Table of Contents

Advertisement

Quick Links

• Basic

Section 1: Safety Information

Section 2: Machine Information

Section 3: Copying Operations

Section 4: Helpful Functions

Section 5: Troubleshooting

Section 6: Machine Specifications

• Advanced

Section 7: Colour Image Adjustment

Section 8: Advanced Information

Section 9: Special Original

Section 10: Applications

Section 11: Network Function

Section 12: Paper and Original Information

Section 13: Maintenance & Supplies

Section 14: Key Operator Mode

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Konica Minolta bizhub pro c500

- Page 1 • Basic Section 1: Safety Information Section 2: Machine Information Section 3: Copying Operations Section 4: Helpful Functions Section 5: Troubleshooting Section 6: Machine Specifications • Advanced Section 7: Colour Image Adjustment Section 8: Advanced Information Section 9: Special Original Section 10: Applications Section 11: Network Function Section 12: Paper and Original Information...

-

Page 3: Table Of Contents

Contents Contents Features of the bizhub PRO C500 Legal Restrictions on Copying Basic Section 1: Safety Information Safety Information................1-2 Regulation Notices................. 1-8 Caution Labels and Indicators ............. 1-10 Installation Space................. 1-13 Section 2: Machine Information Machine Configuration ..............2-2 External Machine Items .............. - Page 4 Contents (continued) Section 3: Copying Operations Selecting Colour Mode..............3-2 Positioning Originals ..............3-4 Positioning Originals in RADF............3-4 Positioning Original on Platen Glass..........3-8 Setting Print Quantity ..............3-10 To Set Print Quantity................ 3-10 To Change Print Quantity..............3-10 Setting Job During Warm-up............

- Page 5 Contents (continued) Section 4: Helpful Functions Making Sample Copy (Proof Copy) ..........4-2 Checking Feature Selections / Proof Copying (Check Mode)..4-4 Interrupt Copying ................4-8 Storing Job Conditions (Job Memory: Job Store) ......4-11 Recalling Stored Job Settings (Job Memory: Job Recall).... 4-14 Recalling Previous Job Settings ..........

- Page 6 Contents (continued) Advanced Section 7: Colour Image Adjustment About Colours ................7-2 RGB and CMYK Models ..............7-2 HSB Model ..................7-3 Colour Copy Quality ............... 7-4 Modifying Colours ................7-4 Reproducing Images ................ 7-11 What Is Image Detection?..............7-12 Applying Filters.................

- Page 7 Contents (continued) Section 9: Special Original Selecting Binding Direction ............9-2 Specifying Original Direction............9-4 Copying Non-Standard Size Originals (Original Form) ....9-6 Copying Mixed Size Originals (Mixed Original)......9-8 Copying Z-Folded Originals (Z-Folded Original) ......9-10 Scanning Thin/Thick Originals in RADF (Original Thickness)..9-12 Section 10: Applications To Display Application Selection Screen ........

- Page 8 Contents (continued) Section 11: Network Function To Use Web Utilities..............11-2 To Display Information on Machine..........11-4 To Display Current Machine Status (Job Status) ......11-5 Setting E-Mail Transmission Function.......... 11-7 Setting E.K.C. Function..............11-9 Setting Scan Transmission Function.......... 11-20 Transmitting/Editing Machine Setting File........

- Page 9 Contents (continued) Section 14: Key Operator Mode An Outline of the Key Operator Mode.......... 14-2 How to Access the Key Operator Mode........... 14-2 [1] System Initial Setting .............. 14-4 [1] Date & Time Setting..............14-4 [2] Language Select Setting............. 14-6 [3] IP Address Setting ..............

- Page 10 Contents (continued) Section 14: Key Operator Mode (continued) [18] Scan Transmission Setting ..........14-48 [19] Non-Image Area Erase Setting ........... 14-50 [20] AE Adjustment ..............14-51 [21] Execute Adjustment Operation ........... 14-52 [22] Magnification Adjustment ............ 14-53 [23] Timing Adjustment .............. 14-54 [24] Centring Adjustment............

- Page 11 Features of the bizhub PRO C500 AE - Automatic Exposure Automatically adjusts exposure to compensate for quality of the original. AMS - Automatic Magnification Selection Automatically selects an appropriate magnification ratio when Paper Size is selected manually. APS - Automatic Paper Selection Automatically selects paper size to match the original documents.

- Page 12 Features of the bizhub PRO C500 (continued) Density Shift Shifts each of nine density levels in four density modes (Auto, Text, Photo, Map) to three levels lighter or three levels darker. Dual Page Copies both pages of an open book or A3/B4 size sheet separately onto two A4/B5 size sheets in 1a1 mode or separately onto each side of one A4/B5 size sheet in 1a2 mode.

- Page 13 Non STD Size for Original Identifies the special original size which the bizhub PRO C500 cannot detect, in order to select the optimal paper size for copying or printing. Original Image Enhances photo image in PHOTO mode, regular image in TEXT/PHOTO mode, text image in TEXT mode, coloured image with small text in MAP mode.

- Page 14 Selects the horizontal image area across the page, and repeats it down the page as many times as the repeat width setting (10 ~ 150 mm) permits in manual or auto. Reserve Scans in subsequent copy jobs while the bizhub PRO C500 is busy printing or copying. Reverse Image Reverses the positive image to negative image or vice versa in the selected colour mode.

- Page 15 Features of the bizhub PRO C500 (continued) Stamp Prints watermark, regular stamp, date/time, page number, and numbering onto the output copies to enhance the presentation and usefulness of the copies. Staple Selects the stapling position and number of staples. STD Size (Special) Detects the standard paper sizes which cannot normally be detected when loaded in a main body tray or Multi-sheet bypass tray.

-

Page 16: Legal Restrictions On Copying

Legal Restrictions on Copying Certain types of documents must never be copied with the purpose or intent to pass copies of such documents off as the originals. The following is not a complete list, but is meant to be used as a guide to responsible copying. - Page 17 Basic...

- Page 19 Section 1: Safety Information Precautions for Installation and Use Safety Information ............1-2 Regulation Notices ............1-8 Caution Labels and Indicators ........1-10 Installation Space ............1-13...

-

Page 20: Safety Information

Safety Information This section contains detailed instructions on the operation and maintenance of this machine. To achieve optimum utility of this device, all operators should carefully read and follow the instructions in this manual. Please read the following section before connecting the machine to the supply. It contains important information related to user safety and preventing equipment problems. -

Page 21: Section 1: Safety Information

Safety Information (continued) Disassemble and modification WARNING • Do not attempt to remove the covers and panels which have been fixed to the product. Some products have a high-voltage part or a laser beam source inside that could cause an electr ical shock or blindness. - Page 22 Safety Information (continued) Power source WARNING • Use only the specified power source voltage. Failure to do that could result in a fire or electrical shock. • Connect power plug directly into wall outlet having the same configuration as the plug. Use of an adapter leads to the product connecting to inadequate power supply (voltage, current capacity, grounding), and may result in fire or shock.

- Page 23 Safety Information (continued) Grounding WARNING • Connect the power cord to an electrical outlet that is equipped with a grounding terminal. Installation WARNING • Do not place a flower vase or other container that contains water, or metal clips or other small metallic objects on this product.

- Page 24 Safety Information (continued) Actions in response to troubles WARNING • Do not keep using this product, if this product becomes inordinately hot or emits smoke, or unusual odor or noise. Immediately turn OFF the power switch, unplug the power cord from the power outlet, and then call your authorized service representative.

- Page 25 Safety Information (continued) When moving the machine CAUTION • Whenever moving this product, be sure to disconnect the power cord and other cables. Failure to do this could damage the cord or cable, resulting in a fire, electrical shock, or breakdown. •...

-

Page 26: Regulation Notices

Regulation Notices m Laser Safety This product employs a Class 3B laser diode having maximum power of 7 mW and wavelength of 650 nm. This product is certified as a Class 1 laser product. Since the laser beam is concealed by protective housings, the product does not emit hazardous laser radiation as long as the product is operated according to the instructions in this manual. -

Page 27: Ozone Release

Regulation Notices (continued) KONICA MINOLTA BUSINESS TECHNOLOGIES, INC. 1-6-1, Marunouchi, Chiyoda-ku, Tokyo, Japan MANUFACTURED: KHK THIS PRODUCT COMPLIES WITH 21 CFR CHAPTER I, SUBCHAPTER J CLASS 1 LASER PRODUCT APPAREIL A RAYONNEMENT LASER DE CLASSE 1 LASER KLASSE 1 PRODUKT m Ozone Release During print operation, a small quantity of ozone is released. -

Page 28: Caution Labels And Indicators

Caution Labels and Indicators The caution labels and indicators are attached to the machine areas, as shown below, where you are advised to pay special attention to avoid any dangerous situations or serious injury. (Right side of the fixing unit) CAUTION CAUTION High temperature! - Page 29 Caution Labels and Indicators (continued) CAUTION DO NOT INSERT your finger into the two RADF hinge portions; otherwise you may be injured. (Rear side of the RADF) (Right rear side of the Main body) (Inside of the LCT) WARNING CAUTION DO NOT throw the toner To avoid any unexpected recovery box into a fire.

