) - Page 44 Optidrive Eco User Guide Revision 2.01 11.3.4. BACNet MSTP commissioning In order to connect the drive and operate on a BACNet MSTP network, the following procedure should be used. Set P1-14 = 101 to allow access to the extended parameters On each drive, set a unique MAC ID in parameter P5-01 Set the required MSTP baudrate in P5-03 Select the required data format in P5-04...

- Page 45 Optidrive Eco User Guide Revision 2.01 Analog Value Object Analog Value Objects Table Instance ID Object Name Access Description Unit Motor Frequency Motor output frequency Hertz Motor Speed Motor output speed (0 if P1-10=0) Motor Current Motor output current Amps Motor Power Motor output power Kilowatts...

- Page 46 Optidrive Eco User Guide Revision 2.01 11.3.8. Object/Property Support Matrix Object Type Property Device Binary Value Analog Value Object Identifier × × × Object Name × × × Object Type × × × System Status × Vendor Name × Firmware Revision ×...

- Page 47 Optidrive Eco User Guide Revision 2.01 11.3.9. BACnet Protocol Implementation Conformance Statement Date: April, 2015 Vendor Name: Invertek Drives Ltd Product Name: OPTIDRIVE ECO Product Model Number: ODV-3-xxxxxx-xxxx-xx Application Software Version: 2.00 Firmware Revision: 2.00 BACnet Protocol Revision: Product Description:...

-

Page 48: Technical Data

12.4. Output Power and Current ratings The following tables provide the output current rating information for the various Optidrive Eco models. Invertek Drives always recommend that selection of the correct Optidrive is based upon the motor full load current at the incoming supply voltage. - Page 49 The maximum motor cable length stated applies to using a shielded motor cable. When using an unshielded cable, the maximum cable length limit is increased by 50%. When using the Invertek Drives recommended output choke, the maximum cable length limited can be increased by 100% ...

-

Page 50: Derating Information

Optidrive Eco User Guide Revision 2.01 12.5. Derating Information Derating of the drive maximum continuous output current capacity is require when Operating at ambient temperature in excess of 40°C / 104°F (IP55 & IP66) or 50°C / 122°F (IP20) ... -

Page 51: Troubleshooting

A historical log is stored at 20ms intervals prior to a trip in parameter P0-37 Check all three supply phases are present and within the 3% supply voltage level imbalance tolerance. Reduce the motor load If the fault persists, contact your local Invertek Drives Sales Partner P-Loss Input phase loss Input phase missing trip Drive intended for use with a 3 phase supply, one input phase has been disconnected or lost. - Page 52 Optidrive Eco User Guide Revision 2.01 Fault Code OLED Message Description Corrective Action User Parameter Default User Parameter Defaults User Parameter default has been loaded. Press the Stop key. Three button U-Def default – see section 5.6 Motor PTC over heat Motor PTC Over Temperature The connected motor PTC device has caused the drive to trip (analog input 2 F-Ptc...

Need help?

Do you have a question about the Eco Optidrive Series and is the answer not in the manual?

Questions and answers