- Page 30 Caution Labels and Indicators (continued) (Finisher with PI-110 Cover Sheet Feeder only) CAUTION CAUTION ATTENTION ATTENTION VORSICHT PRECAUCION PRECAUCION ATTENZIONE CUIDADO 注意 CAUTION CAUTION To avoid injury, DO NOT DO NOT insert your put your hand on top of finger into the bottom the printed sheets.

-

Page 31: Installation Space

PRO C500 + CV-131 (Right side) Unit: mm Unit: mm 1619 1619 1021 1021 1275 1475 1959 bizhub PRO C500 + DF-319 (Front) bizhub PRO C500 + DF-319 (Right side) Unit: mm 1619 1021 1701 1901 bizhub PRO C500 + DF-319 + FS-513 (Front) 1-13... - Page 32 1280 3162 3462 bizhub PRO C500 + DF-319 + FS-606 + PI-110 + LT-211 + TU-109A Kit + TU-109 (Front) Finisher primary (main) tray of FS-513/FS-606 Finisher gradually goes down while printed materials output. DO NOT allow any object to interfere with the operation of the tray on the left side of the finisher, as any interference may cause damage to the finisher.

-

Page 33: Section 2: Machine Information

Section 2: Machine Information Machine Configuration, Turning On the Power and Loading Paper Machine Configuration............2-2 Turning On the Power Switch ......... 2-16 Loading Paper ..............2-22... -

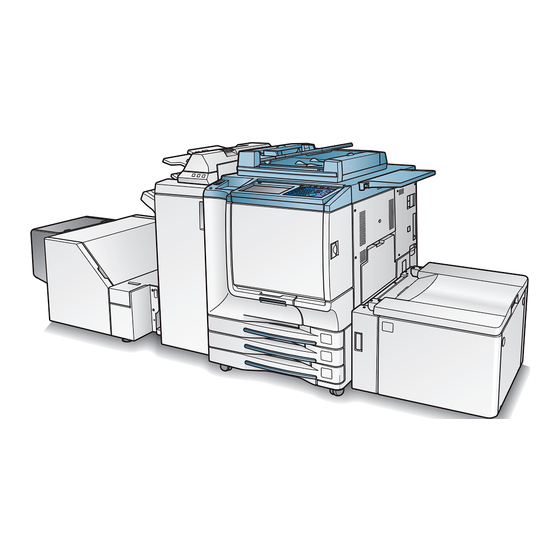

Page 34: Machine Configuration

Machine Configuration External Machine Items 1 RADF (option) 21 Control panel 2 Platen cover 20 LCD Touch screen (option) 19 Power switch 4 Key counter (option) 5 Toner access door 6 Toner recovery box door Multi-sheet 14 FS-513 Finisher bypass tray (option) 9 Right side door 13 Front door... - Page 35 Machine Configuration (continued) RADF (Reversing Automatic Document Feeder) (option) automatically feeds multiple originals one at a time to the platen glass for copying. Platen cover (option) covers documents to be copied and holds them in place. Work table provides a convenient workspace for documents both before and after copying.

-

Page 36: Internal Machine Items

Machine Configuration (continued) Internal Machine Items 5 Black print counter 4 Total counter 3 Main power switch 2 Fixing unit 1 Lever A Lever A can be moved to withdraw the conveyance fixing unit for removal of mishandled paper. Fixing unit fuses the toner onto the copy paper. Main power switch used only by service representative turns machine power on/off when pressed. -

Page 37: Standard/Optional Equipment

PK-507/PK-508 Punching kit PI-110 Cover sheet feeder DF-319 Document feeder CV-131 Platen cover Work table Key counter FS-513 Finisher bizhub PRO C500 LT-211 Large main body capacity tray MU-412 Memory unit HD-106 Hard disk drive IP-901Printer controller (Fiery S300 50C-K) -

Page 38: Control Panel Layout

Machine Configuration (continued) Control Panel Layout 19 18 CONTRAST ADJUSTMENT DIAL can be turned to adjust the touch panel contrast. LCD TOUCH SCREEN displays machine and copying status, help information, interactive screens, and touch keys for selecting all functions. CHECK displays a screen showing all settings that are selected for the current job. - Page 39 Machine Configuration (continued) JOB MEMORY displays screens for selecting job store/job recall functions. ACCESS sets the machine to allow copying only when the EKC password is entered. The touch screen of the control panel is covered with glass. Do not drop heavy objects on the glass or put excess weight or pressure on it, otherwise the glass may be scratched or break to cause injury.

-

Page 40: Basic Screen

Machine Configuration (continued) Basic Screen 10 STATUS key 1 Folder keys 9 Memory indicator 6 Original count 2 Word icons 8 Count/Set indicator 5 Reserve job 3 Graphic icons 4 Message area 7 TYPE/SIZE key 19 Colour mode area 17 Paper size area 15 STORE key 20 Output mode keys 18 Copy mode area... - Page 41 Machine Configuration (continued) Original count counts the original pages placed in the document feeder as they are scanned. TYPE/SIZE key appears when the Bypass key is selected, and is touched to specify the type and size of the paper loaded in the Multi-sheet bypass tray. Count/Set indicator indicates the print quantity entered from the control panel keypad, and also indicates the print count on the left of the set count while printing.

-

Page 42: Fs-513/Fs-606 Finisher (With Pk-507/Pk-508 Punching Kit)

Machine Configuration (continued) FS-513/FS-606 Finisher (with PK-507/PK-508 Punching Kit) 4 Secondary 4 Secondary (Sub) tray (Sub) tray 1 Finisher door 1 Finisher door 3 Primary 3 Primary (Main) tray (Main) tray 2 Booklet tray (FS-606 Finisher only) FS-513 Finisher FS-606 Finisher Finisher door opens to the internal Finisher to allow clearing mishandled paper, replenishing staples, and emptying waste basket of Punching kit. - Page 43 Machine Configuration (continued) 4 Sub tray conveyance lever 3 Cover sheet conveyance lever 1 Entrance lever 4 Sub tray conveyance lever 3 Cover sheet 5 Stacker conveyance conveyance lever lever 2 PK-507/PK-508 Punching kit FS-513 Finisher (option) 1 Entrance lever 9 Trash basket (option) 8 Stacker unit...

-

Page 44: Cover Sheet Feeder

Machine Configuration (continued) PI-110 Cover Sheet Feeder 3 Upper tray guide plates 4 Upper tray 2 Upper unit release lever 5 Lower tray 6 Lower tray guide plates 1 Cover sheet feeder control panel Cover sheet feeder control panel controls cover sheet feeder operations. Upper unit release lever can be moved to slide the upper unit of cover sheet feeder for removal of mishandled paper. -

Page 45: Large Capacity Tray

Machine Configuration (continued) LT-211 Large Capacity Tray 5 Paper feed roller 6 LCT paper guides 4 Paper loading button 7 LCT paper guide knobs 8 Rear stopper 2 LCT top door 1 LCT lever 9 Rear stopper knob 10 LCT bottom plate 3 LCT left side door LCT lever can be moved downward to ease removal of mishandled paper. -

Page 46: Trimmer Unit

Machine Configuration (continued) TU-109 Trimmer Unit 7 FS-606 Finisher 6 TU-109A kit 5 Trimmer stacker cover 4 Trimmer unit tray 1 Front-right cover 2 Front door 3 Trimmer stacker Front-right cover opens to allow removal of mishandled paper. Front door opens to allow removal of mishandled paper or waste paper. Trimmer stacker holds sets output in Trimming mode. - Page 47 Machine Configuration (continued) 1 Trimmer unit knob 3 Trimmer pressure 2 Wast basket release lever Trimmer unit knob can be turned to ease removal of mishandled paper. Waste basket holds waste paper cut off from the booklets. Trimmer pressure release lever opens to allow removal of mishandled paper. 2-15...

-

Page 48: Turning On The Power Switch

Turning On the Power Switch To Turn On the Power Turn ON the power switch. The power switch is located on the left side of the control panel. The main power switch is located on the upper-left side of the internal main body. - Page 49 Turning On the Power Switch (continued) You can set reserve jobs while the machine is warming up. Touch the LCD screen to change the Warm-up Screen to the Basic Screen, then check that the message “Ready to copy reserve” is displayed on the Basic Screen. See p.

-

Page 50: To Turn Off The Power

Turning On the Power Switch (continued) To Turn Off the Power Turn OFF the power switch. The power switch is located on the left side of the control panel. The touch screen and all the LEDs on the control panel will go out. Be sure not to use the main power switch in usual operation. -

Page 51: Reducing The Power In Standby Mode (Auto Low Power)

Turning On the Power Switch (continued) Reducing the Power in Standby Mode (Auto Low Power) This function automatically lowers the power after a specified period (initially 15 minutes) of copier inactivity. The LCD screen will go off. The Auto Low Power function can be set to 5 minutes/ 10 minutes/ 15 minutes/ 30 minutes/ 60 minutes/ 90 minutes/ 120 minutes/ 240 minutes in the Key Operator mode. -

Page 52: Shutting Off / Reducing The Power Manually

Turning On the Power Switch (continued) Shutting Off / Reducing the Power Manually Follow the procedure below to shut off the power manually. The machine is initially set to activate the Manual Shut-Off function. The Manual Low Power can be selected in the Key Operator setting. See p. 14-37 to p. -

Page 53: Entering An Ekc Password (Ekc)

Turning On the Power Switch (continued) Entering an EKC Password (EKC) The Electronic Key Counter (EKC) allows the Key Operator to monitor all copying activities by controlling EKC password accounts. Copy quantity limits for specific accounts can be set. The EKC is not factory-set. An EKC password is required only when the EKC is activated, a User Password is assigned, and “Enter E.K.C. -

Page 54: Loading Paper

Loading Paper A paper indicator is shown on each tray key of the Basic Screen to indicate the paper level (six levels are provided: ) of the tray. (The Multi-sheet bypass tray displays only “ ” when paper in the tray becomes empty.) When paper supply in a tray becomes low, the indicator “... -

Page 55: Loading Paper In Tray 1 ,2, And 3

Loading Paper (continued) Loading Paper in Tray 1 ,2, and 3 Withdraw tray 1, 2, or 3, and open the paper feed roller. Do not withdraw the tray forcibly; otherwise you may be injured. Withdraw the tray completely until the green line appears at the left rear side of the tray. - Page 56 Loading Paper (continued) Be sure to fix the side guide plate in position according to the size indication on the tray bottom plate so that the machine can detect the correct paper size. Adjust the position of the rear stopper. To slide the rear stopper to the right, hold it at the upper part and slide it while pressing down slightly.

- Page 57 Loading Paper (continued) When paper is seated properly, close the paper feed roller. Gently push in the tray until it locks into place. “ ” on the tray key will change to “ ”. The indicator Do not clam the tray into the main body; otherwise machine trouble may be caused.

-

Page 58: Loading Paper In Multi-Sheet Bypass Tray

Loading Paper (continued) Loading Paper in Multi-Sheet Bypass Tray When using the Multi-sheet bypass tray, specify the paper type to be loaded on the tray at the same time. See p. 3-18 to p. 3-21 for details. Open the Multi-sheet bypass tray located on the right side of the copier. -

Page 59: Loading Paper In Lct (Lt-211)

Loading Paper (continued) Loading Paper in LCT (LT-211) Be sure to load only the paper type and weight set for the LCT. Key Operator can change this setting. See p. 14-21 to p. 14-22. Open the LCT top door. The LCT bottom plate will go up. Without the power turned on, the LCT bottom plate will not function. - Page 60 Loading Paper (continued) (2) Move the upper part of the two LCT paper guides to the appropriate positions according to the size indication, then turn the LCT paper guide knobs (two for each) clockwise to fix the guides. (3) Move the position of the rear stopper to the appropriate positions according to the size indication on the bottom plate, then turn the two rear stopper knobs clockwise to fix the rear stopper.

- Page 61 Loading Paper (continued) Repeat the step 3 until the bottom plate will not go down any more. • Do not load above the limit indicated on the LCT paper guides. • Be sure that the rear stopper is correctly positioned according to the paper size to be loaded;...

-

Page 62: Loading Tabbed Sheets In Tray 1, 2, Or 3

Loading Paper (continued) Loading Tabbed Sheets in Tray 1, 2, or 3 When TAB is displayed on the tray key of the Basic Screen, follow the procedure below to supply the tray with tabbed sheets. The tray paper type can be specified in the Key Operator setting. For details, see p. -

Page 63: Loading Tabbed Sheets In Lct (Lt-211)

Loading Paper (continued) Loading Tabbed Sheets in LCT (LT-211) Rear Example: 3 Tabbed sheets loaded in position for one finished set. 1st TAB 1st TAB Section 1 2nd TAB Introduction Section 1 Introduction Printed 2nd TAB side 3rd TAB Front 3rd TAB ONE FINISHED SET Example: 9 Tabbed sheets loaded in position for 3 finished sets. -

Page 64: Loading Tabbed Sheets In Multi-Sheet Bypass Tray

Loading Paper (continued) Loading Tabbed Sheets in Multi-Sheet Bypass Tray Example: 3 Tabbed sheets loaded in position for one finished set. Rear 1st TAB 1st TAB Section 1 2nd TAB Introduction Section 1 2nd TAB Introduction 3rd TAB Printed side 3rd TAB Front ONE FINISHED SET... - Page 65 Section 3: Copying Operations How to Make a Basic Copy Selecting Colour Mode ............. 3-2 Positioning Originals............3-4 Setting Print Quantity ............. 3-10 Setting Job During Warm-up .......... 3-11 To Stop Scanning/Printing ..........3-13 Selecting Paper Size ............3-14 Copying Using Special Paper (Multi-Sheet Bypass Tray) ... 3-18 Selecting Magnification Ratio (Lens Mode) ....

-

Page 66: Selecting Colour Mode

Selecting Colour Mode The following four colour modes are available: AUTO mode detects whether the scanned original is coloured or black-and-white image, and automatically selects either FULL COLOUR mode or BLACK mode for copying. FULL COLOUR mode makes full-coloured copies whether the original image is coloured or not. - Page 67 Selecting Colour Mode (continued) FULL COLOUR is already highlighted when the initial settings are restored. The initial settings may have been altered by Key Operator. See p. 14-10 for details. Selecting SINGLE COLOUR will display the popup menu to specify a colour.

-

Page 68: Positioning Originals

Positioning Originals Set the originals in the RADF or on the platen glass to copy. Positioning Originals in RADF The document feeder (RADF) automatically feeds up to 100 originals directly to the platen area, starting with the top sheet. The RADF should only be used for unstapled, smooth, flat originals. - Page 69 Positioning Originals (continued) Adjust paper guides.

- Page 70 Positioning Originals (continued) Positioning originals in Mixed original mode Mixed size originals can be copied together from the document feeder. • To use the Mixed original mode, see procedure on p. 9-8 to p. 9-9. • See p. 12-10 for available combinations of mixed originals. Arrange originals in order.

- Page 71 Positioning Originals (continued) Positioning originals in Z-Folded original mode Z-Folded original mode detects the folded original size without using the size detection sensor of the RADF. • To use the Z-Folded original mode, see procedure on p. 9-10 to p. 9-11. •...

-

Page 72: Positioning Original On Platen Glass

Positioning Originals (continued) Positioning Original on Platen Glass Use the platen glass when originals are not suitable for use with the document feeder, e.g., when size is incompatible, or when originals are folded, stapled, torn, or in generally poor condition. Raise the document feeder or platen cover. - Page 73 Positioning Originals (continued) Do not place too heavy originals, or do not press strongly when thick original is placed and is under pressure of RADF; otherwise the glass may be broken and you may be injured.

-

Page 74: Setting Print Quantity

Setting Print Quantity This section describes how to set or change print quantity. To Set Print Quantity The copier is initially set to copy the original set in amounts determined by the print quantity setting, then outputs sorted sets. Enter the desired print quantity from the control panel keypad. -

Page 75: Setting Job During Warm-Up

Setting Job During Warm-up While the copier is warming up after power is turned on, select copy conditions and start scanning so that the copier may start printing immediately when the copier engine is ready. Turn on the power switch of the machine. Seven types of Warm-up Screens display in succession. - Page 76 Setting Job During Warm-up (continued) Press [START]. The original for the job will be scanned, and the highlighted FREE JOB folder key will change to SCAN JOB. When scanning is completed, SCAN JOB will change to RESERVE JOB, and the next FREE JOB becomes active. If setting more than one reserve job, touch the next FREE JOB to highlight it.

-

Page 77: To Stop Scanning/Printing

To Stop Scanning/Printing Follow the procedure below to stop scanning or printing. Touch to highlight SCAN JOB or PRINT JOB to be suspended. Press [STOP]. The current machine operation of the selected job will be suspended. If wrong job is suspended, touch CONTINUE on the popup menu immediately, select the correct job, then press [STOP] to suspend it. -

Page 78: Selecting Paper Size

Selecting Paper Size To select an appropriate paper size for getting your desired copy result, use APS (Automatic Paper Selection), or select paper size manually on the touch screen, as required. To Select Paper Size Automatically (APS) APS detects the size of originals placed on the RADF or platen glass and automatically selects and feeds copy paper of the same size, or selects an appropriate size according to the magnification ratio selected. - Page 79 Selecting Paper Size (continued) • If the appropriate copy paper is not loaded in any tray, no copying will be performed, and a message will prompt you to load the appropriate paper. • Copy result may not be satisfactory due to the Rotation function. In this case, turn the function OFF manually.

-

Page 80: To Specify Desired Paper Size (Ams)

Selecting Paper Size (continued) To Specify Desired Paper Size (AMS) When a paper size is specified on the touch screen, an appropriate reduction or enlargement ratio will be selected automatically according to the original size detected from the RADF or the platen glass. Wide paper size can be specified when AMS is in use. - Page 81 Selecting Paper Size (continued) • Copy result may not be satisfactory due to the Rotation function. In this case, turn the function OFF manually. See. p. 8-4. • See the table below for the relation of original size, copy paper size, and magnification ratio automatically selected.

-

Page 82: Copying Using Special Paper (Multi-Sheet Bypass Tray)

Copying Using Special Paper (Multi-Sheet Bypass Tray) Use the Multi-sheet bypass tray to copy using special (non-standard) paper. Select the special paper type and weight from the selections previously specified by the Key Operator, then select the size to be loaded on the Multi-sheet bypass tray, as described below. - Page 83 Copying Using Special Paper (Multi-Sheet Bypass Tray) (continued) Select the paper type and weight. To select the paper type and weight: Select the desired one out of the six keys on the menu to highlight it. • If the desired paper type and weight cannot be found on the popup menu, specify it in the Key Operator mode.

- Page 84 Copying Using Special Paper (Multi-Sheet Bypass Tray) (continued) To select the STD size (special): Touch STD size (special) to display the popup menu, then use arrow keys to scroll to the desired size. To select the Non STD size Touch Non STD size to display the popup menu, touch the vertical or horizontal size key to highlight it, then use the keypad on the popup menu to enter the vertical/horizontal size, or use arrows to scroll to that number.

- Page 85 Copying Using Special Paper (Multi-Sheet Bypass Tray) (continued) Touch Wide size paper to display the popup menu, use arrow keys to scroll to the desired wide size, then touch Lead edge or Rear edge to select the paper dimensions corresponding to the wide paper sizes entered. Touch Input size to display the Input Size popup menu, touch the vertical or horizontal size key to highlight it, then use the keypad on the popup menu to enter the vertical/horizontal size, or use arrow keys to scroll to that...

-

Page 86: Selecting Magnification Ratio (Lens Mode)

Selecting Magnification Ratio (Lens Mode) When the copier is turned ON, the magnification ratio is set to 1.000 (100%) automatically on the Basic Screen. Follow each procedure described in this section to select the desired magnification ratio. To Copy in 1.000 Magnification Mode Follow this procedure to make a 100% copy of the original image. -

Page 87: To Change Magnification Ratio (Fixed Magnification / Zoom Mode)

Selecting Magnification Ratio (Lens Mode) (continued) To Change Magnification Ratio (Fixed Magnification / Zoom Mode) Use the 8 preset ratios (0.500, 0.707, 0.816, 0.866, 1.154, 1.224, 1.414, 2.000) and 3 user preset ratios to increase or decrease magnification in fixed amounts, or use the Zoom mode to reduce or enlarge the copied original image in 0.1% (0.001) increments. - Page 88 Selecting Magnification Ratio (Lens Mode) (continued) To specify a zoom ratio: Touch the Vertical/Horizontal zoom key in the ZOOM area to highlight it. Use the keypad on the popup menu to enter the desired magnification ratio, then touch OK. The selected ratio will be displayed on the Basic Screen. •...

-

Page 89: Making Double-Sided Copies (1A2, 2A2)

Making Double-Sided Copies (1a2, 2a2) The Basic Screen is initially set to 1a1 copy mode to make single-sided copies from single-sided originals. Follow the procedure below to make double-sided copies from the originals scanned from the document feeder or from the platen glass. Using RADF Select the copy mode according to the original type (single-sided or double-sided). - Page 90 Making Double-Sided Copies (1a2, 2a2) (continued) Check and specify the original set direction and binding mode. The Original direction icon is located at the upper left corner of the Basic Screen. To change the original set direction, touch SPECIAL ORIGINAL on the Basic Screen to display the Special Original popup menu, then touch the desired original direction key to highlight it.

- Page 91 Making Double-Sided Copies (1a2, 2a2) (continued) Selecting TOP BIND will make copies upside down on the reverse side, while RIGHT&LEFT BIND copies normally. Copies Binding mode Touch OK to return to the Basic Screen. Select additional copy conditions, as desired. Some incompatible conditions may automatically release the selected copy mode.

-

Page 92: Using Platen Glass

Making Double-Sided Copies (1a2, 2a2) (continued) Using Platen Glass Use the platen glass to scan originals unsuitable for the document feeder. Specification for Double-Sided Copying Using Platen Glass ❒ Use the Platen store mode. ❒ See p. 12-9 for the information on unsuitable RADF originals. ❒... - Page 93 Making Double-Sided Copies (1a2, 2a2) (continued) Selecting TOP BIND will make copies upside down on the reverse side, while RIGHT&LEFT BIND copies normally. Copies Binding mode Touch OK to return to the Basic Screen. Position original FACE DOWN on the platen glass according to the original direction, then close the document feeder or platen cover.

- Page 94 Making Double-Sided Copies (1a2, 2a2) (continued) DO NOT press [AUTO RESET] at this point, otherwise the platen mode will be released to disable the copier from scanning the original placed on the platen glass. Select additional copy conditions, as desired. Some incompatible conditions may automatically release the selected copy mode.

-

Page 95: Making Single-Sided Copies From Double-Sided Originals (2A1)

Making Single-Sided Copies from Double-Sided Originals (2a1) Use RADF and select 2a1 copy mode to make single-sided copies from double- sided originals. Specification for Single-Sided Copying from Double-Sided Originals ❒ See p. 12-9 for the information on unsuitable RADF originals. ❒... - Page 96 Making Single-Sided Copies from Double-Sided Originals (2a1) (continued) Check and specify the original set direction and binding mode. The Original direction icon is located at the upper left corner of the Basic Screen. To change the original set direction, touch SPECIAL ORIGINAL on the Basic Screen to display the Special Original popup menu, then touch the desired original direction key to highlight it.

-

Page 97: To Scan Originals Into Memory (Store Mode)

To Scan Originals into Memory (Store Mode) Store mode allows you to scan all the originals first, then to start a continuous printing job. Use RADF store mode to scan a large amount of originals. Use Platen store mode for originals that cannot be fed through the document feeder due to thickness, size or condition. - Page 98 To Scan Originals into Memory (Store Mode) (continued) Using RADF: Position originals with page one FACE UP. Up to 100 originals can be loaded. If the number of originals exceeds 100, divide them into blocks not exceeding 100 sheets and load them beginning with the block with the first page.

-

Page 99: To Set Next Copying Job (Reserve)

To Set Next Copying Job (Reserve) The Reserve function allows you to set up a new job while a current job is in process. When the current job is finished, the Reserve job starts printing immediately. Specifications for Reserve ❒ Job settings: Max. 10 (current job plus 9 reserve jobs) ❒... - Page 100 To Set Next Copying Job (Reserve) (continued) Position original(s) after completing the scan for the current job. See p. 3-4 to p. 3-9 for details on positioning originals. To cancel the reserve job, touch STATUS on the Basic Screen to display the Job Status Screen.

- Page 101 To Set Next Copying Job (Reserve) (continued) To set the seventh copying job, touch the active FREE JOB key at the far right to scroll to the next reserve setting screen. The number of reserve jobs including current job will be indicated in the middle of the message area.

-

Page 102: To Check/Control Jobs In Progress (Job Status Screen)

To Check/Control Jobs in Progress (Job Status Screen) The Job Status Screen allows you to perform the following functions. • Confirm machine status • Change order of reserve job • Delete reserve job • View previous job list • View noncomplete job list Not only the copy reserve jobs but the print jobs made in Printer mode can also be checked and controlled on this screen. - Page 103 To Check/Control Jobs in Progress (Job Status Screen) (continued) To check user name (print jobs only): Touch USER NAME CHECK to display the User Name Check Screen. Check the user name indicated on the right side of the job number and operation mode.

- Page 104 To Check/Control Jobs in Progress (Job Status Screen) (continued) Contents of Job Status Screen NO. : Displays the No. (01-99) for each job assigned to the machine. MODE: Displays the machine’s current mode of operation. Three modes are listed below. COPIER PRINTER SCANNER...

-

Page 105: Output Mode For Machine Without Finisher

Output Mode for Machine without Finisher This section describes the output modes for a copier without the Finisher. The Non-sort mode is initially selected. 1 Non-sort mode copies the original set in amounts determined by the print quantity setting, then outputs sorted sets normally. 2 Rotation sort mode rotates every other sorted sets by 90°... - Page 106 Output Mode for Machine without Finisher (continued) Specification for Output Modes without Finisher ❒ Incompatible with Group mode: Proof Copy, Sheet/Cover Insertion, Chapter, Combination, Booklet, Image Insert, Program Job, Repeat, AUTO Layout, Non-Image Area Erase, Stamp (Numbering) ❒ Incompatible with Rotation Group mode: Proof Copy, Mixed Original, Z-Folded Original, Non STD Size (FULL AREA), Sheet/Cover Insertion, Chapter, Combination, Booklet, Image Insert, Dual Page, Program Job, Repeat, AUTO Layout, Non-Image Area Erase, Stamp (Numbering), Overlay...

- Page 107 Output Mode for Machine without Finisher (continued) Touch OK on the Output Mode popup menu. The Basic Screen will be restored with the output icon indicating the Output mode currently selected. Touch CANCEL on the Output Mode popup menu to restore the previous setting.

- Page 108 Output Mode for Machine without Finisher (continued) Output Icons on the Basic Screen Face Down Non-sort Rotation sort Group Rotation group Face Up Non-sort Rotation sort Group Rotation group 3-44...

-

Page 109: Output Mode For Machine With Finisher

Output Mode for Machine with Finisher Finisher FS-513/FS-606 is equipped with a primary (main) and a secondary (sub) exit trays. Without using any optional equipment, each exit tray provides the output modes as described below. When the Memory switch No. 58 "Finisher operating (Thick)" of the Key Operator mode is set to prefer image quality, copy speed may become maximum one-sixth lower depending upon the paper type or specified output mode. - Page 110 Output Mode for Machine with Finisher (continued) Secondary (Sub) Tray: 1 Face down non-sort exit outputs simplex copies and odd numbered duplex copies face down, without offsetting the sorted sets. 2 Face down group exit outputs multiple copies of each original face down, without offsetting the grouped sets upon exit.

- Page 111 Output Mode for Machine with Finisher (continued) ❒ Incompatible with Group using Secondary (sub) tray: 1a2 or 2a2 mode using platen glass (unless Platen store mode is used), Proof Copy, Fold, Stitch & Fold, Three-Fold, Trimming, Punch, Cover sheet feeding, Sheet/Cover Insertion, Chapter, Combination, Booklet, Image Insert, Repeat ❒...

- Page 112 Output Mode for Machine with Finisher (continued) To set Staple-sort mode: (1) Touch STAPLE on the Basic Screen to highlight it. The staple position icon will be displayed in the output icon area. To change the staple position, proceed to the next step. Proceed to step (3), if the present setting is desired.

- Page 113 Output Mode for Machine with Finisher (continued) (3) Check the original set direction with the Original direction icon at the upper left corner of the Basic Screen. To change the original set direction, touch SPECIAL ORIGINAL on the Basic Screen to display the Special Original popup menu, touch the desired original set direction key, then touch OK to return to the Basic Screen.

- Page 114 Output Mode for Machine with Finisher (continued) See p. 3-10 for details on setting print quantity. Position original(s). See p. 3-4 to p. 3-9 for details on positioning originals. Press [START]. Press [STOP] to suspend the scanning or printing job. See p. 3-13 for details. Finisher primary (main) tray of Finisher FS-513/FS-606 gradually goes down while printed materials output.

- Page 115 Output Mode for Machine with Finisher (continued) Primary (Main) tray: Staple-Sort Left 1 posi. Right 1 posi. Left 2 posi. Up 2 posi. Secondary (Sub) tray: Face down Secondary (Sub) tray: Face up Non-sort Group Non-sort Group 3-51...

-

Page 116: Selecting Binding Mode

Selecting Binding Mode When copying in 1a2 or 2a2 mode, specify the binding mode on the Output Mode popup menu to obtain the desired copy result. Right & Left bind: Normal duplex copies Top bind: Duplex copies arranged upside down on the reverse side The same binding mode is initially selected as the original binding mode specified on the Special Original popup menu. - Page 117 Section 4: Helpful Functions How to Use Helpful Functions Making Sample Copy (Proof Copy) ........4-2 Checking Feature Selections / Proof Copying (Check Mode) ..4-4 Interrupt Copying .............. 4-8 Storing Job Conditions (Job Memory: Job Store)... 4-11 Recalling Stored Job Settings (Job Memory: Job Recall)... 4-14 Recalling Previous Job Settings ........

-

Page 118: Making Sample Copy (Proof Copy)

Making Sample Copy (Proof Copy) Use Proof copy to produce a sample of the copied set before making multiple copies. This is a convenient and cost effective way of viewing the results of the following copying selections. • Copying conditions using Store mode •... - Page 119 Making Sample Copy (Proof Copy) (continued) If the copy result is satisfactory, proceed to step 5. If any setting changes are required, refer to p. 4-6 under the next heading. Repeat proof copying until the copy result becomes satisfactory. Change the print quantity, as required. Proof copy can be performed as needed, until the print quantity amount on the Basic Screen reaches zero.

-

Page 120: Checking Feature Selections / Proof Copying (Check Mode)

Checking Feature Selections / Proof Copying (Check Mode) Use the Check mode to confirm copying selections before starting print operation. In this mode, use Proof copy to produce a sample of the copied set before making multiple copies. This is a convenient and cost effective way of viewing the results of the following copying selections. - Page 121 Checking Feature Selections / Proof Copying (Check Mode) (continued) The Check Screen will be displayed. Exclusive Paper Title Check Screen Tray Setting Check Screen Touch the lower arrow key to scroll to the next screen in order as shown above. Touching the upper arrow key will resume the previous screen. Touch TrayConfirm to display the Tray Setting Check Screen.

- Page 122 Checking Feature Selections / Proof Copying (Check Mode) (continued) To change the settings: Touch the desired copying condition key on the Check Screen to highlight it. Any key that cannot be highlighted indicates that the copying condition cannot be changed from the Check Screen. Touch CHANGE SETTING.

- Page 123 Checking Feature Selections / Proof Copying (Check Mode) (continued) Press [PROOF COPY] on the control panel or touch PROOF COPY on the Check Screen. A sample copy will be output. • Press [STOP] to suspend the proof copying. In this case, the scanned image data will not be deleted from memory.

-

Page 124: Interrupt Copying

Interrupt Copying Use the Interrupt mode to interrupt copying in progress to perform a simple job. When interrupt copying is completed, the settings for the initial job restore automatically and the Basic Screen displays. Interrupt copying is available when the copier is performing the following operations: •... - Page 125 Interrupt Copying (continued) In Reserve mode, pressing [INTERRUPT] before the copier finishes scanning the reserve job originals clears the settings selected for the reserve job. For details of Reserve mode, see p. 3-35 to p. 3-37. Set copy conditions, as desired. The initial settings in Interrupt mode are as follows.

- Page 126 Interrupt Copying (continued) For particular jobs in progress, copying will cease only after certain phases of the immediate operation are completed, as indicated by the [INTERRUPT] LED conditions described below. • Collectively printing image stored in memory The LED blinks until one set of the current job is printed. Then the LED remains steady for the temporary job performed in Interrupt mode.

-

Page 127: Storing Job Conditions (Job Memory: Job Store)

Storing Job Conditions (Job Memory: Job Store) Use Job Store to store up to 30 frequently used copy job settings, which can be recalled at any time. The stored jobs can be given alphabetical names. Specifications for Job Memory ❒ All copying functions can be selected. ❒... - Page 128 Storing Job Conditions (Job Memory: Job Store) (continued) Review the settings on the Job Store Check Screen. Touch the lower arrow key to scroll to the following pages. Check that the selections made in step 1 are correctly entered. If any correction is required, touch CANCEL to return to the Basic Screen. Make new selections, then restart the Job Store operation from step 2.

- Page 129 Storing Job Conditions (Job Memory: Job Store) (continued) If you wish to cancel the job number selection, touch CANCEL to restore the Basic Screen, which displays the settings made in step 1. If you wish to cancel the settings, press [AUTO RESET]. Touch OK.

-

Page 130: Recalling Stored Job Settings (Job Memory: Job Recall)

Recalling Stored Job Settings (Job Memory: Job Recall) Use Job Recall to recall jobs that are already stored in Job Memory. Press [JOB MEMORY] on the control panel. The Job No. Selection Screen will be displayed. Touch to highlight a job number key to select a job you want to recall. -

Page 131: Recalling Previous Job Settings

Recalling Previous Job Settings Follow the procedure below to copy with a previous job’s settings. • Only the last-completed output job settings can be recalled as the previous job settings. Non-complete job or reserve job settings cannot be recalled, even if the setting operations have been made last. •... -

Page 132: Displaying Screen For Operation Guide (Help Mode)

Displaying Screen for Operation Guide (Help Mode) The Help Screen provides you with the information about the current screen mode and about setting procedures. Help mode can be accessed from any screen except Job Memory and Key Operator Screens. Help mode provides two types of Help Screens according to the current screen mode: 1 Help Screen accessed from Basic Screen 2 Help Screen accessed from screens other than Basic Screen... - Page 133 Displaying Screen for Operation Guide (Help Mode) (continued) • PANEL CONTRAST displays the screen to adjust the contrast of the LCD panel. • Toner Recovery box provides information on exchanging the toner recovery box. • FOR ASSISTANCE displays the extension number of the Key Operator. •...

-

Page 134: To Display Help Screen From Other Screens

Displaying Screen for Operation Guide (Help Mode) (continued) To Display Help Screen from Other Screens While in any screen other than the Basic Screen, press [HELP]. The Help Screen displays to provide the information about the current screen mode and setting procedures. Touch EXIT. -

Page 135: Troubleshooting

Section 5: Troubleshooting How to Handle Machine Troubles When “Call for Service” Message Is Displayed ....5-2 Clearing Mishandled Paper ..........5-4 When “JAM” Appears on Folder Key (Or Arrow Key Flashes) ..5-6 When “ADD PAPER” Appears on Folder Key (Or Arrow Key Flashes) .. 5-8 When “Memory Full”... -

Page 136: When "Call For Service" Message Is Displayed

When “Call for Service” Message Is Displayed A “Call for Service” message indicates a machine condition that requires the attention of your service representative. The Call for Service Screen usually displays the telephone and facsimile numbers of your service representative. When the Call for Service Screen is displayed, be sure to contact your service representative immediately by following the procedure below. -

Page 137: Limited Use Of The Copier In Trouble

When “Call for Service” Message Is Displayed (continued) Unplug the machine. Contact your service representative and report the condition and code No. Limited Use of the Copier in Trouble If the message shown below is displayed on the Call for Service Screen, you may continue operating the copier on a limited function basis and utilize the trays and ADU that are not affected by the trouble. -

Page 138: Clearing Mishandled Paper

Clearing Mishandled Paper When a paper misfeed occurs, the copier stops making copies and mishandled paper codes display on the screen to indicate misfeed area(s). Copying operation cannot be continued until all the misfeed locations are cleared. Graphic Illustration key Touch to display the subsequent screens for the disposal action. - Page 139 Clearing Mishandled Paper (continued) The drum unit generates high voltage. To avoid bodily electrical shock, NEVER TOUCH the area. The internal fixing unit is very hot. To avoid getting burned, DO NOT TOUCH. Be careful of removing staples stuck inside the machine so as not to get injured.

-

Page 140: When "Jam" Appears On Folder Key (Or Arrow Key Flashes)

When “JAM” Appears on Folder Key (Or Arrow Key Flashes) If a misfeed occurs with the print/scan job in progress while you are setting a reserve job, SCAN or PRINT JOB folder key on the Basic Screen will change to flashing JAM JOB. - Page 141 When “JAM” Appears on Folder Key (Or Arrow Key Flashes) (continued) Touch Graphic Illustration. The screen illustrating the method for the disposal action will be displayed. See p. 5-4 to p. 5-5 for details on clearing procedure. Follow the procedure on the screen to remove misfed paper. When all procedures are completed, the Basic Screen will be restored.

-

Page 142: When "Add Paper" Appears On Folder Key (Or Arrow Key Flashes)

When “ADD PAPER” Appears on Folder Key (Or Arrow Key Flashes) If the paper supply for a print job in progress becomes depleted while you are setting a reserve job, PRINT JOB on the Basic Screen will change to flashing ADD PAPER. When more than four jobs have been specified and the folder key of the print job in trouble is not currently displayed on the screen, the arrow key to scroll to that job will flash. -

Page 143: When "Memory Full" Message Is Displayed (Memory Overflow)

When “Memory Full” Message Is Displayed (Memory Overflow) In certain modes, this printer/copier uses memory to make operations convenient and smooth flowing. Occasional memory overflow may occur if the installed memory is inadequate for the copy conditions selected. To handle the Memory overflow condition while performing a job, take the appropriate action described below. -

Page 144: Memory Overflow In Reserve Job

When “Memory Full” Message Is Displayed (Memory Overflow) (continued) Memory Overflow in Reserve Job When memory overflow occurs during the reserve operation, CONTINUE also appears on the active screen. In this case, the machine will not stop until all the jobs on standby for printing are completed. -

Page 145: When Power Off/On Screen Is Displayed

When Power OFF/ON Screen Is Displayed When any trouble affects the electrical signal of the copier, the Power OFF/ON Screen will be displayed. Follow the procedure below to turn the machine power off then on. Turn OFF the power switch. Wait about 10 seconds. -

Page 146: Troubleshooting Tips

Troubleshooting Tips COPIER DOES NOT OPERATE WHEN POWER SWITCH IS ON Fully insert paper trays. Close RADF. Close Front doors of main body. Close Finisher door. Check to be sure main power switch is ON. Check to be sure power plug is firmly inserted in electrical socket. COPY IMAGE IS TOO LIGHT Manually adjust copy density to darker density. - Page 147 Troubleshooting Tips (continued) COPYING DOES NOT RESUME AFTER MISHANDLED PAPER IS REMOVED Check copier diagram on touch screen for additional indications of mishandled paper. COPY QUALITY IS POOR Check paper for dampness, and replace it if necessary. THE ORIGINAL PAPER IS MISHANDLED OR SKEWED IN THE DOCUMENT FEEDER Originals should conform to the recommended size and weight.

- Page 148 Troubleshooting Tips (continued) “PLEASE CHECK ORIGINAL” This message displays when the copier detects a non-standard paper size on the platen glass. Select paper size and press [START]. 1.000 magnification will be selected automatically. If this message continues to display after selecting paper size, select 1.000 magnification, even if it is already indicated, then press [START].

-

Page 149: Section 6: Machine Specifications

Section 6: Machine Specifications Main Body & Option Specifications Main Body Specifications ..........6-2 Option Specifications............6-4... -

Page 150: Main Body Specifications

Main Body Specifications Main Body Name: bizhub PRO C500 Type: Console type Transfer method: Indirect electrostatic method Platen glass: Fixed Light-sensitive unit: Light source: Xenon lamp Developing method: Dry, 2-component magnetic brush developing Fixing method: Heat roller Density adjustment: Automatic and manual (9 steps) Magnification ratio: 1.0 %... - Page 151 Main Body Specifications (continued) Power: AC 230 V / 50 Hz (This equipment selects the correct voltage automatically.) Power consumption: 3.4 KW max. (with option) Sound power level: 78 dB max. (with option) Weight: Approx. 313 kg (main body) + 1.6 kg w/Platen cover (CV-131) + 14.5 kg w/RADF + 56 kg w/Finisher (FS-513) + 66 kg w/Finisher (FS-606)

-

Page 152: Option Specifications

Option Specifications RADF (DF-319) Function: Feeds 1- and 2-sided originals automatically Type of original: 35 g/m ~ 200 g/m in Simplex mode (Use Thin mode of THICKNESS/SPECIAL ORIGINAL for 35 g/m ~ 49 g/m paper) 50 g/m ~ 200 g/m in Duplex mode (Use Thick mode of THICKNESS/SPECIAL ORIGINAL for 129 g/m... -

Page 153: Cover Sheet Feeder

Option Specifications (continued) PI-110 Cover Sheet Feeder Function: Paper feed into Finisher FS-513/FS-606 Configuration: 2 trays (upper/lower) Types of paper: 50 to 256 g/m paper Paper sizes: Upper tray A4, A4R, B5, B5R, A5, 8.5"x11", 8.5"x11"R, 5.5"x8.5" Lower tray A3, B4, F4, A4, A4R, B5, B5R, A5, 11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R, 5.5"x8.5", and those Wide sizes (max. -

Page 154: Pk-507/Pk-508 Punching Kit

Option Specifications (continued) PK-507/PK-508 Punching Kit Function: Punching file holes in copies Number of punch holes: Hole diameter: 6.5 mm 0.5 mm ± Hole pitch: 80 mm 0.5 mm ± Paper sizes: A3, B4, A4, B5, 11"x17", 8.5"x11" Types of paper: 50 g/m ~ 128 g/m paper... - Page 155 Advanced...

- Page 157 Section 7: Colour Image Adjustment About Colours..............7-2 Colour Copy Quality ............7-4 Selecting Density Level and Whitening the Background(Copy Density) ..7-15 Changing Colours Using RGB and HSB Values (Colour Adjustment) . 7-19 Changing Colours Using CMYK Value (Colour Balance Adjustment).. 7-24 Selecting Line Screen, Dot Screen, or High Compression (Screen Setting) 7-26 Adjusting Sharpness and Contrast / Selecting Gloss Mode ..

-

Page 158: About Colours

About Colours RGB and CMYK Models Have you ever wondered why the world surrounding us appears coloured to our eyes? Light is electromagnetic waves with wavelengths between about 380 - 780 nm, also called visible rays. The wavelengths of visible rays can be separated into the rainbow colours violet, indigo, blue, green, yellow, orange, and red, from the shortest wavelength in order. -

Page 159: Hsb Model

About Colours (continued) HSB Model This model is based on the human perception of colour. When our eyes perceive colours in objects, we receive the information not only on the colour itself (reddish, bluish, etc.) but the brightness (rather bright, dark, etc.) and the purity (vivid, dull, etc.) of the colour. -

Page 160: Colour Copy Quality

Colour Copy Quality Modifying Colours As mentioned above, colours can be reproduced by mixing four pigments, the three primary colours cyan (C), magenta (M), yellow (Y), and black (K). To enhance the copy quality, this machine allows you to modify colours by means of the three attributes of colour based upon the human eye and perception. - Page 161 Colour Copy Quality (continued) Adjust the hue, saturation, and brightness. Original –4 Saturation –4...

- Page 162 Colour Copy Quality (continued) Brightness –4 The hue adjustment leads the colour of the image to another colour adjacent in the colour circle of red (R), yellow (Y), green (G), cyan (C), blue (B), and magenta (M).

- Page 163 Colour Copy Quality (continued) Change the hue by varying the image’s red (R), green (G), and blue (B) individually or mutually. Original –4 Green –4...

- Page 164 Colour Copy Quality (continued) Blue –4...

- Page 165 Colour Copy Quality (continued) Change the hue by varying the image’s cyan (C), magenta (M), yellow (Y), and black (K) individually or mutually. Original Cyan –4 Magenta –4...

- Page 166 Colour Copy Quality (continued) Yellow –4 Black –4 7-10...

-

Page 167: Reproducing Images

Colour Copy Quality (continued) Reproducing Images This machine provides two methods for reproducing images. The Dither (Error Diffusion) method uses small dots (600 dots per inch) to reproduce the image. This method is appropriate for text originals. The Screen method also provides two methods, Line Screen and Dot Screen. The Line Screen uses many halftone lines, like scanning lines of a television, while Dot Screen uses small dots to reproduce the image. -

Page 168: What Is Image Detection

Colour Copy Quality (continued) What Is Image Detection? In many cases, originals include both photo and text. Although the text is normally printed in black, a colour printer inevitably uses not only the black toner but cyan, magenta, and yellow in layers to reproduce the black text. Using the Screen method, the colour printer may add colours in large or bold characters to reproduce the text in the same way as the photo. -

Page 169: Applying Filters

Colour Copy Quality (continued) Applying Filters In addition to the colour adjustment and image reproduction methods, this machine allows you to apply the following filters to improve the copy image quality. Sharpen the outline of the image. (Sharpness) Sharpness Original –4 Increase the contrast of the image. -

Page 170: Improving Colour Copy Quality

Colour Copy Quality (continued) Increase shine on the image. (Gloss Mode) Gloss mode Original Improving Colour Copy Quality To improve the colour copy quality, this machine provides the three types of adjustment methods: Colour adjustment, Selecting the image reproduction method and its adjustment, and other adjustments. -

Page 171: Selecting Density Level And Whitening The Background(Copy Density)

Selecting Density Level and Whitening the Background(Copy Density) Automatic Exposure (AE) operates to detect the density level of the original image while scanning, and automatically selects the appropriate density for the copy. The density to be selected automatically using AE can be adjusted on the machine. - Page 172 Selecting Density Level and Whitening the Background(Copy Density) (continued) Touch COPY DENSITY to display the Copy Density Adjustment Screen. Touch the desired density level key from -1 to -4 to make the copy image lighter, or from +1 to +4 to make it darker. •...

-

Page 173: Setting Density Shift

Selecting Density Level and Whitening the Background(Copy Density) (continued) Setting Density Shift Use this function to shift each of nine density levels to three levels lighter or three levels darker. This function can be set to use in combination with each of the four Original Image modes (Text/Photo, Photo, Text, and Map) in each of the three colour modes (Full colour, Black, and Single colour), therefore twelve sorts of settings are available for the density adjustment. - Page 174 Selecting Density Level and Whitening the Background(Copy Density) (continued) Selected Original image mode: TEXT, Colour mode: SINGLE COLOUR Density Shift (Text Single colour) 3 (0 - 6) Selected Original image mode: MAP, Colour mode: FULL COLOUR Density Shift (Map Full colour) 3 (0 - 6) For details of the Original Image mode, see p.

-

Page 175: Changing Colours Using Rgb And Hsb Values (Colour Adjustment)

Changing Colours Using RGB and HSB Values (Colour Adjustment) Change colour by modifying each value of red (R), green (G), and blue (B), and also adjust the value of hue, saturation, and brightness. Modifying RGB Value Change the colour of the copy image by modifying each value of red (R), green (G), and blue (B). - Page 176 Changing Colours Using RGB and HSB Values (Colour Adjustment) (continued) Touch the desired level key from -1 to -4 to make the colour lighter, or from +1 to +4 to make it deeper. • Touch STD. to select the middle level. •...

-

Page 177: Modifying Hsb Value

Changing Colours Using RGB and HSB Values (Colour Adjustment) (continued) Modifying HSB Value Change the colour of the copy image by making adjustments to Hue, Saturation, and Brightness. Touch IMAGE ADJUST on the Basic Screen. Touch COLOUR ADJUST to display the Colour Adjustment Screen. Make an adjustment to Hue. - Page 178 Changing Colours Using RGB and HSB Values (Colour Adjustment) (continued) Or, touch a key from +1 to +4 to make yellow closer to green, and green closer to cyan (Adjustment goes clockwise in the colour circle.). Touch STD. to select the middle level. Touch OK.

- Page 179 Changing Colours Using RGB and HSB Values (Colour Adjustment) (continued) Touch STD. to select the middle level. Touch OK. The Colour Adjustment Screen will be restored. To resume the previous setting, touch CANCEL. Touch OK. The Basic Screen will be restored, with the IMAGE ADJUST key highlighted. •...

-

Page 180: Changing Colours Using Cmyk Value (Colour Balance Adjustment)

Changing Colours Using CMYK Value (Colour Balance Adjustment) Change the hue by varying the image’s cyan (C), magenta (M), yellow (Y), and black (K) individually or mutually. This adjustment can be made in each density area (shadow, mid tone, or highlight) of the individual colour, or in the whole density area of each colour. - Page 181 Changing Colours Using CMYK Value (Colour Balance Adjustment) (continued) Select the colour and adjustment value. Touch CYAN(C), MAGENTA(M), YELLOW(Y), or BLACK (K) to highlight it. Then, touch the c or d key to display the desired adjustment value from -10 to +10.

-

Page 182: Selecting Line Screen, Dot Screen, Or High Compression (Screen Setting)

Selecting Line Screen, Dot Screen, or High Compression (Screen Setting) This machine provides two methods to reproduce the print image; Line Screen and Dot Screen. The machine selects an appropriate method automatically according to the other copy conditions selected for the job. See p. - Page 183 Selecting Line Screen, Dot Screen, or High Compression (Screen Setting) (continued) Select the desired reproducing method. To select the Line Screen, touch HIGH RESOLUTION or SMOOTH TONE under the LINE SCREEN indication to highlight it. To select the Dot Screen, touch HIGH RESOLUTION or SMOOTH TONE under the DOT SCREEN indication to highlight it.

- Page 184 Selecting Line Screen, Dot Screen, or High Compression (Screen Setting) (continued) Touch OK. The Basic Screen will be restored, with the IMAGE ADJUST key highlighted. • To resume the previous setting, touch CANCEL. • To restore the initial settings, touch RECALL STANDARD. 7-28...

-

Page 185: Adjusting Sharpness And Contrast / Selecting Gloss Mode

Adjusting Sharpness and Contrast / Selecting Gloss Mode In addition to the colour adjustment and reproducing method selection, this machine allows you to apply the following filters to improve the copy image quality. Sharpen the outline of the image. (Sharpness) Increase the contrast of the image. - Page 186 Adjusting Sharpness and Contrast / Selecting Gloss Mode (continued) Select the desired sharpness level. Touch SHARPNESS, then touch the desired level key from -1 to -4 to make the outline softer, or from +1 to +4 to make it sharper. Touch STD.

- Page 187 Adjusting Sharpness and Contrast / Selecting Gloss Mode (continued) To resume the previous setting, touch CANCEL. Select the Gloss Mode. Touch GLOSS MODE to highlight it. Touch OK. The Basic Screen will be restored, with the IMAGE ADJUST key highlighted. •...

-

Page 188: Making Fine Adjustment In Image Detection (Image Judge)

Making Fine Adjustment in Image Detection (Image Judge) Image Detection detects and determines the photo portion and text area of the original when scanned, allowing you to obtain the optimum print result by modifying the standard for detection according to the character size of the text or its proportion in the whole original. - Page 189 Making Fine Adjustment in Image Detection (Image Judge) (continued) Touch IMAGE JUDGE. Make an adjustment to TEXT/PHOTO. Touch the desired level key from -1 to -4 to increase the proportion of photo. Or, touch a key from +1 to +4 to increase the proportion of text. Touch STD.

-

Page 190: Specifying Original Type (Original Image/Type In Special Original)

Specifying Original Type (Original Image/Type in Special Original) The image quality or type of the original may affect the copy result. Use Original Image to improve the image quality by specifying the original image type as follows. • Originals including both text and photo (TEXT/PHOTO) •... - Page 191 Specifying Original Type (Original Image/Type in Special Original) (continued) Touch OK. The Basic Screen will be restored, with the SPECIAL ORIGINAL key highlighted and the selected Original Image icon displayed. • To resume the previous setting, touch CANCEL. • To restore the initial settings, touch RECALL STANDARD. 7-35...

- Page 193 Section 8: Advanced Information How to Use Advanced Functions Programmed Shut-Off (Weekly Timer) ......8-2 Rotation ................8-4 Vertical/Horizontal Zoom Mode ........8-5 Making Folded Booklet (Fold / Stitch & Fold) ....8-8 Punching File Holes in Copies (Punch) ......8-11 Output Three-Folded Copies (Three-Fold) .....

-

Page 194: Programmed Shut-Off (Weekly Timer)

Programmed Shut-Off (Weekly Timer) The Weekly Timer function turns a copier on and off at the time specified by the Key Operator. This function is not factory-set. When the copier is using the Weekly Timer function, the TIMER indicator on the right side of the control panel is lit. IMPORTANT: WHEN THE TIMER INDICATOR IS LIT, THE COPIER WILL TURN OFF AUTOMATICALLY. - Page 195 Programmed Shut-Off (Weekly Timer) (continued) The Timer Interrupt password is not factory set and must be entered by the Key Operator. In the event the Timer Interrupt password has not been entered by the Key Operator, the following message will display instead. Input copy time 0 hour(s) 05 minute(s)

-

Page 196: Rotation

Rotation This function allows you to utilize APS or AMS and copy the original documents onto size A4 or B5, irrespective of the copy paper feeding direction. By default, Rotation requires APS or AMS to function. The Key Operator can set this function ON, or to operate when APS, AMS or reduce functions. -

Page 197: Vertical/Horizontal Zoom Mode

Vertical/Horizontal Zoom Mode Use the Vertical/Horizontal zoom mode to reduce or enlarge vertical and horizontal dimensions, independently. Vertical/Horizontal Zoom Mode Specifications ❒ Vertical/Horizontal zoom range: 0.250~4.000 ❒ Incompatible Conditions: APS, AMS, Reduce & Shift in Image Shift The figure shown below is the sample image using the Vertical/Horizontal zoom. Length: 0.500, Width: 0.500 Length: 0.500, Width: 1.000 Length: 0.500, Width: 2.000... - Page 198 Vertical/Horizontal Zoom Mode (continued) The popup menu for setting a zoom ratio will be displayed. When starting a new copying job, be sure to close the RADF securely, then press [AUTO RESET]. Touch the vertical zoom key on the popup menu to highlight it, then set the vertical zoom ratio.

- Page 199 Vertical/Horizontal Zoom Mode (continued) The figure shown below is the sample image using the Vertical/Horizontal zoom with an original placed slanted on the platen glass. 30° Length: 0.500, Width: 2.000 Length: 2.000, Width: 0.500 30° Length: 0.500, Width: 2.000 Length: 2.000, Width: 0.500...

-

Page 200: Making Folded Booklet (Fold / Stitch & Fold)

Making Folded Booklet (Fold / Stitch & Fold) The Fold and modes are available only when the FS-606 Finisher option Stitch & Fold is installed. When any of these modes is selected, the Booklet feature is automatically selected and indicated on the Application Selection Screen. •... - Page 201 Making Folded Booklet (Fold / Stitch & Fold) (continued) Fold Stitch & Fold 80 g/m 20 sheets max. 19 sheets max. with a thick cover paper 105 g/m or less: 3 sheet max. 105 g/m : 16 sheets max. 15 sheets max. with a thick cover paper Touch OUTPUT MENU on the Basic Screen to display the Output Mode popup menu.

- Page 202 Making Folded Booklet (Fold / Stitch & Fold) (continued) Selecting FOLD or STITCH & FOLD will automatically switch the output tray to Booklet tray. Notice that the arrow pointing from the Main tray shifts to the Booklet tray. When selecting STITCH & FOLD, the machine with the trimmer unit installed selects TRIM automatically.

-

Page 203: Punching File Holes In Copies (Punch)

Punching File Holes in Copies (Punch) The Punch mode is available only when the PK-507/PK-508 Punching kit option is installed on the FS-513/FS-606 finisher. When the Punch mode is selected in combination with any of the Primary (Main) tray output modes, each copied sheet is punched and output to the Primary tray according to the selected output mode. - Page 204 Punching File Holes in Copies (Punch) (continued) Touch MAIN TRAY, if not highlighted. Touch PUNCH to display the Punch Position popup menu. Touch the desired punch position key to highlight it. Touch OK on the Punch Position popup menu to restore the Output Mode popup menu.

- Page 205 Punching File Holes in Copies (Punch) (continued) Specify the original set direction. Touch SPECIAL ORIGINAL on the Basic Screen to display the Special Original popup menu. Touch to select the desired original set direction, then touch OK to return to the Basic Screen.

-

Page 206: Output Three-Folded Copies (Three-Fold)

Output Three-Folded Copies (Three-Fold) The Three-Fold mode is available only when the FS-606 Finisher option is installed. In this mode, the original image is copied on A4R/8.5”x11”R copy paper and output to the Booklet tray of the finisher. Specifications for Three-Fold Mode ❒... - Page 207 Output Three-Folded Copies (Three-Fold) (continued) Touch THREE-FOLD to highlight it. Touch OK on the popup menu to complete the setting and return to the Basic Screen. The THREE-FOLD icon will be displayed in the OUTPUT icon area. Select additional copying features, as required. Touch to highlight the A4R or 8.5”x11”R tray key, if not already highlighted.

-

Page 208: Making Trimmed Booklets (Trimming)

Making Trimmed Booklets (Trimming) The Trimming mode is available only when the TU-109 Trimmer unit option is installed on the FS-606 Finisher. This function can be used with Fold or Stitch & Fold mode to make each copied set folded or stitched & folded, trimmed at the edge that opens the booklet, then output to the Trimmer unit tray. - Page 209 Making Trimmed Booklets (Trimming) (continued) Touch MAIN TRAY, if not highlighted. Select the desired trimming mode. Touch STITCH & FOLD or FOLD, as desired. When selecting FOLD, also touch TRIM to highlight it. When selecting STITCH & FOLD, the machine with the trimmer unit installed selects TRIM automatically.

- Page 210 Making Trimmed Booklets (Trimming) (continued) Enter the desired print quantity from the control panel keypad. See p. 3-10 for details on setting print quantity. Position originals. See p. 3-4 to p. 3-9 for details on positioning originals. When loading originals, heed the following limits on capacity: Fold mode: 12 pages or less for simplex copying 6 pages or less for duplex copying...

-

Page 211: Cover Sheet Feeding

Cover Sheet Feeding The Cover Sheet Feeder (PI-110) is available as an option on the FS-513/FS-606 finisher. Load cover sheet paper into this device and use the sheets as front covers for copied sets output to the Main tray or use the sheets as booklet-type covers for copied sets output to the Booklet tray in the Fold or Stitch &... - Page 212 Cover Sheet Feeding (continued) Touch MAIN TRAY, if not highlighted. Touch COVER SHEET to display the Cover Sheet Insert Selection Screen. Touch FRONT, FRONT+BACK, or BACK to highlight it, then select the covers tray. When selecting FRONT+BACK mode, different tray sources can be specified for each.

- Page 213 Cover Sheet Feeding (continued) Load the cover sheet paper into the optional cover sheet feeder of the FS-513/FS-606 finisher. Upper tray Lower tray If the paper size loaded in the cover sheet feeder is not suitable, the following messages will be displayed and copying will be unavailable till the correct size is loaded.

-

Page 214: Off-Line Finishing

Off-Line Finishing The Off-Line Finishing function enables you to finish documents independent of copier operation. The Off-Line Finishing function is available only with the Cover Sheet Feeder option (PI-110) installed on the FS-513/FS-606 Finisher. To use this convenient function, simply place a set of paper into the lower tray of the cover sheet feeder, select the desired mode from the Off-Line Finishing operation panel located on the top of the finisher, then press the Start/Stop button. - Page 215 Off-Line Finishing (continued) Specifications for Manual Three-Fold ❒ Paper size: A4R, 8.5”x11”R ❒ Paper weight: 60 ~ 105 g/m ❒ Three-fold capacity: 3 sheets ❒ Output tray: Booklet tray Start/Stop button Stitch & Fold 1 oblique staple 2 parallel staples Three-Fold Punch Place a set of paper to be...

- Page 216 Off-Line Finishing (continued) Press Staple Mode Selection button and/or Punch button to select the desired mode. Punch mode is compatible with 1 oblique staple, 2 parallel staples, or Stitch & Fold mode. Press Start/Stop button. Finished sheets will be delivered to the appropriate tray according to the selected mode.

-

Page 217: Tray Adjustment

Tray Adjustment This function allows you to perform image adjustments for printing on pages contained in a specific paper tray and enables you to recall adjustment values from the Basic Screen. The Tray Adjustment key will appear on the Basic Screen if this function has been enabled by your service representative. -

Page 218: To Recall/Delete The Adjustment Value

Tray Adjustment (continued) Enter the desired profile name. Use the screen keypad to enter the desired profile name. Max. 12 letters can be entered. Touch OK to complete the setting and return to the Tray Adjustment popup menu. Touch OK. The Basic Screen will be restored, indicating the registered tray number on the Tray Adjustment key. - Page 219 Tray Adjustment (continued) Touch the number (profile name) key to highlight it, then touch RECALL or DELETE, as desired. When RECALL is touched, the Tray Adjustment popup menu will be restored, with the selected adjustment value recalled in the text area. When DELETE is touched, the Delete Confirmation popup menu will be displayed.

-

Page 221: Special Original

Section 9: Special Original How to Make a Copy of Special Original Selecting Binding Direction..........9-2 Specifying Original Direction ..........9-4 Copying Non-Standard Size Originals (Original Form) ..9-6 Copying Mixed Size Originals (Mixed Original) ....9-8 Copying Z-Folded Originals (Z-Folded Original)..... 9-10 Scanning Thin/Thick Originals in RADF (Original Thickness).. -

Page 222: Selecting Binding Direction

Selecting Binding Direction When copying in 2a1 or 2a2 mode, specify the binding direction of the originals on the Special Original popup menu to obtain the desired copy result. RIGHT&LEFT BIND is initially selected to make copies in the same direction as the originals. - Page 223 Selecting Binding Direction (continued) Position originals FACE UP in the document feeder or FACE DOWN on the platen glass. See p. 3-4 to p. 3-9 for details on positioning originals. Press [START]. When the finisher / trimmer unit / paper exit tray capacity is exceeded due to the print quantity selected, remove the copied sets as they exit;...

-

Page 224: Specifying Original Direction

Specifying Original Direction Specify the direction of the originals placed on RADF or platen glass. This setting is required to obtain copy results as expected when making double-sided copies with binding position specified or when staple position is specified. Originals on platen glass: Originals on RADF: Touch SPECIAL ORIGINAL on the Basic Screen. - Page 225 Specifying Original Direction (continued) Touch OK to complete the setting and return to the Basic Screen. The SPECIAL ORIGINAL key on the Basic Screen is highlighted, and the icon in the message area indicates the selected original direction. Make other compatible selections. Enter the desired print quantity from the control panel keypad.

-

Page 226: Copying Non-Standard Size Originals (Original Form)

Copying Non-Standard Size Originals (Original Form) The copier usually detects the standard size of originals fed through RADF or positioned on the platen glass (STD size mode). Use Non STD size mode to specify the scanning area manually for copying or printing special size originals. - Page 227 Copying Non-Standard Size Originals (Original Form) (continued) Touch the desired size key. When selecting FULL AREA on the Non STD size mode menu, the copier scans the full area of the platen glass and copies with the paper size or magnification ratio currently selected.

-

Page 228: Copying Mixed Size Originals (Mixed Original)